Precision Purification: How Molecularly Imprinted Polymers Are Revolutionizing Pharmaceutical Impurity Separation

This article provides a comprehensive analysis of Molecularly Imprinted Polymers (MIPs) for the selective separation of impurities in pharmaceutical development.

Precision Purification: How Molecularly Imprinted Polymers Are Revolutionizing Pharmaceutical Impurity Separation

Abstract

This article provides a comprehensive analysis of Molecularly Imprinted Polymers (MIPs) for the selective separation of impurities in pharmaceutical development. Tailored for researchers and drug development professionals, it covers the foundational principles of MIP synthesis, detailed methodologies for impurity capture, strategies for troubleshooting and optimizing selectivity and capacity, and rigorous validation against traditional techniques like solid-phase extraction and chromatography. The goal is to offer a practical guide for implementing MIPs to enhance drug purity, safety, and regulatory compliance.

Molecularly Imprinted Polymers 101: The Science of Creating Synthetic Antibodies for Impurities

In pharmaceutical science, an impurity is any component of a drug substance or drug product that is not the active pharmaceutical ingredient (API) or an excipient. The presence, identity, and quantity of impurities directly impact the safety, efficacy, and quality of the final medicinal product. The classification and control of impurities are mandated by global regulatory authorities (e.g., ICH, FDA, EMA). Molecularly Imprinted Polymer (MIP) research focuses on developing selective sorbents to separate and remove specific impurities, making their precise definition critical.

Classification of Impurities

Impurities are categorized based on their origin and nature. The primary classification is outlined in ICH guidelines Q3A(R2) (for drug substances) and Q3B(R2) (for drug products).

Table 1: Classification and Control Thresholds for Organic Impurities

| Impurity Type | Definition & Origin | Reporting Threshold | Identification Threshold | Qualification Threshold |

|---|---|---|---|---|

| Organic Impurities | Arise during synthesis, manufacturing, or storage. Include starting materials, by-products, intermediates, degradation products, reagents, ligands, catalysts. | 0.05% | 0.10% or 1.0 mg/day (whichever is lower) | 0.15% or 1.0 mg/day (whichever is lower) |

| Inorganic Impurities | Derived from manufacturing processes: reagents, ligands, catalysts, heavy metals, inorganic salts, filter aids, charcoal. | Typically controlled by pharmacopeial or other appropriate tests. | N/A | N/A |

| Residual Solvents | Organic volatile chemicals used in manufacturing. Classified per ICH Q3C. | Based on PDE (Permitted Daily Exposure) for Class 1, 2, or 3 solvents. | N/A | N/A |

| Genotoxic Impurities | Impurities with potential to damage DNA, posing carcinogenic risk. Controlled per ICH M7. | Requires (Q)SAR assessment. Control at TTC (Threshold of Toxicological Concern, 1.5 µg/day) or compound-specific limits. | N/A | N/A |

Note: Thresholds in table are for drug substances with maximum daily dose ≤2 g/day. Percentages are relative to the API.

Key Regulatory and Analytical Concepts

Identification Threshold: Level above which an impurity must be identified (chemical structure elucidated). Qualification Threshold: Level above which an impurity must undergo toxicological assessment ("qualified") to demonstrate safety at the specified level. Specification Limit: The established acceptance criterion for an impurity, not to be exceeded in the marketed product batch.

Experimental Protocol: MIP Synthesis for Selective Impurity Capture

This protocol details the synthesis of a MIP targeting a specific genotoxic impurity, 4-aminophenol (degradant of acetaminophen), as a model system.

Protocol: Bulk Polymerization of a MIP for 4-Aminophenol

Objective: To synthesize a MIP with selective binding sites for 4-aminophenol.

Materials (Research Reagent Solutions Toolkit):

| Reagent/Material | Function | Notes |

|---|---|---|

| Template (4-Aminophenol) | Target molecule around which the polymer is imprinted. | The "impurity" to be separated. |

| Functional Monomer (Methacrylic Acid, MAA) | Contains functional groups that interact with the template via non-covalent bonds (H-bonding, ionic). | Forms the complementary binding site. |

| Cross-linker (Ethylene Glycol Dimethacrylate, EGDMA) | Creates a rigid, porous polymer network, fixing the binding sites' geometry. | High ratio (70-90% mol) ensures stability. |

| Porogenic Solvent (Acetonitrile) | Dissolves all components and creates pores during polymerization. | Affects morphology and template-monomer interaction. |

| Initiator (AIBN, 2,2'-Azobisisobutyronitrile) | Free-radical initiator, thermally decomposes to start polymerization. | Use at ~1 mol% relative to monomers. |

| Acetic Acid / Methanol (1:9 v/v) | Washing solvent for template removal (extraction). | Must disrupt template-monomer interactions without damaging polymer. |

Procedure:

- Pre-complexation: In a glass vial, dissolve the template 4-aminophenol (0.25 mmol) and the functional monomer MAA (1.0 mmol) in the porogen acetonitrile (5 mL). Sonicate for 10 minutes. Allow to equilibrate for 1 hour at room temperature.

- Polymerization Mixture: Add the cross-linker EGDMA (5.0 mmol) and the initiator AIBN (0.05 mmol) to the pre-complex solution. Sparge the mixture with nitrogen or argon for 5 minutes to remove oxygen, which inhibits free-radical polymerization.

- Polymerization: Seal the vial and place it in a water bath at 60°C for 24 hours to initiate polymerization.

- Polymer Processing: After polymerization, grind the monolithic polymer block mechanically. Sieve the particles to obtain a size fraction (e.g., 25-50 µm).

- Template Extraction: Soxhlet extract the polymer particles with acetic acid/methanol (1:9 v/v) for 24-48 hours, or until no template is detected in the washings by HPLC-UV.

- Drying: Dry the extracted MIP particles under vacuum at 40°C overnight.

- Control Polymer (NIP): Synthesize a non-imprinted polymer (NIP) following the identical procedure but omitting the template. This serves as the critical control to assess imprinting efficiency.

Characterization: Binding capacity and selectivity are evaluated via batch rebinding experiments and HPLC analysis, comparing MIP vs. NIP performance.

Experimental Protocol: Batch Rebinding Assay for MIP Evaluation

Objective: To quantify the binding capacity and selectivity of the synthesized MIP for the target impurity.

Procedure:

- Prepare stock solutions of the target impurity (4-aminophenol) and a structural analog (e.g., phenol) in an appropriate buffer or solvent.

- Weigh 10.0 mg of dry MIP (or NIP) into separate 2 mL HPLC vials (n=3 for each concentration).

- Add 1.0 mL of impurity solution at varying concentrations (e.g., 0.1, 0.5, 1.0, 2.0 mM) to each vial.

- Seal and agitate the vials on a shaker at room temperature for 24 hours to reach binding equilibrium.

- Centrifuge the vials and carefully withdraw an aliquot of the supernatant.

- Analyze the supernatant by HPLC-UV to determine the free concentration (Cf) of the impurity.

- Calculate: Bound amount Q = (C0 - Cf) * V / m, where C0 is initial concentration, V is volume, m is polymer mass.

- Fit Q vs. Cf data to a binding isotherm model (e.g., Langmuir) to determine maximum binding capacity (Qmax) and affinity (Kd).

- Perform the same assay with the structural analog to assess selectivity. Calculate an imprinting factor (IF) = QMIP / QNIP at a specific Cf.

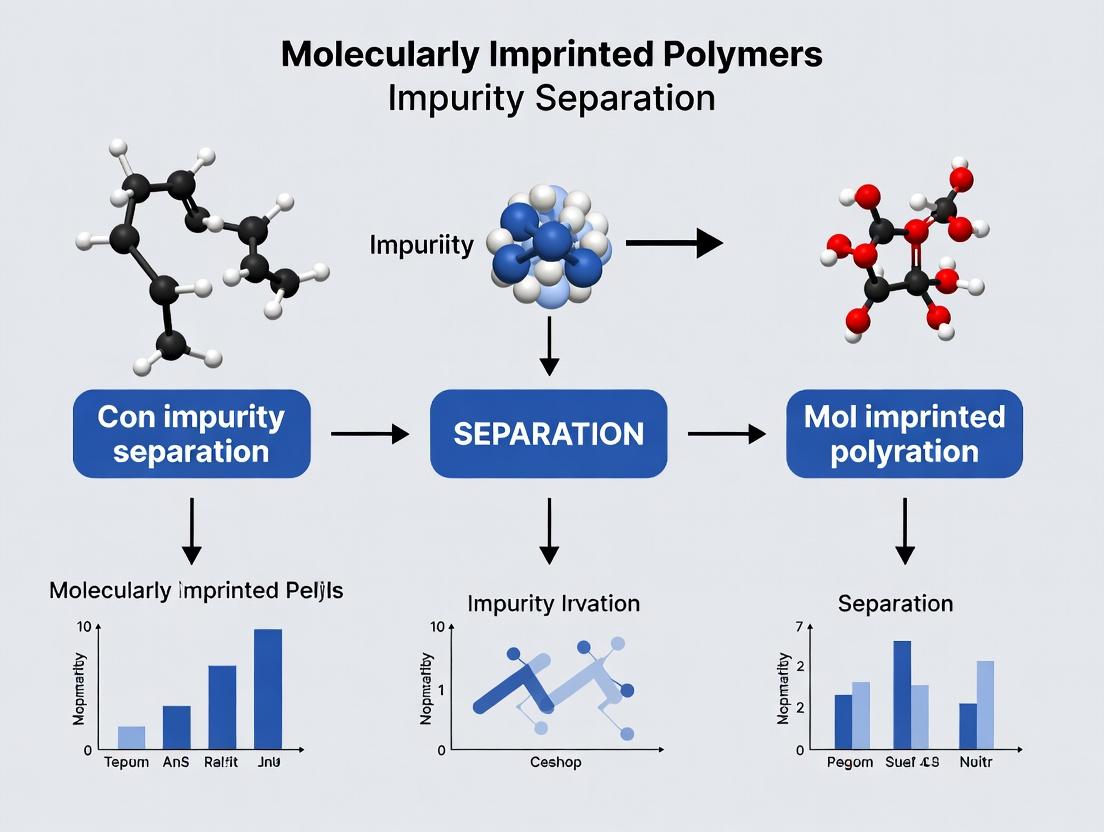

Visualization: Pathways and Workflows

Title: Pharmaceutical Impurity Classification and Risk Flow

Title: MIP Synthesis Workflow for Impurity Capture

Within the broader research thesis on "Molecularly Imprinted Polymers (MIPs) for Impurity Separation," understanding the core templating mechanism is paramount. The strategic creation of tailor-made binding cavities in synthetic polymers enables the selective capture of target molecules (e.g., genotoxic impurities, process-related isomers) from complex matrices, offering a robust alternative to traditional chromatography in drug development.

