Viscosity Index Improvers Performance Comparison: A Data-Driven Analysis for Lubricant Researchers

This article provides a comprehensive, data-driven comparison of viscosity index improvers (VIIs), essential additives in modern lubricants.

Viscosity Index Improvers Performance Comparison: A Data-Driven Analysis for Lubricant Researchers

Abstract

This article provides a comprehensive, data-driven comparison of viscosity index improvers (VIIs), essential additives in modern lubricants. It explores the fundamental chemistry and mechanisms of major VII polymers, evaluates performance testing methodologies, and addresses common formulation challenges. A core focus is the comparative analysis of VIIs like OCP, PMA, and PIB under multi-objective constraints, incorporating insights from cutting-edge research that utilizes high-throughput molecular dynamics and explainable AI. The analysis synthesizes key performance indicators—including shear stability, thickening efficiency, and oxidative resistance—to guide researchers in selecting and optimizing VIIs for advanced applications, from high-stress internal combustion engines to electric vehicle powertrains.

Understanding Viscosity Index Improvers: Chemistry, Types, and Core Mechanisms

Defining the Viscosity Index and Its Critical Role in Lubricant Performance

Viscosity Index (VI) is a fundamental parameter in lubricant science that quantifies how much a fluid's viscosity changes with temperature. Developed by Dean and Davis of Standard Oil in 1929, this empirical scale establishes a standardized method for evaluating the viscosity-temperature relationship of petroleum products [1]. The fundamental principle underlying VI is straightforward: the higher the viscosity index, the less the oil's viscosity is affected by temperature changes [2] [3]. This property is crucial for lubricants operating in environments with significant temperature variations, as it ensures consistent performance and protection across diverse operating conditions.

The viscosity of a lubricant represents its resistance to flow and shear, with two primary measurement types: dynamic viscosity (force needed to make the lubricant flow, measured in mPa·s) and kinematic viscosity (how fast the lubricant flows when force is applied, measured in mm²/s) [2]. All lubricants experience viscosity reduction as temperature increases, but the rate of this change varies significantly between formulations. The VI provides a standardized method for comparing this rate of change, enabling engineers and researchers to select optimal lubricants for specific applications and temperature ranges [2] [1].

The original VI scale was based on two reference oils: a Pennsylvania crude oil assigned a VI of 100 (representing low viscosity-temperature dependence) and a Texas Gulf Coast crude assigned a VI of 0 (representing high viscosity-temperature dependence) [1]. Modern lubricants often exceed these original boundaries, with synthetic formulations frequently demonstrating VIs significantly above 100. Contemporary determination of VI involves measuring kinematic viscosity at 40°C and 100°C, then comparing these measurements to the results from the two reference oils [2].

Experimental Determination of Viscosity Index

Standardized Testing Methodologies

The accurate determination of viscosity index follows internationally recognized standards, primarily ASTM D2270, which relies on kinematic viscosity measurements performed according to ASTM D445 [1]. This methodology requires precise temperature control and measurement at two standardized temperatures: 40°C and 100°C. The experimental protocol involves immersing the oil sample in a temperature-controlled bath, allowing it to reach equilibrium, then measuring the time it takes for the fluid to flow through a calibrated glass capillary viscometer. This measured flow time is converted to kinematic viscosity using the viscometer's calibration constant [1].

For waxy base oils that may solidify at lower temperatures, a modified approach is sometimes necessary. When the cloud and pour points of samples exceed 40°C, it becomes impossible to measure viscosity at this standard temperature. In such cases, researchers commonly measure viscosity at 50°C or 60°C and back-calculate to 40°C using established ASTM or API correlations. It is important to note that this approach introduces variability, with VI calculated from viscosities measured at 60°C and 100°C typically yielding results approximately 5 VI points higher than those calculated from measurements at 50°C and 100°C [1].

Methodological Limitations and Analytical Alternatives

Despite its widespread adoption, the conventional VI measurement approach faces significant challenges regarding precision and reproducibility. The ASTM D445 method has a stated repeatability limit of 0.35% and a reproducibility limit of 0.70%, which translates to substantial uncertainty in calculated VI values—approximately 0.8 for repeatability and 4.5 for reproducibility [1]. This variability presents challenges for precise comparative studies of lubricant formulations.

To address these limitations, researchers have developed alternative methodologies using 13C Nuclear Magnetic Resonance (NMR) spectroscopy [1]. This analytical approach quantifies hydrocarbon composition and molecular structure, enabling VI prediction through mathematical correlations. Studies have demonstrated that VI correlates with structural parameters including average carbon number (ACN) and average branching number (ABN), following the relationship: VI = -0.0008x² + 0.7599x - 17.449, where x = (ACN)²/ABN [1]. This NMR-based method offers a complementary approach to traditional viscometric analysis, particularly for research applications requiring insights into molecular structure-property relationships.

Table 1: Comparison of Viscosity Index Determination Methods

| Method | Principle | Standard Conditions | Repeatability | Key Limitations |

|---|---|---|---|---|

| Conventional (ASTM D2270) | Kinematic viscosity measurement at two temperatures | 40°C and 100°C | ±0.8 VI | Poor reproducibility (±4.5 VI); problematic for waxy oils |

| Alternative for Waxy Oils | Viscosity measurement at higher temperatures with calculation | 50/60°C and 100°C | Varies with method | Introduces bias (≈+5 VI at 60°C) |

| 13C NMR Spectroscopy | Quantitative analysis of molecular structure | Not temperature-dependent | Not established | Requires specialized equipment and calibration |

Viscosity Index Improvers: Mechanisms and Performance Comparison

Molecular Mechanisms of Viscosity Modification

Viscosity Index Improvers (VIIs) are polymer-based additives that reduce the rate of viscosity decrease as temperature rises. These macromolecular compounds function through a temperature-dependent conformational mechanism. At lower temperatures, the polymer chains remain tightly coiled, contributing minimally to the fluid's overall viscosity. As temperature increases, these chains gradually uncoil and expand, increasing their hydrodynamic volume and effectively thickening the fluid to counteract the natural viscosity reduction [4] [5]. This molecular expansion at higher temperatures helps maintain adequate lubricating film thickness while preserving cold-flow properties.

The analogy of a crowded hallway effectively illustrates this mechanism: at cold temperatures, people (polymer molecules) stand with arms close to their bodies, allowing relatively easy movement. At high temperatures, people extend their arms, creating more resistance to movement through the crowd [5]. Similarly, the expanding polymer molecules create more resistance to flow at elevated temperatures, thereby moderating the temperature-viscosity relationship. Different polymer classes exhibit varying expansion capabilities and shear stability, leading to significant performance differences among VII technologies.

Comparative Performance of Major VII chemistries

The global VII market encompasses several polymer classes, each with distinct performance characteristics and application suitability. The dominant categories include polymethylmethacrylates (PMAs), olefin copolymers (OCPs), and hydrogenated styrene-diene copolymers (HSD/SIP/HRIs) [4]. The ethylene propylene copolymer (OCP) segment represents the largest market share at approximately 30.4%, valued for its balance of performance and cost-effectiveness [6]. PMAs offer superior performance in specific applications, while HSD copolymers provide excellent thermal oxidation stability for demanding engine oil formulations [4] [6].

Table 2: Performance Comparison of Major Viscosity Index Improver Types

| Polymer Type | Molecular Architecture | Shear Stability | Low-Temperature Performance | Primary Applications | Market Position (2025) |

|---|---|---|---|---|---|

| Olefin Copolymer (OCP) | Ethylene-propylene copolymers, sometimes with diene | Medium | Good | Engine oils, tractor fluids, hydraulic fluids [4] [6] | 30.4% share [6] |

| Polymethacrylate (PMA) | Acrylic ester polymers | Medium to High | Excellent | Industrial oils, gear oils, hydraulic fluids [4] | Not specified |

| Hydrogenated Styrene-Diene (HSD/SIP/HRI) | Styrene-butadiene or styrene-isoprene hydrogenated | Medium | Good | Engine oils, automatic transmission fluids [4] | Growing demand for thermal oxidation stability [6] |

Shear Stability and Performance Limitations

A critical limitation of VII technology involves mechanical shear degradation. Under high shear conditions, such as in gear contacts or journal bearings, the elongated polymer molecules may experience permanent scission, breaking into smaller fragments [4] [5]. This irreversible molecular degradation diminishes the VII's thickening effectiveness, particularly at high temperatures, potentially leading to viscosity loss and reduced lubricating film thickness over time [5].

This shear susceptibility creates a fundamental trade-off in VII design: higher molecular weight polymers provide better viscosity modification but exhibit poorer shear stability, while lower molecular weight polymers demonstrate improved shear resistance but require higher treat rates to achieve equivalent viscosity modification [5]. Advanced polymer architectures, including star-shaped molecules and controlled rheology formulations, have been developed to optimize this balance, though the fundamental compromise remains. This degradation mechanism underscores the importance of evaluating both fresh and sheared viscosity in lubricant performance testing, particularly for applications experiencing high mechanical stress.

