Polymer Science Revolution 2024: Cutting-Edge Careers, Research Frontiers, and Breakthrough Applications in Biomedicine

This article provides a comprehensive roadmap for researchers, scientists, and drug development professionals navigating the dynamic field of polymer science.

Polymer Science Revolution 2024: Cutting-Edge Careers, Research Frontiers, and Breakthrough Applications in Biomedicine

Abstract

This article provides a comprehensive roadmap for researchers, scientists, and drug development professionals navigating the dynamic field of polymer science. It explores the foundational principles and emerging frontiers (Intent 1), details advanced methodologies for creating smart biomaterials and delivery systems (Intent 2), addresses critical troubleshooting and optimization challenges in synthesis and scaling (Intent 3), and examines validation frameworks and comparative analyses of polymeric platforms (Intent 4). The synthesis offers actionable insights into career pathways and the transformative impact of polymers on next-generation therapeutics and biomedical devices.

The Evolving Landscape: Core Principles and Emerging Frontiers in Modern Polymer Science

Polymer science stands at a critical inflection point. Once defined by the mass production of commodity plastics like polyethylene and polypropylene, the field's frontiers are now dominated by the design and synthesis of precision biomaterials for advanced therapeutic and diagnostic applications. This evolution presents new career trajectories and research paradigms, shifting focus from bulk properties and cost efficiency to molecular-level control, bioactivity, and dynamic function within biological systems.

This technical guide delineates the technical scope of modern polymer science, mapping the material and methodological transition from commodity platforms to engineered biomaterials, framed within the career and research opportunities this shift enables.

Quantitative Evolution: A Data-Driven Comparison

The defining characteristics of commodity polymers versus precision biomaterials are summarized in the table below, highlighting the paradigm shift in design philosophy and application.

Table 1: Core Distinctions Between Commodity Plastics and Precision Biomaterials

| Parameter | Commodity Plastics (e.g., PE, PP, PS, PVC) | Precision Biomaterials (e.g., PEG-based, Smart Polymers, Poly(α-hydroxy esters)) |

|---|---|---|

| Primary Market Value | Low cost, high volume (Global market > $600 Bn) | High value, low volume (Biomaterials market ~ $130 Bn, fastest-growing segment) |

| Molar Mass Dispersity (Đ) | Broad (Đ > 2.0 common) | Narrow (Đ < 1.1 achievable via controlled polymerization) |

| Stereochemical Control | Typically atactic or low syndiotacticity | High isotactic or syndiotactic control possible for biomimicry |

| Functional Group Density | Low; often requires post-polymerization modification | High; precise placement of bioactive motifs (e.g., peptides, sugars) |

| Degradation Profile | Non-degradable or decades-long environmental degradation | Tunable degradation (hours to months) via hydrolytic/enzymatic cleavage |

| Key Performance Metrics | Tensile strength, melt flow index, opacity | Biocompatibility, drug release kinetics, cell adhesion, immune evasion |

The Scientist's Toolkit: Research Reagent Solutions

Transitioning research from traditional polymer chemistry to precision biomaterial synthesis requires a specialized toolkit of reagents and techniques.

Table 2: Essential Toolkit for Precision Biomaterial Synthesis

| Item | Function | Example (Vendor) |

|---|---|---|

| RAFT/Macro-CTA Agent | Controls radical polymerization for narrow Đ, enables block copolymer synthesis. | 2-(((Butylthio)carbonothioyl)thio)propanoic acid (Sigma-Aldrich) |

| Functional Monomer (e.g., NHS-ester acrylate) | Introduces reactive handles for post-polymerization conjugation of biomolecules. | N-Acryloxysuccinimide (TCI Chemicals) |

| End-Capping Reagent | Modifies polymer chain-ends for click chemistry (e.g., azide-alkyne cycloaddition). | Propargylamine (for end-group functionalization) |

| Telechelic Polymeric Crosslinker | Forms hydrogels with controlled mesh size and degradation. | 4-Arm PEG-Acrylate (MW 10kDa, JenKem Technology) |

| Enzymatically Cleavable Peptide Crosslinker | Creates hydrogels responsive to specific cellular proteases (e.g., MMP-2/9). | GCGPQG↓IWGQCK peptide (GL Biochem) |

| Fluorescently Labeled Monomer | Enables visualization of polymer localization in in vitro and in vivo studies. | Cy5-acrylamide (Lumiprobe) |

Experimental Protocol: Synthesis of an MMP-Responsive Drug-Eluting Hydrogel

This protocol exemplifies the precision required in modern biomaterial fabrication, integrating controlled polymerization, peptide conjugation, and drug encapsulation.

Title: Synthesis and Characterization of a Matrix Metalloproteinase (MMP)-Responsive Poly(ethylene glycol) Hydrogel for Controlled Drug Release.

Objective: To fabricate a hydrogel that crosslinks via MMP-sensitive peptides and releases a model drug (e.g., Doxorubicin) in response to specific enzymatic activity.

Materials: 4-Arm-PEG-Thiol (20 kDa), 4-Arm-PEG-Maleimide (20 kDa), MMP-cleavable peptide (sequence: KCGPQG↓IWGQCK, with N- and C-terminal cysteine), Doxorubicin hydrochloride, PBS buffer (pH 7.4), recombinant MMP-2 enzyme.

Procedure:

- Peptide Functionalization: Dissolve the MMP-cleavable peptide (5 mg) in 1 mL of degassed PBS. Add a 10% molar excess of Traut's reagent (2-Iminothiolane) to introduce additional thiol groups on lysine residues, reacting for 1 hour at 4°C under nitrogen. Purify via desalting column.

- Polymer Precursor Formation: Separately dissolve 4-Arm-PEG-Maleimide (100 mg) and the thiolated peptide from step 1 (molar ratio of maleimide:thiol = 1:1.1) in 2 mL of degassed PBS. Mix gently and allow to react for 30 minutes at room temperature under inert atmosphere to form peptide-bridged PEG macromers.

- Drug Loading & Gelation: Add Doxorubicin (2 mg) to the precursor solution. Initiate final crosslinking by adding 4-Arm-PEG-Thiol (100 mg in 1 mL PBS) to the precursor/drug mixture. Vortex gently for 30 seconds and transfer to a mold. Gelation occurs within 5-10 minutes via Michael addition between remaining maleimides and thiols.

- Enzymatic Degradation & Release Study: Immerse the formed hydrogel in PBS (pH 7.4) at 37°C with gentle shaking. To the experimental group, add recombinant MMP-2 (100 nM). Collect release medium at predetermined intervals and assay for Doxorubicin content via fluorescence (Ex/Em: 480/590 nm). Compare to a control group without MMP-2.

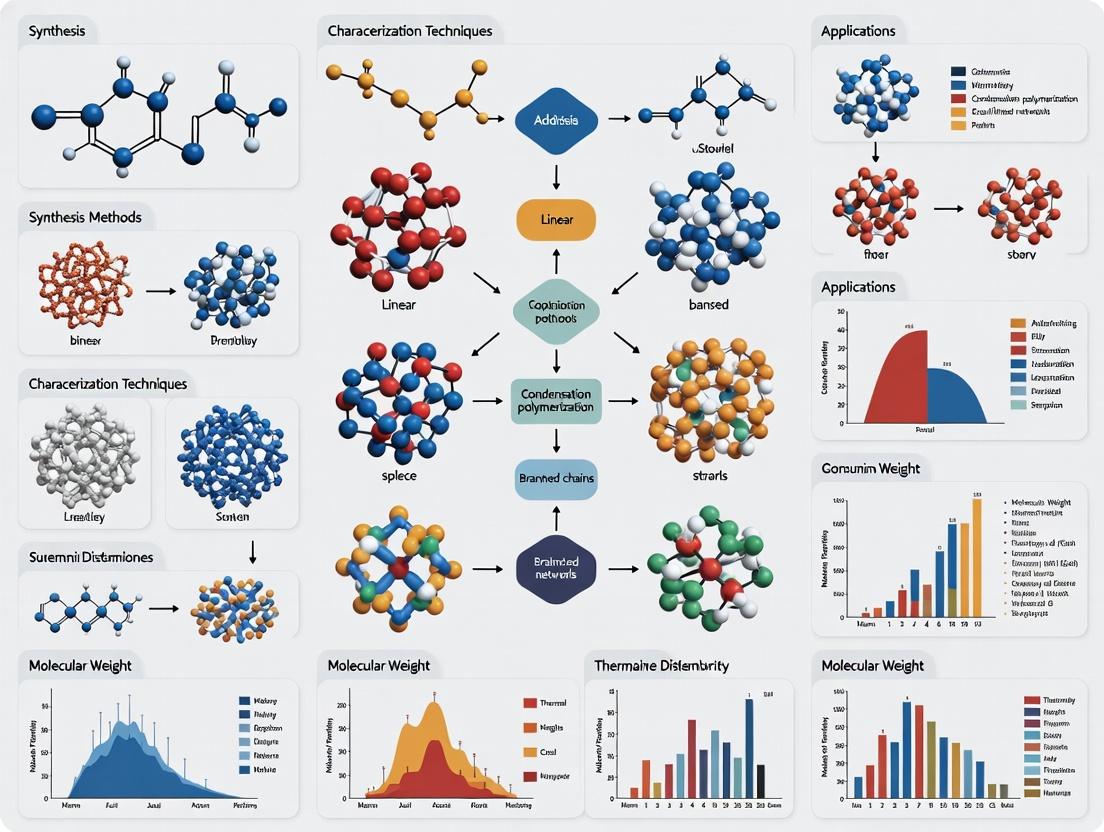

Visualizing Key Concepts and Pathways

The logic of material design and biological interaction is central to the field.

Diagram 1: From Monomer to Biomaterial: A Design Logic Workflow

Diagram 2: MMP-Responsive Hydrogel Drug Release Mechanism

The scope of polymer science has expanded irreversibly from commodity production to precision bioengineering. This whitepaper outlines the technical foundations of this shift—narrow dispersity, sequence control, and bio-responsive design. For researchers and drug development professionals, this translates to a career landscape rich in interdisciplinary challenges, demanding fluency in polymer chemistry, molecular biology, and translational medicine. The future lies in designing materials that not only interface with biology but actively participate in its logic, creating new frontiers in personalized therapeutics and regenerative medicine.

This whitepaper explores four pivotal synthetic polymer classes enabling advanced biomedical applications, framed within the research frontiers and career opportunities in modern polymer science. These materials address critical challenges in drug delivery, tissue engineering, and diagnostics.