Fundamental Mechanism: Creating the Molecular Memory

The process of molecular imprinting creates specific binding sites through a "lock-and-key" fabrication approach. It involves the copolymerization of functional and cross-linking monomers around a template molecule (the target analyte or a close analog). Subsequent template removal leaves behind cavities complementary in size, shape, and functional group orientation.

Key Stages of MIP Synthesis

Diagram Title: Molecular Imprinting Polymer Synthesis Workflow

Application Notes

Primary Application in Thesis Context: Selective Solid-Phase Extraction (SPE) sorbents for the pre-concentration and separation of low-abundance pharmaceutical impurities (e.g., alkylating agents, catalyst residues) from Active Pharmaceutical Ingredient (API) streams.

Performance Metrics: Key quantitative parameters for evaluating MIPs in impurity separation include Binding Capacity (Q), Selectivity Coefficient (α), and Imprinting Factor (IF).

Table 1: Comparative Performance of MIPs for Select Impurity Separation

| Target Impurity | Polymer Matrix | Binding Capacity (µmol/g) | Imprinting Factor (IF) | Selectivity vs. API (α) | Ref. Year |

|---|---|---|---|---|---|

| 2-Aminopyrimidine | MAA-co-EGDMA | 18.7 | 3.2 | 5.8 | 2023 |

| Benzyl Mercaptan | 4-VP-co-TRIM | 12.3 | 4.1 | >10 | 2022 |

| Palladium (II) Ions | VI-co-DVB | 45.2* | 8.5 | N/A | 2024 |

| 5-Hydroxymethylfurfural | APM-co-PETA | 9.8 | 2.8 | 4.3 | 2023 |

*Capacity in mg/g.

Detailed Protocols

Protocol 1: Synthesis of a MIP for a Genotoxic Impurity (2-Aminopyrimidine Model)

Objective: To synthesize a MIP for the selective extraction of 2-aminopyrimidine from an API solution.

The Scientist's Toolkit: Key Reagents & Materials

| Item | Function/Explanation |

|---|---|

| Template: 2-Aminopyrimidine | Target impurity molecule; shapes the complementary cavity. |

| Functional Monomer: Methacrylic Acid (MAA) | Provides H-bond donor/acceptor sites for template interaction. |

| Cross-linker: Ethylene Glycol Dimethacrylate (EGDMA) | Creates a rigid, highly cross-linked polymer network. |

| Initiator: Azobisisobutyronitrile (AIBN) | Thermal radical initiator for polymerization. |

| Porogen: Acetonitrile/Toluene (9:1 v/v) | Solvent controlling polymer morphology and porosity. |

| Solid-Phase Extraction (SPE) Cartridges | Housing for crushed/packed MIP particles as a separation column. |

Procedure:

- Pre-assembly: Dissolve the template (0.25 mmol), functional monomer (MAA, 1.0 mmol), and cross-linker (EGDMA, 5.0 mmol) in 15 mL of porogen mixture in a glass vial.

- Degassing: Sparge the solution with nitrogen or argon for 10 minutes to remove oxygen, which inhibits free-radical polymerization.

- Initiation: Add AIBN (10 mg, 0.06 mmol), re-sparge briefly, and seal the vial.

- Polymerization: Place the vial in a thermostated water bath at 60°C for 24 hours.

- Grinding & Sieving: Mechanically grind the resulting hard polymer block. Sieve particles to 25-45 µm diameter.

- Template Extraction: Pack particles into a Soxhlet apparatus. Extract with methanol:acetic acid (9:1 v/v) for 24 hours, followed by pure methanol for 6 hours. Dry particles under vacuum at 50°C.

- Control Polymer (NIP): Synthesize a Non-Imprinted Polymer (NIP) identically but without the template molecule.

Protocol 2: MIP-SPE for Impurity Capture & Analysis

Objective: To evaluate the MIP's binding performance and selectively isolate the impurity from a spiked API solution.

Procedure:

- Cartridge Packing: Pack 50 mg of dry MIP (or NIP for control) into a 1 mL empty SPE cartridge body between two polyethylene frits.

- Conditioning: Sequentially wash the cartridge with 2 mL methanol and 2 mL equilibration buffer (e.g., 10 mM phosphate, pH 7.0).

- Sample Loading: Load 1 mL of a sample solution containing the target impurity (e.g., 50 µg/mL) and the parent API (500 µg/mL) in equilibration buffer. Use a slow flow rate (0.5 mL/min).

- Washing: Apply 2 mL of a mild wash solvent (e.g., equilibration buffer with 5% acetonitrile) to remove non-specifically bound interferents (like the API).

- Elution: Elute the specifically bound impurity with 2 mL of a strong eluent (e.g., methanol with 2% trifluoroacetic acid). Collect the eluate.

- Analysis & Quantification: Analyze the load, wash, and elution fractions using HPLC-UV. Calculate Binding Capacity (Q), Imprinting Factor (IF = QMIP / QNIP), and Selectivity Coefficient (α = IFtarget / IFcompetitor).

Diagram Title: MIP-SPE Impurity Capture Protocol Steps

Application Notes

Molecularly imprinted polymers (MIPs) are synthetic receptors designed for the specific recognition of target molecules. In pharmaceutical impurity separation, the "triad" of template (the impurity), functional monomer, and cross-linker dictates selectivity and performance. Current research focuses on rational design using computational screening and green synthesis principles to enhance MIP affinity and robustness for challenging impurity profiles in Active Pharmaceutical Ingredients (APIs).

Key Quantitative Parameters in MIP Synthesis for Impurity Separation

| Parameter | Typical Range/Value | Impact on MIP Performance |

|---|---|---|

| Template:Monomer Molar Ratio | 1:4 to 1:8 | Optimizes binding site affinity; lower ratios reduce nonspecific binding. |

| Cross-linker Percentage | 70-90% of total monomers | Governs polymer rigidity, porosity, and stability. |

| Porogen Solvent Polarity (log P) | -1.0 to 4.0 | Critical for template solubility and pore morphology. |

| Rebinding Capacity | 5-50 µmol/g polymer | Direct measure of MIP efficacy for the target impurity. |

| Imprinting Factor (IF) | 1.5 - 10.0 (IF>1.5 desirable) | Ratio of MIP/NIP binding; indicates specificity. |

| Binding Site Heterogeneity (KD range) | 10⁻⁶ to 10⁻³ M | Affinity distribution; lower KD indicates higher affinity sites. |

Research Reagent Solutions Toolkit

| Reagent/Material | Function in MIP Synthesis |

|---|---|

| Methacrylic Acid (MAA) | Versatile functional monomer for H-bonding and ionic interactions with basic impurities. |

| Ethylene Glycol Dimethacrylate (EGDMA) | Common cross-linker; provides a rigid, hydrolytically stable polymer network. |

| Acetonitrile (HPLC Grade) | Aprotic porogen; favors dipole-dipole interactions, yields consistent mesoporosity. |

| 2,2'-Azobis(2-methylpropionitrile) (AIBN) | Thermo-initiator for free-radical polymerization at 60-70°C. |

| Trifluoromethylacrylic Acid | Strongly acidic monomer for imprinting against basic impurities with high selectivity. |

| 4-Vinylpyridine (4-VPy) | Basic functional monomer for targeting acidic impurity compounds. |

| Divinylbenzene (DVB) | Highly rigid, aromatic cross-linker for creating stable, high-surface-area MIPs. |

| Tetrahydrofuran (THF) | Polar aprotic porogen for dissolving a wide range of pharmaceutical templates. |

Experimental Protocols

Protocol 1: Computational Pre-Screening of Monomers (Molecular Modeling)

Objective: To identify the most promising functional monomer for a given impurity template prior to synthesis.

Materials: Schrödinger Maestro or AutoDock Vina software, impurity template molecule (3D structure), library of common functional monomers (MAA, 4-VPy, acrylamide, etc.).

Procedure:

- Template Preparation: Obtain the 3D molecular structure of the impurity (template). Optimize its geometry using DFT (e.g., B3LYP/6-31G*) or MMFF94 force field.

- Monomer Library Preparation: Generate 3D structures for candidate functional monomers. Optimize their geometries similarly.

- Docking/Interaction Analysis: Perform molecular docking or systematic conformational analysis to form template-monomer complexes (1:1 to 1:4 ratios).

- Binding Energy Calculation: Calculate the interaction energy (∆E) for each complex using semi-empirical (PM6/PM7) or DFT methods.

∆E = E(complex) - [E(template) + E(monomer)]More negative ∆E indicates stronger pre-polymerization affinity. - Selection: Rank monomers based on ∆E and analyze interaction modes (H-bonds, π-π stacking, ionic). Proceed with the top 2-3 monomers for synthesis.

Protocol 2: Bulk Polymerization Synthesis of MIP for a Basic Impurity

Objective: To synthesize a MIP specific to a basic pharmaceutical impurity (e.g., a genotoxic alkylamine) via non-covalent bulk polymerization.

Materials: Template impurity (alkylamine), Methacrylic Acid (MAA), Ethylene Glycol Dimethacrylate (EGDMA), AIBN, HPLC-grade acetonitrile, magnetic stirrer, heating block, glass vials (10 mL), ultrasound bath.

Procedure:

- Pre-Assembly Solution: Weigh the template (0.1 mmol) into a 10 mL glass vial. Add the selected functional monomer, MAA (0.4 mmol, 1:4 ratio). Dissolve in 2.5 mL of acetonitrile. Cap and sonicate for 10 minutes. Allow to pre-complex at room temperature for 1 hour.