Research Toolkit for VII Performance Evaluation

Essential Research Reagents and Materials

Table 3: Essential Research Reagents and Materials for VII Studies

| Reagent/Material | Function/Application | Research Considerations |

|---|---|---|

| Base Oils (Group I-V) | VII carrier and formulation medium | Group III-V enable higher VI; composition affects VII response [2] [1] |

| Reference Oils (H/L series) | VI scale calibration | Pennsylvania (H=100) and Texas Gulf (L=0) crudes as original references [1] |

| Polymer VIIs (PMA, OCP, HSD) | Experimental additives | Molecular weight and architecture dictate performance [4] |

| Solvents for Polymer Dissolution | VII incorporation into formulations | OCP available in liquid concentrates or solid bales/pellets [7] |

| Antioxidants | Prevent oxidative degradation during testing | Necessary for high-temperature viscosity stability evaluation [2] |

Analytical Instrumentation and Experimental Workflows

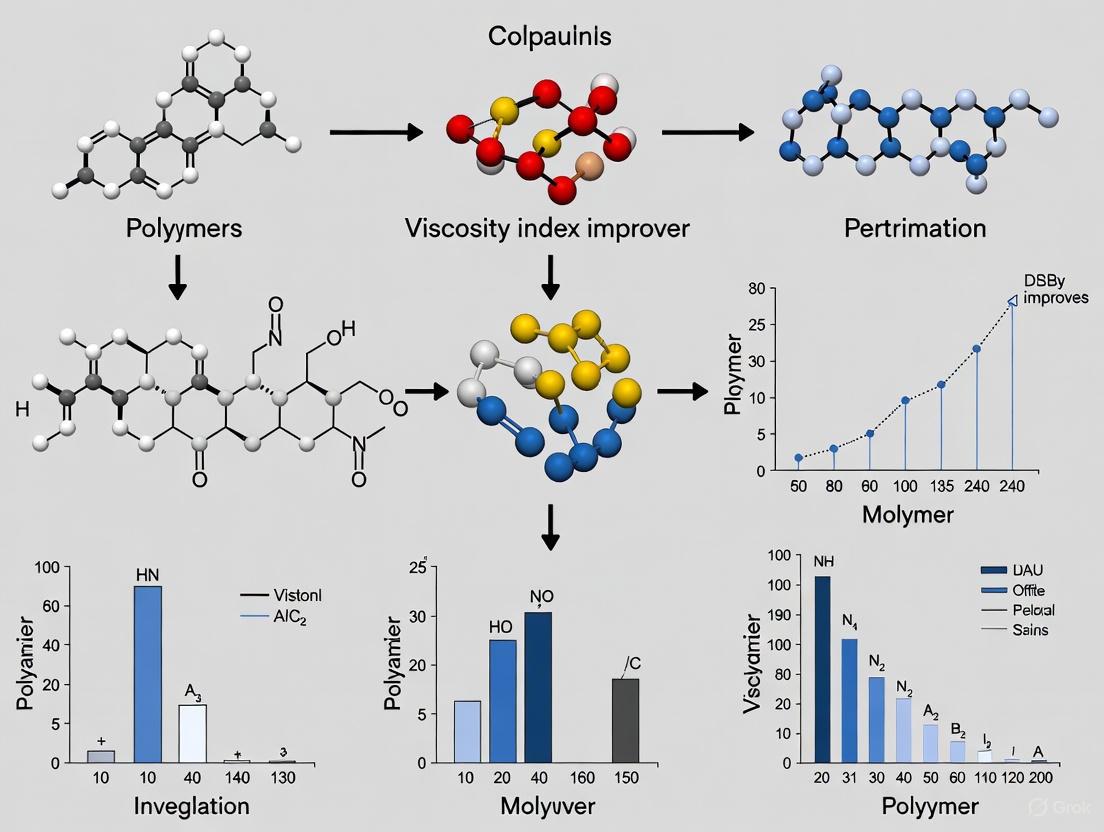

The diagram below illustrates the core experimental workflow for evaluating viscosity index improver performance, integrating both standard protocols and advanced characterization techniques.

Future Research Directions and Market Trends

The viscosity index improver market demonstrates steady growth, projected to reach USD 5.6 billion by 2035 with a Compound Annual Growth Rate (CAGR) of 2.9% [6]. This expansion reflects increasing demand for high-performance lubricants across automotive and industrial sectors, particularly in emerging economies. Regionally, Asia-Pacific shows the most rapid growth, driven by expanding industrialization and automotive production in China and India, while North America maintains the largest market share at approximately 26.5% [7] [6].

Several transformative trends are shaping VII research and development. The electric vehicle revolution is creating demand for specialized VIIs that address unique e-mobility requirements, including compatibility with dielectric coolants, battery thermal management fluids, and reduced electrical conductivity [7]. By 2035, approximately 880 million liters of coolant fluids will be required for electric cars, presenting substantial opportunities for advanced VII formulations [7]. Simultaneously, nanoparticle-enhanced lubricants are emerging as a promising research direction, with studies investigating multi-walled carbon nanotubes (MWCNT) and zinc oxide (ZnO) nanoparticles for reduced cold-start viscosity and improved film strength [6].

Sustainability considerations are increasingly influencing VII technology development, driving research into bio-based viscosity improvers derived from renewable sources like vegetable oils and esters [6]. Regulatory pressures for improved fuel efficiency and reduced emissions continue to accelerate the adoption of low-viscosity lubricants with sophisticated VII packages. These interconnected trends—electrification, nanotechnology integration, and sustainability—will define the next generation of viscosity index improvers, requiring continued interdisciplinary research at the intersection of chemistry, materials science, and tribology.

Viscosity Index Improvers (VIIs) are specialized polymer additives that perform an essential function in modern lubricants: they reduce the rate at which oil's viscosity decreases as temperature rises. This regulation is crucial because lubricants must maintain adequate film thickness to prevent wear at high operating temperatures while remaining fluid enough to circulate freely at low startup temperatures. The viscosity index (VI) itself is a unitless number developed by Dean and Davis in 1929 to quantify this relationship between viscosity and temperature change, with higher values indicating more stable viscosity across temperature ranges [8].

At the molecular level, VIIs function through complex mechanisms that involve changes in polymer chain conformation and supramolecular organization in response to thermal energy. Traditional VIIs like poly(methyl acrylate) (PMA) and olefin copolymers (OCP) operate through physicochemical principles distinct from emerging supramolecular systems, which represent a paradigm shift in viscosity modification technology. This guide provides a comparative analysis of these different VII classes, examining their molecular mechanics, experimental performance data, and research methodologies to inform material selection and development strategies.

Molecular Mechanisms of Conventional Polymer VIIs

The Coil Expansion Mechanism

Conventional polymer-based VIIs, such as polymethacrylates (PMA), olefin copolymers (OCP), and polyisobutylene (PIB), primarily function through a physical mechanism known as coil expansion. At lower temperatures, these polymer chains adopt a tightly coiled conformation in the base oil, presenting a relatively small hydrodynamic volume and thus contributing minimally to the lubricant's viscosity. As temperature increases, the polymers undergo gradual uncoiling, expanding their hydrodynamic radius and effectively increasing their volume fraction within the solution [9] [10]. This expansion counteracts the natural thinning of the base oil at elevated temperatures, thereby maintaining a more stable viscosity profile across the operational temperature range.

The molecular architecture of these polymers directly influences their performance as VIIs. Key structural factors include:

- Molecular weight: Higher molecular weight generally enhances viscosity modification but may reduce shear stability

- Chemical composition: Determines solubility in various base oils and temperature responsiveness

- Architecture: Linear, branched, or star-shaped polymers exhibit different rheological behaviors

- Polarity: Affects interaction with base oil molecules and other additive components

Market Dominance of Conventional VIIs

The global VII market demonstrates significant reliance on these conventional polymer systems, with Olefin Copolymers (OCP) capturing approximately 26.5% of the market share by 2035, followed by Polymethacrylate and Polyisobutylene-based products [7]. The ethylene propylene copolymer (OCP) segment alone is projected to contribute 30.4% of the VII market revenue in 2025, establishing itself as the leading product type due to its strong performance in enhancing viscosity stability across wide temperature ranges and compatibility with various base oils [6].