Hydrogels

Definition & Significance: Three-dimensional, hydrophilic polymer networks that swell in water, mimicking native tissue extracellular matrix. They are central to soft tissue engineering, wound healing, and controlled release. Key Mechanism: Crosslinking (chemical or physical) governs mesh size, swelling ratio, and mechanical properties, dictating diffusion kinetics for therapeutics and cell infiltration. Recent Advancements: Focus is on "smart" hydrogels responsive to pH, temperature, or enzymes, and on enhancing mechanical toughness for load-bearing applications.

Quantitative Data Summary: Table 1: Key Properties of Representative Hydrogel Systems

| Polymer Base | Crosslink Method | Typical Swelling Ratio (%) | Elastic Modulus (kPa) | Primary Biomedical Application |

|---|---|---|---|---|

| Poly(ethylene glycol) (PEG) | Photopolymerization | 150-300 | 10-100 | Cartilage repair, drug elution |

| Alginate | Ionic (Ca²⁺) | 200-500 | 5-50 | Cell encapsulation, wound dressings |

| Poly(N-isopropylacrylamide) (pNIPAM) | Thermal phase separation | 100-200 | 2-20 | Injectable depots, actuators |

| Hyaluronic Acid | Enzymatic | 300-1000 | 1-15 | Dermal fillers, visco-supplementation |

Experimental Protocol: Fabrication and Swelling Characterization of a PEG-DA Hydrogel

- Preparation: Dissolve Poly(ethylene glycol) diacrylate (PEG-DA, Mn 700 Da) at 20% (w/v) in phosphate-buffered saline (PBS).

- Photoinitiation: Add 0.5% (w/v) Irgacure 2959 photoinitiator. Vortex until clear.

- Crosslinking: Pipette 100 µL solution into a cylindrical mold (8mm diameter). Expose to UV light (365 nm, 10 mW/cm²) for 5 minutes.

- Swelling Test: Weigh initial gel mass (Wi). Immerse in PBS at 37°C. At set time points, remove gel, blot surface, and weigh (Ws). Calculate swelling ratio: SR = (Ws - Wi)/W_i * 100%.

- Mechanical Testing: Perform unconfined compression test on swollen gel using a rheometer to determine elastic modulus.

Dendrimers

Definition & Significance: Perfectly branched, monodisperse, nano-sized polymers with a core, interior layers (generations), and a high density of surface functional groups. They are precision nanocarriers. Key Mechanism: The multivalency allows for high payload conjugation, while the controlled architecture enables tailored drug release kinetics and targeting via surface modification. Recent Advancements: Development of biodegradable dendrimers and "dendrimersomes" for combination therapy and gene delivery.

Quantitative Data Summary: Table 2: Characteristics of Common Dendrimer Platforms

| Dendrimer Core | Generation (G) | Approx. Diameter (nm) | Surface Groups | Drug Loading Capacity (wt%) Example |

|---|---|---|---|---|

| Poly(amidoamine) (PAMAM) | G4 | 4.5 | 64 -NH₂ | Doxorubicin: ~10-15% |

| Poly(propylene imine) (PPI) | G5 | 4.2 | 64 -NH₂ | Cisplatin: ~8-12% |

| Phosphorus-hydrazone | G3 | 3.0 | 16 -COOH | Methotrexate: ~25% |

Experimental Protocol: Synthesis and Drug Conjugation of PAMAM Dendrimer (G4)

- Purification: Dialyze commercial PAMAM G4-NH₂ dendrimer solution (1 mM in methanol) against methanol for 24h, then deionized water for 48h. Lyophilize.

- Drug Conjugation: Dissolve 10 mg dendrimer in 5 mL DMSO. Add a 20:1 molar excess of NHS-activated drug (e.g., Doxorubicin-NHS ester) and 10 µL triethylamine. Stir under N₂, in the dark, for 24h at room temperature.

- Purification: Use size-exclusion chromatography (Sephadex LH-20 column) with DMSO as eluent to separate conjugated dendrimer from free drug.

- Characterization: Analyze by ¹H NMR to calculate conjugation efficiency. Use dynamic light scattering (DLS) for hydrodynamic diameter.

Block Copolymers

Definition & Significance: Polymers composed of two or more distinct homopolymer subunits linked covalently. They self-assemble into nanostructures (micelles, vesicles) in selective solvents. Key Mechanism: Microphase separation of chemically distinct blocks drives self-assembly. Critical micelle concentration (CMC) determines in vivo stability. Recent Advancements: Focus on multi-responsive blocks, stereocomplexation, and polymeric prodrugs where the drug is part of the polymer backbone.

Quantitative Data Summary: Table 3: Self-Assembled Structures from Block Copolymers

| Polymer Composition (Block A-B) | Morphology | Typical Size (nm) | CMC (mg/L) | Key Application |

|---|---|---|---|---|

| PEG-PLGA | Spherical Micelle | 20-100 | 1-10 | Solubilize hydrophobic drugs |

| PEG-PCL | Worm-like Micelle | 20-50 (diameter) | 5-20 | Prolonged circulation |

| PLA-PEO-PLA | Polymersome | 100-400 | <1 | Protein/RNA delivery |

Experimental Protocol: Preparation of PEG-PLGA Diblock Copolymer Micelles

- Polymer Synthesis: Synthesize PEG-PLGA via ring-opening polymerization of D,L-lactide and glycolide onto a monomethoxy-PEG-OH macroinitiator using stannous octoate catalyst (130°C, 24h, under vacuum).

- Micelle Formation (Nanoprecipitation): Dissolve 10 mg PEG-PLGA in 1 mL acetone (organic phase). Using a syringe pump, add this dropwise (1 mL/min) into 10 mL stirred deionized water.

- Solvent Removal: Stir the milky solution openly for 6h to evaporate acetone.

- Characterization: Determine CMC using pyrene fluorescence assay. Measure size and polydispersity index (PDI) via DLS. Visualize morphology by transmission electron microscopy (TEM) with negative staining (uranyl acetate).

Bioconjugates

Definition & Significance: Covalent hybrids of synthetic polymers and biomolecules (proteins, peptides, oligonucleotides). They enhance the stability, pharmacokinetics, and efficacy of biologics. Key Mechanism: Polymer attachment (e.g., PEGylation) masks the biologic from immune recognition, reduces renal clearance, and can provide passive or active targeting. Recent Advancements: Site-specific conjugation techniques (e.g., click chemistry at engineered cysteine residues), releasable PEGylation, and polymer-antibody drug conjugates (pADCs).

Quantitative Data Summary: Table 4: Examples of Clinically Approved Polymer Bioconjugates

| Biologic | Polymer | Conjugation Site/Strategy | Key Improvement (vs. native) |

|---|---|---|---|

| Interferon α-2b | PEG (40 kDa) | Lysine (random) | Half-life: 4h → 40h |

| Uricase (Pegloticase) | PEG (10 kDa) | Lysine (random) | Reduces immunogenicity |

| siRNA (Patisiran) | Lipid nanoparticle (ionizable cationic lipid) | Complexation | Enables intracellular delivery to hepatocytes |

Experimental Protocol: Site-Specific PEGylation of a Therapeutic Protein via Cysteine Chemistry

- Protein Engineering: Ensure the protein has a single, solvent-accessible cysteine residue. Reduce any disulfides with 5 mM TCEP for 30 min at 4°C. Purify via desalting column.

- Activation of Polymer: Dissolve maleimide-functionalized mPEG (40 kDa) in conjugation buffer (PBS, pH 6.5-7.2, with 1 mM EDTA). Use a 3:1 molar excess of polymer to protein.

- Conjugation Reaction: Add activated PEG solution dropwise to the reduced protein solution. Gently mix and incubate at 4°C for 2-4 hours.

- Quenching & Purification: Add a 10x molar excess of free cysteine to quench unreacted maleimide. Purify the conjugate using size-exclusion chromatography (Superdex 200 column) with PBS as eluent.

- Analysis: Use SDS-PAGE (with and without reducing agent) and MALDI-TOF mass spectrometry to confirm conjugation and assess mono-PEGylation efficiency.

Mandatory Visualizations

Diagram 1: Hydrogel Fabrication and Swelling Workflow

Diagram 2: Active Targeting by Surface-Functionalized Nanoparticles

The Scientist's Toolkit: Research Reagent Solutions

Table 5: Essential Materials for Polymer-Based Biomedical Research

| Reagent/Material | Function & Key Characteristics | Example Supplier/Product |

|---|---|---|

| Poly(ethylene glycol) diacrylate (PEG-DA) | Photocrosslinkable hydrogel precursor. MW and functionality determine mesh size. | Sigma-Aldrich, "PEGDA 700" |

| Irgacure 2959 | UV photoinitiator for free radical polymerization. Biocompatible, water-soluble. | BASF |

| PAMAM Dendrimer, G4-NH₂ | Polycationic, amine-terminated dendrimer for drug conjugation or complexation. | Dendritic Nanotechnologies Inc. |

| NHS-Ester Activated Drug | Enables facile conjugation to amine groups on dendrimers or proteins. | BroadPharm (for model drugs) |

| PLGA-PEG Diblock Copolymer | Amphiphilic polymer for self-assembling micelles. LA:GA ratio controls degradation. | PolySciTech (AK097) |

| Maleimide-PEG-NHS Ester | Heterobifunctional linker for site-specific protein/peptide conjugation. | Thermo Fisher, "SM(PEG)24" |

| Dialysis Membranes (MWCO) | Purifies polymers/conjugates by removing small molecules (salts, unreacted drug). | Spectra/Por (3.5kD, 10kD MWCO) |

| Size-Exclusion Chromatography Columns | Separates conjugated from unconjugated species based on hydrodynamic volume. | Cytiva, "Superdex 200 Increase" |

Within the expanding research frontier of polymer science, stimuli-responsive 'smart' polymers represent a critical paradigm shift towards precision medicine. This field is not only a premier area for scientific discovery but also a fertile ground for career development, offering interdisciplinary roles spanning synthetic chemistry, materials engineering, nanomedicine, and pharmacology. The core principle involves macromolecular systems engineered to undergo sharp, reversible physical or chemical changes in response to specific biological or external triggers, enabling spatiotemporal control over therapeutic delivery.

Core Mechanisms and Quantitative Data

Smart polymers respond to endogenous (pH, redox, enzymes) or exogenous (temperature, light, magnetic fields, ultrasound) stimuli. Key mechanisms include conformational change, solubility switch, or cleavage of pendant groups.

