Precision Control of MWD in Pharmaceutical Polymer Synthesis: Advanced Algorithms for Targeted Drug Delivery Systems

This article provides a comprehensive overview of Molecular Weight Distribution (MWD) control algorithms essential for synthesizing polymers in drug development.

Precision Control of MWD in Pharmaceutical Polymer Synthesis: Advanced Algorithms for Targeted Drug Delivery Systems

Abstract

This article provides a comprehensive overview of Molecular Weight Distribution (MWD) control algorithms essential for synthesizing polymers in drug development. We explore the fundamental importance of MWD in determining pharmacokinetics and bioactivity, detail state-of-the-art algorithmic methodologies for real-time control, address common troubleshooting and optimization challenges in pharmaceutical contexts, and validate these approaches through comparative analysis of performance and clinical relevance. Tailored for researchers and drug development professionals, this guide bridges polymer science and therapeutic efficacy.

Why MWD Matters in Pharmaceuticals: Linking Polymer Properties to Drug Efficacy and Safety

Technical Support Center: Troubleshooting MWD Analysis & Control

This support center provides guidance for researchers working within the context of developing MWD control algorithms for polymerization processes, specifically for drug delivery applications. The FAQs address common experimental challenges in measuring, interpreting, and controlling Molecular Weight Distribution (MWD) to achieve desired drug release profiles.

Frequently Asked Questions (FAQs)

Q1: My Gel Permeation Chromatography (GPC/SEC) trace shows multiple peaks or unexpected shoulders. What could be causing this, and how does it affect my drug release kinetics? A: Multiple peaks often indicate a poorly controlled polymerization process, such as:

- Broad or Bimodal Distribution: Can result from slow initiation, side reactions (e.g., chain transfer), or inadequate mixing. This typically leads to triphasic or unpredictable drug release (initial burst, lag phase, non-linear decay).

- Unexpected High-MW Shoulder: May suggest cross-linking or aggregation. This can severely retard drug release or cause incomplete release.

- Unexpected Low-MW Shoulder: Often due to chain scission during synthesis or the presence of unreacted monomer/initiator. This usually causes a significant initial burst release.

- Troubleshooting Protocol:

- Verify Solvent & Temperature: Ensure the GPC solvent fully dissolves the polymer and that the column temperature is stable. Filter all samples (0.45 µm).

- Check for Aggregation: Run GPC with added salt (e.g., LiBr) or a different solvent to disrupt potential hydrogen-bonding aggregates.

- Cross-reference with NMR: Use end-group analysis via ¹H NMR to estimate Mn and compare with GPC Mn. A large discrepancy suggests GPC calibration issues or polymer aggregation.

- Review Polymerization Parameters: For your control algorithm, audit reactor temperature stability, monomer addition rate fidelity, and initiator half-life.

Q2: When developing a feedback control algorithm, which MWD parameter (Mn, Mw, Đ) should be the primary control variable for predictable drug release? A: For sustained, controlled release, the primary target should be low Dispersity (Đ), followed by precise target weight-average molecular weight (Mw).

- Rationale: Đ (Mw/Mn) defines the breadth of the distribution. A low Đ (typically <1.2 for ATRP/RAFT) ensures polymer chains are nearly uniform in length, leading to more monophasic, predictable erosion/diffusion release kinetics. Controlling Mw is critical as it directly influences hydrogel mesh size, degradation rate, and diffusion coefficients.

| MWD Parameter | Impact on Drug Release Profile | Target for Controlled Release |

|---|---|---|

| Number-Avg MW (Mn) | Influences initial burst release via fraction of short chains. | Keep within ±5% of target. |

| Weight-Avg MW (Mw) | Primary driver of release rate and matrix degradation time. | Critical control variable. |

| Dispersity (Đ) | Defines release profile shape; high Đ causes multi-phasic release. | Minimize (<1.2 is ideal). |

Q3: My in vitro drug release assay shows high initial burst release despite a target Đ of 1.1. What are the likely material-level causes? A: This common issue often stems from MWD artifacts or polymer architecture:

- Cause 1: Residual low molecular weight oligomers not resolved by GPC. These can leach out rapidly.

- Cause 2: Improper polymer processing (e.g., hot-melt extrusion) causing chain scission, creating low-MW fragments.

- Cause 3: Poor encapsulation efficiency or surface-adsorbed drug.

- Experimental Protocol: MALDI-TOF MS for Low-MW Oligomer Detection:

- Sample Preparation: Prepare a 10 mg/mL polymer solution in a compatible solvent (e.g., THF). Mix 1:10 with matrix solution (e.g., Dithranol at 20 mg/mL in THF).

- Cationization: Add a cationizing agent (e.g., Sodium Trifluoroacetate) to the mix for a final concentration of ~1 mg/mL.

- Spotting: Deposit 0.5-1 µL of the final mixture onto the MALDI target plate and allow to dry.

- Analysis: Acquire spectra in reflection positive ion mode. The spectrum will reveal the mass of individual oligomers, identifying low-MW species undetected by GPC.

Q4: How do I translate a target drug release profile (e.g., zero-order for 30 days) into specific MWD parameters for my polymerization control algorithm? A: This requires an iterative, model-informed design of experiments (DoE) approach.

- Workflow Protocol:

- Define Target Profile: Quantify target release rate (e.g., 5% per day) and duration.

- Initial Synthesis: Run controlled polymerization (e.g., ATRP) at setpoints for target Mw and low Đ.

- Characterize: Measure full MWD (not just Mn/Mw/Đ) via GPC-MALLS for accuracy.

- Fabricate & Test: Formulate drug-loaded particles/films and run in vitro release.

- Model & Correlate: Use mathematical models (e.g., Higuchi, Korsmeyer-Peppas) to correlate MWD moments (Mn, Mw, Mz) to release rate constants.

- Algorithm Refinement: Feed the correlation back into the control algorithm to adjust setpoints (e.g., monomer conversion, chain transfer agent ratio) for the next synthesis batch.

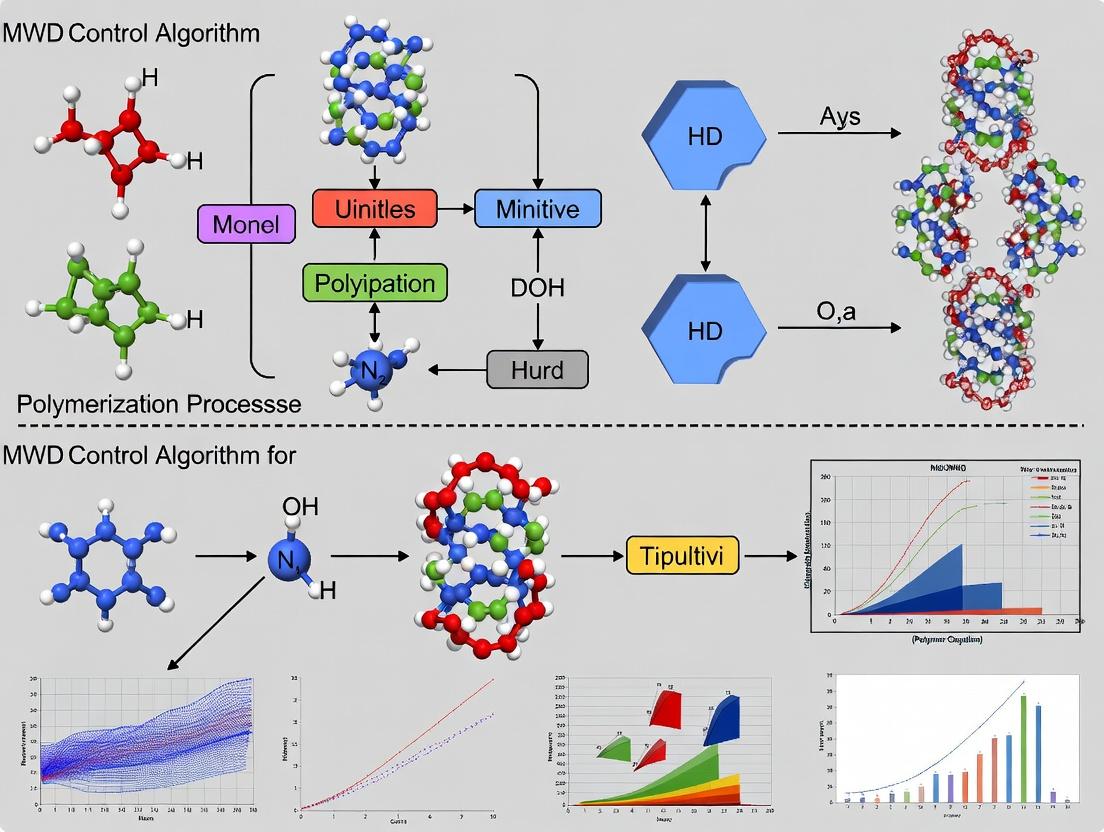

Diagram Title: Model-Informed MWD Control Algorithm Development Cycle

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function in MWD Control & Analysis |

|---|---|

| RAFT Chain Transfer Agent (e.g., CPDB) | Provides reversible deactivation for living polymerization, enabling precise control over Mw and low Đ. |

| GPC/SEC with Multi-Angle Light Scattering (MALLS) | Detector that provides absolute molecular weight without calibration, critical for accurate MWD data for algorithm feedback. |

| Deuterated Solvents for NMR (e.g., CDCl₃) | Allows for end-group analysis to determine absolute Mn and confirm living polymerization efficiency. |

| Functionalized Initiators (e.g., Br-PEG-Br) | Enables synthesis of block copolymers; PEG chain length influences hydrophilicity and drug release rate. |

| Enzymatic Degradation Assay (e.g., Proteinase K for polyesters) | Simulates in vivo biodegradation of polymer matrix, linking MWD to release profile under biological conditions. |

Frequently Asked Questions (FAQs)

Q1: Our synthesized polymer with a narrow MWD shows inconsistent oral absorption in rodent models. What could be the issue? A: This is a common challenge. A narrow MWD may not adequately represent the heterogeneity needed for predictable mucoadhesion or penetration through the mucus layer. Broaden your MWD target (increase Đ - dispersity) in your control algorithm to include a fraction of lower MW chains for improved diffusion and higher MW chains for sustained contact. Verify the hydrodynamic radius (Rh) distribution via DLS against your target.