Table 1: Global Market Position of Major Conventional VII Polymer Types

| Polymer Type | Projected Market Share (2025) | Key Characteristics | Primary Applications |

|---|---|---|---|

| Olefin Copolymer (OCP) | 30.4% [6] | Cost-effective, medium to high molecular weight, good shear stability | Engine oils, tractor fluids, hydraulic fluids, industrial lubricants |

| Polymethacrylate (PMA) | Significant but unspecified [7] | Superior low-temperature performance, dispersant properties | High-performance engine oils, specialized industrial applications |

| Polyisobutylene (PIB) | Significant but unspecified [7] | Good thermal stability | Blended with other VIIs for enhanced performance |

Emerging Supramolecular VIIs: A Paradigm Shift in Mechanism

The Ring-Chain Transformation Mechanism

Supramolecular VIIs represent a fundamentally different approach to viscosity regulation based on reversible molecular associations rather than conformational changes of pre-formed polymers. These systems utilize ditopic monomers featuring self-complementary binding sites, such as the guanidiniocarbonyl pyrrole carboxylic acid (GCP) or aminopyridine carbonyl pyrrole carboxylic acid (ACP) motifs, connected by appropriate linker units [9] [10]. Unlike conventional polymers that maintain their covalent backbone integrity, supramolecular VIIs undergo reversible assembly processes that are highly temperature-dependent.

The unique mechanism of supramolecular VIIs involves a ring-chain transformation [9] [10]:

- At low temperatures, the molecular design favors the formation of small cyclic structures through intramolecular interactions

- As temperature increases, a thermodynamic shift occurs toward supramolecular polymerization via chain elongation

- This transformation significantly increases the hydrodynamic radius of the additives, counteracting base oil thinning at elevated temperatures

- The process is fully reversible, with cooling restoring the cyclic monomeric or oligomeric forms

This mechanism creates a reversed viscosity/temperature effect (RVT) within specific concentration ranges, directly opposing the natural behavior of both base oils and conventional VIIs [9]. The effect is concentration-dependent, occurring within a narrow optimal range—if concentration is too low, cyclic structures predominate across all temperatures; if too high, supramolecular polymers form even at lower temperatures, diminishing the transformative effect [9].

Molecular Engineering of Supramolecular Systems

Research has identified critical structural requirements for effective supramolecular VIIs [9] [10]:

- Binding unit strength: Self-complementary motifs with high dimerization constants (e.g., GCP with Ka > 10¹⁰ M⁻¹ in DMSO) are essential for sufficient supramolecular polymerization

- Linker unit preorganization: Structural features like the gem-dimethyl unit (Thorpe-Ingold effect) or BINAM backbone promote cyclic formation at low temperatures

- Solubility considerations: Less polar binding units (e.g., ACP) improve compatibility with nonpolar environments like motor oils

- Optimal linker length: Force field calculations indicate propionamide as the shortest linker enabling cyclization while allowing subsequent chain formation

Table 2: Experimental Performance of Supramolecular VII Candidates

| Compound | Binding Unit | Linker Unit | Optimal Concentration | Temperature Range for RVT Effect | Performance Characteristics |

|---|---|---|---|---|---|

| 1 | GCP (zwitterionic) | BINAM with propionamide | 50 mM in DMSO | 45-65°C [9] | Distinct viscosity maximum in narrow range |

| 2 | ACP (neutral) | BINAM with propionamide | Not specified | 25-85°C (near-constant viscosity) [9] | Broader temperature stability |

| 4 | ACP | Dihexyl-substituted BINAM | Not specified | Effective in motor oils [9] | Enhanced solubility in nonpolar systems |

Comparative Performance Analysis: Conventional vs. Supramolecular VIIs

Quantitative Performance Metrics

The effectiveness of VIIs is quantitatively assessed using several key parameters, with the viscosity index itself being the primary metric calculated according to ASTM D2270 based on viscosities at 40°C and 100°C [8]. Conventional lubricants with VIIs typically achieve viscosity indices in the range of 100-200, with high-performance synthetics reaching values over 400 [8]. For conventional VIIs, the molecular weight and architecture critically influence both viscosity modification capability and shear stability—higher molecular weight enhances viscosity thickening but increases susceptibility to permanent shear loss through mechanical degradation.

Experimental studies of supramolecular systems demonstrate their unique rheological behavior. For GCP-based derivative 1, a distinct viscosity maximum occurs within a specific temperature window (45-65°C), while ACP-based derivative 2 maintains nearly constant specific viscosity across a broader range (25-85°C) [9]. This concentration-dependent behavior highlights the delicate balance required in supramolecular system design, where the RVT effect only manifests within optimal concentration ranges determined by the specific molecular structure and solvent environment.

Application-Specific Performance Considerations

Different applications prioritize distinct VII performance characteristics:

- Automotive engine oils: Require excellent shear stability, thermal oxidative resistance, and compatibility with additive packages

- Industrial hydraulic fluids: Demand consistent viscosity maintenance across operating temperatures and long-term stability

- Electric vehicle applications: Need specialized formulations for components like electric motors and battery cooling systems

- Food processing and mining: Have unique environmental and operational requirements

Conventional VIIs offer the advantage of established performance profiles and cost-effectiveness, with OCPs being particularly valued for their balance of performance and economics [7]. PMAs provide superior performance in specific applications, especially where low-temperature properties are critical. Supramolecular VIIs offer potential advantages in design flexibility and reversible behavior but face challenges in solubility optimization and manufacturing scalability.

Experimental Methodologies for VII Characterization

Viscosity Measurement Protocols

Standardized methodologies for evaluating VII performance include:

Kinematic Viscosity Measurement (ASTM D445)

- Purpose: Determination of viscosity at standard temperatures (40°C and 100°C)

- Methodology: Measure time for fixed volume of fluid to flow through calibrated capillary viscometer

- Calculation: VI calculated according to ASTM D2270 using measured viscosities

High-Temperature High-Shear Viscosity (ASTM D4683)

- Purpose: Evaluation of viscosity under severe operating conditions

- Methodology: Rotational viscometer with precise temperature control

- Significance: Correlates with engine performance under operating conditions

Falling Sphere Viscometry (for Supramolecular Systems)

- Purpose: Characterize temperature-dependent behavior of novel VIIs

- Methodology: Measure terminal velocity of sphere falling through fluid column at controlled temperatures

- Application: Particularly valuable for screening supramolecular VII candidates with RVT effects [9]

Molecular Dynamics Simulation Approaches

Computational methods have emerged as powerful tools for understanding VII mechanics and screening candidates:

High-Throughput Molecular Dynamics (MD)

- Implementation: Automated curation pipelines integrating MD simulations with machine learning

- Capability: Screening of 1166 VII entries starting from only five polymer types [11]

- Outcome: Identification of 366 high-performance candidates under multi-objective constraints [11]

- Validation: Six representative polymers validated through direct MD simulations [11]

Explainable AI and Symbolic Regression

- Purpose: Extract quantitative structure-property relationships (QSPR) from complex data

- Methodology: SHapley Additive exPlanations (SHAP) and symbolic regression (SR) applied to high-dimensional physical features [11]

- Output: Explicit mathematical models for VII performance prediction [11]

The Researcher's Toolkit: Essential Methods and Reagents

Experimental Research Reagents

Table 3: Essential Research Reagents for Supramolecular VII Development

| Reagent / Material | Function in Research | Application Notes |

|---|---|---|

| GCP Binding Motif | Self-complementary zwitterionic binding unit with high dimerization constant | Forms strong sixfold hydrogen-bonding networks; limited solubility in nonpolar solvents [9] |

| ACP Binding Motif | Neutral analog of GCP with reduced polarity | Improved solubility in nonpolar systems; sufficient association strength (Ka > 10⁶ M⁻¹ in chloroform) [9] |

| BINAM Linker | Preorganizing backbone for cyclic formation | Concave arrangement promotes intramolecular cyclization at low temperatures [9] |

| Propionamide Spacer | Optimal distance connector between BU and LU | Force field calculations identify as shortest linker enabling cyclization [9] |

| Dihexyl-Substituted Derivatives | Solubility-enhancing modified linkers | Improve compatibility with nonpolar environments like motor oils [9] |

- High-Throughput MD Platforms: Automated systems for batch computation of polymer properties [11]

- Symbolic Regression Algorithms: For deriving interpretable mathematical models from complex data [11]

- Falling Sphere Viscometers: Essential for characterizing temperature-dependent viscosity of novel systems [9]

- Green-Kubo Relation Methods: Calculate viscosities from equilibrium MD simulations via stress-tensor autocorrelation [12]

The molecular mechanics of viscosity index improvers encompass diverse phenomena, from the coil expansion of conventional polymers to the reversible supramolecular assembly of emerging systems. Conventional VIIs like OCP and PMA provide reliable performance through well-established physicochemical principles, while supramolecular approaches offer unprecedented control through molecular design. The future VII research landscape will likely focus on several key areas: developing improved compatibility with bio-based lubricants, creating specialized formulations for electric vehicle applications, and enhancing sustainability profiles through green chemistry approaches.

For researchers, the current state of VII technology presents rich opportunities in multiple domains: computational screening and prediction using advanced ML and MD methods, molecular engineering of supramolecular systems with tailored properties, and hybrid approaches combining conventional and supramolecular strategies. As regulatory pressures increase and lubricant performance requirements become more demanding, the fundamental understanding of how polymers regulate viscosity across temperatures will continue to drive innovation in this critical field of materials science.