- Polymerization Mixture: To the pre-assembly solution, add the cross-linker EGDMA (2.0 mmol) and the initiator AIBN (10 mg). Purge the headspace with nitrogen or argon for 3 minutes to remove oxygen.

- Polymerization: Seal the vial and place it in a heating block at 60°C for 18-24 hours to complete the polymerization.

- Processing: Crush the resulting monolithic polymer block gently. Wash sequentially with: a) 50 mL of methanol:acetic acid (9:1, v/v) to extract the template. b) 50 mL of methanol to remove acetic acid. (Use Soxhlet extraction for 24h as an alternative). Dry the polymer particles under vacuum at 50°C overnight.

- Control (NIP) Synthesis: Synthesize a Non-Imprinted Polymer (NIP) following the identical protocol but in the absence of the template impurity.

Protocol 3: Batch Rebinding & Isotherm Analysis

Objective: To quantify the binding capacity and affinity of the synthesized MIP for the target impurity.

Materials: Synthesized MIP and NIP, template impurity stock solution (e.g., 1 mM in methanol), HPLC system with UV/Vis detector, centrifuge, microcentrifuge tubes.

Procedure:

- Equilibrium Binding: Weigh 5.0 mg of finely ground MIP (or NIP) into a series of 1.5 mL microcentrifuge tubes. Add 1.0 mL of template solution at varying concentrations (e.g., 0.05, 0.1, 0.2, 0.5, 1.0 mM) in a suitable solvent (e.g., acetonitrile/water mix mimicking API process stream).

- Incubation: Vortex briefly and agitate on a shaker for 24 hours at room temperature to reach binding equilibrium.

- Separation: Centrifuge the tubes at 10,000 rpm for 5 minutes. Carefully collect the supernatant.

- Analysis: Quantify the free (unbound) template concentration in the supernatant using a validated HPLC-UV method.

- Calculation: Calculate the amount bound (Q, µmol/g) to the polymer:

Q = [(C₀ - Cₑ) * V] / mwhere C₀ = initial concentration (mM), Cₑ = equilibrium concentration (mM), V = volume (L), m = polymer mass (g). - Data Fitting: Plot Q vs. Cₑ. Fit data to the Langmuir-Freundlich isotherm model to determine maximum binding capacity (Qmax) and average dissociation constant (KD).

Visualizations

MIP Synthesis & Recognition Workflow

Key Experimental Steps for MIP Synthesis

Application Notes

Molecularly Imprinted Polymers (MIPs) are synthetic receptors designed for the selective recognition of target molecules. The choice of polymerization technique is critical for the resultant polymer's morphology, binding site accessibility, and performance in impurity separation applications within pharmaceutical development. The following notes detail the application of four core techniques within impurity separation research.

Bulk Polymerization yields a macroporous, monolithic polymer that is subsequently ground and sieved. While simple, this method often results in irregular particles with heterogeneous binding sites, some buried within the matrix. In impurity separation, bulk MIPs are primarily used in solid-phase extraction (SPE) cartridges for the off-line pre-concentration and cleanup of complex samples, such as removing genotoxic impurities from reaction mixtures.

Precipitation Polymerization occurs in a dilute monomer solution where polymer chains precipitate out as they grow, forming micro- or nanospheres. This technique offers high surface area and relatively homogeneous binding sites. For impurity separation, these spherical MIPs are ideal for dispersive SPE and as selective sorbents in HPLC columns, providing excellent resolution for separating structurally similar impurities from Active Pharmaceutical Ingredients (APIs).

Suspension Polymerization involves dispersing the monomer phase as droplets in a continuous aqueous phase via vigorous stirring and stabilizers. It yields regularly sized spherical beads (10-500 µm). Bead morphology makes them perfectly suited for packing into HPLC or LC-MS columns for the online, continuous separation of impurities. They are also used in membrane formats and catalytic scavenging of process-related impurities.

Surface Imprinting confines the imprinting sites to the surface of a pre-formed support material (e.g., silica, magnetic nanoparticles, membranes). This technique maximizes site accessibility and eliminates mass transfer limitations. In modern pharmaceutical research, surface-imprinted MIPs on magnetic nanoparticles (MIP-MNPs) are revolutionary for the rapid, selective magnetic separation of trace impurities from bulk API solutions, offering high recovery and minimal solvent use.

Table 1: Comparison of MIP Polymerization Techniques for Impurity Separation

| Technique | Typical Particle Size | Binding Site Accessibility | Primary Application in Impurity Separation | Key Advantage | Key Limitation |

|---|---|---|---|---|---|

| Bulk | Irregular, 25-50 µm | Moderate (some sites buried) | Off-line solid-phase extraction (SPE) for sample cleanup. | Simplicity, high polymer yield. | Irregular size, slow binding kinetics. |

| Precipitation | 0.1-5 µm microspheres | High | Dispersive SPE and selective sorbents in analytical HPLC columns. | Uniform spherical particles, good site access. | Requires extensive solvent use. |

| Suspension | Spherical beads, 10-500 µm | High | Packing material for preparative HPLC columns for continuous impurity isolation. | Excellent flow properties, scalable. | Requires stabilizers, potential for aqueous contamination. |

| Surface Imprinting | Depends on support (e.g., 50-200 nm MNPs) | Very High | Magnetic separation of impurities; MIP-coated HPLC stationary phases. | Fast kinetics, excellent for complex matrices. | More complex synthesis, lower binding capacity per gram. |

Experimental Protocols

Protocol 2.1: Synthesis of Bulk MIP for SPE of a Genotoxic Impurity (e.g., Alkyl Sulfonate)

- Objective: To synthesize a bulk MIP for the selective solid-phase extraction of methyl benzenesulfonate from an API solution.

- Materials: Template (Methyl benzenesulfonate, 1.0 mmol), Functional monomer (Methacrylic acid, 4.0 mmol), Cross-linker (Ethylene glycol dimethacrylate, 20.0 mmol), Initiator (AIBN, 0.2 mmol), Porogen (Toluene, 5 mL).

- Procedure:

- Dissolve the template, functional monomer, cross-linker, and initiator in the porogen in a glass vial.

- Sparge the solution with nitrogen or argon for 5 minutes to remove oxygen.

- Seal the vial and place it in a water bath at 60°C for 18-24 hours.

- After polymerization, gently crush the monolithic polymer and grind it mechanically (e.g., in a mortar).

- Sieve the ground polymer to obtain particles of 25-45 µm.

- Extract the template sequentially using methanol:acetic acid (9:1, v/v) in a Soxhlet apparatus for 24 hours, followed by pure methanol for 6 hours.

- Dry the particles under vacuum at 40°C overnight.

Protocol 2.2: Synthesis of Precipitation MIP Microspheres for Dispersive SPE

- Objective: To prepare spherical MIP microspheres for the dispersive SPE of an isomeric impurity.

- Materials: Template (Target impurity, 0.05 mmol), Functional monomer (4-Vinylpyridine, 0.2 mmol), Cross-linker (Divinylbenzene, 1.0 mmol), Initiator (AIBN, 0.015 mmol), Porogen (Acetonitrile, 50 mL).

- Procedure:

- Combine all reagents in a 100 mL round-bottom flask.

- Sonicate until fully dissolved. Sparge with nitrogen for 10 minutes.

- Place the sealed flask in a thermostated oil bath at 60°C for 24 hours under gentle stirring (magnetic stir bar, 100 rpm).

- Centrifuge the resulting milky suspension at 10,000 rpm for 10 minutes. Discard the supernatant.

- Wash the polymer microsphere pellet repeatedly with methanol:acetic acid (9:1, v/v) via centrifugation until no template is detected in the supernatant (monitor by UV-Vis).

- Perform a final wash with methanol and dry under vacuum.

Protocol 2.3: Synthesis of Suspension MIP Beads for Column Packing

- Objective: To synthesize uniformly sized MIP beads for packing into an HPLC column for impurity separation.

- Materials:

- Organic Phase: Template (0.5 mmol), MAA (2.0 mmol), EGDMA (10.0 mmol), AIBN (0.1 mmol) in 5 mL chloroform.

- Aqueous Phase: 0.5% (w/v) poly(vinyl alcohol) (PVA, MW 31-50 kDa) in 50 mL deionized water.

- Procedure:

- Prepare the aqueous phase in a three-necked reactor equipped with a mechanical stirrer, condenser, and nitrogen inlet. Heat to 60°C.

- Dissolve all organic phase components. Add this solution to the stirred (300-500 rpm) aqueous phase to form a stable emulsion.

- Purge with nitrogen while stirring for 15 minutes.

- Maintain at 60°C under a nitrogen atmosphere with continuous stirring for 24 hours.

- Cool, collect beads by filtration, and wash extensively with hot water, methanol, and methanol:acetic acid (9:1) to remove PVA and template.

- Sieve beads to a narrow size range (e.g., 25-38 µm). Dry under vacuum.

Protocol 2.4: Synthesis of Surface-Imprinted MIP on Magnetic Nanoparticles (MIP-MNPs)

- Objective: To create core-shell MIP-MNPs for magnetic separation of a trace pharmaceutical impurity.

- Materials: Vinyl-functionalized Fe3O4 MNPs (100 mg), Template (0.1 mmol), APTES (as silane monomer, 0.4 mmol), TEOS (as cross-linker, 2.0 mmol), Ammonia solution (25%, catalyst), Ethanol/Water mixture (4:1, v/v, 40 mL).

- Procedure:

- Disperse MNPs in the ethanol/water mixture in a flask by sonication.

- Add template and APTES. Stir for 1 hour at room temperature for pre-assembly.

- Add ammonia solution and TEOS. Stir vigorously at room temperature for 24 hours.

- Separate the particles using a magnet. Wash sequentially with ethanol, methanol:acetic acid (9:1), and methanol.

- Dry the resulting MIP-MNPs under vacuum at 40°C.

