The Twin Crisis Beneath Our Feet

Look down. The sidewalk, the building you're in, the bridges you cross – our world is built on concrete. But this ubiquitous material has a dirty secret: its production spews 8% of global CO₂ emissions. Meanwhile, landfills groan under mountains of plastic waste, particularly PET from bottles, taking centuries to decompose. What if we could tackle both problems at once?

Concrete CO₂ Emissions

Responsible for 8% of global CO₂ emissions, making it one of the largest industrial polluters.

Plastic Waste

Only 9% of all plastic waste ever produced has been recycled, with PET bottles being a major contributor.

Enter a revolutionary fusion: reinforcing concrete with recycled Polyethylene Terephthalate (PET) and microscopic Carbon Nanotubes (CNTs). This isn't just recycling; it's reimagining concrete for the 21st century, making it stronger, lighter, and greener. Let's dive into the science of how plastic bottles and super-tiny tubes are building a better future.

The Science of Stronger Stuff: PET, CNTs, and Concrete's Secret Life

Concrete isn't just a boring grey lump. It's a complex composite:

-

Cement Paste: The glue, formed when cement reacts with water. Its microscopic structure – its crystallite phase (like the arrangement of tiny mineral crystals) – dictates much of the concrete's strength and durability.

-

Aggregates: Sand and gravel that provide bulk and resist compression.

-

The Weakness: Traditional concrete is strong under compression (squishing) but weak under tension (pulling). That's why we add steel rebars. But steel corrodes, and mining/producing it is energy-intensive.

Here's how our heroes step in:

PET Fibers (The Recycled Reinforcer)

Shredded PET plastic from bottles is processed into small fibers or flakes. Mixed into concrete, these fibers:

- Bridge Cracks: As micro-cracks start to form under stress, the fibers act like tiny stitches, holding the concrete together longer.

- Improve Toughness: They absorb energy during impact, making the concrete less brittle.

- Reduce Weight: PET is lighter than cement and aggregate, leading to slightly lighter concrete structures.

Carbon Nanotubes (CNTs - The Nano-Superheroes)

Imagine cylinders of carbon atoms arranged in a honeycomb lattice, thousands of times thinner than a human hair. CNTs possess extraordinary properties:

- Exceptional Strength & Stiffness: Far stronger than steel, gram-for-gram.

- High Aspect Ratio: Their long, thin shape means they can weave through the cement paste, reinforcing it at the nano-scale.

- Filling the Gaps: They can fill the tiniest pores in the cement paste, making it denser and less permeable to water and harmful chemicals.

The Synergy

Combining PET and CNTs is where the magic happens. PET fibers handle the larger cracks, while CNTs reinforce the nano-structure of the cement paste itself. This dual-scale reinforcement tackles concrete's weaknesses more comprehensively than either material alone. Crucially, we assess this by studying:

Crystallite Phase

Using techniques like X-ray Diffraction (XRD), we see if PET/CNTs change the types or sizes of the tiny crystals forming in the cement paste.

Morphology

Examining the concrete's microstructure (using Scanning Electron Microscopy - SEM) reveals dispersion and bonding.

Mechanical Properties

The ultimate test! We measure compressive strength, flexural strength, and fracture toughness.

Deep Dive: The Compression Crucible - Testing PET/CNT Concrete

Imagine scientists in a lab, meticulously mixing, pouring, and then crushing concrete cubes to see just how much improvement PET and CNTs really bring. Let's look at a typical, crucial experiment designed to measure the core mechanical property: compressive strength.

Methodology: Building and Breaking Miniature Monoliths

- PET Fibers: Cleaned PET bottles were shredded into fibers of specific length (e.g., 20mm) and width.

- CNT Dispersion: Multi-walled CNTs (MWCNTs) were dispersed in water using a surfactant (like a detergent) and intense ultrasonic energy (sonication) to prevent clumping.

- Concrete Mix: Standard Portland cement, sand, gravel, and water were prepared following common mix design ratios.

- Control: Plain concrete mix (just cement, sand, gravel, water).

- PET Only: Control mix + PET fibers (e.g., 1% by volume of concrete).

- CNT Only: Control mix + dispersed CNTs (e.g., 0.05% by weight of cement).