Viscosity Index Improvers (VIIs) are high molecular weight, oil-soluble polymers that are crucial components in modern lubricants, particularly multigrade oils [13]. Their primary function is to reduce the rate at which lubricating oil's viscosity decreases with rising temperature [14]. The Viscosity Index (VI) is a key metric quantifying this relationship, where a higher VI indicates less viscosity change across temperatures—a highly desirable property for lubricants operating in fluctuating conditions [15] [14]. The foundational mechanism by which most VIIs operate is coil expansion, where polymer molecules adopt a more compact structure at lower temperatures and expand as temperature increases, thereby providing greater thickening effect precisely when the base oil thins [15].

This guide provides a comparative analysis of the four major VII polymer families: Olefin Copolymers (OCP), Polymethacrylates (PMA), Polyisobutylene (PIB), and Hydrogenated Styrene-Diene (HSD). The performance of these VIIs is evaluated based on key parameters including thickening efficiency, shear stability, viscosity index improvement, and low-temperature performance [13] [14]. The data and experimental insights presented are framed within the broader research context of optimizing lubricant formulations for enhanced efficiency and durability.

VII Polymer Families: Structure, Properties, and Performance Data

Olefin Copolymers (OCP)

- Chemical Structure: OCPs are copolymers of ethylene and propylene. The mass ratio of ethylene to propylene (E/P ratio) significantly influences their physical properties. At E/P ratios above ~60/40, the polymers can develop semicrystalline regions due to longer ethylene sequences [13].

- Key Properties: OCPs are recognized for their high thickening efficiency and cost-effectiveness [15] [14]. A potential drawback is their poor shear stability compared to other VIIs, which can be mitigated by using lower molecular weight grades [15]. Their performance is highly dependent on the E/P ratio; higher ethylene content can lead to wax-like behavior and impaired low-temperature properties [15].

- Performance Data:

Polymethacrylates (PMA)

- Chemical Structure: PMAs are linear polymers synthesized from methacrylate esters. Their structure incorporates side chains of varying lengths (short, intermediate, and long alkyl groups) to balance oil solubility, low-temperature performance, and wax interaction [13].

- Key Properties: PMAs are considered a premium VII chemistry, offering exceptional VI improvement and superior low-temperature performance [15] [13]. They are highly effective at reducing viscosity in cold cranking simulator (CCS) tests, ensuring easier engine starts [14]. The main disadvantages are their higher cost and moderate thickening efficiency compared to OCP and HSD [15] [14].

- Performance Data:

Polyisobutylene (PIB)

- Chemical Structure: PIB is a unique homopolymer with a hydrocarbon backbone featuring numerous methyl side groups, resulting in a relatively rigid molecular chain [14].

- Key Properties: PIB is one of the earliest VIIs and is characterized by its excellent shear stability and low cost [15] [14]. Its key limitation is poor performance at low temperatures, as its rigid chain causes viscosity to increase rapidly upon cooling [14]. Due to its relatively low molecular weight, PIB often functions more as a thickener than a highly effective VII [15].

- Performance Data:

Hydrogenated Styrene-Diene (HSD)

- Chemical Structure: HSD polymers, also known as styrene-isoprene copolymers, can be engineered with different architectures, including linear diblock and star-shaped structures [15] [17].

- Key Properties: HSD polymers offer a balanced profile with thickening efficiency on par with OCP and good shear stability [15] [14]. Star-branched HSD architectures, in particular, are known for combining high thickening efficiency with improved shear stability, as mechanical degradation tends to occur near the core rather than breaking the main chain [15]. Their oxidation stability is generally considered moderate [14].

- Performance Data:

Table 1: Qualitative Comparison of Major VII Polymer Families

| Polymer Family | Thickening Efficiency | Shear Stability | Oxidation Stability | Low-Temperature Performance | Relative Cost |

|---|---|---|---|---|---|

| OCP | High [14] | Poor to Moderate [15] | Moderate [14] | Moderate to Poor [15] | Low [15] |

| PMA | Moderate [14] | Moderate [15] | Excellent [14] | Excellent [15] [14] | High [15] |

| PIB | Low [14] | Excellent [15] [16] | Good [14] | Poor [14] | Low [15] |

| HSD | High [14] | Good [15] | Moderate [14] | Good [15] | Moderate |

Table 2: Key Molecular and Performance Characteristics

| Polymer Family | Typical Molecular Weight (g/mol) | Primary Performance Mechanism | Common Form |

|---|---|---|---|

| OCP | ~100,000 (can be very high) [15] | Coil expansion; performance depends on E/P ratio [15] [13] | Solid or liquid concentrate in oil [13] |

| PMA | 20,000 - 750,000 [13] | Polarity-driven coil expansion/contraction with temperature [13] | Liquid concentrate in mineral oil (30-80% polymer) [13] |

| PIB | ~1,000 (relatively small) [15] | Functions more as a thickener; limited coil expansion [15] | Not specified in search results |

| HSD | Not specified in search results | Architecture-dependent (e.g., star-shaped for shear stability) [15] | Dry glue or liquid concentrate [17] |

Experimental Analysis and Methodologies

Evaluating VII performance requires standardized tests to measure critical parameters under controlled conditions. The following section outlines key experimental protocols and findings from recent research.

Viscometric Properties and Thickening Efficiency

- Experimental Protocol: A standard method for investigating VII behavior involves dissolving different amounts of VII polymers in various base oils (e.g., API Group I, II, III) and measuring the kinematic viscosities (KV) at 40°C and 100°C [15]. The intrinsic viscosity (IV), calculated using methods like the Huggins equation, serves as a criterion for estimating polymer molecular size in solution [15] [18]. Thickening efficiency (TE) can be predicted based on these intrinsic viscosities [18].

- Key Findings: Research shows that intrinsic viscosity is higher at lower temperatures, confirming the coil expansion mechanism [15]. Furthermore, intrinsic viscosity and thickening efficiency exhibit a clear dependence on polymer molecular weight [15] [13].

Shear Stability Testing

- Importance: Shear stability is a VII's ability to resist mechanical degradation. Permanent shear loss occurs when polymer chains break, leading to an irreversible loss of viscosity [13] [14].

- Experimental Insight: High-molecular-weight polymers like some OCPs and PMAs are most susceptible to permanent shear loss [15] [13]. The architecture matters; for example, star-shaped polymers exhibit improved shear stability because chain scission is more likely near the core, preserving the overall molecular weight of the arms better than a random break in a linear chain [15].

Tribological Performance in Lubricated Contacts

- Experimental Protocol: Studies often employ tribometers to simulate conformal and non-conformal contacts under boundary and mixed lubrication regimes. For example, research on PIB added to a paraffinic base oil (N150) evaluated its performance as a friction and anti-wear modifier [19].

- Key Findings: PIB was found to enhance the anti-wear and friction characteristics of low-viscosity mineral oil under light loading conditions [19]. The study also highlighted that polymers with polar, dispersant moieties (like certain PMAs) can form boundary films on metal surfaces, further reducing friction and wear [19].

Advanced Research and Future Directions

Data-Driven Discovery and Molecular Dynamics

The development of new VII polymers is being revolutionized by data-driven approaches. Researchers are now using high-throughput all-atom molecular dynamics (MD) simulations to efficiently generate data on polymer properties and screen for high-performance candidates [20]. This pipeline addresses data scarcity in materials science. By combining MD with explainable AI and symbolic regression, researchers can build interpretable quantitative structure-property relationship (QSPR) models, providing explicit mathematical frameworks to guide the design of next-generation VIIs with tailored viscosity-temperature performance [20].

Polymer Blends and Architectural Innovations

- Polymer Blends: Formulators are increasingly using blends of different VIIs to achieve a balance of properties that a single polymer cannot provide. For instance, PMA and OCP can be blended (sometimes with a compatibilizer) to combine the superior VI and low-temperature rheology of PMA with the cost-efficient thickening of OCP [15]. Another patent demonstrates that blending PMA and PIB creates a composition with both good low-temperature performance and shear stability for gear oil applications [16].

- Architectural Control: Advancements in polymer synthesis have moved beyond linear structures to branched, comb, and star-shaped architectures [15]. These advanced architectures are designed to optimize the trade-off between thickening efficiency and shear stability. For example, star-branched PMAs and HSDs have demonstrated superior thickening efficiency and shear stability compared to their linear counterparts [15].