Table 1: Quantitative Comparison of Primary Stimuli-Responsive Polymer Systems

| Stimulus Type | Common Polymer Backbone | Typical Trigger Range | Response Time | Key Therapeutic Application |

|---|---|---|---|---|

| pH | Polyacrylic acid (PAA), Polyhistidine, Chitosan | Endosomal pH (5.0-6.5), Tumor pH (~6.8) | Seconds to Minutes | Tumor-targeted drug release, Oral insulin delivery |

| Redox (GSH) | Disulfide-crosslinked PEG, PEI, Dextran | Intracellular [GSH] >10 mM vs. Extracellular ~2 µM | Minutes to Hours | Cytoplasmic nucleic acid delivery, Intracellular protein release |

| Enzyme | Peptide-conjugated PEG, Dextran-prodrugs | MMP-9, Cathepsin B, Esterase | Hours | Tumor microenvironment targeting, Arthritis therapy |

| Temperature | Poly(N-isopropylacrylamide) (pNIPAM), PLGA-PEG-PLGA | Lower Critical Solution Temp (LCST: 32-40°C) | Seconds | Hyperthermia-triggered release, Tissue engineering scaffolds |

| Light (UV-NIR) | o-Nitrobenzyl, Coumarin, ICG-conjugated polymers | UV (365 nm) to NIR (700-900 nm) | Milliseconds to Seconds | Photodynamic therapy, Spatial control in regenerative medicine |

| Ultrasound | Perfluorocarbon-loaded PLGA, Micelles | High-Intensity Focused US (HIFU) | Seconds | Blood-brain barrier opening, Deep-tissue drug release |

| Magnetic Field | SPION-embedded PCL, PEG | Alternating Magnetic Field (100-500 kHz) | Minutes | Magnetic hyperthermia, Remote-controlled release |

Detailed Experimental Protocols

Protocol: Synthesis and Characterization of pH-Responsive Poly(β-amino ester) (PBAE) Nanoparticles for siRNA Delivery

Objective: To synthesize a PBAE via Michael addition, formulate siRNA-polyplex nanoparticles, and assess pH-dependent release. Materials: 1,4-butanediol diacrylate, 5-amino-1-pentanol, anhydrous tetrahydrofuran (THF), siRNA (e.g., anti-GFP), acetate buffer (pH 5.0), phosphate buffer (pH 7.4), dialysis membrane (MWCO 3.5 kDa).

Methodology:

- Polymer Synthesis: Under nitrogen, dissolve 1,4-butanediol diacrylate (1.0 equiv) and 5-amino-1-pentanol (1.2 equiv) in anhydrous THF. React at 90°C for 48h. Precipitate in cold diethyl ether, filter, and dry under vacuum. Confirm structure via ¹H-NMR and determine molecular weight by GPC.

- Nanoparticle Formation: Dissolve PBAE in DMSO. Add polymer solution dropwise to siRNA in 25 mM sodium acetate buffer (pH 5.0) under vortexing to achieve an N/P ratio of 30. Incubate for 30 min at RT.

- Size and Zeta Potential: Dilute polyplexes in buffers at pH 7.4 and pH 5.0. Measure hydrodynamic diameter and polydispersity index (PDI) via Dynamic Light Scattering (DLS). Measure zeta potential.

- pH-Triggered Release Study: Load polyplexes with fluorescently labeled siRNA. Place in dialysis cassettes submerged in release media (PBS at pH 7.4 or acetate buffer at pH 5.0) at 37°C. At predetermined intervals, sample the external medium and measure fluorescence (Ex/Em 490/520 nm). Calculate cumulative release.

- In Vitro Efficacy: Transfert GFP-expressing HeLa cells with polyplexes for 48h. Quantify GFP knockdown via flow cytometry and cell viability via MTT assay.

Protocol: Fabrication of NIR Light-Responsive Nanocarriers with o-Nitrobenzyl Linkers

Objective: To synthesize a copolymer with photolabile side-chains and evaluate NIR-induced drug release via upconversion nanoparticles (UCNPs). Materials: Poly(allylamine) (PAAm), 4-((hydroxymethyl)-2-nitrobenzyloxy)butyric acid (HMNBB), EDC/NHS coupling reagents, NaYF₄:Yb,Tm UCNPs, Doxorubicin (Dox), Dimethylformamide (DMF).

Methodology:

- Polymer Conjugation: Activate HMNBB (2.0 equiv) with EDC (2.2 equiv) and NHS (2.2 equiv) in DMF for 1h. Add to a solution of PAAm (1.0 equiv of amine groups) in DMF. React for 24h at RT in the dark. Dialyze and lyophilize.

- Nanocomposite Assembly: Mix UCNPs (absorb 980 nm, emit 365 nm) with the HMNBB-conjugated polymer and Dox in aqueous solution. Allow self-assembly via hydrophobic interactions. Purify by centrifugation.

- Photocleavage Validation: Irradiate nanocomposite solution with a 980 nm NIR laser (1.0 W/cm², 5 min intervals). Analyze supernatant by HPLC after centrifugation to quantify free Dox release. Compare to dark control.

- Cellular Uptake and Photoactivation: Incubate nanocomposites with MCF-7 cells for 4h. Irradiate with NIR laser (980 nm, 0.8 W/cm², 3 min). Stain with Hoechst and LysoTracker. Image via confocal microscopy to observe subcellular release.

Visualizations

Diagram Title: Smart Polymer Trigger Mechanisms and Outcomes

Diagram Title: pH-Triggered Endosomal Escape for siRNA Delivery

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Smart Polymer Research

| Item | Function & Relevance | Example Supplier/Cat. No. (Illustrative) |

|---|---|---|

| RAFT Chain Transfer Agents | Enables controlled synthesis of stimuli-responsive block copolymers with low PDI. | Sigma-Aldrich, 723085 (CPDB) |

| Poly(ethylene glycol) methyl ether acrylate (O950) | Provides hydrophilic corona for stealth nanoparticles; used in thermo-responsive copolymers. | Sigma-Aldrich, 447943 |

| Disulfide-based Crosslinkers (e.g., DSP) | Introduces redox-sensitive linkages into hydrogel networks or nanogels. | Thermo Fisher, 22585 |

| 4-(Hydroxymethyl)-3-nitrobenzoic acid | Precursor for synthesizing photolabile o-nitrobenzyl ester linkages. | TCI America, H0978 |

| N-Isopropylacrylamide (NIPAM) | Monomer for synthesizing gold-standard thermo-responsive pNIPAM. | Sigma-Aldrich, 415324 |

| NaYF₄:Yb,Er/Tm Upconversion Nanoparticles | Converts deep-penetrating NIR light to UV/visible for remote photoactivation. | Nanocs, UCNP-100) |

| Matrix Metalloproteinase-9 (MMP-9) | Enzyme used to validate enzyme-responsive cleavage of peptide-linked polymer conjugates. | R&D Systems, 911-MP) |

| Glutathione (Reduced, GSH) | Key reducing agent to simulate intracellular redox conditions for disulfide cleavage studies. | MilliporeSigma, G6529 |

| Fluorescent Dye-Conjugated Polymers (Cy5-PEI) | Tracers for visualizing polymer cellular uptake and trafficking via flow cytometry or microscopy. | Nanocs, PEI-1000-Cy5) |

| Dialysis Membranes (Spectra/Por) | Critical for purification of synthesized polymers and in vitro release studies. | Repligen, 132676 |

Future Research Frontiers and Career Pathways

The trajectory of this field points toward multi-stimuli responsive systems, closed-loop feedback using biosensors (e.g., glucose-responsive insulin delivery), and advanced manufacturing (3D bioprinting). For polymer scientists, career opportunities extend beyond academia into biotech R&D, medical device innovation, and regulatory science. Mastering the integration of polymer design, biological validation, and device engineering will be key for researchers aiming to lead in this translational frontier.

The clinical success of mRNA-LNP vaccines during the COVID-19 pandemic has solidified lipid nanoparticles (LNPs) as a benchmark for nucleic acid delivery. However, the limitations of LNPs—including systemic reactogenicity, poor tissue-specific targeting, instability under certain storage conditions, and complex manufacturing scale-up—have catalyzed a paradigm shift. Polymer-based delivery systems are emerging as a powerful "Beyond-LNP" frontier, offering unparalleled chemical versatility, tunable degradation profiles, and functional diversity for next-generation mRNA and CRISPR-Cas therapeutics. This whitepaper explores this frontier, framing it within the broader career and research trajectories in modern polymer science.

Polymer Architectures and Synthesis: Building Blocks for Delivery

Polymers provide a synthetic playground for optimizing nucleic acid complexation, protection, release, and biodistribution. Key architectures include:

- Linear Cationic Polymers: Polyethylenimine (PEI), the historical gold standard, offers high transfection efficiency but significant cytotoxicity. Modern research focuses on controlled molecular weight variants and derivatives like PBAEs.

- Polymer Libraries (e.g., Poly(β-amino esters) - PBAEs): These are synthesized via Michael addition, allowing high-throughput generation of diverse, biodegradable, and pH-sensitive polymers. Their properties are easily tuned by varying diacrylate and amine monomers.

- Dendrimers: Hyperbranched, monodisperse structures (e.g., PAMAM) offer multivalent binding and well-defined nano-architectures but face complex synthesis.

- Block Copolymers: PEG-b-polycation structures (e.g., PEG-PLGA, PEG-PLL) form polyplex micelles or polymersomes, enhancing stability and stealth properties.

Table 1: Comparative Analysis of Key Polymer Classes for Nucleic Acid Delivery

| Polymer Class | Example(s) | Key Advantages | Primary Limitations | Best Suited For |

|---|---|---|---|---|

| Polyethylenimine (PEI) | Linear (25 kDa), Branched | High proton-sponge effect, strong complexation | High cytotoxicity, non-biodegradable | In vitro transfections, proof-of-concept |

| Poly(β-amino ester)s | Custom PBAE libraries | Biodegradable, low cytotoxicity, pH-responsive | Can have lower stability than LNPs | Rapid prototyping, organ-specific delivery |

| Dendrimers | PAMAM, PPI | Monodisperse, multivalent surface | Complex/expensive synthesis, toxicity at high gens | Targeted delivery, mechanistic studies |

| Block Copolymers | PEG-PLGA, PEG-PLL | Stealth (PEGylation), controlled release | Potential for anti-PEG antibodies, slower release | Systemic delivery, sustained release formulations |

Core Mechanisms: From Complexation to Intracellular Release

Polymers function via a multi-step mechanism distinct from ionizable lipids in LNPs.