Q2: How does MWD specifically influence hepatic clearance predictions in in vitro hepatocyte assays? A: High-MW fractions (>40-50 kDa) may show artificially low clearance in hepatocyte monolayers due to impaired cellular uptake via passive diffusion. This can lead to overestimation of half-life in vivo where alternative uptake mechanisms exist. We recommend fractionating your polymer batch by SEC and testing individual fractions for a more accurate structure-activity relationship.

Q3: We observe unexpected polymer accumulation in the spleen during biodistribution studies, despite a low average MW. Why? A: The spleen filters particulates and large macromolecular aggregates. Even with a low number-average MW (Mn), a long "tail" of high-MW polymers in your distribution (high Mw/Mn) can promote aggregation in vivo. Check the weight-average MW (Mw) and the z-average from light scattering. Modify your polymerization algorithm's termination kinetics to clip this high-MW tail.

Q4: How critical is MWD data for regulatory submission of a polymeric drug conjugate? A: Extremely critical. Agencies require full characterization of the distribution. You must report Mn, Mw, Đ, and preferably a chromatogram overlay for all GMP batches. Your MWD control algorithm must demonstrate batch-to-batch reproducibility. Include SEC-MALS data in your CMC section.

Troubleshooting Guides

Issue: Poor Correlation Between In Vitro and In Vivo PK Data.

- Check 1: Characterize the full MWD of the polymer after incubation in your release medium (e.g., plasma, buffer). Degradation or aggregation can shift the MWD.

- Check 2: Ensure your in vitro dialysis membrane molecular weight cut-off (MWCO) accounts for the entire MWD, not just Mn. A 10 kDa MWCO membrane may retain a significant portion of your polymer if the MWD is broad.

- Action: Implement a quality-by-design (QbD) approach: Use your MWD control algorithm to synthesize three batches with identical Mn but varying Đ. Run parallel PK studies. This will isolate the MWD variable.

Issue: Unpredictable Renal Clearance Threshold.

- Symptom: Polymers with Mn below the theoretical renal filtration cutoff (~45 kDa) are not cleared as expected.

- Diagnosis: Renal clearance is sensitive to hydrodynamic volume (radius), not just molecular weight. A branched, high-Đ polymer has a larger Rh than a linear, low-Đ polymer of the same Mn.

- Solution: Correlate clearance rate with Rh (from DLS or SEC-MALS) rather than Mn. Tune your polymerization algorithm's branching agent feed rate to control Rh distribution.

Experimental Protocols

Protocol 1: Correlating MWD to Cellular Uptake (Metabolism/Distribution Studies) Objective: To quantify the dependence of cellular internalization rate on polymer molecular weight within a distribution.

- Fractionation: Separate your polymeric API using preparative Size Exclusion Chromatography (SEC). Collect 5-7 narrow fractions.

- Characterization: Analyze each fraction via analytical SEC with Multi-Angle Light Scattering (MALS) to determine absolute Mw and Rh.

- Labeling: Label each fraction with an identical fluorescent probe (e.g., Cy5) using a standardized conjugation and purification protocol.

- Uptake Assay: Treat cultured hepatocytes (e.g., HepG2) or macrophages (e.g., THP-1) with each fraction at equal fluorophore concentration. Use flow cytometry to measure cellular fluorescence at 1, 2, 4, and 24 hours.

- Data Analysis: Plot uptake rate (slope of early time points) versus Mw and Rh.

Protocol 2: In Vivo Biodistribution as a Function of Dispersity (Đ) Objective: To isolate the impact of MWD breadth on tissue distribution.

- Polymer Synthesis: Using your MWD control algorithm, synthesize two polymer-drug conjugate batches:

- Batch A: Target Đ = 1.1 (Narrow)

- Batch B: Target Đ = 1.8 (Broad)

- Maintain identical monomer composition and number-average molecular weight (Mn).

- Radiolabeling: Label each batch with a radioisotope (e.g., Zr-89 for antibodies, I-125 for small molecules) using a consistent method.

- Animal Study: Administer each batch to separate groups of mice (n=5 per time point). Use SPECT/CT imaging at 6, 24, 48, and 72 hours.

- Ex Vivo Analysis: At terminal time points, harvest major organs (liver, spleen, kidney, heart, lung). Measure radioactivity via gamma counting and calculate % injected dose per gram (%ID/g).

- Correlation: Compare the tissue distribution profiles, focusing on reticuloendothelial system (RES) uptake in the liver and spleen.

Data Presentation

Table 1: Impact of MWD Parameters on ADME Processes

| ADME Phase | Key MWD Parameter | Typical Trend | Quantitative Example |

|---|---|---|---|

| Absorption | Đ (Dispersity) | Higher Đ can enhance mucoadhesion and permeation. | Đ=1.8 showed 2.3x higher intestinal permeation than Đ=1.1 at same Mn (20 kDa). |

| Distribution | Mw (Weight-Avg MW) | High Mw tail (>50 kDa) increases RES uptake. | Fraction with Mw >70 kDa accounted for 85% of total liver accumulation. |

| Metabolism | Mn (Number-Avg MW) | Lower Mn fractions are metabolized/cleared faster. | Fraction with Mn=10 kDa had 4x faster in vitro degradation rate vs. Mn=30 kDa. |

| Excretion | Hydrodynamic Radius (Rh) | Renal clearance sharply decreases for Rh > ~4-5 nm. | Polymers with Rh > 5 nm showed a >90% reduction in renal clearance. |

Table 2: Essential Analytical Techniques for MWD-ADME Studies

| Technique | Primary Measured Parameter | Role in ADME Studies |

|---|---|---|

| SEC-MALS | Absolute Mw, Mn, Đ, Rh | Gold standard for full MWD characterization pre-in vivo dosing. |

| Dynamic Light Scattering (DLS) | Z-average size, Polydispersity Index (PdI) | Quick assessment of aggregation state in biological fluids. |

| Asymmetric Flow FFF-MALS | MWD of complex/nanoparticulate systems | Characterizes MWD of large or aggregating conjugates in serum. |

| LC-MS/MS | Drug payload release kinetics | Correlates drug release rate with the MW of the residual polymer carrier. |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function |

|---|---|

| N-hydroxysuccinimide (NHS)-ester fluorescent dyes (e.g., Cy5-NHS) | For consistent, amine-reactive labeling of polymer fractions to track uptake and distribution. |

| SEC Standards (Narrow & Broad MWD) | For accurate calibration and validation of SEC system performance specific to your polymer chemistry. |

| Preparative SEC Columns | For physical fractionation of a polydisperse batch into narrow MWD samples for controlled experiments. |

| Size-exclusion spin columns (various MWCO) | For rapid buffer exchange and separation of free drug/fluorophore from polymer conjugate post-reaction. |

| Stable Cell Lines with Fluorescent Organelle Markers | To visualize intracellular trafficking pathways of different polymer MW fractions (e.g., lysotracker). |

| Activity-Based Protein Profiling (ABPP) Probes | To monitor the impact of polymer MWD on specific metabolizing enzyme activity (e.g., cytochrome P450). |

Visualizations

Diagram 1: MWD Control Algorithm's Role in PK Study Design

Diagram 2: MWD Influence on Key ADME Pathways

In the context of developing a Molecular Weight Distribution (MWD) control algorithm for polymerization processes, precise characterization of polymer products is paramount. For therapeutic polymers (e.g., PEGylation agents, polymeric drug carriers, hydrogel components), the key metrics of Number-Average Molecular Weight (Mn), Weight-Average Molecular Weight (Mw), and the Polydispersity Index (PDI) are critical quality attributes that directly influence efficacy, safety, and pharmacokinetics. This technical support center addresses common experimental challenges in measuring and interpreting these parameters.

Definitions & Significance Table

| Metric | Definition | Calculation (GPC/SEC) | Significance for Therapeutic Performance |

|---|---|---|---|

| Mn | Number-average molecular weight. The total weight of all molecules divided by the total number of molecules. | Σ(NiMi) / ΣNi | Predicts osmotic pressure, correlates with drug loading capacity for some systems, and influences basic solution properties. |

| Mw | Weight-average molecular weight. Emphasizes the contribution of heavier molecules. | Σ(NiMi²) / Σ(NiMi) | More sensitive to high-MW species; impacts viscosity, in vivo circulation time, and immune recognition. |

| PDI | Polydispersity Index (Đ). A measure of the breadth of the MWD. | Mw / Mn | Đ = 1: Monodisperse. High Đ indicates heterogeneous chain lengths, leading to batch-to-batch variability in drug release profiles, pharmacokinetics, and potency. |

Troubleshooting Guides & FAQs

Q1: Our GPC/SEC chromatogram for a therapeutic PEG shows a shoulder or tailing peak. What could cause this, and how does it affect PDI and therapeutic consistency? A: This indicates a broadening or multi-modal MWD. Causes include:

- Incomplete initiation or side reactions: Review monomer purity and initiator efficiency in your polymerization algorithm.