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for VII Research

| Item | Function in Research |

|---|---|

| Base Oils (API Groups I, II, III) | The solvent medium for evaluating VII performance; different base oil groups can interact differently with the same VII, affecting solvency and coil dimensions [15]. |

| Commercial VII Concentrates | Sources of OCP, PMA, PIB, and HSD polymers in a handleable liquid form, typically dissolved in a light mineral oil [13] [17]. |

| Cold Cranking Simulator (CCS) | A high-shear-rate viscometer that measures apparent viscosity at low temperatures to simulate engine startability, a critical test for multi-grade oils [14]. |

| Kinematic Viscometry Bath | Precision equipment for measuring kinematic viscosity at standard temperatures of 40°C and 100°C, which are essential for calculating Viscosity Index [15] [20]. |

| Shear Stability Test Rig | Equipment (e.g., using diesel injectors, tapered bearing simulators, or sonic shearers) to subject VII-containing oils to high shear stresses and quantify permanent viscosity loss [14]. |

Visualizing VII Polymer Behavior and Research Workflows

VII Molecular Mechanism and Temperature Response

Data-Driven VII Research Pipeline

Viscosity Index Improvers (VIIs) are high molecular weight polymer additives essential to modern lubricant formulation. Their primary function is to reduce the rate at which a lubricant's viscosity decreases with increasing temperature, thereby ensuring consistent performance across a wide operational temperature range [21]. This is achieved through the coil expansion mechanism, where polymer molecules expand at higher temperatures, providing greater thickening effect to counteract the natural thinning of the base oil [15] [22]. The performance of VIIs is critically evaluated through three fundamental parameters: Thickening Efficiency, which determines the viscosity increase per unit mass of polymer; Shear Stability, which reflects the polymer's resistance to mechanical degradation; and Oxidative Resistance, which indicates the polymer's ability to withstand thermal and oxidative breakdown [22] [14]. This guide provides a comparative analysis of major VII chemistries—Olefin Copolymer (OCP), Polymethacrylate (PMA), Polyisobutylene (PIB), and Hydrogenated Styrene-Diene (HSD)—to inform researchers and formulators in selecting optimal additives for specific applications.

Comparative Performance of VII Chemistries

Quantitative Performance Comparison

The performance of VIIs varies significantly with polymer chemistry and molecular structure. The following table summarizes key parameters for major VII types based on experimental and commercial data.

Table 1: Comprehensive Performance Comparison of Major Viscosity Index Improvers

| VII Type | Thickening Efficiency | Shear Stability | Oxidative Resistance | Low-Temperature Performance | Primary Applications |

|---|---|---|---|---|---|

| Olefin Copolymer (OCP) | High [14] | Moderate to High (P-SSI as low as 20) [23] | Moderate [14] | Moderate (can be poor if ethylene content >50%) [15] | Engine oils, Hydraulic oils [23] [21] |

| Polymethacrylate (PMA) | Moderate [14] | High [23] | Excellent [14] | Excellent (lowest CCS viscosity) [14] | High-performance engine oils, Hydraulic oils (for water tolerance) [23] [21] |

| Polyisobutylene (PIB) | Low to Moderate [14] | Excellent (due to low MW) [15] | Good [14] | Poor (viscosity increases rapidly at low temps) [14] | Gear oils [21] |

| Hydrogenated Styrene-Diene (HSD) | High [14] | High (especially star-shaped architectures) [15] | Moderate [14] | Moderate | Engine oils [21] |

Detailed Parameter Analysis

Thickening Efficiency

Thickening Efficiency (TE) quantifies the viscosity increase a polymer provides at a specific treat rate, typically measured at 100°C [22]. It is strongly dependent on molecular weight; higher molecular weight linear polymers generally provide better TE [22]. OCP and HSD offer the highest thickening efficiency, making them cost-effective choices where high treat rates are undesirable. PMA provides moderate thickening, while PIB's efficiency is lowest, acting more as a thickener than a true VII due to its small molecular size [15] [14].

Shear Stability

Shear Stability measures a VII's resistance to mechanical degradation under high shear stress, which can cause irreversible polymer chain scission and permanent viscosity loss [14]. It is evaluated by standards like ASTM D6278, with results expressed as Shear Stability Index (SSI) or Permanent Shear Stability Index (P-SSI) [23]. Lower SSI values indicate superior stability. PIB and star-branched architectures (e.g., star PMA or HSD) exhibit the highest shear stability due to robust molecular structures [15]. Functional Products Inc. reports OCP grades with P-SSI values as low as 20, indicating high shear stability [23].

Oxidative Resistance

Oxidative Resistance determines a VII's ability to withstand thermal-oxidative degradation at high operating temperatures (100-200°C), which can lead to viscosity loss, increased acid number, and deposit formation [14]. PMA demonstrates the highest oxidative stability, followed by PIB, with OCP and HSD being moderately stable [14]. The presence of ester groups in PMA and the saturated structure of PIB contribute to their robust performance.

Experimental Protocols for VII Evaluation

Standard Testing Methodologies

Researchers employ standardized tests to quantitatively assess VII performance. The workflow for a comprehensive evaluation typically involves sequential testing of key parameters.

Diagram 1: VII Performance Evaluation Workflow

1. Viscosity Index Determination (ASTM D2270):

- Protocol: Kinematic viscosity of the formulated lubricant is measured at 40°C and 100°C using glass capillary viscometers. The Viscosity Index is calculated using standardized equations that compare the oil's viscosity-temperature relationship to reference oils [15].

- Data Interpretation: A higher VI indicates superior viscosity-temperature performance. Modern VIIs can achieve VIs exceeding 400, far beyond the original scale of 0-100 [21].

2. Shear Stability Testing (ASTM D6278):

- Protocol: The lubricant sample is circulated through a diesel injector rig for a set number of cycles (e.g., 30 or 90 passes) at a specific temperature and pressure. The kinematic viscosity at 100°C is measured before and after the test [23].

- Data Interpretation: The Permanent Shear Stability Index (P-SSI) is calculated as:

P-SSI = [(KV_initial - KV_final) / (KV_initial - KV_base)] × 100, where KV_base is the base oil viscosity. Lower P-SSI values indicate better shear stability [23].

3. Oxidation Stability Testing:

- Protocol: Tests like the Thin-Film Oxygen Uptake Test (TFOUT) expose the oil to oxygen, catalysts, and elevated temperatures to accelerate oxidation. Viscosity change, acid number increase, and catalyst metal content are monitored [21].

- Data Interpretation: Smaller changes in viscosity and acid number indicate higher oxidative resistance. PMA-based VIIs typically show minimal degradation under these conditions [14].

Advanced Research Techniques

Beyond standard tests, advanced techniques provide deeper molecular-level insights:

High-Throughput Molecular Dynamics (MD):

- Protocol: All-atom MD simulations automate the calculation of viscosity and polymer conformational changes across temperatures. Researchers input polymer structures (e.g., via SMILES notation) and run high-throughput simulations to predict VI and TE [20].

- Data Interpretation: Coil size, quantified by the radius of gyration, is correlated with viscosity. Polymers with electronegative atoms (e.g., oxygen in PMA) often exhibit greater coil expansion with temperature, enhancing VI [20] [22].

Traction Coefficient Measurement:

- Protocol: Using a Mini-Traction-Machine (MTM), a ball-on-disk tribometer, the traction coefficient is measured under varied slide-to-roll ratios, contact pressures, and temperatures [22].

- Data Interpretation: Low traction coefficients reduce shearing forces in hydrodynamic contacts, improving energy efficiency in applications like hydraulic systems [22].

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Materials and Experimental Systems for VII Evaluation

| Reagent/Equipment | Function & Research Application | Experimental Context |

|---|---|---|

| Base Oils (API Groups I, II, III) | Solvent medium for VII dissolution; performance varies with base oil composition and solvency [15]. | Essential for all formulation studies; VII effectiveness is base-oil dependent. |

| Commercial VII Polymers (OCP, PMA, PIB, HSD) | Target additives for performance comparison and formulation optimization. | Core test materials; available from manufacturers like Lubrizol, Infineum, Chevron Oronite, Functional Products [7] [23]. |

| Glass Capillary Viscometers | Measure kinematic viscosity at standardized temperatures (40°C, 100°C) for VI calculation [15]. | Key instrument for ASTM D2270 compliance. |

| Cold Cranking Simulator (CCS) | Measures apparent viscosity at high shear rates and low temperatures to simulate engine starting [14]. | Critical for evaluating low-temperature performance of engine oils (SAE J300). |

| Diesel Injector Shear Rig | Subjects lubricant to high mechanical shear to simulate permanent viscosity loss in service [23]. | Standard equipment for ASTM D6278 shear stability testing. |

| Mini-Traction-Machine (MTM) | Quantifies traction coefficient under elastohydrodynamic lubrication (EHL) conditions [22]. | Used for advanced studies on fluid friction and energy efficiency. |

Molecular Mechanisms and Structure-Property Relationships

The performance differences between VII chemistries originate from their fundamental molecular structures and conformational behaviors in solution.

Diagram 2: VII Structure-Property Relationship Framework

Coil Expansion Mechanism: The widely accepted Selby mechanism explains that VII polymers expand coil size at higher temperatures, providing greater thickening effect to compensate for base oil thinning [15] [22]. However, MD simulations reveal this behavior is chemistry-dependent: ester-based polymers like PMA with polar backbones show significant expansion, while nonpolar hydrocarbons like OCP may show constant or decreasing coil size with temperature [22].