- Electrostatic Complexation: Cationic polymer amines protonate at physiological pH, enabling electrostatic interaction with anionic nucleic acid phosphate backbones to form polyplexes.

- Cellular Uptake: Polyplexes are typically internalized via endocytosis.

- Endosomal Escape: The critical step. pH-sensitive polymers (e.g., PBAEs) buffer the endosome via the "proton sponge" effect, leading to osmotic swelling, rupture, and payload release into the cytosol.

- Payload Release: Biodegradable polymer backbones hydrolyze or enzymatically degrade in the cytosol, releasing the nucleic acid (mRNA for translation, CRISPR RNP for nuclear entry).

Diagram 1: Polyplex Mechanism of Action

Title: Polyplex Delivery Pathway from Formation to Function

Experimental Protocols: Key Methodologies for Polymer-Based Delivery Research

Protocol 1: High-Throughput Synthesis & Screening of a PBAE Library

- Objective: Synthesize and screen a diverse polymer library for mRNA delivery efficiency.

- Materials: Acrylate-terminated polymer (e.g., PEG-diacrylate), various amine-terminated small molecules (e.g., 1,4-butanediol diacrylate, 5-amino-1-pentanol), anhydrous solvent (DMSO or THF).

- Procedure:

- In a 96-well plate, dispense acrylate and amine monomers in varying molar ratios in triplicate.

- Add anhydrous solvent to each well. Seal and react at 90°C for 48 hours with agitation.

- Cool plates. For polyplex formation, dilute polymer stocks in acetate buffer (pH 5.0).

- Add mRNA (e.g., eGFP) solution to polymer solutions at desired N:P ratios, vortex, incubate 15 min.

- Transfer polyplexes to cells in a 384-well plate. Assay for transfection (fluorescence) and cytotoxicity (e.g., CellTiter-Glo) after 24-48h.

Protocol 2: Characterization of Polyplex Formulations

- Objective: Physically characterize polyplexes for size, charge, and stability.

- Dynamic Light Scattering (DLS): Dilute polyplexes in filtered PBS or HEPES buffer. Measure hydrodynamic diameter (nm) and polydispersity index (PDI). Target: <200 nm, PDI <0.2.

- Zeta Potential Measurement: Using the same instrument, measure surface charge (mV) in low-conductivity buffer. Target: Slightly positive (+5 to +20 mV) for cellular interaction.

- Gel Retardation Assay: Load polyplexes at varying N:P ratios onto an agarose gel. Run electrophoresis; stained nucleic acid retained in the well indicates complete complexation.

- Serum Stability Assay: Incubate polyplexes with 10-50% FBS at 37°C. Measure size by DLS over 1-24 hours. Stable formulations show minimal size increase.

Table 2: Key Quantitative Parameters for Polyplex Optimization

| Parameter | Measurement Technique | Target Range for In Vivo Delivery | Significance |

|---|---|---|---|

| Hydrodynamic Diameter | Dynamic Light Scattering (DLS) | 50 - 150 nm | Affects biodistribution, cellular uptake, and EPR effect. |

| Polydispersity Index (PDI) | DLS | < 0.25 | Indicates monodisperse, uniform nanoparticle population. |

| Zeta Potential | Electrophoretic Light Scattering | +5 to +15 mV (pre-injection) | Moderately positive for cell binding; near-neutral in vivo reduces clearance. |

| N:P Ratio | Calculation (amine:phosphate) | 5:1 to 30:1 (polymer-specific) | Balances complexation efficiency with cytotoxicity. |

| Encapsulation Efficiency | Ribogreen Assay | > 90% | Maximizes delivered payload, reduces waste/toxicity. |

| pKa | Acid-base titration | ~6.5 - 7.0 | Crucial for pH-responsive endosomal escape. |

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Core Reagents for Polymer-Based Nucleic Acid Delivery Research

| Item | Function | Example Vendor/Product |

|---|---|---|

| Cationic Polymer Building Blocks | Backbone for polyplex formation; defines biodegradability, charge density, and pH-response. | Polyethylenimine (Polysciences), bespoke PBAE monomers (Sigma-Aldrich, Alfa Aesar). |

| PEGylation Reagents | Imparts "stealth" properties, reduces opsonization, increases circulation half-life. | mPEG-NHS, PEG-diacrylate (BroadPharm, JenKem). |

| Targeting Ligands | Enables tissue/cell-specific delivery via conjugation to polymer. | Folate, GalNAc, peptide ligands (RGD, iRGD), antibody fragments. |

| Fluorescent Tags/Dyes | For tracking polymer or nucleic acid in vitro and in vivo. | Cy5/Cy7 dyes, FITC, Rhodamine (Lumiprobe), fluorescently labeled mRNA (TriLink). |

| In Vitro/In Vivo Reporter Systems | Quantify delivery efficiency (transfection/editing). | Luciferase mRNA, eGFP mRNA, CRISPR-Cas9 RNP with reporter cell lines. |

| Characterization Buffers | For consistent polyplex formation and measurement. | Nuclease-free water, sodium acetate buffer (pH 5.0), 1x PBS, HEPES buffered saline. |

Beyond Simple Polyplexes: Advanced Polymer Formulations

The frontier involves sophisticated engineering:

- Targeted Delivery: Conjugating polymers with ligands (e.g., GalNAc for hepatocytes) for cell-specific uptake.

- Stimuli-Responsive Systems: Polymers responsive to redox potential (GSH in cytosol), enzymes (matrix metalloproteinases in tumors), or light for spatiotemporal control.

- Polymer-LNP Hybrids: Merging polymer advantages with LNP structural benefits, such as using polymers as functional components within LNPs.

Diagram 2: Advanced Polymer Design Strategies

Title: Modular Design of Advanced Polymeric Nanoparticles

Career and Research Frontiers in Polymer Science

This domain offers rich opportunities for polymer scientists:

- Synthetic Chemistry: Designing novel monomers and controlled polymerization techniques (RAFT, ATRP) for precise architectures.

- Computational Materials Science: Using AI/ML to predict polymer-nucleic acid interactions and in vivo performance from chemical structure.

- Formulation Science: Developing robust, scalable, and GMP-compliant manufacturing processes for polymeric nanoparticles.

- Translational Research: Navigating the regulatory path for novel polymer excipients, focusing on safety, biodegradability, and immunogenicity profiles.

The move beyond LNPs is not an abandonment but an evolution. Polymer science provides the foundational toolkit to build the next generation of precise, effective, and broadly applicable nucleic acid medicines, representing one of the most dynamic frontiers at the intersection of chemistry, biology, and medicine.

Within the evolving landscape of polymer science research, the development of sustainable and bio-derived polymers represents a critical frontier, merging environmental imperatives with advanced technological applications. This field is not only defining new research trajectories but also creating high-impact career opportunities in green chemistry R&D, biomedical engineering, and pharmaceutical sciences. This whitepaper provides a technical guide to core material classes, synthesis pathways, and experimental methodologies driving innovation in this domain.

Key Polymer Classes and Quantitative Performance Data

The following tables summarize leading bio-derived polymers, their sources, key properties, and applications, based on current research benchmarks.

Table 1: Primary Bio-Derived Polymer Feedstocks and Characteristics

| Polymer Class | Primary Feedstock (Monomers) | Key Polymerization Method | Glass Transition (Tg) / Melting (Tm) Range | Notable Properties |

|---|---|---|---|---|

| Poly(lactic acid) (PLA) | Lactic acid (from corn starch, sugarcane) | Ring-opening polymerization (ROP) of lactide | Tg: 55-60°C, Tm: 170-180°C | High strength, brittle, compostable |

| Poly(hydroxyalkanoates) (PHA) | Hydroxyalkanoates (from microbial fermentation) | Microbial synthesis in vivo | Tg: -30 to 10°C, Tm: 60-177°C (varies by type) | Biocompatible, biodegradable, tunable properties |

| Poly(ethylene furanoate) (PEF) | 2,5-Furandicarboxylic acid (FDCA) from sugars | Polycondensation with ethylene glycol | Tg: 86°C, Tm: 235°C | Superior barrier (O₂, CO₂) vs. PET, bio-based |

| Bacterial Cellulose | Glucose (from microbial culturing) | Microbial synthesis (Acetobacter) | N/A (nanofibrillar network) | High purity, crystallinity, water retention, mechanical strength |

Table 2: Comparative Mechanical & Barrier Properties for Packaging

| Polymer | Tensile Strength (MPa) | Oxygen Barrier (cm³·mm/m²·day·atm) | Source Year / Reference Trend |

|---|---|---|---|

| PLA (neat) | 50-70 | 150-200 | Industry Standard |

| PEF | 60-85 | 0.7-1.1 | 2023 Review Data |

| PET (Fossil-based) | 55-75 | 2.5-3.5 | Reference Benchmark |

| PHB (a type of PHA) | 25-40 | 30-50 | 2022 Research Data |

Experimental Protocols for Key Syntheses and Evaluations

Protocol 3.1: Enzymatic Ring-Opening Polymerization (e-ROP) of Lactide for PLA Synthesis Objective: To synthesize PLA using a lipase enzyme catalyst under mild, solvent-free conditions.

- Materials: L-lactide monomer (purified by recrystallization), immobilized lipase B from Candida antarctica (Novozym 435), vacuum line or inert gas (N₂/Ar) manifold.

- Procedure: Dry all glassware overnight at 120°C. In a flame-dried Schlenk flask, combine L-lactide (10 g) and Novozym 435 (1 wt% relative to monomer). Evacuate the flask and backfill with nitrogen three times.

- Polymerization: Immerse the sealed flask in an oil bath preheated to 90°C with magnetic stirring at 200 rpm. Monitor reaction progress by sampling for (^1)H-NMR to determine lactide conversion via the methine proton signal (δ ~5.0 ppm vs. δ ~1.5 ppm for polymer).

- Termination & Purification: After 24-48 hrs (target conversion >90%), dissolve the crude product in chloroform, filter to remove enzyme catalyst, and precipitate the polymer into a 10-fold volume excess of cold methanol. Dry the white precipitate under vacuum at 50°C to constant weight.

Protocol 3.2: Fabrication and Characterization of PHA-Based Nanoparticles for Drug Delivery Objective: To prepare drug-loaded nanoparticles from PHBV (poly(3-hydroxybutyrate-co-3-hydroxyvalerate)) using nanoprecipitation.