- Inadequate mixing or temperature gradients in the reactor during the controlled polymerization.

- Column degradation or overloading: Perform a system suitability test with a narrow standard.

- Polymer aggregation in solution: Ensure complete dissolution and use appropriate mobile phase additives. Impact: A high shoulder often raises Mw disproportionately, increasing PDI. This can lead to inconsistent drug conjugation efficiency and altered clearance rates in vivo.

Q2: We are synthesizing a block copolymer for drug delivery. Mn from NMR end-group analysis differs significantly from GPC results. Which one should we trust? A: This is common. Trust NMR Mn for absolute, chemical structure-based values, especially for low Mn (<20,000 Da). GPC Mn is relative to polymer standards (e.g., polystyrene). The discrepancy highlights the need for accurate calibration in your MWD algorithm.

- Action: Use multiple characterization techniques. Perform a light scattering detection (if available) for absolute Mw. Correlate GPC retention time with NMR Mn to create a custom calibration curve for your specific polymer.

Q3: How sensitive is in vivo circulation time to Mw and PDI changes in our polymeric nanocarrier? A: Extremely sensitive. Mw directly impacts renal clearance threshold (~40 kDa for linear polymers). A high PDI means a significant fraction of chains fall below this threshold, causing rapid renal elimination of the low-MW fraction, while very high-MW fractions may accumulate. This leads to non-linear, unpredictable pharmacokinetics.

- Experimental Protocol for Correlation: Synthesize a series of batches with controlled Mw and varying PDI via your algorithm. Label with a fluorescent tag. Administer to animal models and perform blood sampling over time. Plot concentration vs. time curve. You will observe wider variability in half-life for high-PDI batches.

Q4: During GPC analysis, our protein-polymer conjugate shows abnormal retention. How should we prepare samples? A: Protein-polymer conjugates are challenging due to potential secondary interactions.

- Protocol:

- Use a mobile phase with 0.1-0.2 M NaCl to shield ionic interactions.

- Use a column with smaller pore sizes (e.g., 100-300 Å) suited for globular proteins/conjugates.

- Filter samples with a 0.22 µm centrifugal filter (not membrane) to avoid shear degradation.

- Always include a control run of the native protein and the separate polymer component.

Essential Experimental Protocol: Determining Mn, Mw, and PDI via GPC/SEC

Title: Absolute Molecular Weight Determination Using Multi-Angle Light Scattering (MALS) Detection.

Methodology:

- System Setup: Equip GPC/SEC system with online MALS detector, refractive index (RI) detector, and UV detector.

- Column Selection: Select appropriate pore-size columns (e.g., 2-3 columns in series) for the expected molecular weight range.

- Mobile Phase: Use filtered (0.1 µm) and degassed solvent identical to the polymer storage solvent (e.g., PBS for conjugates, THF for synthetics). Add 0.02% NaN3 if running aqueous.

- Sample Preparation: Dissolve polymer accurately to 2-4 mg/mL. Agitate gently (no vortex) for 12-24 hours. Filter through 0.22 µm PTFE syringe filter directly into a vial.

- Calibration: Normalize MALS detectors using a toluene standard or pure mobile phase. Determine the inter-detector delay volume using a narrow, low-MW standard.

- Injection: Inject 100 µL of sample at a flow rate of 1.0 mL/min.

- Data Analysis: Use the ASTRA or equivalent software. The MALS detector directly measures the root-mean-square radius and absolute molecular weight at each elution slice. The RI detector provides concentration. The software integrates to calculate Mn (MALS), Mw (MALS), and PDI across the entire peak.

Visualizations

Title: GPC/SEC-MALS Workflow for Absolute Polymer Characterization.

Title: Impact of Mw and PDI on Therapeutic Performance.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in MWD Analysis for Therapeutics |

|---|---|

| Narrow Dispersity Polymer Standards (e.g., PMMA, PEG) | Essential for calibrating GPC/SEC systems to obtain relative Mn, Mw values. |

| HPLC-Grade Solvents with 0.1 µm Membrane Filters | To prepare particulate-free mobile phase, preventing column damage and baseline noise. |

| 0.22 µm PTFE Syringe Filters | For filtering polymer samples without adsorption or shear degradation. |

| Stabilized THF or DMF (with BHT) | Prevents peroxide formation which can degrade columns and alter polymer samples. |

| Multi-Angle Light Scattering (MALS) Detector | Provides absolute molecular weight measurement independent of elution time. |

| Refractive Index (RI) Detector | Universal concentration detector for calculating molecular weight from light scattering. |

| Analytical Balance (0.01 mg sensitivity) | Critical for accurate sample weighing for concentration-dependent analyses. |

| Lyophilized, End-Group Characterized Polymer | Used as an internal control to validate the entire GPC/MALS protocol. |

Technical Support Center: Troubleshooting Guides & FAQs

FAQ 1: Why is my PLGA nanoparticle batch exhibiting inconsistent drug loading efficiency?

- Answer: Inconsistent drug loading in PLGA nanoparticles is frequently tied to poor control over the polymer's Molecular Weight Distribution (MWD). A broad MWD leads to variable chain packing and degradation rates during the emulsification/solvent evaporation process. Low molecular weight fractions degrade and release the drug too quickly during fabrication, while very high molecular weight fractions may not encapsulate efficiently.

- Troubleshooting Protocol:

- Characterize MWD: Run GPC on your PLGA feedstock. Note the Đ (Dispersity, Đ = Mw/Mn).

- Correlate: Plot drug loading efficiency (DLE%) against MWD parameters (Mn, Mw, Đ) from multiple batches.

- Solution: Source PLGA with a narrow Đ (<1.3). If using in-house synthesized polymer, optimize your MWD control algorithm to reduce dispersity. For formulation, consider a more rigorous purification step (e.g., fractionation) of the polymer prior to nanoparticle synthesis.

FAQ 2: How does PEGylation efficiency relate to PEG's MWD, and why does it affect circulation half-life?

- Answer: PEGylation—the conjugation of Polyethylene Glycol (PEG) chains to a drug or nanoparticle—creates a hydrophilic "cloud" that reduces opsonization. The efficiency of this shielding is highly dependent on PEG chain length (MW) and MWD. A broad MWD results in a population of molecules with varying degrees of protection. Shorter chains provide inadequate stealth, while very long chains may induce immunogenicity or steric hindrance.

- Troubleshooting Protocol:

- Analyze Conjugate: Use MALDI-TOF or analytical SEC to assess the MWD of PEG after conjugation.

- Test In Vivo: Perform pharmacokinetic studies in a rodent model. Compare circulation half-life (t1/2β) of conjugates made from PEG with different Đ values.

- Solution: Use heterofunctional PEG (e.g., mPEG-NHS) with a narrow Đ (<1.05) for reproducible conjugation chemistry and consistent biological performance.

FAQ 3: My sustained-release PLGA microsphere formulation has a problematic initial burst release. How can MWD tuning help?

- Answer: A high initial burst release is often due to rapid diffusion of drug located near or on the surface of the microsphere. This is exacerbated by the presence of low molecular weight (LMW) PLGA fractions, which hydrate and degrade faster, creating immediate pores.

- Troubleshooting Protocol:

- Profile Release: Conduct a standard in vitro release study (PBS, 37°C). Quantify the % drug released at 24 hours (burst release).

- Fractionate Polymer: Separate your PLGA into distinct MW fractions via preparative GPC or fractionated precipitation.

- Formulate & Compare: Fabricate microspheres using the LMW fraction, the high MW (HMW) fraction, and the raw broad-MWD polymer.

- Solution: Employ a PLGA feedstock with a higher Mn and a narrow Đ, or deliberately blend HMW and LMW fractions in a controlled ratio to engineer a more precise, biphasic release profile.

Table 1: Impact of PLGA Dispersity (Đ) on Nanoparticle Properties

| PLGA Đ (Mw/Mn) | Avg. Particle Size (nm) ± SD | Drug Loading Efficiency (%) ± SD | Initial Burst Release (24h, %) |

|---|---|---|---|

| 1.1 | 152 ± 8 | 78 ± 3 | 15 ± 2 |

| 1.5 | 185 ± 25 | 65 ± 7 | 32 ± 5 |

| 2.2 | 221 ± 41 | 48 ± 12 | 45 ± 8 |

Table 2: Circulation Half-Life vs. PEG MWD for a Conjugated Protein

| PEG Mw (kDa) | Đ (Mw/Mn) | Conjugation Efficiency (%) | Circulation t1/2β (h) |

|---|---|---|---|

| 20 | 1.02 | 95 | 40 |

| 20 | 1.20 | 88 | 28 |

| 40 | 1.03 | 91 | 65 |

| 40 | 1.15 | 84 | 49 |

Experimental Protocols

Protocol 1: Assessing MWD Impact on PLGA Nanoparticle Fabrication (Single Emulsion)

- Objective: To correlate PLGA MWD with nanoparticle characteristics.

- Materials: See "Scientist's Toolkit" below.

- Method:

- Dissolve 100 mg of characterized PLGA (varying Đ) and 10 mg of model drug (e.g., coumarin-6) in 4 mL of dichloromethane (DCM).

- Emulsify this organic phase in 40 mL of 1% (w/v) polyvinyl alcohol (PVA) aqueous solution using a probe sonicator (70% amplitude, 60 s on ice).

- Stir the emulsion overnight at room temperature to evaporate DCM.

- Centrifuge nanoparticles at 20,000 x g for 30 min, wash twice with DI water, and resuspend.

- Characterize size (DLS), drug loading (HPLC after dissolution), and in vitro release.