Molecular Architecture Effects: Beyond chemistry, molecular architecture critically influences performance. Star-shaped and comb architectures provide superior shear stability compared to linear polymers because mechanical scission occurs near the core or branches rather than in the middle of long chains [15]. For example, star-branched PMA offers better thickening efficiency and shear stability than linear PMA at the same SSI [15].

Polarity and Solubility: Polymers must have sufficient but limited solubility in base oil at ordinary temperatures to function effectively. Increased solubility at higher temperatures enables greater thickening effect [21]. The presence of electronegative atoms (e.g., oxygen in PMA) enhances temperature-dependent solubility and coil expansion [22].

The selection of optimal viscosity index improvers involves balancing thickening efficiency, shear stability, and oxidative resistance against application requirements and cost constraints. OCP polymers offer the best combination of high thickening efficiency and cost-effectiveness for general engine oil applications. PMA polymers provide superior oxidative resistance, low-temperature performance, and VI improvement for high-stress and wide-temperature-range applications. PIB delivers exceptional shear stability, making it suitable for gear oils and applications with extreme mechanical shear. Emerging research in polymer architecture, including star-shaped and comb polymers, along with high-throughput molecular dynamics screening, continues to advance VII performance, enabling more energy-efficient and durable lubricants for future automotive and industrial applications.

Testing, Selection, and Advanced Formulation Strategies for VIIs

Standardized Laboratory Methods for Evaluating VII Performance

Viscosity Index Improvers (VIIs) are polymer additives that reduce the rate of viscosity change in lubricants across temperature variations [5] [4]. These additives are crucial components in multigrade engine oils, transmission fluids, hydraulic fluids, and gear oils, where they ensure optimal lubrication performance during both cold-start conditions and high-temperature operation [5] [4]. The primary function of VIIs is to maintain viscosity within optimal ranges across operating temperatures, ensuring adequate lubrication while minimizing energy losses [4].

Evaluating VII performance requires standardized laboratory methods that objectively quantify key parameters including viscosity-temperature relationships, shear stability, thermal-oxidative stability, and thickening efficiency. These standardized tests enable researchers and lubricant developers to compare different VII chemistries and select optimal formulations for specific applications [5] [4]. This guide provides a comprehensive comparison of standardized test methods essential for rigorous VII evaluation in research and development settings.

Core Laboratory Evaluation Methods

Viscosity-Temperature Relationship Analysis

The viscosity index (VI) is the fundamental metric for quantifying how viscosity changes with temperature. According to standardized methods referenced in technical literature, kinematic viscosity is measured at both 40°C and 100°C, with the resulting change compared to empirical reference scales [4]. The calculation follows established protocols where Pennsylvania crude was arbitrarily assigned a VI of 100 and Texas Gulf crude a VI of 0 [4].

Test Method Overview:

- Principle: Measure kinematic viscosity at precisely controlled temperatures of 40°C and 100°C using calibrated glass capillary viscometers

- Standard Reference: ASTM D2270 - Practice for Calculating Viscosity Index from Kinematic Viscosity

- Key Parameters: Kinematic viscosity at 40°C (ν40) and 100°C (ν100), calculated Viscosity Index

- Apparatus: Calibrated glass capillary viscometers, precision temperature control bath (±0.01°C)

- Procedure:

- Condition sample at 40°C in temperature bath

- Measure flow time through calibrated capillary

- Repeat at 100°C

- Calculate kinematic viscosity at each temperature

- Compute VI using standardized calculation procedures

Table 1: Standardized Viscosity-Temperature Test Methods

| Test Method | Measured Parameters | Application in VII Evaluation | Standard Reference |

|---|---|---|---|

| Kinematic Viscosity at 40°C & 100°C | ν40, ν100 | Base viscosity measurement | ASTM D445 |

| Viscosity Index Calculation | VI value | Quantifies temperature-viscosity relationship | ASTM D2270 |

| Cold Cranking Simulator | Apparent viscosity at low temperatures | Predicts low-temperature performance | ASTM D5293 |

| High-Temperature High-Shear Viscosity | Viscosity under shear at 150°C | Evaluates high-temperature film maintenance | ASTM D4683 |

Shear Stability Testing

Shear stability represents a VII's resistance to mechanical degradation under stress, a critical performance parameter since polymer chain scission permanently reduces viscosity [5] [4]. As one technical source explains: "As the additive is repeatedly sheared, it loses its ability to act as a more viscous fluid at higher temperatures. Higher molecular weight polymers make better thickeners but tend to have less resistance to mechanical shear" [5]. This mechanical degradation occurs because polymeric VII molecules uncoil under high temperature and shear stress, and if molecular bonds break, they cannot reform their original coil structure, resulting in permanent viscosity loss [4].

Standardized Shear Stability Tests:

- European Diesel Injector Test (CEC L-45-A-99): Forces lubricant through diesel injector nozzles under high pressure for specified cycles

- SONIC Shear Test (ASTM D5621): Subjects sample to high shear in acoustic resonator

- Kurt Orbahn Test (ASTM D6278): Utilizes diesel injector system to simulate mechanical shear

- Tapered Roller Bearing Test (ASTM D5133): Measures viscosity loss in tapered bearing configuration

Table 2: Standardized Shear Stability Test Methods for VII Evaluation

| Test Method | Shear Mechanism | Test Duration | Measured Outcome |

|---|---|---|---|

| Kurt Orbahn (ASTM D6278) | Diesel injector | 30-90 cycles | % Viscosity loss at 100°C |

| SONIC Shear (ASTM D5621) | Acoustic shearing | 5-40 minutes | % Viscosity loss |

| Tapered Bearing (ASTM D5133) | Bearing contact stresses | 20 hours | % Viscosity loss |

| European Injector (CEC L-45) | Diesel injector | 30-90 cycles | % Viscosity loss |

Thermal and Oxidative Stability Assessment

VII performance degrades under elevated temperatures and oxidative conditions. Standardized tests evaluate resistance to thermal breakdown and oxidation, which is particularly important for modern engines operating at higher temperatures and extended drain intervals [4] [6].

Key Stability Test Methods:

- Thermal Stability (ASTM D2070): Assesses deposit formation and viscosity change after heating

- Oxidative Stability (ASTM D2893): Evaluates viscosity increase and acid number change under oxygen

- Pressurized Differential Scanning Calorimetry (ASTM D6186): Measures oxidation induction time

- Thin-Film Oxygen Uptake Test (ASTM D7547): Determines oxidation stability under thin-film conditions

The experimental workflow for comprehensive VII evaluation follows a systematic progression from basic characterization to specialized performance testing, as illustrated below:

Comparative Performance Data for Major VII Types

Polymethacrylates (PMA)

PMA-based VIIs demonstrate exceptional shear stability and pour point depression capabilities [24]. They are particularly valued in premium synthetic lubricants and specialized applications where extended fluid life outweighs cost considerations [24]. PMAs provide excellent low-temperature performance and are often selected for hydraulic fluids and transmission applications where thermal resistance is critical.

Performance Characteristics:

- Shear Stability Index: 0-5% viscosity loss in Kurt Orbahn test (30 cycles)

- Viscosity Improvement: Moderate thickening efficiency

- Low-Temperature Performance: Excellent pour point depression

- Thermal Stability: Stable up to 300°C in oxidative environments

- Compatibility: Broad compatibility with Group II-IV base oils

Olefin Copolymers (OCP)

OCP VIIs represent the most widely used viscosity modifiers globally, dominating the passenger car motor oil market due to their favorable balance of cost and performance [7] [24]. Accounting for approximately 62% of global VII revenue, OCPs offer versatile performance across automotive and industrial applications [24]. Technical literature notes they are "cost-effective alternative to heavy petroleum oils, offering better low-temperature fluidity and increased high-temperature viscosity" [7].

Performance Characteristics:

- Shear Stability Index: 5-15% viscosity loss in Kurt Orbahn test (30 cycles)

- Viscosity Improvement: High thickening efficiency

- Low-Temperature Performance: Good low-temperature properties

- Thermal Stability: Stable up to 280°C

- Compatibility: Excellent with Group I-III base oils

Hydrogenated Styrene-Diene (HSD/HSI)

HSD copolymers provide superior performance in high-load environments, particularly in gear oils and heavy-duty applications where extreme pressure conditions prevail [6] [24]. Their molecular structure enables maintained viscosity under extreme mechanical stress, making them ideal for industrial gearboxes, wind turbines, and mining equipment [24].