- Materials: PHBV copolymer (8% hydroxyvalerate), docetaxel (model drug), poly(vinyl alcohol) (PVA, Mw 31-50 kDa), dichloromethane (DCM), phosphate-buffered saline (PBS, pH 7.4).

- Formulation: Dissolve 50 mg PHBV and 5 mg docetaxel in 5 mL DCM (organic phase). Dissolve 200 mg PVA in 100 mL deionized water (aqueous phase).

- Nanoprecipitation: Using a syringe pump, add the organic phase dropwise (1 mL/min) into the aqueous phase under sonication (70% amplitude, probe sonicator). Continue sonication for 3 minutes post-addition.

- Evaporation & Harvesting: Stir the emulsion overnight at room temperature to evaporate DCM. Centrifuge the suspension at 18,000 rpm for 30 min at 4°C. Wash the pellet twice with DI water and resuspend in 10 mL PBS for characterization.

- Characterization: Determine particle size and PDI via dynamic light scattering (DLS). Analyze drug loading (DL%) and encapsulation efficiency (EE%) using HPLC: ( DL\% = \frac{Weight\ of\ drug\ in\ NPs}{Weight\ of\ NPs} \times 100\% ).

Visualizing Synthesis Pathways and Workflows

Diagram 1: PLA Biosynthesis from Biomass to Polymer

Diagram 2: Nanoprecipitation for Drug-Loaded NPs

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for Sustainable Polymer Research

| Reagent / Material | Function / Rationale | Example (Non-promotional) |

|---|---|---|

| Immobilized Lipase B (CAL-B) | Green catalyst for enzymatic ROP of lactones/lactide; eliminates metal catalysts. | Novozym 435 (Immobilized on acrylic resin) |

| Tin(II) 2-ethylhexanoate (Sn(Oct)₂) | Industry-standard metal catalyst for high-rate ROP of lactide. | Sigma-Aldrich, >92.5% purity |

| 2,5-Furandicarboxylic Acid (FDCA) | Renewable, rigid diacid monomer for high-performance polyesters (e.g., PEF). | Carbosynth, derived from HMF |

| PHBV Copolymer | Model bio-derived, biodegradable polyester for tissue engineering & drug delivery. | Goodfellow or Sigma-Aldrich, with defined HV% |

| Poly(vinyl alcohol) (PVA) | Common stabilizer/emulsifier for forming polymeric nanoparticles. | Mw 31-50 kDa, 87-89% hydrolyzed |

| MTT Reagent | Tetrazolium dye for in vitro cytotoxicity assay of polymer extracts/degradation products. | (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) |

| Gel Permeation Chromatography (GPC) Kit | Essential for determining molecular weight (Mn, Mw) and dispersity (Đ) of synthesized polymers. | System with refractive index detector, using polystyrene or PMMA standards. |

Essential Skills and Interdisciplinary Knowledge for a Polymer Scientist in Pharma/Biotech

Within the evolving landscape of polymer science research, the pharma and biotech sectors present unique frontiers. Success here demands a polymath approach, blending deep polymer expertise with adjacent scientific disciplines to solve complex therapeutic and delivery challenges. This guide details the core competencies and integrated knowledge base required.

Core Polymer Science Expertise

A polymer scientist must command fundamental principles, with a focus on materials relevant to biological systems.

Table 1: Key Polymer Classes in Pharma/Biotech Applications

| Polymer Class | Example Materials | Key Properties | Primary Applications |

|---|---|---|---|

| Polyesters | PLGA, PLA, PCL | Biodegradable, tunable erosion kinetics, FDA history | Sustained-release depots, sutures, scaffolds |

| Polyethers | PEG, Poloxamers | Hydrophilic, non-fouling, FDA-approved | Protein conjugation, hydrogel matrices, micelles |

| Poly(amino acids) | Poly(L-lysine), Poly(glutamic acid) | Biocompatible, charged side chains | Drug conjugates, polyplexes for nucleic acid delivery |

| Acrylics | p(HEMA), p(DMAEMA) | pH-responsive, tunable glass transition | Contact lenses, mucoadhesive or pH-triggered systems |

| Natural/Semi-synthetic | Chitosan, Hyaluronic Acid, Cellulose derivatives | Inherent bioactivity, degradable, often charged | Targeted delivery, wound healing, viscosupplementation |

Interdisciplinary Knowledge Integration

Therapeutic development requires seamless integration with biology, chemistry, and pharmaceutical sciences.

Biophysics & Colloid Science

Understanding macromolecular interactions in biological fluids is critical. Key concepts include:

- Hydrophobic Effect: Drives self-assembly of amphiphilic block copolymers into micelles or polymersomes.

- DLS & Zeta Potential: Essential for characterizing nanoparticle size (PDI) and surface charge, predicting colloidal stability in vivo.

- Protein Corona Formation: Adsorption of serum proteins alters nanoparticle identity, impacting biodistribution.

Table 2: Quantitative Characterization Techniques

| Technique | Measured Parameter | Typical Target Range for Nano-DDS | Relevance |

|---|---|---|---|

| Dynamic Light Scattering (DLS) | Hydrodynamic diameter, PDI | 50-200 nm, PDI < 0.2 | Blood circulation, EPR effect |

| Zeta Potential Analysis | Surface charge (mV) | ±10-30 mV for colloidal stability | Predicts aggregation in saline |

| SEC/MALS | Absolute Mw, conformation | Varies by polymer | Controls degradation rate, mechanical properties |

| ITC / SPR | Binding affinity (Kd), thermodynamics | nM-µM range for targeted systems | Quantifies ligand-receptor interactions |

Principles of Drug Delivery & Pharmacokinetics

Polymer scientists must design systems that navigate the body’s barriers.

- Controlled Release Kinetics: Model drug release (zero-order, Higuchi, Korsmeyer-Peppas) from monolithic matrices or reservoirs.

- PK/PD Modeling: Understand how polymer properties influence absorption, distribution (volume of distribution), metabolism, and excretion (clearance).

Experimental Protocol: In Vitro Drug Release Study (USP Apparatus 4 Compatible)

- Preparation: Load precisely weighed polymer-drug matrices (e.g., millicylinders, nanoparticles) into flow-through cells.

- Media: Use phosphate-buffered saline (PBS, pH 7.4) or biorelevant media (e.g., FaSSIF) with 0.1% w/v sodium azide as antimicrobial. Maintain at 37±0.5°C.

- Flow Rate: Set a closed-loop system with a peristaltic pump to circulate release medium at 10 mL/min.

- Sampling: At predetermined intervals (e.g., 1, 4, 8, 24, 72 hrs), sample 1 mL from the reservoir and replace with fresh pre-warmed medium.

- Analysis: Quantify drug concentration via HPLC-UV, using a validated method. Calculate cumulative release percentage.

- Modeling: Fit release data to mathematical models (e.g., Korsmeyer-Peppas) to elucidate release mechanism (Fickian diffusion vs. polymer erosion).

Basic Cell Biology and Immunology

Polymer carriers interact with complex biological systems. A foundational understanding of cellular uptake pathways and immune recognition is non-negotiable.

Title: Cellular Uptake Pathways for Polymer Nanoparticles

Analytical and Regulatory Chemistry

The path to the clinic requires rigorous characterization and adherence to guidelines (ICH, FDA).

- Impurity Profiling: Use LC-MS, NMR to quantify residual monomers, catalysts, and degradation products.

- Sterility & Pyrogenicity: Apply techniques like LAL testing for endotoxin, ensure methods for sterile filtration or aseptic processing of heat-labile polymers.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Polymer-Based Formulation

| Item | Function & Relevance |

|---|---|

| PLGA (50:50, ester-terminated) | Benchmark biodegradable polymer for controlled release; erosion rate depends on LA:GA ratio. |

| mPEG-NHS | Gold-standard for "PEGylation" to impart stealth properties and prolong circulation half-life. |

| Dicyclohexylcarbodiimide (DCC) | Coupling agent for polymer-polymer or polymer-drug conjugation via amide/ester bonds. |

| Dialysis Membranes (MWCO 3.5k-100k) | Critical for purifying polymeric nanoparticles and removing unencapsulated drug/solvent. |

| Fluorescent Dyes (Cy5, Nile Red) | For labeling polymers to track cellular uptake, biodistribution, and degradation visually. |

| Transwell Permeation Systems | To model and quantify transport of polymer carriers across epithelial/endothelial barriers. |

| CCK-8 Assay Kit | Standard colorimetric assay to evaluate polymer or formulation cytotoxicity in vitro. |

Title: Polymer Therapeutic Development Workflow

Experimental Protocol: Formulating siRNA-Polyplexes

A representative advanced methodology integrating polymer synthesis and biological application.

Objective: Formulate and characterize cationic polymer-based polyplexes for siRNA delivery. Materials: Branched Polyethylenimine (bPEI, 25 kDa), control siRNA (e.g., GFP-targeting), RNase-free water, sodium acetate buffer (pH 5.0), Hepes-buffered saline (HBS, pH 7.4), agarose, ethidium bromide.

Procedure:

- Polymer Solution: Prepare bPEI at 1 mg/mL in RNase-free water, filter sterilize (0.22 µm).

- siRNA Solution: Dilute siRNA to 0.1 mg/mL in 30 mM sodium acetate buffer (pH 5.0).

- Complexation: Rapidly mix the bPEI solution with the siRNA solution under vortexing to achieve desired N/P (Nitrogen/Phosphate) molar ratios (e.g., 5, 10, 20). Incubate 30 min at RT.

- Characterization:

- Size/Zeta: Dilute polyplexes in HBS, measure by DLS and zeta potential.

- Gel Retardation Assay: Load samples onto 1% agarose gel containing ethidium bromide. Run at 80 V for 60 min in TAE buffer. Visualize under UV; complete siRNA complexation shows no free siRNA band.

- In Vitro Transfection: Seed HEK293 cells in 24-well plates. Add polyplexes containing 50 nM siRNA. After 48h, assay for target gene knockdown via qRT-PCR.

- Data Analysis: Correlate N/P ratio with particle size, charge, and transfection efficiency/cytotoxicity.

The Frontier: Emerging Skills

Staying at the research frontier now requires familiarity with:

- AI/ML for Polymer Design: Using predictive models for polymer properties or formulation optimization.

- Advanced Manufacturing: Continuous flow synthesis, microfluidics for nanoparticle production, and 3D bioprinting of polymer scaffolds.

- High-Throughput Screening: Automated platforms for rapid synthesis and testing of polymer libraries.

Mastering this integrated skill set positions the polymer scientist not just as a material specialist, but as a central architect in the multidisciplinary endeavor to create the next generation of biotherapeutics, advanced delivery systems, and regenerative medicine solutions.