Visualizations

MIP Synthesis General Workflow

MIP-Based Solid-Phase Extraction Protocol

Technique Selection for Target Applications

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for MIP Synthesis

| Item | Function in MIP Synthesis |

|---|---|

| Functional Monomers (e.g., Methacrylic Acid, 4-Vinylpyridine, Acrylamide) | Provide complementary interactions (H-bonding, ionic, hydrophobic) with the template molecule during pre-polymerization complex formation. |

| Cross-linkers (e.g., Ethylene Glycol Dimethacrylate, Divinylbenzene, TRIM) | Create the rigid, porous three-dimensional polymer network that stabilizes the shape and position of the imprinted cavities after template removal. |

| Porogens (e.g., Toluene, Acetonitrile, Chloroform) | Solvent medium dictating polymer morphology. Affects pore structure, surface area, and the stability of the template-monomer complex. |

| Initiators (e.g., AIBN, Potassium Persulfate) | Generate free radicals upon thermal or photochemical decomposition to initiate the chain-growth polymerization reaction. |

| Stabilizers (e.g., Poly(vinyl alcohol), Surfactants) | Used specifically in suspension polymerization to prevent coalescence of monomer droplets, ensuring formation of discrete spherical beads. |

| Surface Modifiers (e.g., APTES, Vinyltrimethoxysilane) | For surface imprinting; introduce polymerizable groups onto support materials (silica, MNPs) to enable grafting of the MIP layer. |

| Template Analog (or the actual impurity) | The "mold" molecule around which the polymer forms. Its careful selection and subsequent complete removal are critical for creating specific binding sites. |

| Washing Solvents (e.g., Methanol:Acetic Acid, Soxhlet apparatus) | Used to quantitatively extract the template molecule from the polymer matrix without destroying the imprinted cavities. |

Within the broader thesis on Molecularly Imprinted Polymers (MIPs) for impurity separation in pharmaceuticals, template removal is the critical, defining step that transforms a synthesized polymer from a static composite into a functional, selective sorbent. The process, also termed "template extraction" or "rebinding site activation," directly determines the availability, specificity, and binding affinity of the imprinted cavities for the target analyte or impurity. Incomplete removal compromises performance, leading to high background interference, analyte leakage, and unreliable quantification of trace impurities during drug development.

Quantitative Data on Template Removal Efficiency

Table 1: Efficacy of Common Template Removal Solvents and Methods

| Removal Method | Typical Solvent/Medium | Temperature (°C) | Duration (h) | Reported Removal Efficiency (%) | Key Advantages | Potential Drawbacks |

|---|---|---|---|---|---|---|

| Soxhlet Extraction | Methanol:Acetic Acid (9:1 v/v) | Solvent BP | 24-48 | 95-99+ | High efficiency, continuous washing | Long duration, high solvent use, heat exposure |

| Ultrasonication-Assisted | Acetonitrile:TFA (95:5 v/v) | 25-40 | 1-3 | 85-95 | Rapid, good for monolithic MIPs | Possible polymer fragmentation, less complete |

| Microwave-Assisted | Ethanol:Water (8:2 v/v) | 80-120 | 0.5-2 | 90-98 | Very fast, reduced solvent consumption | Requires specialized equipment, risk of hot spots |

| Supercritical Fluid (SCF) | CO₂ with 10-20% MeOH modifier | 40-60 | 1-4 | 97-99+ | Clean, solvent-free residue, rapid | High-pressure equipment cost, optimization needed |

| Continuous Flow | Methanol:Acetic Acid (8:2 v/v) | 30-60 | 4-12 | 90-97 | Amenable to automation, online monitoring | Requires packed columns, higher initial setup |

Table 2: Analytical Techniques for Verification of Template Removal

| Technique | Detection Limit for Template Residue | Information Gained | Typical Sample Preparation |

|---|---|---|---|

| HPLC-UV/FLD | 0.01-0.1% of original load | Quantifies free template in extraction washates | Direct injection or mild dilution |

| LC-MS/MS | ppm to ppb level | Confirms template identity, highest sensitivity | Extraction, concentration often required |

| Thermogravimetric Analysis (TGA) | ~1% (mass loss) | Bulk mass loss attributable to template/ solvent | Dry, powdered polymer sample |

| ¹H NMR (of dissolved MIP) | ~0.5-1% | Chemical confirmation of residual template | Digest polymer (e.g., with KOH/DMSO-d6) |

| Radiolabel Tracing (¹⁴C) | <0.01% | Ultimate sensitivity, tracks all remnants | Use of radiolabeled template during synthesis |

Detailed Experimental Protocols

Protocol 3.1: Standard Soxhlet Extraction for MIP Monoliths

Objective: To achieve near-complete removal of template molecules from a polymerized MIP monolith. Materials: Synthesized MIP monolith, Soxhlet extractor, round-bottom flask, heating mantle, condenser, appropriate solvent (e.g., Methanol:Acetic Acid 9:1 v/v). Procedure:

- Gently crush the synthesized MIP block into coarse particles (<1 mm).

- Place the particles into a cellulose or thimble and load into the main chamber of the Soxhlet extractor.

- Fill the round-bottom flask with 200-300 mL of extraction solvent. Assemble the apparatus.

- Heat the flask to reflux. The cycle time should be adjusted so that the chamber fills and siphons 8-12 times per hour.

- Continue extraction for 24-48 hours.

- After completion, recover the MIP particles and dry them under vacuum at 60°C for 12 h.

- Verification: Collect an aliquot of the solvent from the flask, evaporate, and reconstitute in mobile phase for HPLC analysis to confirm template presence in washes and its eventual absence.

Protocol 3.2: Microwave-Assisted Template Extraction

Objective: To rapidly remove template using targeted microwave heating. Materials: Powdered MIP (ground and sieved), microwave reaction system with temperature/pressure control, Teflon vessels, extraction solvent (e.g., Ethanol:Water 8:2 v/v). Procedure:

- Weigh 100-200 mg of synthesized MIP powder into a microwave vessel.

- Add 10-15 mL of extraction solvent. Seal the vessel securely.

- Program the microwave system: Ramp to 100°C over 2 min, hold at 100°C for 15-30 min with moderate stirring.

- After cooling, open the vessel and separate the MIP by centrifugation or filtration.

- Repeat the extraction cycle 2-3 times with fresh solvent.

- Wash the polymer with pure methanol (2x) to remove acetic acid/trace water, then dry under vacuum.

- Verification: Analyze the combined extraction solvents by UV-Vis or HPLC to quantify total template removed.

Protocol 3.3: Verification via LC-MS/MS

Objective: To detect and quantify trace levels of residual template in the "cleaned" MIP. Materials: Dried MIP post-extraction, appropriate dissolution/digestion solvent (e.g., 0.1 M NaOH for hydrolysis), LC-MS/MS system, template standard for calibration. Procedure:

- Sample Prep: Accurately weigh 10 mg of dried MIP into a vial. Add 1.0 mL of a mild basic digestion solution. Sonicate for 30 min. Centrifuge and filter (0.22 µm) the supernatant.

- Calibration: Prepare a standard curve of the template molecule in the same matrix covering a range from 1 ppb to 1000 ppb.

- LC-MS/MS Analysis:

- Column: C18, 2.1 x 50 mm, 1.7 µm.

- Mobile Phase: (A) Water + 0.1% Formic Acid, (B) Acetonitrile + 0.1% Formic Acid.

- Gradient: 5% B to 95% B over 5 min.

- MS: Operate in Multiple Reaction Monitoring (MRM) mode using the two most intense transitions for the template.

- Calculation: Quantify the template in the sample against the standard curve. Report residual template as µg per mg of polymer or as a percentage of the original imprinting amount.

Visualization of Workflows and Concepts

Diagram Title: MIP Template Removal and Validation Workflow

Diagram Title: Molecular States During Template Removal

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Template Removal Studies

| Reagent/Material | Function/Application | Critical Notes for Impurity Separation Research |

|---|---|---|

| Methanol:Acetic Acid (9:1, v/v) | Gold-standard Soxhlet solvent. Acid disrupts ionic/hydrogen bonds with template. | Acetic acid must be thoroughly removed post-wash to prevent interference in subsequent binding of basic impurities. |

| Trifluoroacetic Acid (TFA) | Strong ion-pairing agent used in organic solvents (ACN) for ultrasonic extraction. | Highly effective for peptide/protein templates; requires complete removal due to potential MS ion suppression. |

| Deuterated Solvents (DMSO-d₆, CD₃OD) | For NMR verification of template removal after polymer digestion. | Essential for conclusive chemical proof of residual template structure when developing GMP-relevant MIPs. |

| Supercritical CO₂ with Modifiers | Green extraction medium; penetrates micropores efficiently. | Methanol modifier concentration is critical for polar pharmaceutical templates; optimizes for minimal polymer swelling. |

| Radiolabeled Template (e.g., ¹⁴C) | Ultimate tracer for quantifying removal efficiency down to ppm/ppb. | Required for definitive mass balance in regulatory-facing research (e.g., MIPs for cleaning validation). |

| Solid-Phase Extraction (SPE) Cartridges | For quick clean-up of extraction washates prior to HPLC/LC-MS analysis. | Isolates template from polymer degradation products that may co-elute and confuse the analysis. |

Application Notes and Protocols Within the thesis on "Molecularly Imprinted Polymers (MIPs) for Impurity Separation in Pharmaceutical Research," the rigorous characterization of MIPs is fundamental. The tripartite analysis of Selectivity, Affinity, and Binding Capacity dictates their utility for selectively scavenging process-related impurities or degradation products from Active Pharmaceutical Ingredients (APIs). These parameters are interdependent and must be evaluated holistically to advance from proof-of-concept to scalable purification.