Performance Characteristics:

- Shear Stability Index: 3-8% viscosity loss in Kurt Orbahn test (30 cycles)

- Viscosity Improvement: High thickening efficiency

- Low-Temperature Performance: Moderate pour point depression

- Thermal Stability: Excellent thermal-oxidative stability

- Compatibility: Good with synthetic and mineral base oils

Table 3: Comparative Performance of Major VII Polymer Types in Standardized Tests

| Performance Parameter | Polymethacrylate (PMA) | Olefin Copolymer (OCP) | Hydrogenated Styrene-Diene (HSD) |

|---|---|---|---|

| Viscosity Index Improvement | Moderate | High | High |

| Shear Stability Index (% viscosity loss) | 0-5% | 5-15% | 3-8% |

| Low-Temperature Viscosity (CCS at -25°C) | Excellent | Good | Moderate |

| Thermal Stability Limit | 300°C | 280°C | 290°C |

| Oxidative Stability (RBOT life, minutes) | 120-180 | 100-150 | 140-200 |

| Thickening Efficiency | Moderate | High | High |

| Typical Treat Rate (%) | 0.5-2.0% | 0.3-1.5% | 0.4-1.8% |

Advanced Testing for Emerging Applications

Electric Vehicle Fluids Testing

The rapid growth in electric vehicles has created new testing requirements for VIIs in specialized e-fluids [7] [6]. EV applications demand VIIs that perform in distinct environments characterized by lower average temperatures, high torque at startup, and potential electrical influences [7] [24]. Technical reports note that "EVs require specialized lubricants for components like electric motors, transmissions, battery cooling systems, and drivetrains" that must perform under high temperatures and electrical loads [7].

Specialized EV Fluid Tests:

- Dielectric Compatibility: Measures fluid's electrical properties after shear

- E-Motor Compatibility: Assesses material compatibility with motor components

- Copper Corrosion (ASTM D130): Evaluates electrical conductivity impacts

- Battery Cooling Efficiency: Measures heat transfer properties with degraded VII

Bio-based Lubricant Compatibility

Increasing environmental regulations have driven development of VIIs compatible with bio-based lubricants [6] [24]. These formulations present unique challenges due to different polarity and solvency characteristics compared to mineral oil base stocks [24].

Specialized Compatibility Tests:

- Bio-degradability (OECD 301): Measures environmental impact

- Hydrolytic Stability (ASTM D2619): Assesses water resistance

- Seal Compatibility (ASTM D471): Evaluates elastomer interactions

- Storage Stability: Measures phase separation in bio-based formulations

Essential Research Reagent Solutions

Successful VII evaluation requires specific research reagents and specialized materials that enable consistent, reproducible testing across different laboratories and research programs.

Table 4: Essential Research Reagents for VII Performance Evaluation

| Research Reagent | Technical Specification | Application in VII Testing |

|---|---|---|

| Reference Base Oils | Group I-V, defined viscosity grades | Baseline formulation and compatibility testing |

| VII Polymer Standards | Certified molecular weight distributions | Calibration and method validation |

| Shear Stability Reference Oils | Certified viscosity loss values | Instrument calibration and QC |

| Oxidation Catalyst | ASTM E1064 certified metals | Oxidative stability test standardization |

| Viscosity Standard Oils | NIST-traceable viscosity values | Viscometer calibration and verification |

| Pour Point Reference | Certified pour point values | Low-temperature instrument calibration |

Standardized laboratory methods provide the foundation for rigorous, reproducible evaluation of viscosity index improver performance. The test methodologies outlined in this guide enable direct comparison of different VII technologies across key performance parameters including viscosity-temperature relationships, shear stability, and oxidative resistance. As lubricant technology evolves toward higher performance specifications and specialized applications like electric vehicles, these standardized methods continue to provide the critical data needed for research-driven VII selection and formulation optimization.

Viscosity Index Improvers (VIIs) are essential polymer additives engineered to reduce the rate at which a lubricant's viscosity changes with temperature [25]. A higher Viscosity Index (VI) indicates less viscosity change, which is critical for ensuring consistent lubrication, reducing wear, and improving fuel efficiency across the operating temperature range of engines and industrial machinery [26] [25]. The core challenge in VII selection lies in balancing key performance properties, as polymers with higher molecular weights are better thickeners but are often more prone to breaking under mechanical shear, which affects long-term shear stability [26]. This guide provides a structured framework for researchers and scientists to objectively compare major VII chemistries and select the optimal polymer based on specific application requirements, supported by experimental data and protocols.

Comparative Performance of Major VII Polymers

The performance of a VII is governed by its molecular architecture, weight, and chemical composition. The following table summarizes the key characteristics of the most prevalent VII polymers to guide initial screening.

Table 1: Key Characteristics of Major Viscosity Index Improver Polymers

| Polymer Type | Shear Stability | Thickening Efficiency | Low-Temperature Performance | Primary Application Fit |

|---|---|---|---|---|

| Olefin Copolymer (OCP) | Moderate to Good | Good [27] | Moderate | Cost-effective solution for engine oils and hydraulic fluids [27] [28]. |

| Polymethacrylate (PMA) | Good | Superior [27] | Excellent [27] [29] | Premium lubricants, automatic transmission fluids (ATFs) requiring excellent low-temperature fluidity [27]. |

| Styrenic Elastomers (e.g., SEPTON) | Good [25] | Good (Higher VI vs. OCP) [25] | Excellent (Lower viscosity at low temp) [25] | Applications requiring a high VI and good shear stability across a wide temperature range [25]. |

| Hydrogenated Styrene-Diene (HSD) | Information from Search | Information from Search | Information from Search | A established chemistry used in lubricant formulations [20]. |

Quantitative performance data is crucial for direct comparison. The table below consolidates experimental findings from research and industry profiles.

Table 2: Quantitative Performance Comparison of VII Polymers

| Performance Parameter | Olefin Copolymer (OCP) | Polymethacrylate (PMA) | Styrenic Elastomers (e.g., SEPTON) |

|---|---|---|---|

| Relative Thickening Efficiency (TE) | Baseline (Good) [27] | Higher than OCP (Superior) [27] | Higher VI than OCP [25] |

| Low-Temperature Viscosity | Moderate | Low (Excellent) [27] [29] | Lower viscosity ≤20°C vs. OCP [25] |

| Shear Stability (Relative) | Moderate to Good | Good | Good (Narrow MWD contributes to stability) [25] |

| Molecular Weight Distribution | Information from Search | Information from Search | Narrow [25] |

| Key Performance Trade-off | Cost-effectiveness vs. ultimate low-temperature performance [28]. | Superior performance often at a higher cost [27]. | Balance of high VI and good shear stability [25]. |

Experimental Protocols for VII Evaluation

High-Throughput Molecular Dynamics for VII Screening

A modern approach to VII screening leverages High-Throughput All-Atom Molecular Dynamics (MD) to generate extensive datasets and predict performance virtually [20].

Workflow Overview:

Figure 1: High-throughput MD screening workflow for VII discovery.

Detailed Methodology:

- Polymer Input: The process begins with a Simplified Molecular Input Line Entry System (SMILES) string for each polymer candidate, enabling automated processing [20].

- Force Field & Simulation: An automated computational workflow configures force fields and performs high-throughput MD simulations. Systems are built with the polymer blended into a model base oil [20].

- Viscosity Calculation: Shear viscosity is computed using Non-Equilibrium Molecular Dynamics (NEMD) simulations. The system is subjected to a shear flow, and the resulting stress response is used to calculate viscosity across a range of temperatures to derive the Viscosity Index [20].

- Data Analysis & Screening: Molecular features (descriptors) are extracted from the simulations. Machine learning models (e.g., Random Forest, XGBoost) are trained on this data to predict VI and shear stability. Recursive Feature Elimination (RFE) can be used to optimize the descriptor set [20]. Finally, models perform virtual screening to identify candidates that simultaneously maximize VI and shear stability.

Rheological Characterization for Experimental Validation

Rotational rheometry is the standard experimental method for characterizing the viscoelastic properties of VII-modified lubricants.

Workflow Overview:

Figure 2: Experimental rheological characterization workflow for VII performance.

Detailed Methodology:

- Amplitude Sweep Test:

- Objective: To determine the Linear Viscoelastic Range (LVR), where the material's microstructure remains unchanged during testing [30].

- Protocol: A sinusoidal oscillatory deformation is applied to the sample at a constant frequency and temperature, while the deformation (strain or stress) is gradually increased. The storage modulus (G') and loss modulus (G") are monitored. The test ensures subsequent frequency sweeps are performed within the LVR for accurate results [30].

Oscillatory Frequency Sweep Test:

- Objective: To obtain the "viscoelastic fingerprint" of the formulation, revealing the influence of molecular weight (Mw) and molecular weight distribution (MWD) [30].

- Protocol: Within the LVR, a small oscillatory deformation is applied across a wide range of frequencies (e.g., 0.01 to 100 rad/s) at a constant temperature. The complex viscosity (|η*|), G', and G" are measured as a function of frequency. According to the Cox-Merz rule, the complex viscosity versus angular frequency from this test is identical to the steady-state shear viscosity versus shear rate, avoiding measurement artifacts encountered in rotational tests [30]. The zero-shear viscosity (η₀) in the plateau region at low frequencies correlates with the average Mw [30].