Within the broader context of careers and research frontiers in polymer science, the biomaterials sector represents a dynamic and high-impact domain. This guide provides a comparative analysis of career pathways in academia, industrial R&D, and startups, focusing on the technical requirements, skill sets, and current research trends in polymer biomaterials for drug delivery, tissue engineering, and regenerative medicine.

Current Landscape and Quantitative Data

The following tables summarize key quantitative data related to the field's growth, funding, and career metrics.

Table 1: Market and Funding Landscape (2023-2024 Estimates)

| Metric | Academia/Grants | Industrial R&D | Startup Ecosystem |

|---|---|---|---|

| Global Market Size | N/A | $120-150 Billion (Biomaterials) | $5-7 Billion (Polymer Bio-Startups) |

| Typical Project Funding | $250K - $2M (NIH R01) | $2M - $20M+ (Division Budget) | $500K - $10M (Seed-Series A) |

| Annual R&D Growth | ~4% (Grant Budgets) | 7-9% | 12-15% |

| Key Funding Sources | NIH, NSF, DoD, ERC | Corporate Revenue, Strategic Budget | VC, Angel Investors, SBIR/STTR Grants |

Table 2: Career Profile Comparison

| Aspect | Academia | Industrial R&D | Startup |

|---|---|---|---|

| Primary Focus | Fundamental knowledge, publishing, teaching | Product development, process optimization, IP | Innovation, proof-of-concept, rapid iteration |

| Key Roles | PI, Postdoc, Graduate Student | Senior Scientist, Research Lead, Project Manager | Founding Scientist, Technical Co-founder, R&D Engineer |

| Typical Time to Impact | 3-7 years (Grant cycle) | 1-3 years (Project milestone) | 6-18 months (MVP/Prototype) |

| Skill Emphasis | Deep specialization, grant writing, mentoring | Cross-functional teamwork, regulatory knowledge, scalability | Versatility, business acumen, resilience |

Technical Deep Dive: Core Experimental Protocols

A central experiment in polymer biomaterials is the synthesis and characterization of a degradable polymeric nanoparticle for drug encapsulation. Below is a detailed protocol.

Protocol: Synthesis and Characterization of PLGA-PEG Nanoparticles for Drug Delivery

Objective: To formulate and characterize poly(lactic-co-glycolic acid)-polyethylene glycol (PLGA-PEG) copolymer nanoparticles loaded with a model hydrophobic drug (e.g., Paclitaxel) using the nanoprecipitation method.

Materials: PLGA-PEG copolymer (50:50 LA:GA, PEG 5kDa), paclitaxel, acetone (HPLC grade), deionized water, polysorbate 80 (Tween 80), dialysis tubing (MWCO 12-14 kDa), dynamic light scattering (DLS) instrument, scanning electron microscope (SEM).

Methodology:

- Organic Phase Preparation: Dissolve 50 mg of PLGA-PEG copolymer and 5 mg of paclitaxel in 10 mL of acetone. Stir magnetically at room temperature until fully dissolved.

- Aqueous Phase Preparation: Prepare 40 mL of a 0.1% (w/v) polysorbate 80 solution in deionized water.

- Nanoprecipitation: Using a syringe pump, add the organic phase dropwise (rate: 1 mL/min) into the aqueous phase under constant magnetic stirring (600 rpm). The nanoparticles form spontaneously as the acetone diffuses into the water.

- Solvent Removal: Stir the resulting suspension for 4 hours at room temperature to allow complete evaporation of acetone. Alternatively, remove residual solvent via rotary evaporation under reduced pressure at 30°C.

- Purification: Transfer the nanoparticle suspension to dialysis tubing and dialyze against 2 L of deionized water for 12 hours, changing water every 4 hours, to remove free drug, surfactant, and solvent.

- Lyophilization: Add 5% (w/v) trehalose as a cryoprotectant to the purified suspension. Freeze at -80°C and lyophilize for 48 hours to obtain a dry powder for storage.

Characterization:

- Size and Zeta Potential: Reconstitute nanoparticles in DI water. Use DLS to measure hydrodynamic diameter and polydispersity index (PDI). Measure zeta potential using electrophoretic light scattering.

- Morphology: Dilute suspension, deposit on a silicon wafer, air dry, and sputter-coat with gold. Analyze morphology using SEM.

- Drug Loading & Encapsulation Efficiency: Dissolve 5 mg of lyophilized nanoparticles in DMSO. Analyze paclitaxel concentration using HPLC or UV-Vis spectroscopy against a standard curve. Calculate Loading Capacity (%) = (Mass of drug in nanoparticles / Mass of nanoparticles) x 100. Calculate Encapsulation Efficiency (%) = (Mass of drug in nanoparticles / Mass of drug fed initially) x 100.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Polymeric Nanoparticle Development

| Reagent/Material | Function & Rationale |

|---|---|

| PLGA-PEG Diblock Copolymer | Forms the nanoparticle core-shell structure; PLGA provides biodegradability and drug encapsulation, PEG confers "stealth" properties to reduce immune clearance. |

| Polysorbate 80 (Tween 80) | A non-ionic surfactant used to stabilize the emulsion during nanoprecipitation, preventing nanoparticle aggregation. |

| Trehalose | A disaccharide cryoprotectant; forms a glassy matrix during lyophilization to protect nanoparticle integrity and prevent fusion. |

| Dialysis Tubing (MWCO 12-14 kDa) | Allows for the selective removal of small molecules (solvent, unencapsulated drug) while retaining larger nanoparticles during purification. |

| MTT Assay Kit | Standard colorimetric assay using (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) to assess in vitro cytotoxicity of nanoparticles. |

Career Pathway Decision Logic and Workflows

Career Decision Logic for Polymer Biomaterial Scientists

Project Workflows Across Career Pathways

The choice between academia, industrial R&D, and startups in polymer biomaterials hinges on aligning personal drivers—be it deep discovery, scaled impact, or agile innovation—with the structural realities of each pathway. Success across all domains requires a robust foundation in core synthesis and characterization protocols, coupled with the agility to navigate distinct project lifecycles and strategic goals. The field's continued growth ensures dynamic opportunities for researchers to contribute to the next frontier of polymer-based therapeutic and diagnostic solutions.

From Bench to Bedside: Advanced Synthesis, Characterization, and Therapeutic Applications

Within the broader thesis on careers and research frontiers in polymer science, the mastery of controlled/living polymerization (CLP) is paramount. These techniques enable the precise synthesis of polymers with defined molecular weights, low dispersity (Ð), and complex architectures—attributes critical for advanced applications in drug delivery, nanotechnology, and smart materials. This whitepaper provides an in-depth technical guide to three cornerstone techniques: Reversible Addition-Fragmentation Chain-Transfer (RAFT), Atom Transfer Radical Polymerization (ATRP), and Ring-Opening Isomerization Polymerization (ROIP).

Core Principles and Quantitative Comparison

CLP techniques maintain a dynamic equilibrium between active and dormant polymer chains, minimizing irreversible termination. This allows for sequential monomer addition to create block copolymers, stars, and other precision structures.

Table 1: Quantitative Comparison of CLP Techniques

| Parameter | RAFT | ATRP | ROIP |

|---|---|---|---|

| Typical Dispersity (Ð) | 1.05 - 1.3 | 1.05 - 1.3 | 1.05 - 1.2 |

| Key Regulatory Agent | Chain Transfer Agent (CTA) | Transition Metal Complex (e.g., Cu(I)/L) | Organometallic Catalyst (e.g., Pd, Ru) |

| Tolerance to Protic Functionalities | High | Moderate (requires ligand optimization) | Low (moisture/oxygen sensitive) |

| Typical Temp. Range (°C) | 60 - 90 | 25 - 110 | 25 - 70 |

| Key Architectural Strength | Excellent for block copolymers, complex topologies | Excellent for functional (meth)acrylates, grafting | Precise cyclic, branched, and gradient polymers |

| Post-Polymerization Purification | CTA residue removal | Metal catalyst removal | Metal catalyst removal |

Detailed Methodologies and Protocols

RAFT Polymerization of a Poly(Methyl Methacrylate)-block-Polystyrene (PMMA-b-PS) Diblock Copolymer

Objective: Synthesize a well-defined diblock copolymer with low Ð.

Protocol:

- Synthesis of PMMA Macro-CTA: In a Schlenk flask, dissolve methyl methacrylate (MMA, 10.0 g, 99.9 mmol), 2-Cyano-2-propyl benzodithioate (RAFT CTA, 111 mg, 0.50 mmol), and AIBN initiator (8.2 mg, 0.050 mmol) in anhydrous toluene (20 mL). Degas the solution via three freeze-pump-thaw cycles. Seal under inert atmosphere and place in an oil bath at 70°C for 6 hours. Terminate by rapid cooling in ice water. Precipitate the polymer into a 10-fold excess of cold methanol. Recover PMMA macro-CTA by filtration and dry in vacuo. Characterize via SEC ([M]n, theo ~ 10,000 g/mol, Ð < 1.15).

- Chain Extension to Form Diblock: In a new Schlenk flask, dissolve the purified PMMA macro-CTA (5.0 g, 0.50 mmol) and styrene (5.2 g, 50 mmol) in anhydrous toluene (10 mL). Degas via three freeze-pump-thaw cycles. Add AIBN (0.82 mg, 0.005 mmol) under inert flow. Seal and polymerize at 70°C for 12 hours. Terminate by cooling and exposure to air. Precipitate the block copolymer into cold methanol. Recover and dry in vacuo. Analyze via SEC for molecular weight increase and low Ð.

Diagram 1: RAFT Equilibrium Mechanism

ARGET ATRP of Poly(Oligo(Ethylene Glycol) Methyl Ether Methacrylate) (POEGMA)

Objective: Synthesize a biocompatible, functional homopolymer with low catalyst loading.

Protocol:

- Setup: In a Schlenk flask, charge OEGMA (2.0 g, ~3.4 mmol for Mn~500), methyl 2-bromopropionate (initiator, 5.0 µL, 0.045 mmol), CuBr2 catalyst (1.0 mg, 0.0045 mmol), and ligand Tris(2-pyridylmethyl)amine (TPMA, 2.6 mg, 0.009 mmol). Add a 1:1 v/v mixture of anisole and water (4 mL total) as solvent.

- Degassing and Initiation: Degas the mixture by sparging with N2 for 30 minutes. Add the reducing agent, ascorbic acid (1.6 mg, 0.009 mmol), under N2 flow to generate the active Cu(I) species in situ. Immediately seal the flask.