1. Quantitative Data Summary

Table 1: Comparative Binding Parameters of a Theoretical API-Impurity MIP System

| Analytic (Template) | Binding Capacity (Qmax, μmol/g) | Apparent Dissociation Constant (Kd, μM) | Selectivity Factor (α) vs. Structural Analog |

|---|---|---|---|

| Target Impurity (A) | 18.5 ± 1.2 | 0.15 ± 0.03 | 1.0 (Reference) |

| Active Pharmaceutical Ingredient (B) | 5.1 ± 0.8 | 12.7 ± 1.5 | 0.012 |

| Structural Impurity (C) | 7.3 ± 0.9 | 8.4 ± 1.1 | 0.018 |

Table 2: Common Analytical Techniques for MIP Characterization

| Parameter | Primary Technique(s) | Key Output Metrics | Throughput |

|---|---|---|---|

| Binding Capacity | Batch Binding/Depletion | Qmax (Saturation capacity), Binding kinetics | Medium |

| Affinity | Isothermal Titration Calorimetry (ITC) | Kd, ΔH, ΔS, n (stoichiometry) | Low |

| Affinity & Capacity | Equilibrium Batch Binding | Kd, Qmax via Scatchard/Langmuir | Medium |

| Selectivity | Competitive Batch Binding, HPLC | Selectivity Factor (α), Imprinting Factor (IF) | Medium-High |

2. Experimental Protocols

Protocol 1: Equilibrium Batch Binding for Qmax and Kd Determination Objective: To determine the saturation binding capacity and apparent affinity of a MIP for its target analyte. Materials: MIP and Non-Imprinted Polymer (NIP) particles (10 mg), target analyte stock solution (1 mM in acetonitrile/water), binding buffer (e.g., 10 mM phosphate, pH 7.0), microcentrifuge tubes, HPLC system. Procedure:

- Prepare Analyte Series: Create 8-10 concentrations of target analyte (e.g., 5–200 μM) in binding buffer.

- Incubate: Add 1.0 mL of each concentration to pre-weighed MIP and NIP (in triplicate). Vortex and incubate with end-over-end mixing for 120 min at 25°C.

- Separate: Centrifuge at 10,000 x g for 5 min. Carefully collect the supernatant.

- Quantify: Analyze supernatant concentration (Cfree) via HPLC-UV. Calculate bound amount (Cbound) = (Cinitial – Cfree).

- Data Fitting: Plot Cbound vs. Cfree. Fit data using the Langmuir isotherm model: Cbound = (Qmax * Cfree) / (Kd + Cfree) to derive Qmax and Kd.

Protocol 2: Competitive Binding Assay for Selectivity Factor (α) Objective: To assess the MIP's ability to discriminate between the target impurity and a closely related analog (e.g., the API). Materials: MIP and NIP (10 mg), equimolar mixture of target and competitor (e.g., 50 μM each in binding buffer). Procedure:

- Incubate Mixture: Add 1.0 mL of the analyte mixture to MIP and NIP tubes (n=4). Incubate as in Protocol 1.

- Analyte Quantification: Measure the free concentration of both analytes in the supernatant using a selective method (e.g., LC-MS/MS).

- Calculate Distribution Coefficients: K = Cbound / Cfree for each analyte on MIP and NIP.

- Calculate Imprinting Factor (IF): IF = KMIP / KNIP for each analyte.

- Calculate Selectivity Factor (α): α = IF(target) / IF(competitor). An α >> 1 indicates high selectivity for the target.

3. Visualization: Experimental Workflows

Diagram Title: Workflows for MIP Binding Capacity & Selectivity Assays

4. The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions for MIP Characterization

| Item | Function & Critical Notes |

|---|---|

| Molecularly Imprinted Polymer (MIP) | The functional material synthesized against the target impurity template. Must be thoroughly washed (template removed) and sieved to defined particle size. |

| Non-Imprinted Polymer (NIP) | Control polymer synthesized identically but without the template. Critical for distinguishing specific imprinting effects from non-specific adsorption. |

| Binding/Incubation Buffer | Aqueous or aqueous-organic medium that mimics the application environment (e.g., process stream). pH and ionic strength must be controlled to ensure reproducible binding. |

| Template & Analog Standards | High-purity (>95%) target impurity, API, and structural analogs. Required for preparing calibration curves and competitive binding studies. |

| Solid-Phase Extraction (SPE) Cartridges | Used for rapid washing/conditioning of MIPs prior to binding studies, or for small-scale purification feasibility tests. |

| HPLC/UPLC with UV/PDA Detector | Standard workhorse for quantifying analyte depletion in supernatant for single-component binding studies. |

| LC-MS/MS System | Essential for selectively quantifying individual analytes in competitive binding assays from complex mixtures without complete chromatographic resolution. |

From Lab to Process: A Step-by-Step Guide to Applying MIPs for Impurity Removal

Within the broader thesis on Molecularly Imprinted Polymers (MIPs) for impurity separation in pharmaceuticals, the initial and most critical step is the precise definition of the target impurity and the strategic selection of an appropriate template molecule. This phase determines the success of the subsequent polymer synthesis and its ultimate efficacy in selective recognition. Erroneous scoping or template selection leads to non-selective polymers, rendering the entire process ineffective. This protocol details a systematic workflow for impurity characterization and template molecule identification, incorporating current best practices and computational approaches.

Workflow for Impurity Scoping & Template Selection

The following diagram illustrates the logical, iterative decision-making pathway for this foundational phase.

Diagram Title: Workflow for Impurity Scoping and Template Molecule Selection

Key Experimental Protocols

Protocol: In-silico Characterization of the Target Impurity

Objective: To computationally determine key physicochemical properties of the impurity to guide template selection and monomer choice.

- Input Structure: Obtain the SMILES string or mol file of the target impurity from chemical databases (PubChem, ChemSpider) or via drawing (Chemsketch, MarvinSketch).

- Property Calculation: Use computational chemistry software (e.g., OpenBabel, RDKit, Schrödinger Suite) or online platforms (Molinspiration, SwissADME) to calculate:

- Molecular Weight (MW)

- Partition Coefficient (LogP)

- Ionization Constants (pKa)

- Topological Polar Surface Area (TPSA)

- Identification of hydrogen bond donors/acceptors (HBD/HBA)

- Analysis: Tabulate results. High TPSA and HBD/HBA count indicate potential for non-covalent imprinting.

Protocol: Virtual Screening for Template Analogues

Objective: To identify commercially available, structurally suitable, and safe compounds for use as a template analogue.

- Define Pharmacophore/Feature Query: Based on the impurity characterization, define the essential 2D/3D chemical features required for recognition (e.g., a carboxylic acid group at a specific distance from an aromatic ring).

- Select Screening Library: Choose a database (e.g., ZINC, eMolecules, in-house inventory).

- Perform Similarity Search: Conduct a 2D similarity search (Tanimoto coefficient >0.7) using the impurity as a query.

- Filter Results: Apply filters for:

- MW (< 10% deviation from impurity)

- Availability (commercial source, cost < $X/g)

- Safety (non-toxic, non-carcinogenic flags)

- Final Selection: Rank by similarity score and filter compliance. Select the top 2-3 candidates for experimental validation.

Data Presentation: Comparative Analysis

Table 1: Decision Matrix for Template Selection Strategy

| Selection Strategy | Template Candidate | Rationale & Use Case | Key Advantages | Key Risks/Drawbacks |

|---|---|---|---|---|

| Impurity Itself | The actual degradation product or process-related impurity. | Gold standard when impurity is available in sufficient quantity (>100 mg), stable, and safe to handle. | Maximum binding site complementarity. | Cost, toxicity, or instability of the impurity may preclude its use. |

| Close Structural Analogue | A derivative with minor modifications (e.g., -CH3 vs. -C2H5). | Impurity is unavailable or too expensive. The analogue preserves key functional groups for monomer interaction. | Often cheaper, safer, and more available. Ease of template removal. | Risk of imprinting for analogue-specific features, reducing selectivity for the actual impurity. |

| Fragment / Mimic | A smaller molecule containing the critical binding motif. | For large, complex impurities (e.g., peptides). Focuses on a key substructure. | Simplifies synthesis and template removal. Cost-effective. | May lack selectivity if the full impurity structure is needed for recognition. |

| Dummy Template | A functionally similar but structurally distinct molecule. | Used when the impurity is highly toxic or regulated. Designed based on computational modeling. | Eliminates safety and regulatory concerns. | Requires sophisticated design; risk of poor fidelity. |

Table 2: Computational Characterization of a Model Impurity (Hypothetical API Degradant)

| Property | Value | Method/Software Used | Implication for MIP Design |

|---|---|---|---|

| Molecular Formula | C₁₆H₁₅NO₄ | PubChem CID Lookup | - |

| Molecular Weight | 285.29 g/mol | RDKit | Indicates a mid-size target. |

| LogP (iLOGP) | 2.1 | SwissADME | Moderately lipophilic. May favor certain porogens. |

| TPSA | 75.6 Ų | SwissADME | High polarity; suggests strong potential for H-bonding. |

| H-Bond Donors | 2 | RDKit | Carboxylic acid and amine likely available for interaction with functional monomers (e.g., MAA). |

| H-Bond Acceptors | 5 | RDKit | Multiple sites for complementary interactions. |

| pKa (Acid) | 4.2 | Marvin Sketch | Will be ionized at neutral pH; may require ionic monomer. |

| pKa (Base) | 9.1 | Marvin Sketch | Protonated at acidic pH. |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for the Scoping & Template Selection Phase

| Item | Function/Benefit | Example Suppliers |

|---|---|---|

| Pure Impurity Standard | The ideal template molecule. Provides the most accurate molecular fingerprint for imprinting. | TLC PharmaChem, Sigma-Aldrich, Waterstone. |

| Template Analogues | Structurally similar, safe, and affordable surrogate molecules for imprinting when the impurity is unavailable. | Combi-Blocks, Enamine, Sigma-Aldrich. |

| Computational Chemistry Software (RDKit, Open Babel) | Open-source toolkits for calculating molecular descriptors, similarity searching, and handling chemical data. | Open-source. |

| Chemical Database Access (PubChem, ZINC) | Sources for retrieving impurity structures and screening for commercially available analogue compounds. | NIH, UCSF. |

| Molecular Modeling Software (Schrödinger, MOE) | Advanced platforms for pharmacophore modeling, docking, and precise physicochemical property prediction. | Schrödinger, Chemical Computing Group. |

| Chemical Drawing Software | For generating and visualizing 2D/3D structures of impurities and potential analogues. | ChemDraw, MarvinSketch. |

Within the research framework of a thesis on Molecularly Imprinted Polymers (MIPs) for impurity separation in pharmaceuticals, the synthesis of pharmaceutical-grade MIPs presents a critical challenge. The objective is to produce materials with high specificity, affinity, and robustness for the selective extraction of trace impurities (e.g., genotoxic impurities, isomeric by-products) from Active Pharmaceutical Ingredients (APIs). This requires moving beyond academic proof-of-concept to protocols that ensure batch-to-batch reproducibility, scalability, and compliance with Good Manufacturing Practice (GMP) principles. Key optimization parameters include the choice of monomers, cross-linkers, porogenic solvents, and initiation methods to achieve a homogeneous, high-fidelity binding site distribution. The following protocols detail optimized conditions for producing MIPs targeting a model pharmaceutical impurity, 4-aminophenol (a common paracetamol/acetaminophen degradation product), with a focus on thermodynamic and kinetic optimization.