Temperature Ramp Test:

- Objective: To calculate the Viscosity Index by measuring viscosity change with temperature.

- Protocol: Using the rheometer, viscosity is measured at two key temperatures: 40°C and 100°C. These values are then used in standard calculation methods (e.g., ASTM D2270) to determine the VI.

Continuous Shear Stability Test:

- Objective: To evaluate the mechanical durability of the VII polymer under prolonged shear.

- Protocol: The sample is subjected to continuous high shear in a mechanical shear simulator or a high-shear viscometer for a defined period. The viscosity of the sample at 100°C is measured before and after the test. The percentage loss in viscosity quantifies the shear stability of the VII, with lower viscosity loss indicating higher shear stability [26] [25].

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Essential Materials and Tools for VII Research

| Item / Reagent | Function in VII Research |

|---|---|

| Base Oils (Mineral, Synthetic) | The medium into which VIIs are dissolved; the base oil type significantly influences VII performance and solubility [26]. |

| Polymer Standards (OCP, PMA, HSD) | Reference materials for benchmarking new formulations and validating experimental protocols [20] [27]. |

| Hybrid / Rotational Rheometer | The primary instrument for characterizing viscosity and viscoelastic properties (G', G", complex viscosity) across temperature and shear rates [31] [30]. |

| High-Throughput Screening (HTS) Software | For automating molecular dynamics simulations, data aggregation, and machine learning model training in virtual screening pipelines [20]. |

| Shear Simulator | Specialized equipment for mechanically degrading lubricant samples to experimentally determine the shear stability index of a VII-containing formulation [25]. |

A Decision Framework for VII Selection

The following diagram synthesizes the comparative data into a logical selection pathway for researchers.

Figure 3: Decision framework for selecting VII polymer chemistry.

Selecting the optimal Viscosity Index Improver requires a systematic approach that matches polymer chemistry to specific application demands. As illustrated, OCPs offer a robust, cost-effective solution for many engine oil applications, while PMAs excel where superior low-temperature performance is critical. Styrenic elastomers present a strong alternative for achieving a high VI with good stability. The integration of advanced methods like high-throughput molecular dynamics and explainable AI with traditional rheological characterization provides a powerful, data-driven pipeline for accelerating the discovery and validation of next-generation VII polymers, moving the field beyond traditional trial-and-error approaches [20]. This framework equips researchers with the comparative data and experimental protocols needed to make informed decisions in lubricant formulation and advanced VII development.

The global push for enhanced energy efficiency and reduced emissions is fundamentally transforming lubricant requirements, creating new challenges and opportunities for viscosity index improvers (VIIs). These specialized polymer additives are crucial for ensuring lubricants maintain optimal viscosity across a wide range of operating temperatures. The market for VIIs is experiencing steady growth, projected to reach USD 5.6 billion by 2035, with a compound annual growth rate (CAGR) of 2.9% [6]. This evolution is primarily driven by two parallel trends: the rapid adoption of electric vehicles (EVs) requiring specialized thermal management fluids, and the ongoing transition toward lower-viscosity engine oils in conventional heavy-duty fleets to improve fuel economy [7] [32] [33]. This guide provides an objective comparison of VII performance across these emerging applications, supported by experimental data and detailed methodologies for researchers and formulation scientists.

Market Context and Growth Drivers

Quantitative Market Outlook

The VII market demonstrates robust growth across multiple regions and segments, influenced by varying regulatory and industrial factors.

Table 1: Global Viscosity Index Improvers Market Forecast

| Metric | Value | Time Period | Source |

|---|---|---|---|

| Market Size (2024) | USD 4.06 billion | 2024 | [33] |

| Projected Market Size | USD 5.39 billion | 2034 | [33] |

| Forecast CAGR | 2.9% | 2024-2034 | [6] [33] |

| Alternative Market Size | USD 4.2 billion | 2025 | [6] |

| Alternative Projection | USD 5.6 billion | 2035 | [6] |

Table 2: Regional Growth Variations for VIIs

| Region/Country | Projected CAGR | Key Growth Drivers |

|---|---|---|

| India | 4.3% | Industrial production, automotive demand, rising disposable incomes [33] |

| China | 3.2% | Rapid industrialization, increased vehicle ownership [33] |

| Spain | 2.2% | Automotive manufacturing, power generation applications [33] |

| United States | 1.6% | Steady automotive sector growth, commercial vehicle sales [6] [33] |

| United Kingdom | 1.1% | Industrial lubricants across automotive and manufacturing [33] |

Key Growth Sectors

- Electric Vehicle Revolution: EVs require specialized lubricants for components like electric motors, transmissions, battery cooling systems, and drivetrains. These fluids must perform under high temperatures and electrical loads, necessitating VIIs with enhanced thermal stability and viscosity consistency. Projections indicate approximately 880 million liters of coolant fluids will be required for electric cars by 2035 [7].

- Heavy-Duty Vehicle Efficiency: The transition from SAE 15W-40 to lower viscosity grades like SAE 10W-30 and 5W-30 in heavy-duty diesel engines is accelerating, driven by regulations such as Euro VI and EPA 2027. Field tests demonstrate that this viscosity switch can yield up to 3% fuel savings [32] [34].

- Industrial Sector Expansion: Manufacturing activities, particularly in emerging economies, are increasing demand for industrial lubricants used in heavy machinery and metalworking applications, where VIIs ensure stable viscosity across temperature variations [7].

Technical Challenges in Modern Formulations

Low-Viscosity Engine Oil Challenges

Formulating effective low-viscosity engine oils presents specific technical hurdles that must be addressed through careful VII selection and base stock combination.

Table 3: Technical Challenges in Low-Viscosity Formulations

| Challenge | Impact on Performance | Experimental Measurement |

|---|---|---|

| Durability & Wear Protection | Thinner oil films increase wear rates on components like top rings and bearings [35] | HTHS viscosity assessment; engine teardown analysis for wear [34] |

| Increased Oil Volatility | Lighter components evaporate, increasing oil consumption and altering viscosity [35] | Noack volatility test (API limit: 13% for CK-4/FA-4) [34] |

| Shear Stability | Mechanical shearing of VII polymers reduces viscosity, compromising protection [34] | Shear stability test; HTHS viscosity measurement after shearing [34] |

| Engine-Specific Response | Not all engines deliver the same fuel economy with identical low-HTHS formulations [35] | New European Drive Cycle testing across multiple engine types [35] |

Electric Vehicle Fluid Challenges

EV fluids face unique requirements distinct from conventional engine oils:

- Electrical Compatibility: Fluids must maintain dielectric properties while providing effective cooling and lubrication.

- Thermal Management Efficiency: Optimal viscosity characteristics are crucial for battery thermal management systems.

- Material Compatibility: VII formulations must be compatible with polymers, copper windings, and electrical insulation materials.

Comparative Performance of VII Polymer Types

Leading VII Technologies

Table 4: Performance Comparison of Major VII Polymer Types

| Polymer Type | Market Share | Strengths | Limitations | Optimal Applications |

|---|---|---|---|---|

| Olefin Copolymer (OCP) | 30.4% (2025) [6] | Excellent shear stability, cost-effectiveness, versatility [6] [36] | Medium low-temperature performance [36] | Engine oils, tractor fluids, hydraulic fluids [6] |

| Polymethacrylate (PMA) | Significant share [36] | Superior low-temperature performance, dispersancy capabilities [36] [37] | Higher cost compared to OCP [36] | Industrial lubricants, applications requiring excellent low-temperature properties [36] |

| Hydrogenated Styrene-Diene (HSD) | Not specified | Improved thermal oxidation stability [6] | Potential compatibility issues | Long-drain multistage internal combustion engine oil [6] |

Experimental Assessment Protocols

High-Temperature High-Shear (HTHS) Viscosity Methodology

- Purpose: Assess viscosity under realistic engine conditions (150°C, 10⁶ s⁻¹ shear rate) [34]

- Protocol: Use standardized tapered bearing simulator or capillary viscometers according to ASTM D4683 or ASTM D4741

- Application: Critical for determining potential fuel economy benefits; lower HTHS viscosity (2.9-3.2 cP for FA-4 oils) indicates improved fuel efficiency [34]

Shear Stability Testing

- Objective: Evaluate VII resistance to mechanical degradation [34]

- Methodology:

- Expose oil to high shear stress in diesel injector rig (ASTM D7109) or ultrasonic shear tester (ASTM D5621)

- Measure kinematic viscosity at 100°C before and after shearing

- Calculate percentage viscosity loss; lower values indicate superior shear stability

- Acceptance Criteria: Viscosity must remain within SAE grade specifications after shear exposure

Volatility Assessment

- Test Method: Noack volatility test (ASTM D5800) [34]