Protocol 2: Evaluating PEG MWD in Conjugation Reactions

- Objective: To determine the effect of PEG dispersity on protein conjugation yield.

- Method:

- Dissolve 10 mg of Lysozyme (model protein) in 1 mL of 0.1 M phosphate buffer (pH 7.4).

- Add a 5-fold molar excess of mPEG-NHS ester (of defined MWD) to the protein solution.

- React for 2 hours at 4°C under gentle stirring.

- Quench the reaction with 100 µL of 1 M glycine buffer.

- Purify the conjugate using a size-exclusion PD-10 column.

- Analyze the conjugate and reaction mixture via SDS-PAGE and SEC-MALS to determine conjugation efficiency and product MWD.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for MWD-Sensitive Polymer Formulation

| Item | Function & Relevance to MWD Control |

|---|---|

| PLGA (50:50), Low Dispersity (Đ<1.2) | Benchmark excipient for reproducible, sustained release. Narrow Đ ensures predictable erosion kinetics. |

| mPEG-NHS (5kDa, 20kDa), Đ<1.05 | Gold-standard stealth polymer. Narrow Đ is critical for consistent conjugation and in vivo performance. |

| GPC/SEC System with MALS & RI Detectors | Essential for absolute molecular weight (Mn, Mw) and Đ measurement, not just relative values. |

| Preparative GPC Columns | For fractionating broad-MWD polymer batches into narrow fractions for controlled blending studies. |

| Controlled Polymerization Kit (e.g., for ROP) | Enables in-house synthesis of PLGA with tunable MWD via algorithm-controlled monomer feed rates. |

| Model Hydrophobic Drug (e.g., Coumarin-6) | Fluorescent tracer for quantitative tracking of loading and release without HPLC interference. |

Diagrams

Title: Algorithmic MWD Control Workflow for Polymer Synthesis

Title: Mechanism of MWD-Driven Burst Release from PLGA

Technical Support Center: Troubleshooting & FAQs

Frequently Asked Questions (FAQs)

Q1: Our GPC/SEC analysis shows a consistently broader-than-targeted molecular weight distribution (MWD). What are the primary process variables to investigate? A: Inherent variability often stems from fluctuating initiation and propagation rates. First, verify the consistency of your monomer feed purity and temperature control (±0.5°C is typically required). For free radical polymerizations, examine the half-life of your initiator at the process temperature. A table of common issues is provided below.

Q2: During a controlled/living polymerization (e.g., ATRP, RAFT), we observe high dispersity (Ð) and deviation from first-order kinetics. What could be the cause? A: This indicates a loss of "livingness." Likely culprits are: (1) Oxygen contamination, which terminates active chains. Ensure rigorous degassing protocols. (2) Catalyst/ligand deactivation in ATRP—check for moisture or impurities. (3) Inadequate mixing leading to localized concentration gradients. Implement a standardized troubleshooting protocol (see below).

Q3: How can we decouple thermal effects from mixing effects on MWD variability in a batch reactor? A: Implement a Design of Experiments (DoE) approach. The key is to run a series of small-scale, highly instrumented calibration reactions. A protocol is provided in the Experimental Protocols section.

Table 1: Common Initiators and Their Impact on MWD Variability

| Initiator (Type) | Typical Half-Life @ Process Temp | Recommended Concentration Range (mol%) | Key Variability Factor | Expected Dispersity (Ð) Range in Ideal Conditions |

|---|---|---|---|---|

| AIBN (Thermal) | 1 hour @ 70°C | 0.1 - 1.0 | Temperature sensitivity | 1.5 - 2.5+ |

| Benzoyl Peroxide | 1 hour @ 90°C | 0.1 - 2.0 | Impurity sensitivity | 1.8 - 3.0 |

| NaPS (Redox) | Seconds at RT | 0.01 - 0.5 | Mixing efficiency | 1.2 - 2.0 |

| TPO (Photo) | N/A | 0.5 - 2.0 | Light intensity uniformity | 1.3 - 1.8 |

Table 2: Troubleshooting Guide: Symptoms & Actions

| Observed Symptom (MWD Output) | Possible Root Cause | Immediate Diagnostic Action | Corrective Action |

|---|---|---|---|

| Unpredictable Mn, high Ð | Inconsistent initiator efficiency | Run DSC on initiator batch to check purity/activity. | Source new batch; implement stricter cold chain storage. |

| Bimodal distribution | Poor mixing or thermal hot spots | Use a fluorescent tracer to visualize mixing. | Optimize impeller design/ speed; implement jacket temperature zoning. |

| Drift in Mn over batch cycles | Catalyst deactivation (ATRP) | Sample and analyze catalyst concentration via ICP-MS. | Pre-treat monomer to remove protic impurities; use sealed catalyst addition. |

| Sudden spike in Ð | Introduction of oxygen/water | Install in-line FTIR to monitor for carbonyl formation (oxidation). | Enhance nitrogen sparging protocol; use oxygen scavengers. |

Experimental Protocols

Protocol 1: Calibration Experiment to Isolate Mixing vs. Thermal Effects Objective: To decouple the impact of mixing efficiency from bulk temperature on MWD. Methodology:

- Setup: Use a 500 mL jacketed reactor fitted with a high-precision thermocouple (reactor bulk) and an IR probe at the reactor wall. Employ a pitched-blade turbine impeller.

- Procedure: a. Charge the reactor with solvent (e.g., anisole, 300 mL) and monomer (e.g., styrene, 100 mL) under inert atmosphere. b. Set jacket temperature to target (e.g., 70°C). Begin mixing at a low rate (100 RPM). c. Once thermal equilibrium is reached, inject initiator solution (e.g., AIBN in toluene). d. Run the reaction for 3 half-lives of the initiator. Sample (5 mL) at t=0, 30, 60, 120, 180 minutes. e. Quench samples immediately in cold THF with BHT inhibitor. f. Repeat the experiment at 300 RPM and 600 RPM, keeping all other variables constant.

- Analysis: Analyze all samples via GPC/SEC. Plot Ð and Mn against time for each RPM. Correlate wall IR temperature vs. bulk thermocouple readings. A significant change in Ð with RPM indicates mixing-dominated variability.

Protocol 2: Diagnostic for "Livingness" in ATRP Objective: To confirm the persistence of active chain ends and identify termination events. Methodology:

- Setup: Conduct a seed polymerization in a Schlenk line.

- Procedure: a. Synthesize a low-MW seed polymer (Target Mn ~5000) using standard ATRP conditions ([M]:[I]:[Cat] = 50:1:0.5). b. Purify the seed polymer via precipitation. Characterize thoroughly (Mn, Ð via GPC; chain end functionality via ¹H NMR). c. In a new flask, charge a known mass of the seed polymer, additional monomer (targeting a theoretical doubling of Mn), catalyst, and ligand. d. Allow the chain extension to proceed for a predetermined time (e.g., 4 hours). e. Sample and analyze via GPC.

- Analysis: A successful "living" system will show a clear, monomodal shift to higher molecular weight with low dispersity (Ð < 1.2). A bimodal or broad distribution indicates irreversible termination or loss of end-group fidelity.

Visualizations

Title: Sources of Variability and Algorithm Feedback Loop

Title: Diagnostic Workflow for Living Polymerization Fidelity

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for MWD Control Research

| Reagent / Material | Function & Importance | Critical Specification for Reproducibility |

|---|---|---|

| High-Purity Monomer (e.g., Styrene, MMA) | The building block of the polymer chain. Impurities act as chain transfer agents or inhibitors. | ≥99.5% purity, stabilized (e.g., 4-methoxyphenol) for storage but must be removed via inhibitor-removal column immediately before use. |

| RAFT Agent (e.g., CDB, CPDB) | Mediates controlled chain growth via reversible chain transfer, enabling low-Ð polymers. | ≥97% purity (by HPLC). Store under inert atmosphere at -20°C. Test chain transfer constant in a calibration reaction. |

| ATRP Catalyst (e.g., CuBr) & Ligand (e.g., PMDETA) | Forms the redox-active complex that establishes the atom transfer equilibrium, controlling active/dormant chains. | Catalyst: ≥99.999% trace metals basis. Ligand: Distilled under reduced pressure or recrystallized. |

| In-line FTIR Probe with DiComp Tip | Provides real-time kinetic data (monomer conversion) by monitoring vinyl bond disappearance. | Wavenumber range must cover 1600-1700 cm⁻¹ (C=C stretch). Calibrate with offline GC/MS data for each new monomer system. |

| Certified Narrow Dispersity Polystyrene Standards | Absolute calibration of GPC/SEC for accurate Mn and Ð measurement. | Set covering target MW range (e.g., 1k, 10k, 50k, 200k Da). Ð certified as <1.05. |

| Oxygen Scavenger (e.g., Copper(I) Chloride) | Used in glovebox purification systems to achieve and maintain sub-ppm oxygen levels in solvents. | Essential for reproducible living polymerizations. Solvents must be sparged and passed through activated columns. |

Algorithmic Strategies for MWD Control: From PID to Model Predictive Control (MPC) in Reactor Design

Technical Support & Troubleshooting Center

FAQs & Troubleshooting Guides for MWD Control Algorithm Research in Polymerization Processes

Q1: During closed-loop MWD control using feedback, my reactor exhibits sustained oscillations in the dispersity (Đ) measurement. What are the primary causes and solutions?

A: Sustained oscillations in a feedback loop typically indicate instability. For MWD control in polymerization, common causes are:

- Excessive Controller Gain: Aggressive proportional (P) or integral (I) action in your PID algorithm amplifies noise and process delay.