Table 1: Optimization of Monomer and Cross-linker Ratios for 4-Aminophenol Imprinting

| Functional Monomer | Cross-linker | Molar Ratio (Template:Monomer:Cross-linker) | Binding Capacity (µmol/g) | Imprinting Factor (IF) | Selectivity vs. Phenol |

|---|---|---|---|---|---|

| Methacrylic acid (MAA) | Ethylene glycol dimethacrylate (EGDMA) | 1:4:20 | 18.2 | 3.1 | 2.8 |

| Methacrylic acid (MAA) | Trimethylolpropane trimethacrylate (TRIM) | 1:4:20 | 22.5 | 3.8 | 3.5 |

| 4-Vinylpyridine (4-VP) | EGDMA | 1:4:20 | 15.7 | 2.5 | 1.9 |

| Acrylamide (AAm) | N,N‘-Methylenebisacrylamide (MBA) | 1:6:30 | 12.3 | 2.2 | 2.1 |

| Itaconic acid (IA) | TRIM | 1:5:25 | 25.1 | 4.2 | 4.0 |

Table 2: Effect of Porogen and Polymerization Method on MIP Performance

| Porogen | Polymerization Method | Temperature / Time | Surface Area (m²/g) | Average Pore Diameter (nm) | Rebinding Kinetics (t for 90% uptake) |

|---|---|---|---|---|---|

| Acetonitrile | Thermal (AIBN) | 60°C / 24h | 312 | 3.2 | 45 min |

| Toluene | Thermal (AIBN) | 60°C / 24h | 278 | 5.6 | 30 min |

| Acetonitrile/DMSO (9:1) | Thermal (AIBN) | 60°C / 24h | 398 | 4.1 | 25 min |

| Acetonitrile | Photo (DMPA, 365 nm) | 4°C / 4h | 289 | 3.8 | 40 min |

| Acetonitrile/DMSO (9:1) | Precipitation Polymerization | 60°C / 24h | 165 | N/A | <15 min |

Detailed Experimental Protocols

Protocol 3.1: Optimized Thermal Bulk Polymerization for Pharmaceutical-Grade MIPs

Objective: To synthesize a high-performance MIP against 4-aminophenol using a thermally initiated bulk polymerization protocol optimized for reproducibility and scale-up.

Materials & Reagents:

- Template: 4-Aminophenol (0.25 mmol)

- Functional Monomer: Itaconic acid (1.25 mmol)

- Cross-linker: Trimethylolpropane trimethacrylate (TRIM) (6.25 mmol)

- Porogen: Anhydrous acetonitrile (8.0 mL) and dimethyl sulfoxide (DMSO) (0.9 mL)

- Initiator: 2,2'-Azobis(2-methylpropionitrile) (AIBN) (20 mg)

- Equipment: Glass reaction vial (20 mL), sonicator, heating block or oven, vacuum oven.

Procedure:

- Pre-polymerization Mixture: In a 20 mL glass vial, precisely weigh and dissolve 4-aminophenol (27.3 mg) in the acetonitrile/DMSO (9:1 v/v) porogen mixture. Add itaconic acid (162.5 mg) and allow to pre-complex for 30 minutes with gentle magnetic stirring.

- Cross-linker & Initiator Addition: Add TRIM (1.31 g) to the mixture. Finally, add AIBN (20 mg). Sonicate the homogeneous solution for 5 minutes to degas.

- Oxygen Removal: Sparge the solution with a stream of dry nitrogen or argon for 10 minutes. Seal the vial with a PTFE-lined cap.

- Polymerization: Place the sealed vial in a pre-heated heating block or oven at 60°C ± 0.5°C for 24 hours.

- Post-polymerization Processing: Carefully break the vial to retrieve the monolithic polymer. Mechanically grind the polymer in a mortar and pestle, then sieve to collect particles in the 25-50 µm size range.

- Template Removal (Extraction): Subject the particles to Soxhlet extraction with a methanol:acetic acid (9:1 v/v) mixture for 24 hours, followed by pure methanol for 12 hours.

- Drying: Dry the extracted MIP particles in a vacuum oven at 50°C overnight. Store in a desiccator.

Protocol 3.2: Solid-Phase Extraction (SPE) Protocol for Impurity Binding Assessment

Objective: To quantitatively evaluate the binding capacity and selectivity of the synthesized MIP in a format relevant to pharmaceutical impurity trapping.

Procedure:

- SPE Column Packing: Pack 100 mg of dry MIP (or non-imprinted control polymer, NIP) into a 3 mL empty SPE cartridge fitted with polyethylene frits.

- Conditioning: Sequentially wash the cartridge with 5 mL of methanol and 5 mL of the rebinding solvent (e.g., a water/acetonitrile 95:5 mixture simulating an API process stream).

- Loading: Load 2.0 mL of a standard solution containing 4-aminophenol (50 µg/mL) and structural analogs (e.g., phenol, aniline) in the rebinding solvent. Use a slow flow rate (0.5 mL/min).

- Washing: Wash with 3 mL of the rebinding solvent to remove non-specifically bound interferents.

- Elution: Elute the specifically bound template using 4 mL of the methanol:acetic acid (9:1) eluent. Collect the entire fraction.

- Analysis: Quantify the amount of 4-aminophenol and analogs in the load, wash, and eluate fractions using a validated HPLC-UV method (e.g., C18 column, mobile phase: 25 mM phosphate buffer (pH 6.8)/acetonitrile, 85:15, detection at 254 nm).

- Calculation: Determine binding capacity (µmol/g), imprinting factor (IF = QMIP / QNIP), and selectivity coefficients.

Diagrams

Title: MIP Development & Optimization Workflow

Title: MIP Molecular Recognition Mechanism

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Pharmaceutical-Grade MIP Synthesis

| Item | Function / Role | Key Consideration for Pharmaceutical Use |

|---|---|---|

| High-Purity Template Analogue | Serves as the shape/functional group model for imprinting. | Use a structurally identical but non-toxic analogue (e.g., a stable isotope-labeled version) for synthesis if the target impurity is highly toxic, to avoid residual template leakage concerns. |

| Pharmaceutical-Grade Monomers (e.g., MAA, 4-VP) | Provide complementary interactions (H-bonding, ionic) with the template. | Must be of the highest purity (>99.5%), with certified impurities profile. Stabilizers (e.g., MEHQ) may need removal prior to use. |

| High Cross-linking Purity Monomers (TRIM, EGDMA) | Creates the rigid, three-dimensional polymer network stabilizing the cavities. | Low acid value and peroxide content are critical for reproducible polymerization kinetics and polymer porosity. |

| HPLC-Grade & Anhydrous Porogens | Solvent medium dictating polymer morphology and template-monomer complex fidelity. | Water content <0.01% is often crucial. Consider Class 2 or 3 solvents per ICH Q3C guidelines for potential residual solvent issues. |

| Recrystallized Initiator (AIBN, DMPA) | Generates free radicals to initiate polymerization under controlled conditions. | Recrystallize from methanol to ensure high activity and prevent induction period variability. |

| Extraction Solvents (MeOH/AcOH) | Removes the template molecule post-synthesis to generate accessible cavities. | Use in dedicated, well-ventilated equipment. Complete removal of acetic acid is essential for subsequent use in aqueous API streams. |

| Validated Analytical Standards | For accurate quantification of template during extraction efficiency and binding studies. | Traceable to primary standards, with well-defined stability and concentration. |

Molecularly imprinted polymers (MIPs) are synthetic receptors designed for specific molecular recognition. Within the broader thesis on "Molecularly imprinted polymers for impurity separation research," this document details the critical integration of MIP-based sorbents and stationary phases into three cornerstone purification platforms: Solid-Phase Extraction (SPE) cartridges, filtration membranes, and High-Performance Liquid Chromatography (HPLC) columns. Successful integration is paramount for transitioning MIPs from proof-of-concept materials to robust tools for the selective enrichment, separation, and analysis of target impurities (e.g., genotoxic impurities, process intermediates, degradation products) in complex matrices such as Active Pharmaceutical Ingredient (API) streams and biological fluids.

Application Notes

2.1 MIPs in Solid-Phase Extraction (SPE) Cartridges

- Application: Offline selective clean-up and pre-concentration of target impurities from complex samples prior to analysis (e.g., by HPLC-MS). Ideal for removing a specific problematic impurity or enriching a trace-level impurity for quantification.

- Key Advantage: Provides exceptional selectivity, reducing matrix effects and improving detection limits compared to traditional reversed-phase or ion-exchange SPE.

- Performance Data (Representative Example):

Table 1: Performance of a Theophylline-Imprinted MIP-SPE Cartridge vs. C18-SPE for Serum Analysis

Parameter MIP-SPE Cartridge Conventional C18-SPE Loading Capacity 12.5 µg/mg polymer 15 µg/mg sorbent Recovery of Theophylline 98.2% ± 1.5% 95.1% ± 3.2% Recovery of Interferent (Caffeine) 8.7% ± 2.1% 96.8% ± 2.5% Matrix Removal Efficiency >99% ~85% Limit of Detection (Post-SPE) 0.2 ng/mL 2.1 ng/mL

2.2 MIPs as Functionalized Membranes

- Application: Continuous, flow-through separation for impurity scavenging or in-line purification during chemical synthesis. Used in membrane filtration devices.

- Key Advantage: Combines selective binding with convective flow, enabling faster processing times compared to diffusion-limited packed beds.