- Polymerization: Place the reaction in an oil bath at 30°C with stirring for 2-4 hours. Monitor conversion by 1H NMR.

- Work-up: Terminate by exposing to air. Pass the reaction mixture through a short column of neutral alumina to remove copper catalyst. Dialyze against water (MWCO 3.5 kDa) and lyophilize to obtain the pure polymer.

Diagram 2: ATRP Catalytic Cycle

ROIP of a Gradient Copolymer from Ethylvinyl Ether and a Functional Monomer

Objective: Synthesize a polymer with a controlled gradient composition via chain-running isomerization.

Protocol:

- Catalyst Preparation: In a glovebox, prepare a stock solution of the catalyst, e.g., [Pd(PPh3)4] (5.8 mg, 0.005 mmol) in dry, degassed dichloromethane (DCM, 1 mL).

- Monomer and Initiator Setup: In a reaction vial inside the glovebox, mix ethylvinyl ether (EVE, 0.86 g, 12 mmol) and a functional comonomer (e.g., a malonate derivative, 2 mmol) with 1,4-benzoquinone (as an additive, 5.4 mg, 0.05 mmol). Add dry DCM (2 mL).

- Initiation: To the stirred monomer solution, add the catalyst solution (0.1 mL, 0.5 µmol Pd) and a Lewis acid co-catalyst (e.g., SnCl4, 1.3 µL, 0.01 mmol) to initiate polymerization. Seal the vial.

- Polymerization: Stir at room temperature for 24 hours. The ROIP mechanism leads to a gradient incorporation of the functional monomer as polymerization proceeds.

- Termination: Expose the reaction to air and add a drop of triethylamine to quench catalysts. Concentrate in vacuo and purify by preparative SEC or precipitation.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for CLP Experiments

| Reagent/Chemical | Primary Function | Key Consideration for Research |

|---|---|---|

| RAFT CTA (e.g., CDB, CPADB) | Mediates chain transfer; defines R & Z groups for control/functionality. | Z group affects rate; R group must be a good leaving/re-initiating radical. |

| ATRP Initiator (e.g., Ethyl α-Bromoisobutyrate) | Provides alkyl halide group for metal complex halogen abstraction. | Must match monomer type (e.g., methacrylates use tertiary halides). |

| ATRP Ligand (e.g., PMDETA, TPMA) | Solubilizes Cu salt and tunes redox potential. | Ligand choice dictates activity, solubility in media, and oxygen tolerance. |

| ATRP Catalyst (CuBr, CuBr2) | Undergoes redox cycling to activate/deactivate chains. | ARGET/ICAR techniques use ppm levels of Cu(II) with reducing agents. |

| ROIP Catalyst (e.g., [Pd(PPh3)4]) | Initiates isomerization and coordinates monomer insertion. | Extremely oxygen/moisture sensitive; requires rigorous Schlenk/glovebox. |

| Degassed Solvents | Reaction medium free of O2/H2O to prevent inhibition. | Use freeze-pump-thaw or N2 sparging; store over molecular sieves. |

| AIBN | Thermal radical initiator (for RAFT, or ICAR ATRP). | Recrystallize from methanol for purity; half-life dictates polymerization temperature. |

| Ascorbic Acid / Sn(EH)2 | Reducing agent for regenerative ATRP (ARGET). | Regenerates Cu(I) from Cu(II), allowing very low catalyst loadings. |

Within the evolving frontiers of polymer science research, a multidisciplinary career requires mastery of advanced analytical tools. This technical guide details four cornerstone techniques—SEC-MALS, NMR, AFM, and DSC—for the comprehensive characterization of polymeric and advanced material properties, crucial for applications from drug delivery systems to high-performance composites.

Size Exclusion Chromatography with Multi-Angle Light Scattering (SEC-MALS)

Principle: SEC separates polymers by hydrodynamic volume. Online MALS detection measures the absolute molecular weight (Mw) and root-mean-square radius (Rg) of each fraction without relying on column calibration.

Experimental Protocol:

- Sample Preparation: Dissolve 2-5 mg of polymer in the mobile phase (e.g., THF for synthetics, aqueous buffer for biopolymers). Filter through a 0.1 or 0.2 µm syringe filter.

- System Configuration: Equilibrate SEC columns (e.g., 2-3 pore sizes in series) and the MALS detector (typically with a 658 nm laser) in line with a refractive index (RI) detector.

- Injection & Elution: Inject 50-100 µL of sample. Use isocratic elution at 0.5-1.0 mL/min.

- Data Analysis: Use the Zimm equation to analyze light scattering data at each elution slice: (Rθ/K) = Mw * P(θ) * c - 2A2 * c², where Rθ is the excess Rayleigh ratio, K is an optical constant, P(θ) is the form factor, and A2 is the second virial coefficient. Conjoint analysis with RI concentration yields absolute Mw and Rg distributions.

Key Data Table: SEC-MALS Output for Model Polymers

| Polymer | Mw (kDa) | PDI (Mw/Mn) | Rg (nm) | Conformation (Rg vs. Mw plot slope) |

|---|---|---|---|---|

| Polystyrene (linear) | 250 | 1.03 | 24 | 0.58 (Random Coil) |

| Pullulan (branched) | 100 | 1.10 | 12 | 0.33 (Compact Sphere) |

| DNA (ds, in buffer) | 1,500 | 1.05 | 105 | 0.58 (Random Coil) |

| Monoclonal Antibody | 150 | 1.00 | 5.2 | 0.33 (Globular Protein) |

Diagram 1: SEC-MALS with RI detector workflow.

Nuclear Magnetic Resonance (NMR) Spectroscopy

Principle: NMR, particularly ¹H and ¹³C, provides quantitative data on chemical structure, composition (e.g., copolymer ratio), sequence distribution, end-group analysis, and tacticity.

Experimental Protocol for Polymer Analysis:

- Sample Preparation: Dissolve 10-20 mg of polymer in 0.5-0.7 mL of deuterated solvent (e.g., CDCl₃, DMSO-d6). Add internal standard (e.g., TMS) for chemical shift reference.

- Data Acquisition: For ¹H NMR, use a standard pulse sequence (e.g., zg30) with a 90° pulse, 3-5 sec relaxation delay (D1), and 16-128 scans. For quantitative analysis, ensure D1 > 5*T1 (longest spin-lattice relaxation time).

- Advanced 2D Techniques: For complex structures, perform ¹H-¹³C HSQC or COSY to assign peaks and determine connectivity.

- Data Analysis: Calculate molar composition by integrating characteristic proton peaks. Determine number-average molecular weight (Mn) from end-group to repeat unit proton integral ratios.

Key Data Table: NMR-Derived Polymer Properties

| Polymer Type | Key ¹H NMR Shift (δ) | Information Derived | Quantitative Metric |

|---|---|---|---|

| Poly(lactic-co-glycolic acid) | 5.2 ppm (LA), 4.8 ppm (GA) | Monomer Ratio (LA:GA) | 75:25 mol% |

| Poly(ethylene glycol) diacrylate | 5.8-6.4 ppm (acrylate), 3.6 ppm (EG) | Degree of Acrylation | 95% end-group conversion |

| Poly(methyl methacrylate) | 0.8-1.2 ppm (α-CH3) | Tacticity (mm/mr/rr) | 70% syndiotactic |

| Block Copolymer | Aromatic (7.2 ppm), Aliphatic (1.6 ppm) | Block Composition | 45 wt% Styrene |

Atomic Force Microscopy (AFM)

Principle: AFM probes surface topography and nanomechanical properties via a sharp tip on a cantilever. Modes include tapping mode (topography) and force spectroscopy (modulus, adhesion).

Experimental Protocol for Tapping Mode:

- Sample Preparation: Deposit polymer solution (0.01-0.1 mg/mL) on freshly cleaved mica, spin-coat, or analyze bulk films. Ensure surface is clean and dry.

- Probe Selection: Use a silicon probe with resonant frequency ~300 kHz and spring constant ~40 N/m.

- Imaging: Engage in tapping mode with a setpoint amplitude ratio of 0.7-0.9. Scan at 0.5-1.5 Hz with 512x512 pixel resolution.

- Force Spectroscopy: For Young's modulus measurement, obtain force-distance curves at multiple points. Fit the retract curve with the Derjaguin-Muller-Toporov (DMT) model: F = (4/3) * (E/(1-ν²)) * √(R * d³), where E is modulus, ν is Poisson's ratio, R is tip radius, and d is indentation.

Key Data Table: AFM Characterization of Material Surfaces

| Material | RMS Roughness (nm) | Young's Modulus (GPa) | Adhesion Force (nN) | Morphology Observed |

|---|---|---|---|---|

| Polymer Brush Film | 0.5 | 0.8 | 0.5 | Homogeneous, smooth |

| Drug-Loaded Micelle | 2.1 | 0.05 | 5.2 | Spherical aggregates |

| Semicrystalline Film | 15.3 | 3.5 | 2.1 | Lamellar structures |

| Graphene-Polymer Composite | 8.7 | 12.4 | 1.8 | Flake dispersion |

Diagram 2: AFM imaging and analysis workflow.

Differential Scanning Calorimetry (DSC)

Principle: DSC measures heat flow into/out of a sample versus temperature, providing data on glass transition (Tg), melting (Tm), crystallization (Tc), and heat capacity.

Standard Experimental Protocol:

- Sample Preparation: Precisely weigh 3-10 mg of material into an aluminum crucible. Hermetically seal with a lid. Use an empty pan as reference.

- Method Programming: Typical method: Equilibrate at -50°C, heat to 250°C at 10°C/min (1st heat), cool at 10°C/min, heat again to 250°C at 10°C/min (2nd heat). Use nitrogen purge at 50 mL/min.

- Data Analysis: Determine Tg as the midpoint of the heat capacity step. Integrate peak areas for melting enthalpy (ΔHm) and crystallization enthalpy (ΔHc). Calculate degree of crystallinity: Xc = (ΔHm / ΔHm⁰) * 100%, where ΔHm⁰ is enthalpy for 100% crystalline polymer.