- Troubleshooting: Implement a tuning protocol. First, ensure your measurement (e.g., online SEC/GPC) signal is adequately filtered (low-pass filter with a time constant ~1.5x your sampling interval). Then, perform a step test on your manipulated variable (e.g., chain transfer agent flow rate). Use the Ziegler-Nichols or Tyreus-Luyben method to calculate new, more conservative P and I gains.

- Significant Measurement Delay: Online MWD analyzers (SEC/GPC) have a substantial dead time (θ), which severely limits achievable control performance.

- Troubleshooting: Implement a Smith Predictor compensator within your feedback algorithm. This requires a dynamic model of your polymerization process (see Q3). The model predicts the current state, which is then corrected by the delayed actual measurement.

Q2: How do I design an effective feedforward controller to reject disturbances in monomer feed concentration for a semi-batch reactor?

A: A feedforward controller requires a model that relates the disturbance to the controlled variable (e.g., number-average molecular weight, M_n).

Experimental Protocol for Feedforward Model Identification:

- Setup: Operate your semi-batch polymerization reactor in open-loop (controller off) at your target conditions.

- Disturbance Introduction: Introduce a known, step-change disturbance in monomer feed concentration (ΔC_M,feed). Record the time of the step.

- Data Collection: Use your online or frequent offline SEC/GPC analysis to track the resulting change in M_n over time.

- Model Fitting: Fit a first-order-plus-dead-time (FOPDT) model to the response:

ΔM_n(t) = (K_ff / (τ_ff * s + 1)) * ΔC_M,feed(t - θ_ff)where K_ff is the steady-state gain, τ_ff is the time constant, and θ_ff is the dead time. - Implementation: Program the inverse of this dynamic model into your control system. The feedforward controller will adjust the initiator or chain transfer agent flow rate immediately upon detecting a change in C_M,feed, calculated to cancel its effect on M_n.

Q3: My APC (e.g., MPC) simulation works perfectly, but the real-time performance is poor. What key experimental factors are often overlooked?

A: This discrepancy usually stems from model-plant mismatch and hardware constraints.

- Key Overlooked Factors:

- Actuator Saturation & Rate Limits: Your simulation likely assumes valves/pumps can achieve any flow instantly. In reality, they have maximum/minimum limits and slew rates.

- Solution: Explicitly incorporate these constraints into your APC algorithm's optimization problem. Most modern MPC toolboxes allow direct input of rate and bound constraints.

- Unmeasured Disturbances: Slow catalyst deactivation or reactor fouling are not captured in short-term identification tests.

- Solution: Augment your APC with an integrating disturbance model (e.g., a state that accounts for output bias). This allows the controller to adapt to slow, unmeasured shifts.

- Actuator Saturation & Rate Limits: Your simulation likely assumes valves/pumps can achieve any flow instantly. In reality, they have maximum/minimum limits and slew rates.

Key Quantitative Data for Control Paradigm Selection

Table 1: Comparison of Core Control Paradigms for MWD Control

| Paradigm | Primary Strength | Key Limitation | Best Suited For | Typical Reduction in MWD Variability* |

|---|---|---|---|---|

| Feedback (PID) | Corrects all measurement errors; simple. | Reacts after disturbance affects MWD; poor with long delays. | Well-understood processes with fast, reliable MWD analysis. | 40-60% |

| Feedforward | Pre-emptively rejects measured disturbances. | Requires accurate model; does nothing for unmeasured disturbances. | Processes with dominant, measurable disturbances (e.g., feed temperature). | 50-70% (for the specific disturbance) |

| Model Predictive Control (MPC) | Handles multi-variable interactions and constraints optimally. | Complex to design; requires high-fidelity model and significant computation. | Complex, constrained multi-variable processes (e.g., controlling both M_n and Đ simultaneously). | 60-80% |

*Estimated reduction in standard deviation of *M_n or Đ under typical laboratory conditions versus open-loop operation. Actual results depend heavily on process dynamics and model accuracy.*

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for MWD Control Algorithm Research

| Item | Function in Research |

|---|---|

| Living/Rapidly Reversible Polymerization Kit (e.g., ATRP, RAFT, NMP reagents) | Enables precise, model-friendly kinetics for algorithm development and validation with minimal side reactions. |

| Online SEC/GPC System with Auto-sampler | Provides the critical real-time or frequent at-line MWD data essential for feedback and model identification. |

| Programmable Syringe Pumps (Multiple) | Act as precise, software-controlled actuators for reagent addition (initiator, monomer, CTA) in feedforward and APC experiments. |

| In-line Spectrophotometer (UV-Vis/NIR) | Serves as a fast, secondary sensor for estimating monomer conversion or agent concentration, used in inferential control or soft sensors. |

| Kinetic Modeling Software (e.g., PREDICI, MATLAB/Simulink) | Used to develop and simulate high-fidelity mechanistic models of the polymerization, which form the core of APC strategies. |

| Process Control Software/Hardware (e.g., LabVIEW with cRIO, Pico) | Provides the real-time data acquisition, control execution, and communication platform to implement custom control algorithms. |

Visualized Workflows & Relationships

Feedback Control Loop for MWD

Feedforward with Feedback Trim

Model Predictive Control (APC) Workflow

Troubleshooting Guides and FAQs

Q1: During online MWD prediction, our Extended Kalman Filter (EKF) state estimator diverges, leading to unrealistic molecular weight distribution predictions. What are the primary causes? A1: EKF divergence in polymerization reactors is typically caused by: (1) Incorrect initialization of the state error covariance matrix (P0), (2) Mismatch between the process noise (Q) and measurement noise (R) covariance matrices and the actual system disturbances, or (3) Significant model-plant mismatch in kinetic parameters (e.g., propagation (kp) or termination (kt) rate constants). First, verify the consistency of your initial state guess. Then, perform a tuning sequence offline using historical batch data to empirically determine Q and R. A common starting point is to set Q as a diagonal matrix with values ~10-4 times the square of the nominal state values and R based on your analytical instrument's known precision (e.g., GPC standard deviation).

Q2: Our kinetic model for free-radical polymerization fails to predict the high-molecular-weight tail observed in GPC data. Which model enhancements should we consider? A2: This discrepancy often indicates missing physical phenomena in the kinetic scheme. Standard models assume instantaneous termination. To capture the high-MW tail, you must incorporate gel-effect (diffusion-controlled termination) models and potentially long-chain branching reactions. Implement a termination rate constant (kt) that is a function of conversion and polymer chain length, using a correlation such as the free-volume theory of Vrentas-Duda. Also, review your initiator decomposition kinetics for potential impurities causing slow, continuous initiation.

Q3: When integrating a kinetic Monte Carlo (kMC) model with a moving horizon estimator (MHE) for MWD prediction, the computational time becomes prohibitive for real-time application. How can we reduce it? A3: kMC is inherently computationally expensive. Consider these strategies: (1) Use a hybrid approach: Employ a deterministic method of moments (MoM) model with an optimized number of quadrature points for real-time state estimation, and use the kMC model only infrequently for full MWD reconstruction. (2) Implement model reduction: Develop a parameterized distribution function (e.g., using Laguerre polynomials) to represent the MWD, reducing the state dimension. (3) Employ advanced MHE formulations that use gradient-based solvers with adjoint sensitivity analysis for the kMC model, and ensure you are using an efficient, compiled kMC code.

Q4: The Raman spectroscopy data used for state estimation (monomer concentration) shows significant baseline drift, corrupting the MWD prediction. What preprocessing steps are critical? A4: Baseline drift is a common issue. Implement the following pre-processing protocol in sequence: (1) Savitzky-Golay filtering for high-frequency noise reduction (window size: 9, polynomial order: 2). (2) Asymmetric Least Squares (AsLS) baseline correction (λ smoothness=1e5, p asymmetry=0.001). (3) Standard Normal Variate (SNV) scaling to correct for path length and scattering effects. Validate the preprocessing by ensuring the integrated peak area for a known calibration sample varies by <2% over a 24-hour period.

Q5: How do we validate the accuracy of a closed-loop MWD control algorithm based on these model-based predictors before plant trials? A5: A rigorous three-step validation is recommended:

- Software-in-the-Loop (SIL): Test the control algorithm against a high-fidelity simulation model (your "truth" model, e.g., detailed kMC) that is different from the internal model used by the estimator/controller.

- Hardware-in-the-Loop (HIL): Implement the control algorithm on the target PLC or industrial computer and connect it to a real-time simulator of the polymerization process, introducing simulated sensor delays and noise.

- Pilot-Scale Testing: Conduct experiments using a well-instrumented pilot reactor. Use design of experiments (DoE) to test across the operating space. Key validation metrics are listed in Table 1.

Table 1: Key Validation Metrics for MWD Control Algorithm Performance

| Metric | Formula | Target Value | ||

|---|---|---|---|---|

| Mw Setpoint Tracking IAE | (\int | M{w,sp}(t) - M{w,pred}(t) | \, dt) | < 5% of setpoint over batch |

| Polydispersity Index (PDI) Steady-State Error | ( | PDI{final} - PDI{sp} | ) | < 0.1 |

| MWD Shape Similarity (f^2) | (100 \cdot \sqrt{\sum (w{i,sp} - w{i,pred})^2}) | > 95 |

Experimental Protocols

Protocol 1: Calibration of Online Spectroscopic Sensors for State Estimation

Objective: To establish multivariate calibration models (e.g., PLS) for predicting monomer concentration and conversion from NIR/Raman spectra. Materials: See "Research Reagent Solutions" below. Procedure:

- Prepare a series of calibration samples in an inert atmosphere glovebox with known monomer concentrations (e.g., 0%, 25%, 50%, 75%, 100% w/w) in solvent or pre-polymer.