- Performance Data (Representative Example):

Table 2: Performance of a MIP-Functionalized Flat-Sheet Membrane for Scavenging 2,4-Dichlorophenoxyacetic Acid (2,4-D) from Water

Parameter MIP Membrane Non-Imprinted (NIP) Membrane Permeate Flux 120 L/(m²·h·bar) 125 L/(m²·h·bar) Dynamic Binding Capacity (10% breakthrough) 4.8 mg/g polymer 0.7 mg/g polymer Selectivity Factor (vs. 2-Methylphenol) 9.4 1.1 Regeneration Cycles (with MeOH/Acetic Acid) >20 cycles with <15% capacity loss N/A

2.3 MIPs as HPLC Stationary Phases

- Application: Direct chromatographic separation of structural analogs (e.g., enantiomers, homologs) where traditional columns fail. Critical for analyzing impurity profiles.

- Key Advantage: Provides unique selectivity based on molecular shape and functional group orientation, complementary to hydrophobic (C18) or chiral columns.

- Performance Data (Representative Example):

Table 3: Chromatographic Performance of a MIP-HPLC Column for Separating (±)-Propranolol

Parameter Value for (-)-Propranolol Value for (+)-Propranolol Retention Factor (k') 3.45 2.98 Separation Factor (α) 1.16 1.16 Resolution (Rs) 2.85 2.85 Column Efficiency (plates/m) 28,500 26,800 Run-to-Run Repeatability (%RSD of k') 0.8% (n=10) 1.1% (n=10)

Experimental Protocols

Protocol 1: MIP-SPE Cartridge for Impurity Enrichment from API Solution

- Objective: To isolate and concentrate a genotoxic impurity (GTI) from a crude API solution using a MIP-SPE cartridge specific for the GTI.

- Materials: See "The Scientist's Toolkit" (Table 4).

- Procedure:

- Conditioning: Sequentially pass 3 mL of methanol and 3 mL of loading solvent (e.g., 10 mM phosphate buffer, pH 7.0) through the MIP-SPE cartridge. Do not let the bed dry.

- Loading: Load 10 mL of the filtered API solution (dissolved in loading solvent) onto the cartridge at a controlled flow rate of 1-2 mL/min.

- Washing: Wash with 5 mL of a stringent wash solvent (e.g., loading buffer with 5% acetonitrile) to remove non-specifically bound API and matrix components.

- Elution: Elute the selectively bound GTI with 3 x 1 mL of elution solvent (e.g., methanol with 2% acetic acid). Collect the eluate in a clean vial.

- Regeneration & Storage: Re-equilibrate the cartridge with 3 mL of elution solvent followed by 5 mL of loading buffer. Store in methanol at 4°C.

- Analysis: Evaporate the eluate to dryness under a gentle nitrogen stream, reconstitute in 100 µL of HPLC mobile phase, and analyze by HPLC-UV/MS.

Protocol 2: Packing a MIP-HPLC Analytical Column (Slurry Packing Method)

- Objective: To prepare a 150 x 4.6 mm stainless-steel HPLC column with MIP stationary phase.

- Materials: See "The Scientist's Toolkit" (Table 4).

- Procedure:

- Slurry Preparation: Weigh 2.0 g of dry, sieved (5-10 µm) MIP particles. Disperse in 30 mL of a low-density slurry solvent (e.g., cyclohexanol/chloroform 80:20 v/v) and sonicate for 10 minutes to de-agglomerate.

- Column Setup: Connect the empty column hardware (with bottom frit in place) to the slurry reservoir. Attach the assembly to a high-pressure air-driven fluid pump.

- Packing: Fill the reservoir with the slurry. Immediately apply a pressure of 5000 psi using an iso-propanol push solvent. Maintain pressure for 30 minutes.

- Stabilization: Gradually reduce the pressure to atmospheric over 15 minutes. Disconnect the column and carefully install the top end fitting and frit.

- Conditioning: Connect the column to an HPLC system. Condition by flushing sequentially at 0.5 mL/min: 10 column volumes (CV) of ethanol, 20 CV of ethanol/water (50:50), and 30 CV of the initial intended mobile phase (e.g., phosphate buffer/acetonitrile, 95:5).

- Testing: Evaluate column performance using a standard mixture of the template/analyte and its structural analogs. Calculate efficiency (N/m), asymmetry factor (As), and selectivity (α).

Diagrams

Title: MIP-SPE Workflow for Impurity Enrichment

Title: MIP-HPLC Column Slurry Packing Protocol

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions & Materials

| Item | Function & Rationale |

|---|---|

| MIP Sorbent (Bulk Polymer) | The core material. Must be ground, sieved to desired particle size (e.g., 25-63 µm for SPE, 5-10 µm for HPLC), and thoroughly washed to remove template. |

| Empty SPE Cartridges/Housings | Polypropylene bodies with polyethylene frits (e.g., 3 mL, 6 mL volume) for packing with MIP sorbent. |

| Empty HPLC Column Hardware | Stainless steel columns (e.g., 150 x 4.6 mm) with end fittings and high-quality frits (0.5 µm porosity). |

| Slurry Solvent (e.g., Cyclohexanol/CHCl₃) | Low-density, low-viscosity solvent for dispersing MIP particles to prevent sedimentation during high-pressure column packing. |

| Push Solvent (e.g., Isopropanol) | Compatible, miscible solvent used in the packing pump to pressurize and drive the slurry into the column. |

| Stringent Wash Buffer | Optimized buffer/organic mixture to disrupt weak, non-specific interactions without eluting the specifically bound target analyte from the MIP. |

| Elution Solvent (e.g., MeOH/Acetic Acid) | Strong solvent that disrupts the specific interactions (hydrogen bonding, ionic) between the target analyte and the MIP binding cavities. |

| Regeneration & Storage Solvent (MeOH) | High-quality solvent to clean and store MIP devices, maintaining pore structure and preventing microbial growth. |

The purification of Active Pharmaceutical Ingredients (APIs) from potent, low-level Genotoxic Impurities (GTIs) presents a significant challenge in modern pharmaceutical manufacturing. These impurities, often alkylating agents or reactive intermediates, pose a carcinogenic risk even at trace levels (ppm to ppb). This case study is situated within a broader thesis investigating the design and application of Molecularly Imprinted Polymers (MIPs) as a high-fidelity, selective separation platform for impurity scavenging. Unlike traditional methods like adsorption or derivatization, MIPs offer the potential for targeted, predictable, and reusable capture of specific GTIs directly from complex API solutions, aligning with Quality by Design (QbD) and green chemistry principles.

Current Landscape of GTI Limits and Remediation Strategies

Table 1: Regulatory Thresholds for GTIs (ICH M7)

| GTI Carcinogenic Potency Category | Threshold of Toxicological Concern (TTC) | Permitted Daily Intake (μg/day) | Typical Allowable Concentration in API (ppm)* |

|---|---|---|---|

| 1 (Known mutagenic carcinogen) | N/A | Compound-specific | Compound-specific |

| 2 (Known mutagens, unknown carcinogenicity) | 1.5 μg/day | 1.5 | 1 - 5 |

| 3 (Alerting structure, no mutagenicity data) | 1.5 μg/day | 1.5 | 1 - 5 |

| 4 (No alerting structure) | N/A | No controls needed | N/A |

| 5 (No mutagenic concern) | N/A | No controls needed | N/A |

*Dependent on maximum daily dose of the API.

Table 2: Common GTI Remediation Techniques vs. MIPs

| Technique | Principle | Advantages | Limitations |

|---|---|---|---|

| Activated Carbon | Non-specific adsorption | Low cost, broad-spectrum | Low capacity, may adsorb API, disposal issues |

| Chemical Derivatization | Convert GTI to less toxic form | Effective for specific classes | May form new impurities, complex workup |

| Distillation/Crystallization | Physical separation | Scalable, well-understood | Often ineffective for structurally similar GTIs |

| Scavenger Resins | Chemical reaction with functional groups | Targeted removal | Single-use, can be expensive, may leach |

| Molecularly Imprinted Polymers (MIPs) | Selective affinity based on pre-formed cavities | High selectivity, reusability, design flexibility | Requires GTI template for synthesis, optimization needed |

Application Notes: MIP Development for a Model GTI

Case: Removal of alkyl sulfonate esters (e.g., Methyl Methanesulfonate, MMS) from a model API solution.

Objective: Synthesize a MIP specific to MMS and evaluate its binding efficiency and selectivity versus the non-imprinted polymer (NIP) and the API.

Research Reagent Solutions & Essential Materials

Table 3: Key Materials for MIP Synthesis & Testing

| Item / Reagent | Function / Explanation |

|---|---|

| Methyl Methanesulfonate (MMS) | Template molecule (the target GTI). Removed after polymerization to create cavities. |

| Methacrylic Acid (MAA) | Functional monomer. Forms hydrogen bonds with the sulfonate ester group of MMS. |

| Ethylene Glycol Dimethacrylate (EGDMA) | Cross-linker. Creates rigid, insoluble polymer matrix around the template. |

| 2,2'-Azobis(2-methylpropionitrile) (AIBN) | Thermal initiator for free-radical polymerization. |

| Acetonitrile (HPLC Grade) | Porogenic solvent. Determines pore structure and morphology during synthesis. |

| Acetic Acid/Methanol (9:1 v/v) | Washing solvent for template removal (extraction). |

| Model API (e.g., Acetaminophen) | A structurally dissimilar, non-genotoxic compound to test MIP selectivity. |

| HPLC-MS/MS System | Analytical instrument for quantitative detection of GTIs at ppb levels. |

| Solid-Phase Extraction (SPE) Cartridge Housing | Platform for packing and using MIP/NIP particles in a flow-through system. |

Detailed Experimental Protocols

Protocol 1: Synthesis of MMS-Imprinted Polymer (MIP) and Non-Imprinted Polymer (NIP)

- Pre-complexation: In a glass vial, dissolve the template MMS (0.25 mmol) and functional monomer MAA (1.0 mmol) in 5 mL of dry acetonitrile. Seal and allow to pre-associate for 1 hour at room temperature.

- Polymerization Mixture: Add cross-linker EGDMA (5.0 mmol) and initiator AIBN (20 mg) to the vial. Sonicate for 5 minutes to dissolve and degas.