Key Data Table: Thermal Transitions of Engineering Polymers

| Polymer | Tg (°C) | Tm (°C) | ΔHm (J/g) | % Crystallinity (Xc) |

|---|---|---|---|---|

| Poly(L-lactide) (PLLA) | 60-65 | 170-180 | 50-60 | ~50% |

| Poly(ethylene terephthalate) (PET) | 75-80 | 255-265 | 30-50 | 30-40% |

| Polyether ether ketone (PEEK) | 143 | 343 | 45 | 35% |

| Poly(N-isopropylacrylamide) (PNIPAM) | 130-135 | (N/A) | (N/A) | Amorphous |

Diagram 3: Interpreting key features in a DSC thermogram.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function & Relevance |

|---|---|

| NMR Deuterated Solvents (e.g., CDCl₃, DMSO-d₆) | Provide a lock signal for field/frequency stabilization and eliminate large solvent proton signals in ¹H NMR. |

| SEC-MALS Mobile Phases (e.g., HPLC-grade THF with BHT, 0.1M NaNO₃/0.02% NaN₃ aqueous buffer) | Dissolve and separate polymers without degrading columns or inducing aggregation; BHT prevents radical degradation. |

| AFM Probes & Substrates (e.g., Si cantilevers, freshly cleaved mica) | High-resolution tips for imaging; atomically flat, negatively charged mica is ideal for adsorbing macromolecules. |

| DSC Calibration Standards (e.g., Indium, Tin, Zinc) | Calibrate temperature scale and enthalpy response of the DSC cell for quantitative thermal analysis. |

| Syringe Filters (0.1/0.2 µm, PTFE or Nylon) | Critical for SEC-MALS and any solution-based technique to remove dust/aggregates that cause artifacts. |

| Polymer Standards (e.g., narrow dispersity polystyrene, PEG) | Essential for validating SEC-MALS system performance and column calibration curves. |

Within the dynamic field of polymer science, the design of advanced materials for controlled drug delivery stands as a preeminent research frontier, offering vast career opportunities in biomaterials, nanotechnology, and pharmaceutical development. This technical guide dissects the core principles of engineering polymeric systems for precise control over drug release kinetics, active targeting, and triggered release mechanisms, which are critical for next-generation therapeutics.

Release Kinetics: Mathematical Models and Material Design

Drug release kinetics from polymeric matrices are governed by diffusion, swelling, and degradation mechanisms. The choice of polymer and its architecture dictates the release profile.

Table 1: Common Mathematical Models for Drug Release Kinetics

| Model | Equation | Dominant Mechanism | Applicable Polymer System |

|---|---|---|---|

| Zero-Order | ( Qt = Q0 + k_0 t ) | Erosion-controlled | Reservoir systems, surface-eroding polymers (e.g., polyanhydrides) |

| Higuchi | ( Qt = kH \sqrt{t} ) | Fickian diffusion | Non-swelling, monolithic matrices |

| Korsmeyer-Peppas | ( Qt / Q\infty = k t^n ) | Diffusion & Swelling | Swellable hydrogels (e.g., pHEMA, chitosan); n indicates release mechanism |

| Hixson-Crowell | ( (1 - (1 - Qt/Q\infty)^{1/3}) = k_{HC} t ) | Erosion/Dissolution | Systems where surface area change dictates release |

Experimental Protocol: In Vitro Release Kinetics Study

- Materials: Drug-loaded polymeric nanoparticles/films, phosphate-buffered saline (PBS, pH 7.4) or simulated biological fluids, dialysis membrane bags (MWCO appropriate for drug), shaking water bath, HPLC system.

- Method:

- Precisely weigh drug-loaded sample and place into a dialysis bag containing 1 mL of release medium. Seal the bag.

- Immerse the bag in a vessel containing 200 mL of release medium, maintained at 37°C with constant agitation (50-100 rpm).

- At predetermined time intervals (e.g., 1, 2, 4, 8, 24, 48h...), withdraw 1 mL of the external medium and replace with fresh, pre-warmed medium to maintain sink conditions.

- Analyze the drug concentration in withdrawn samples via HPLC/UV-Vis spectroscopy.

- Plot cumulative drug release (%) vs. time. Fit data to models in Table 1 to determine the dominant release mechanism.

Targeting Strategies: Active and Passive Approaches

Passive targeting leverages the Enhanced Permeability and Retention (EPR) effect in tumor tissues. Active targeting involves surface functionalization with ligands that bind to overexpressed receptors on target cells.

Table 2: Common Targeting Ligands and Their Receptors

| Targeting Ligand | Target Receptor | Common Application | Key Polymer Conjugation Chemistry |

|---|---|---|---|

| Folic Acid | Folate Receptor (FR-α) | Ovarian, breast cancers | EDC/NHS coupling to amine-functionalized polymers |

| Anti-HER2 mAb (Trastuzumab) | HER2 receptor | HER2+ breast cancer | Maleimide-thiol coupling to PEGylated polymers |

| RGD peptide | αvβ3 integrin | Angiogenic tumor vasculature | NHS ester-amine or click chemistry (azide-alkyne) |

| Hyaluronic Acid | CD44 receptor | Many cancer stem cells | Used as the polymer backbone itself or conjugated |

Diagram: Drug Delivery Targeting Pathways

Triggered Release Mechanisms

Smart polymers respond to specific internal or external stimuli to achieve spatiotemporal control.

Table 3: Stimuli-Responsive Polymer Systems for Triggered Release

| Stimulus | Polymer Example | Mechanism & Trigger | Typical Drug Cargo |

|---|---|---|---|

| pH | Poly(acrylic acid) (PAA) | Swelling/carrier dissociation at pH > pKa | Doxorubicin (tumor microenvironment) |

| Redox | Disulfide-crosslinked polymers | Cleavage of S-S bonds in high glutathione (GSH) | siRNA, proteins (intracellular) |

| Enzyme | Peptide/protein-based polymers | Degradation by specific enzymes (e.g., MMPs) | Chemotherapeutics (tumor tissue) |

| Temperature | Poly(N-isopropylacrylamide) (PNIPAM) | Collapse/aggregation above LCST | Various (local hyperthermia) |

| Light | O-nitrobenzyl derivative polymers | Photocleavage of linker under UV light | Small molecules (precise spatial control) |

Experimental Protocol: Evaluating pH-Triggered Release

- Materials: pH-sensitive polymer (e.g., poly(2-(diisopropylamino)ethyl methacrylate)), drug, acetate buffer (pH 5.0), phosphate buffer (pH 7.4), dynamic light scattering (DLS), fluorescence spectrometer.

- Method:

- Synthesize and load drug into polymeric micelles/nanoparticles.

- Characterize particle size and zeta potential via DLS in PBS (pH 7.4).

- Using the dialysis method from Section 1, conduct parallel release studies in pH 7.4 and pH 5.0 buffers.

- For fluorescent drugs (e.g., doxorubicin), monitor fluorescence quenching/dequenching to confirm intracellular release. Incubate particles with cells and track fluorescence intensity via confocal microscopy over time.

- Compare release profiles to confirm accelerated release at the acidic pH.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for Polymer-Based Drug Delivery Research

| Item | Function/Application | Example Brands/Notes |

|---|---|---|

| Biocompatible Polymers | Backbone for carrier synthesis. | PLGA (Lactel), PEG (Sigma-Aldrich), Chitosan (Novamatrix) |

| Crosslinkers | Form hydrogel networks or stabilize structures. | Glutaraldehyde, Genipin, N,N'-methylenebis(acrylamide) |

| Heterobifunctional PEG | For "stealth" coating and ligand conjugation. | NHS-PEG-Maleimide (Creative PEGWorks) |

| Fluorescent Dyes | Tracking particles in vitro/in vivo. | Cy5.5, FITC, DiO (Thermo Fisher) |

| Cell-Specific Ligands | Enable active targeting. | Folic Acid, cRGDfK peptide (MedChemExpress) |

| Prototyping Kits | For rapid nanoparticle formulation screening. | NanoAssemblr (Precision NanoSystems) |

| Characterization Tools | Size, charge, stability analysis. | DLS (Malvern Zetasizer), HPLC (Agilent) |

The future of polymer science in drug delivery lies in the integrated design of multi-functional systems that combine controlled kinetics, multiple targeting modalities, and responsiveness to biological cues. This interdisciplinary frontier demands researchers skilled in polymer chemistry, pharmaceutical formulation, and translational biology, representing a vibrant career pathway aimed at solving unmet clinical needs.

Polymer-Based Scaffolds for Tissue Engineering and Regenerative Medicine

Within the evolving landscape of polymer science research, the design and fabrication of advanced scaffolds represent a premier research frontier with profound implications for biomedicine. This specialization offers significant career opportunities at the intersection of materials chemistry, biology, and clinical translation. Mastering the principles of scaffold synthesis, characterization, and application is pivotal for scientists aiming to contribute to next-generation regenerative therapies and the burgeoning field of organ-on-a-chip technology for drug development.

Core Design Principles and Material Classes

The efficacy of a polymer scaffold is governed by a synergy of material properties and architectural features.

Key Design Parameters:

- Biocompatibility & Biodegradability: The material and its degradation products must be non-toxic. Degradation rate should match tissue ingrowth.

- Mechanical Properties: Stiffness, elasticity, and strength must mimic the target native tissue (e.g., ~10-30 kPa for brain, ~0.1-1 MPa for cartilage, ~100 MPa for bone).

- Porosity & Pore Interconnectivity: High porosity (>90% for some soft tissues) and interconnected pores are essential for cell infiltration, vascularization, and nutrient/waste diffusion.

- Surface Chemistry & Topography: Influences protein adsorption, cell adhesion, proliferation, and differentiation.

Primary Polymer Classes:

| Polymer Class | Specific Examples | Key Properties | Typical Applications | Degradation Timeline |

|---|---|---|---|---|

| Natural Polymers | Collagen, Fibrin, Alginate, Chitosan, Hyaluronic Acid | Inherent bioactivity, cell recognition sites, often weak mechanically. | Soft tissue regeneration (skin, cartilage), hemostatic dressings, drug delivery. | Weeks to several months, enzyme-dependent. |

| Synthetic Polymers | Poly(lactic-co-glycolic acid) (PLGA), Poly(ε-caprolactone) (PCL), Polyethylene glycol (PEG) | Tunable mechanical strength & degradation rate, reproducible, less immunogenic. | Bone scaffolds (PCL), controlled release systems (PLGA), hydrogel networks (PEG). | Months to years, hydrolysis-dependent. |

| Composite/Hybrid | PCL/Collagen, PLGA/Bioactive Glass, PEG-Hyaluronic Acid | Combines mechanical robustness of synthetics with bioactivity of naturals. | Osteochondral interfaces, load-bearing bone grafts, vascular grafts. | Tunable, based on composite ratio. |

Advanced Fabrication Techniques and Protocols