- For each sample, acquire spectroscopic data (NIR: 1100-2200 nm; Raman: 500-2000 cm⁻¹) in triplicate using a fiber-optic probe immersed in the sample.

- Record the reference concentration for each sample using offline Gas Chromatography (GC).

- Preprocess spectral data (see FAQ A4).

- Use 70% of the data for training a Partial Least Squares (PLS) regression model (e.g., 5 latent variables). Validate the model on the remaining 30% of data.

- The model outputs (concentration predictions) will serve as the measurement (z_k) for the state estimator (EKF/MHE).

Protocol 2: Kinetic Parameter Estimation for the Core Model

Objective: To estimate precise rate constants (kd, kp, kt) via laboratory-scale batch experiments. Procedure:

- Conduct isothermal batch polymerization experiments in a 500 ml jacketed reactor with precise temperature control (±0.5°C).

- At regular time intervals, extract small samples (~2 ml) under inert conditions.

- Immediately quench samples in an ice-cold solution containing a radical inhibitor (e.g., HQ).

- Analyze samples for monomer conversion (via GC) and molecular weight distribution (via GPC).

- Formulate a parameter estimation problem: Minimize the sum of squared errors between model predictions and experimental data for conversion vs. time and MWD at each sample point.

- Solve the optimization problem using a global algorithm (e.g., Particle Swarm) followed by a local gradient-based method (e.g., Levenberg-Marquardt). Report confidence intervals.

Diagrams

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Kinetic Modeling & MWD Prediction Experiments

| Item | Function/Benefit | Typical Specification/Example |

|---|---|---|

| Inhibitor-Free Monomer | Ensures polymerization kinetics are not affected by unintended stabilization. Purity is critical for accurate parameter estimation. | Methyl methacrylate (MMA), purified by passing through an alumina column to remove hydroquinone. Purity >99.8% (GC). |

| Radical Initiator | Source of primary radicals to start the chain reaction. Decomposition kinetics (kd) are model inputs. | Azobisisobutyronitrile (AIBN), recrystallized from methanol. Half-life temperature must match process conditions. |

| Chain Transfer Agent (CTA) | Modulates molecular weight. Used to tune MWD breadth and validate transfer kinetics in the model. | n-Butyl mercaptan (nBM) or carbon tetrachloride (CCl4). |

| High-Temperature GPC/SEC System | For absolute MWD measurement. The primary source of validation data for the predictor. | System with multi-angle light scattering (MALS), differential viscometer (DV), and refractive index (RI) detectors. Solvent: THF or DMF at 40-50°C. |

| Spectroscopic Probe (NIR/Raman) | Provides real-time, multivariate data for state estimation of conversion and composition. | Immersion or flow-cell probe with silica fibers, compatible with reactor pressure/temperature. |

| Calibration Software | Builds chemometric models to translate spectral data into chemical concentrations. | PLS toolbox (e.g., in MATLAB) or SIMCA, used with preprocessing scripts from Protocol 1. |

| Numerical Computing Environment | Platform for implementing and solving differential equations, optimization, and state estimation algorithms. | MATLAB with Optimization & Control Toolboxes, Python (SciPy, CasADi, Pyomo), or Julia (DifferentialEquations.jl, Optim.jl). |

Technical Support Center

Troubleshooting Guides & FAQs

- Q1: During online NIR monitoring of polymerization, the baseline shows significant drift, corrupting the PLS model predictions for monomer concentration. What are the likely causes and solutions?

- A: Baseline drift is commonly caused by physical changes in the process stream affecting light scattering. Key causes and mitigation steps are summarized below.

- Troubleshooting Table: NIR Baseline Drift

| Potential Cause | Diagnostic Check | Corrective Action |

|---|---|---|

| Temperature Fluctuation | Correlate baseline shift with reactor temperature logs. | Implement a temperature-compensated NIR model or use a robust preprocessing method (e.g., Standard Normal Variate, SNV). |

| Particle/ Bubble Formation | Visually inspect flow cell window for fouling or bubbles. | Increase back-pressure, install in-line degasser, or implement an automated window cleaning cycle. |

| Probe Fouling | Check for gradual signal attenuation across all wavelengths. | Schedule regular clean-in-place (CIP) protocols. Consider a self-cleaning or retractable probe design. |

| Fiber-Optic Cable Stress | Inspect cable for sharp bends or pinch points. | Re-route cables, secure them properly, and replace if damaged. |

Q2: The Raman signal intensity from our reactor has dropped suddenly, making it difficult to track the consumption of a key monomer. How should we proceed?

- A: A sudden drop in signal-to-noise ratio (SNR) typically points to hardware or alignment issues.

- Protocol: Systematic Raman Signal Recovery

- Safety First: Ensure the laser is in safe mode and the probe is disconnected from the reactor.

- Check Calibration: Measure the spectrum of a stable reference standard (e.g., polystyrene, cyclohexane). Compare intensity to historical data.

- Inspect Probe Window: Examine the immersion or flow cell window for coating, crystallization, or etching. Clean with appropriate solvent.

- Verify Laser Output: Use a power meter at the probe tip (following manufacturer's safety guidelines) to confirm specified laser power is delivered.

- Inspect Fiber Optics: Check for physical damage to the excitation and collection fibers. Reconnect all connections securely.

- Re-optimize Integration Time: If hardware is intact, gradually increase integration time to recover SNR, ensuring no pixel saturation occurs.

Q3: Our integrated SEC/GPC data shows poor correlation with real-time NIR predictions of molecular weight averages (Mn, Mw). What could explain this discrepancy?

- A: Discrepancies often arise from sampling, calibration, or model scope issues. Evaluate the following.

- Comparative Analysis Table: SEC/GPC vs. NIR Discrepancy

| Aspect | SEC/GPC (Offline) | Online NIR Prediction | Reconciliation Action |

|---|---|---|---|

| Sample Point | Discrete, possibly from a side stream. | In-line, representing main reactor body. | Validate that sampling loop is representative and quenched instantly to stop reaction. |

| Calibration Basis | Absolute, based on narrow standards. | Indirect, calibrated against offline SEC/GPC data. | Audit the PLS model training set. Ensure it covers the full range of process conditions (e.g., temperature, comonomer ratio). |

| Measured Property | Direct measurement of hydrodynamic volume. | Prediction based on chemical bond vibrations (C-H, etc.). | Confirm the NIR model includes latent variables for polymer architecture (e.g., branching) which affects SEC elution. |

| Time Delay | Hours (sample prep + analysis). | Real-time (seconds). | Apply time-shift correction to align the datasets before comparison. |

- Q4: How can we validate that the integrated spectroscopic data stream is suitable for closed-loop MWD control algorithm development?

- A: Implement a rigorous, multi-stage validation protocol focusing on data integrity and predictive power.

- Experimental Protocol: Data Stream Validation for MWD Control

- Phase 1: Static Validation. Collect spectra from the reactor under a wide range of held constant conditions (different conversions, temperatures). Take simultaneous grab samples for full SEC/GPC analysis. Develop and cross-validate initial PLS models for Mn, Mw, and dispersity (Đ).

- Phase 2: Dynamic Validation. Perform designed pulse or step changes in reactor inputs (e.g., initiator feed, chain transfer agent). Monitor the multivariate spectroscopic response in real-time. Compare the predicted MWD trajectory from the integrated model against frequent offline SEC/GPC samples taken during the transient.

- Phase 3: Latency & Synchronization Audit. Precisely measure the total time delay from the probe tip to the data arriving in the control algorithm. This includes flow-to-cell delay, spectrometer integration time, data transfer, and preprocessing time. Compensate for this latency in the control model.

- Phase 4: Noise Injection & Robustness Test. Introduce controlled, small disturbances (e.g., flow rate ripple, agitation speed change) to assess the algorithm's ability to filter noise and maintain stable predictions.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Polymerization Monitoring |

|---|---|

| Narrow Dispersity Polystyrene Standards | Calibrate SEC/GPC for absolute molecular weight. Serve as a stable reference material for Raman system performance verification. |

| Chain Transfer Agent (e.g., 1-butanethiol) Tracer | Used in controlled experiments to validate the NIR/Raman model's sensitivity to subtle changes in molecular weight kinetics. |

| Deuterated Solvents (e.g., D₂O, CDCl₃) | Provide solvent signals that do not interfere with C-H/N-H/O-H vibrational bands in NIR/Raman, useful for background subtraction and method development. |

| NIR Reflectance Standard (Spectralon) | A white reference material for calibrating the intensity response of fiber-optic reflectance probes. |

| In-line Filter/Degasser | Prevents particulate matter and gas bubbles from entering the flow cell, eliminating a major source of spectroscopic noise and drift. |

| Quenching Agent Solution | Rapidly stops polymerization in grab samples for offline SEC/GPC, ensuring the analyzed MWD matches the exact moment of sampling. |

Integration & Control Workflow Diagram

Title: Real-Time MWD Control via Integrated Spectroscopy

Implementing Model Predictive Control (MPC) for Multi-Variable MWD Regulation

Technical Support Center: Troubleshooting & FAQs

This support center addresses common issues faced by researchers implementing MPC for Molecular Weight Distribution (MWD) regulation in polymerization reactors, within the context of doctoral research on advanced control algorithms.

Frequently Asked Questions (FAQs)

Q1: During closed-loop simulation, my MPC controller causes the reactor temperature to diverge to unrealistic values, even with constraint handling active. What is the likely cause? A1: This is typically a plant-model mismatch in the reaction kinetics or heat transfer parameters. First, verify your state-space or transfer function model used for prediction against a high-fidelity simulator (e.g., Aspen Polymer Plus, gPROMS). Calibrate the Arrhenius parameters (k0, Ea) for propagation/termination rates and the heat transfer coefficient (U) using steady-state and dynamic historical data. Implement a robust state estimator (Kalman Filter) to reconcile mismatches online.