- Polymerization: Purge the solution with nitrogen or argon for 10 minutes to remove oxygen. Seal the vial and place it in a thermostated water bath at 60°C for 24 hours.

- Polymer Processing: After polymerization, mechanically crush the monolithic polymer block. Sieve to obtain particles of 25-50 μm diameter.

- Template Extraction: Wash the polymer particles repeatedly with a washing solvent (Acetic Acid/Methanol, 9:1 v/v) in a Soxhlet extractor for 48 hours. Perform until MMS is undetectable in the washings by HPLC.

- Drying: Dry the extracted particles under vacuum at 50°C overnight. Store in a desiccator.

- NIP Synthesis: Synthesize the NIP following the identical procedure but in the absence of the MMS template.

Protocol 2: Batch Rebinding and Selectivity Test

- Standard Solutions: Prepare individual stock solutions of MMS (GTI) and acetaminophen (API) in a suitable solvent (e.g., acetonitrile:water mixture mimicking API process stream).

- Equilibrium Binding: Weigh 10 mg of dry MIP (or NIP) into separate 2 mL HPLC vials. Add 1 mL of a solution containing a known concentration of MMS (e.g., 50 μg/mL). Prepare control vials without polymer.

- Incubation: Agitate the vials on a rotary shaker at 25°C for 6 hours to reach binding equilibrium.

- Analysis: Centrifuge the vials and carefully collect the supernatant. Analyze the concentration of MMS (and API in separate selectivity experiments) in the supernatant via calibrated HPLC-MS/MS.

- Calculation: Calculate the amount bound (Q, mg/g) using the formula: Q = (Ci - Cf) * V / m, where Ci and Cf are initial and final concentrations (mg/mL), V is solution volume (mL), and m is polymer mass (g).

- Selectivity Test: Repeat steps 2-5 using a solution containing both MMS and the API. Calculate binding parameters for each analyte.

Protocol 3: SPE-Style Dynamic Removal from a Spiked API Stream

- Cartridge Packing: Pack 100 mg of dry MIP particles into an empty SPE cartridge (e.g., 1 mL volume) between two polyethylene frits.

- Conditioning: Condition the cartridge with 3 mL of the working solvent (e.g., acetonitrile:water 30:70).

- Loading: Prepare a solution of the model API spiked with MMS at 10 ppm. Load 10 mL of this solution onto the cartridge at a controlled flow rate of 0.5 mL/min using a syringe pump. Collect the effluent.

- Washing & Elution: Wash with 2 mL of conditioning solvent. Elute bound species with 3 mL of the strong washing solvent (Acetic Acid/Methanol, 9:1 v/v). Collect fractions.

- Analysis: Analyze the loading effluent, wash, and eluate fractions for both MMS and API content via HPLC-MS/MS.

- Regeneration: The MIP cartridge can be regenerated by washing with 5 mL of the strong solvent followed by re-conditioning, enabling reuse.

Visualization: MIP Workflow and Selectivity Principle

MIP Synthesis and Application Workflow

Selective Binding of GTI vs. API on MIP

Within the broader thesis on advancing Molecularly Imprinted Polymer (MIP) technology for pharmaceutical impurity separation, this case study demonstrates a targeted application. The selective capture of low-abundance, structurally similar process-related impurities and degradation products from active pharmaceutical ingredient (API) streams remains a critical purification and analytical challenge. Traditional methods like preparative chromatography are often inefficient for these specific separations. This application note details the development and validation of a MIP for the selective extraction of a genotoxic impurity, p-toluenesulfonate (pTs), from a model API batch.

Application Notes: Selective Capture ofp-Toluenesulfonate (pTs)

Objective: To synthesize a MIP capable of selectively binding pTs in the presence of a high concentration of structurally similar API (a sulfonamide-based drug molecule).

Rationale: pTs, a common alkylating agent and potential genotoxic impurity, must be controlled to ppm levels. Its structural similarity to the API's sulfonamide moiety complicates separation.

Key Findings from Current Literature (Live Search Summary): Recent research (2023-2024) highlights a shift towards solid-phase extraction (SPE) using MIPs for impurity scavenging. A prominent study achieved a binding capacity of 18.5 µmol/g for pTs with high selectivity (imprinting factor > 5) in methanolic solutions. Another protocol demonstrated the successful application of a similar MIP in a continuous flow setup, reducing impurity levels from 1000 ppm to below 10 ppm in a simulated process stream.

Quantitative Data Summary:

Table 1: Performance Comparison of pTs Capture Methods

| Method | Binding Capacity for pTs | Selectivity (Imprinting Factor) | pTs Reduction in API Stream | Key Advantage |

|---|---|---|---|---|

| Traditional C18 SPE | 2.1 µmol/g | 1.0 (non-selective) | ~30% | Simplicity |

| Non-Imprinted Polymer (NIP) | 3.5 µmol/g | 1.0 | ~35% | Control for non-specific binding |

| MIP (Batch Mode) | 18.5 µmol/g | 5.3 | 95% (1000 ppm to 50 ppm) | High selectivity |

| MIP (Continuous Flow) | 15.2 µmol/g | 4.8 | 99% (1000 ppm to <10 ppm) | Process compatibility |

Experimental Protocols

Protocol 1: Synthesis of pTs-Imprinted Polymer

Principle: Thermal free-radical copolymerization using pTs as the template, methacrylic acid (MAA) as the functional monomer, ethylene glycol dimethacrylate (EGDMA) as the cross-linker, and AIBN as the initiator.

Materials: See "Scientist's Toolkit" below.

Procedure:

- Pre-polymerization Complex Formation: In a 50 mL glass vial, dissolve pTs (0.25 mmol, template) and MAA (1.0 mmol, monomer) in 15 mL of acetonitrile/toluene (3:1 v/v). Sonicate for 10 minutes. Allow the mixture to equilibrate at 4°C for 1 hour to facilitate template-monomer complexation.

- Polymerization: Add EGDMA (5.0 mmol, cross-linker) and AIBN (20 mg, initiator) to the vial. Purge the solution with nitrogen gas for 5 minutes to remove oxygen. Seal the vial and place it in a water bath at 60°C for 24 hours.

- Polymer Recovery: After polymerization, break the rigid polymer monolith and grind it in a mechanical mortar. Sieve the particles to obtain a 25-50 µm size fraction.

- Template Removal: Soxhlet extract the polymer particles with methanol/acetic acid (9:1 v/v) for 48 hours, followed by pure methanol for 12 hours. Dry the resulting MIP particles under vacuum at 50°C overnight.

- Control Polymer (NIP): Synthesize a Non-Imprinted Polymer identically but in the absence of the pTs template.

Protocol 2: Solid-Phase Extraction (SPE) and Binding Analysis

Principle: Packing MIP/NIP into SPE cartridges to measure static binding capacity and selectivity.

Procedure:

- SPE Cartridge Preparation: Pack 100 mg of dry MIP (or NIP) into an empty 3 mL SPE cartridge between two polypropylene frits.

- Conditioning: Condition the cartridge with 5 mL of methanol, followed by 5 mL of equilibration buffer (10 mM ammonium acetate in water, pH 6.5).

- Loading: Load 2 mL of a sample solution containing pTs (100 µg/mL) and the API (10 mg/mL) in equilibration buffer.

- Washing: Wash with 3 mL of equilibration buffer to remove non-specifically bound compounds. Collect wash fraction.

- Elution: Elute specifically bound pTs with 5 mL of methanol/acetic acid (9:1 v/v). Collect elution fraction.

- Analysis: Analyze all fractions (load, wash, elute) by HPLC-UV (λ=254 nm) using a validated method. Calculate the amount of pTs and API bound to the polymer.

- Calculations:

- Binding Capacity (Q):

Q = (C_loaded - C_flowthrough) * V / mwhere C is concentration, V is volume, m is polymer mass. - Imprinting Factor (IF):

IF = Q_MIP / Q_NIP

- Binding Capacity (Q):

Diagrams

MIP Synthesis and SPE Workflow

Selectivity Mechanism: MIP vs NIP

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for MIP-Based Impurity Capture

| Item | Function in Protocol | Typical Specification / Notes |

|---|---|---|

| Template Molecule (e.g., p-Toluenesulfonic acid) | The target impurity used to create specific recognition cavities during polymerization. | High purity (≥98%). Critical for imprinting efficiency. |

| Functional Monomer (Methacrylic Acid - MAA) | Contains complementary functional groups to interact with the template via non-covalent bonds. | Purified by distillation to remove inhibitors prior to use. |

| Cross-linker (Ethylene Glycol Dimethacrylate - EGDMA) | Provides structural rigidity to the polymer, stabilizing the imprinted cavities after template removal. | High cross-linker ratios (≥80 mol%) are typical for MIPs. |

| Porogenic Solvent (Acetonitrile/Toluene mix) | Dissolves all polymerization components and dictates the polymer's porous morphology. | Must be inert and of suitable polarity to promote template-monomer association. |

| Radical Initiator (AIBN) | Initiates the free-radical polymerization reaction upon heating. | Thermolabile; requires storage at <4°C. |

| Extraction Solvent (MeOH/Acetic Acid) | Removes the template molecule from the polymer matrix after synthesis (MIP "activation"). | The acidic component disrupts ionic interactions for complete template recovery. |

| Equilibration/Binding Buffer (Ammonium Acetate, pH 6.5) | Provides a consistent chemical environment for selective rebinding of the impurity during SPE. | pH is optimized to match the conditions of the API process stream. |

| MIP & NIP Particles (25-50 µm) | The active separation media packed into SPE cartridges for binding experiments. | Particle size affects flow characteristics and binding kinetics. |

Application Notes

Within the broader thesis on Molecularly Imprinted Polymers (MIPs) for impurity separation, the integration of continuous flow systems with in-line monitoring presents a transformative approach for the selective removal of genotoxic impurities, process-related intermediates, and enantiomeric impurities in pharmaceutical synthesis. Recent implementations (2023-2024) demonstrate enhanced efficiency, real-time control, and reduced solvent waste compared to batch-mode MIP chromatography.

Table 1: Performance Data of Recent Continuous Flow MIP Purification Systems