Q2: The MWD prediction from the moment-based model in my MPC horizon shows significant error compared to the measured GPC data. How can I improve this? A2: Moment-based models can lose fidelity over long prediction horizons. Consider these steps:

- Increase the number of moments: Use at least 4-6 moments instead of the typical 3 (live, dead, dormant).

- Incorporate a correction term: Add a disturbance model on the MWD output in your MPC formulation to account for unmodeled dynamics.

- Validate the closure method: Ensure the quadrature method (e.g., fixed-points, QMOM) used to reconstruct the MWD from moments is appropriate for your specific polymerization type.

Q3: The optimization solver (e.g., IPOPT, qpOASES) fails to find a solution within the specified sample time, causing a delay in control action. A3: This indicates a problem with the Real-Time Iteration (RTI) scheme.

- Check initial guess: Warm-start the solver with the solution from the previous time step.

- Simplify the model: Reduce the prediction horizon (Np) or control horizon (Nc) as a temporary debug step.

- Review constraints: Ensure your input and output constraints are not conflicting, creating an infeasible problem. Implement soft constraints on critical outputs.

Q4: How do I handle the significant time delay between taking a reactor sample and receiving the GPC analysis for MWD feedback? A4: This is a key challenge. Implement a delay-compensating strategy:

- Use a state estimator to predict the current states.

- Employ a Smith Predictor structure within the MPC framework, where the model used for prediction explicitly includes a delay block.

- Update the MWD state with the delayed measurement when it arrives, triggering a state correction. The block diagram below illustrates this integrated workflow.

Experimental Protocols for Model Identification & Validation

Protocol 1: Step-Test Experiment for Dynamic Model Identification Objective: To generate input-output data for identifying transfer function or state-space models linking Manipulated Variables (MVs) to Controlled Variables (CVs). Materials: See "Research Reagent Solutions" table. Methodology:

- Stabilize the pilot-scale reactor at the desired operating point (e.g., 70°C, 3 bar).

- Implement a pseudo-random binary sequence (PRBS) or carefully designed step changes in one MV (e.g., initiator flow rate) while holding others constant.

- Record the dynamic response of all CVs (reactor temperature, pressure, monomer conversion, and in-line viscosity as a proxy for Mn).

- Allow the system to return to steady-state before perturbing the next MV.

- Use System Identification Toolbox (MATLAB) or similar to fit a multi-input, multi-output (MIMO) model. Validate with a separate dataset.

Protocol 2: Closed-Loop Performance Benchmarking Objective: To compare the performance of the proposed MPC against a conventional PID cascade. Key Performance Indicators (KPIs): IAE (Integral Absolute Error), settling time, overshoot, MWD polydispersity index (PDI) variance. Methodology:

- Define a representative product grade transition trajectory (e.g., Target Mn from 50k to 80k Da).

- Run the experiment first with tuned PID controllers on temperature and feed flow, logging all data.

- Run the identical transition using the MPC controller with MWD regulation.

- Repeat each run three times to assess reproducibility.

- Calculate KPIs from the collected data and summarize as per the table below.

Table 1: Benchmarking Results for PID vs. MPC on Grade Transition

| Performance Metric | PID Control (Avg. ± Std Dev) | MPC with MWD Regulation (Avg. ± Std Dev) | Improvement |

|---|---|---|---|

| IAE for Mn (kg/mol·s) | 1250 ± 210 | 580 ± 95 | 54% |

| Settling Time (min) | 85 ± 12 | 48 ± 7 | 44% |

| Overshoot on Temp (°C) | 4.5 ± 0.8 | 1.2 ± 0.3 | 73% |

| Final PDI Variance | 0.15 ± 0.04 | 0.06 ± 0.02 | 60% |

Table 2: Key Tuning Parameters for the MPC Controller

| Parameter | Symbol | Typical Value Range | Function |

|---|---|---|---|

| Prediction Horizon | Np | 20 - 40 steps | Determines how far ahead the controller predicts. |

| Control Horizon | Nc | 3 - 8 steps | Number of future control moves to optimize. |

| Sample Time | Ts | 30 - 60 s | Must be > solver execution time. |

| Output Weight Matrix | Q | diag([10, 5, 100]) | Prioritizes MWD error (high weight) over temp. |

| Input Rate Weight Matrix | R | diag([0.1, 0.1]) | Penalizes aggressive actuator movement. |

Diagrams

Title: MPC-MWD Control Loop with Delay Compensation

Title: Experimental Validation Workflow for MPC

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Polymerization MPC Experiments

| Item | Function/Description | Example (Styrene Polymerization) |

|---|---|---|

| High-Purity Monomer | The main building block of the polymer chain. Must be purified (inhibitor removed) for reproducible kinetics. | Styrene, purified by passing through an alumina column. |

| Initiator Solution | Provides free radicals to start chain growth. Concentration and flow are key MVs for MPC. | Azobis(isobutyronitrile) (AIBN) in toluene at known concentration. |

| Transfer Agent | Used to regulate molecular weight by terminating chains. A potential MV for MWD control. | Butanethiol (for RAFT-like effect) or CCl4. |

| In-line Viscometer | Provides real-time, correlated estimate of average molecular weight (Mn) for state feedback. | Vibrating needle or capillary viscometer. |

| Off-line GPC/SEC | Gold standard for MWD measurement. Provides delayed feedback for state estimator correction. | Agilent PL-GPC 220 with refractive index detector. |

| Real-Time Control Platform | Hardware/software to execute MPC algorithm within the required sample time. | National Instruments cRIO with LabVIEW or MATLAB/Simulink real-time. |

Technical Support Center

Troubleshooting Guide: Common Reactor & MWD Control Issues

Issue 1: Unexpectedly Broad Molecular Weight Distribution (MWD) in Product

- Question: The MWD (e.g., Đ, PDI) of the synthesized pharmaceutical polymer is consistently broader than the target set by the control algorithm. What are the primary causes?

- Answer: A broad MWD often indicates imperfect mixing or residence time distribution (RTD) issues in the continuous reactor. Key factors to investigate are:

- Inadequate Mixing: Verify agitator speed and baffle configuration. Use tracer studies to characterize RTD.

- Feed Fluctuations: Check precision of monomer, initiator, and solvent feed pumps. Pulsations or calibration drift can cause stoichiometric imbalances.

- Temperature Gradients: Non-uniform temperature along the reactor axis leads to variable kinetics. Validate heater/cooler jacket performance and sensor placement.

- Control Algorithm Tuning: The MWD control algorithm's integral and derivative gains may be poorly tuned for current process dynamics. Re-run system identification experiments.

Issue 2: Oscillations in Monomer Conversion and Reactor Temperature

- Question: The process variables (conversion, temperature) show sustained oscillations, making consistent MWD control impossible.

- Answer: This is a classic sign of feedback loop interaction or excessive controller gain.

- Decouple Loops: The temperature and conversion control loops may be interfering. Consider a cascade or model predictive control (MPC) strategy.

- Check Sensor Dynamics: Ensure temperature and spectroscopic (e.g., ATR-FTIR for conversion) sensors have appropriate response times and are not located in dead zones.

- Review Algorithm's Predictive Horizon: If using an MPC-based MWD controller, the prediction horizon may be too short for the process time constants.

Issue 3: Fouling and Gel Formation in Tubular Reactor Sections

- Question: We observe gradual pressure increase and eventual gel particles in the product, leading to reactor shutdowns.

- Answer: Fouling is often linked to localized high viscosity or thermal runaway.

- Segregation & Hot Spots: Confirm that the static mixer elements are not compromised. Use inline viscosity monitoring to detect early gelation points.

- Initiator Decomposition Rate: Re-evaluate the initiator's half-life at your operating temperature. A too-rapid decomposition can cause localized high radical concentrations.

- Cleaning-in-Place (CIP) Protocol: Ensure CIP cycle frequency and solvent strength (e.g., THF for acrylate-based polymers) are adequate for the polymer chemistry.

Issue 4: MWD Control Algorithm Fails to Compensate for Feedstock Variability

- Question: The algorithm maintains target MWD with standard reagents but fails when a new batch of monomer or initiator is introduced.

- Answer: The algorithm's internal model does not account for impurity-driven kinetics changes.

- Implement Feedforward Action: Integrate a quality attribute check (e.g., inhibitor concentration in monomer via titration) as a disturbance input to the control model.

- Adaptive Tuning: Incorporate a recursive least-squares (RLS) estimator to slowly update the kinetic parameters within the algorithm's model based on recent product data (e.g., from GPC).

Frequently Asked Questions (FAQs)

Q1: What is the most critical real-time measurement for effective MWD control in a continuous pharmaceutical polymerization reactor? A1: Inline or at-line Size Exclusion Chromatography (SEC) / Gel Permeation Chromatography (GPC) is considered the gold standard for direct MWD feedback. However, due to its analysis time (10-30 min), it is often combined with faster spectroscopic methods (e.g., ATR-FTIR, Raman) that correlate spectral data to molecular weight using chemometric models (PLS regression) for intermediary control.

Q2: How do we validate that the MWD control algorithm is functioning correctly within our thesis research framework? A2: Perform a designed step-test or pulse-test experiment. Introduce a known, small disturbance (e.g., ±2% change in initiator flow rate) and record the system's response. Compare the closed-loop response (algorithm active) with the open-loop response. Key validation metrics are summarized in Table 1.

Q3: Which continuous reactor type is most suitable for MWD control research in pharmaceutical applications? A3: For fundamental kinetics and control algorithm development, a continuous stirred-tank reactor (CSTR) or a CSTR cascade offers excellent temperature control and mixing. For scalability studies, a tubular reactor with static mixing elements is more representative of industrial continuous manufacturing. The choice depends on the thesis focus: precise kinetics (CSTR) or process scalability (tubular).

Q4: What safety protocols are paramount when conducting closed-loop control experiments with highly reactive pharmaceutical monomers? A4: 1) Always operate within the certified safe operating window (temperature, pressure) of the reactor. 2) Implement hardware interlocks (independent of the control algorithm) for emergency shutdown on high temperature/pressure. 3) Conduct all closed-loop tests initially with chemically inert simulants (e.g., glycerin for viscosity) to test the algorithm's logic before using active pharmaceutical ingredients (APIs) or reactive monomers.

Data Presentation

Table 1: Validation Metrics for MWD Control Algorithm Performance

| Metric | Formula / Description | Target Value (Example) | Open-Loop Response (to disturbance) | Closed-Loop Response (Algorithm On) |

|---|---|---|---|---|

| Settling Time (tₛ) | Time to reach & stay within ±5% of target MWD | < 3 x Mean Residence Time | 45 min | 18 min |

| Overshoot (Mₚ) | Maximum deviation from target Đ | < 10% | 35% | 8% |

| Integral Absolute Error (IAE) | ∫ |Đ(target) - Đ(actual)| dt | Minimized | 4.7 | 1.2 |

| Steady-State Offset | Persistent error at new steady state | 0 | Yes (Đ +0.15) | No |

Table 2: Common Inline Sensors for Continuous Polymerization Monitoring

| Sensor Type | Measured Parameter | Typical Frequency | Latency | Use in MWD Control |

|---|---|---|---|---|

| ATR-FTIR | Monomer conversion, copolymer composition | 1-2 min | Low (1-2 min) | Primary feedback for conversion control. |

| Inline Viscometer | Solution viscosity (correlates to Mw) | 10-30 sec | Very Low | Secondary, fast feedback for gross changes. |

| Inline GPC/SEC | Full MWD (Mn, Mw, Đ) | 10-30 min | High | Supervisory control & model updating. |

| Raman Spectrometer | Similar to FTIR, can track crystallinity | 1-5 min | Low | Alternative to FTIR, better for aqueous systems. |

Experimental Protocols

Protocol 1: Residence Time Distribution (RTD) Characterization for Reactor Modeling Purpose: To determine the flow non-ideality in the continuous reactor, a critical input for the MWD control algorithm's process model. Materials: Reactor system, inert tracer (e.g., acetone for UV-Vis, deuterated solvent for NMR), inline UV-Vis or conductivity probe, data acquisition system. Methodology:

- Operate the reactor at desired steady-state conditions (flow rates, temperature) with main solvent.

- Introduce a sharp pulse of tracer into the feed stream at time t=0.

- Continuously measure tracer concentration at the reactor outlet using the inline probe.

- Normalize the outlet concentration curve (E(t) curve) to obtain the RTD function.

- Fit the E(t) curve to tank-in-series or dispersion models to quantify back-mixing.

Protocol 2: Closed-Loop MWD Control Using Inline GPC and MPC Purpose: To demonstrate algorithm efficacy in maintaining target MWD despite a disturbance. Materials: Continuous reactor (CSTR or tubular), inline GPC system, control algorithm (MPC) hosted on a PLC/computer, calibrated feed pumps, temperature control system. Methodology:

- Establish steady-state operation at target Mn and Đ. Confirm with offline GPC.

- Activate the MPC algorithm. Setpoints: Target MWD (Mntarget, Đtarget). Manipulated Variables: Initiator flow rate, reactor temperature. Disturbance Variable: Monomer flow rate.

- Record a baseline period of closed-loop operation (≥5 residence times).

- Introduce a deliberate disturbance: Increase monomer feed flow rate by +5%.

- Allow the MPC algorithm to adjust initiator flow and temperature to reject the disturbance.

- Monitor and record the transient and final recovery of the MWD via inline GPC. Calculate IAE and settling time.

Mandatory Visualization

Closed-Loop MWD Control Experimental Workflow

MWD Control Algorithm (MPC) Logical Structure

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Relevance to MWD Control Research |

|---|---|

| High-Purity Pharmaceutical Monomer (e.g., N-vinylpyrrolidone, lactide) | The building block. Purity (>99.8%) is critical as inhibitors or impurities dramatically affect kinetics and final MWD. |

| Controlled-ROP Initiator or RAFT Agent (e.g., Sn(Oct)₂, functionalized trithiocarbonate) | Defines the living/controlled polymerization mechanism. Precise concentration dictates the theoretical Mn and Đ. |

| Anhydrous, Inhibitor-Free Solvent (e.g., toluene, DMSO) | Reaction medium. Water or alcohols can act as chain transfer agents, broadening MWD. |

| Inert Gas Supply (N₂ or Ar) | For rigorous sparging of reactants and reactor headspace to remove O₂, a radical scavenger that inhibits reaction and alters MWD. |

| Narrow MWD Polymer Standards (e.g., PMMA, polystyrene) | Essential for daily calibration of the GPC/SEC system to ensure accurate Mn, Mw, and Đ measurement for algorithm feedback. |

| Chemical Tracers for RTD (e.g., deuterated solvents, UV-active dyes) | Used to characterize reactor mixing performance, a key parameter in the control algorithm's process model. |

| Cleaning-in-Place (CIP) Solvent (e.g., THF, DMF) | For removing polymer residue from reactor and lines between experiments to prevent cross-contamination and fouling that skews MWD. |

Optimizing MWD Algorithms: Solving Common Challenges in Pharmaceutical Synthesis

Troubleshooting Guides & FAQs

Q1: How can I determine if sensor lag is degrading my MWD control loop performance? A: Sensor lag, often from inline spectroscopic probes (e.g., ATR-FTIR for monomer concentration), introduces a phase shift. This can cause oscillations or instability. To diagnose:

- Step Test: Introduce a small, deliberate step change in a manipulated variable (e.g., initiator flow rate). Record the setpoint, the controller output, and the raw sensor reading.

- Analysis: Plot the response. A pure time delay (dead time) and a first-order lag will be visible. Quantify the lag constant (τ) and dead time (θ) by fitting the response curve to a first-order-plus-dead-time (FOPDT) model.

- Impact Assessment: Compare the process time constant to the sensor τ. Control performance significantly degrades when sensor τ approaches or exceeds 10% of the dominant process time constant.

Table 1: Common Sensor Lag Sources in Polymerization

| Sensor Type | Typical Measured Variable | Primary Lag Source | Typical Lag Range |

|---|---|---|---|

| ATR-FTIR | Monomer Concentration | Diffusion to crystal, Scan averaging | 30s - 120s |

| Online Viscometer | Melt Viscosity | Fluid residence in capillary | 60s - 300s |

| SEC/GPC (Offline) | Full MWD | Sample preparation & analysis | 30min - 2hrs |

| NIR Probe | Conversion, Composition | Light path averaging, Model computation | 10s - 60s |

Q2: What are definitive experimental protocols to isolate model mismatch from external disturbances? A: Follow this sequential protocol:

Experiment 1: Open-Loop Characterization.

- Method: Stabilize the reactor at a key operating point. Introduce a precise pseudo-random binary sequence (PRBS) or stepped input in a key manipulated variable (e.g., jacket temperature). Record all process outputs (temperature, pressure, conversion) at high frequency.

- Goal: Develop a high-fidelity dynamic model (e.g., state-space) of the process under ideal, undisturbed conditions. This becomes your baseline model.

Experiment 2: Closed-Loop Model Validation.

- Method: Implement your MWD control algorithm using the baseline model. Operate at the same setpoint under carefully controlled conditions. Log the prediction error (e.g., model-predicted vs. actual conversion).

- Goal: A consistent, bounded error suggests acceptable model mismatch. A slowly drifting or trending error indicates unmodeled dynamics (model mismatch).

Experiment 3: Disturbance Injection Test.

- Method: Introduce a known, measurable disturbance (e.g., a step change in coolant supply temperature or a minor impurity spike in monomer feed). Observe the controller's response and prediction error.

- Goal: A sudden spike in error that the controller rejects identifies the system's disturbance response. Failure to reject indicates a need for improved disturbance modeling or integral action tuning.

Q3: What are the typical signatures of each problem in MWD data (e.g., D, PDI)? A: Analyze trends in molecular weight distributions and their derived metrics.

Table 2: Diagnostic Signatures in MWD Data

| Problem | Signature in Mn, Mw Trends | Signature in Full MWD Shape | Controller Manifestation |

|---|---|---|---|

| Sensor Lag | Oscillations in Mn/Mw with a fixed phase lag behind controller output. PDI may oscillate. | MWD shape appears noisy, but consistent when lag is accounted for. | Persistent, regular oscillations. Increasing gain causes instability. |

| Model Mismatch | Steady, consistent offset between predicted and measured Mn/Mw. Error grows with setpoint change. | MWD shape is consistently broader/narrower than predicted. | Poor setpoint tracking, sluggish or aggressive response to changes. |

| Unmeasured Disturbance | Sudden, unidirectional drift or shift in Mn/Mw (e.g., catalyst deactivation, impurity). | MWD shape shifts or distorts unexpectedly. | Controller "chases" the disturbance. Error is not zero-mean. |

Experimental Protocol: Step Test for Dynamic Identification