- PET/CNT Hybrid: Control mix + PET fibers (1% vol) + CNTs (0.05% wt cement).

- Each mixture was poured into standard cube-shaped molds (e.g., 100mm x 100mm x 100mm).

- Samples were vibrated to remove air bubbles.

- Cubes were covered, left to set for 24 hours, then removed from molds.

- All samples were cured in water at room temperature for exactly 28 days – the standard age for testing concrete strength.

- After curing, each cube was placed in a giant hydraulic compression testing machine.

- A steadily increasing crushing force was applied to the cube until it fractured.

- The maximum load (in Newtons or kN) the cube sustained before failure was recorded.

- Compressive Strength (in Megapascals, MPa) was calculated by dividing the maximum load by the cross-sectional area of the cube.

Results & Analysis: Crushing the Competition

| Sample Type | Avg. Compressive Strength (MPa) | % Change vs. Control |

|---|---|---|

| Control (Plain) | 42.5 | - |

| PET Only (1% vol) | 45.1 | +6.1% |

| CNT Only (0.05% wt) | 46.8 | +10.1% |

| PET/CNT Hybrid | 54.4 | +28.0% |

Key Findings

- PET Only: Shows a modest improvement (+6.1%). The fibers help control cracking after it starts, leading to slightly higher peak strength before complete failure.

- CNT Only: A more significant boost (+10.1%). CNTs actively reinforce the cement paste at the nano-scale, making it intrinsically denser and stronger, delaying the initiation of cracks.

- PET/CNT Hybrid: The standout performer (+28.0%). This synergy is key: CNTs strengthen the cement matrix preventing micro-cracks, while PET fibers bridge and arrest developing macro-cracks.

Microstructure Matters

SEM analysis of the hybrid samples typically reveals:

- Well-dispersed CNTs integrated within the cement paste.

- PET fibers cleanly embedded, showing good bonding.

- Fewer and smaller micro-cracks compared to the control or single-additive samples.

| Sample Type | CNT Dispersion | PET Fiber Bonding | Micro-crack Density |

|---|---|---|---|

| Control | N/A | N/A | High |

| PET Only | N/A | Moderate-Good | Moderate |

| CNT Only | Good | N/A | Low-Moderate |

| PET/CNT Hybrid | Good | Good | Low |

XRD Insights

XRD often shows that the hybrid additive doesn't introduce unwanted new crystal phases but can lead to a slightly denser and more refined crystallite structure in the cement paste, contributing to the strength gain.

The Scientist's Toolkit: Building Better Concrete

What does it take to explore this cutting-edge material? Here's a peek at the essential research reagents and tools:

| Item | Function | Why It's Important |

|---|---|---|

| Portland Cement (Type I/II) | Primary binder reacting with water to form the cement paste matrix. | The foundation of all concrete research. |

| Fine & Coarse Aggregate | Sand and gravel providing bulk and compressive strength. | Standard concrete components; size/grading affects mix properties. |

| Recycled PET Fibers | Macro-scale reinforcement improving toughness and crack resistance. | Turns plastic waste into a valuable resource; key for mechanical enhancement. |

| Carbon Nanotubes (MWCNTs) | Nano-scale reinforcement strengthening cement paste and filling pores. | Provides exceptional strength/stiffness at tiny doses; dispersion is critical. |

| Surfactant (e.g., SDS) | Chemical dispersant preventing CNT clumping in water. | Essential for achieving uniform CNT distribution for effective reinforcement. |

| Ultrasonic Processor (Sonicator) | Applies high-frequency sound energy to break apart CNT agglomerates. | Critical step for dispersing CNTs homogeneously within the mixing water. |

| Compression Testing Machine | Applies controlled crushing force to concrete samples. | The gold standard for measuring concrete's core strength property. |

| Scanning Electron Microscope (SEM) | Provides high-resolution images of concrete microstructure. | Reveals dispersion, bonding, cracks, and morphology crucial to understanding performance. |

| X-Ray Diffractometer (XRD) | Identifies and analyzes the crystalline phases present in the cement paste. | Shows how additives affect the fundamental mineral structure of the hardened concrete. |

SEM Analysis

Scanning Electron Microscopy reveals the microstructure of concrete at extremely high magnifications.

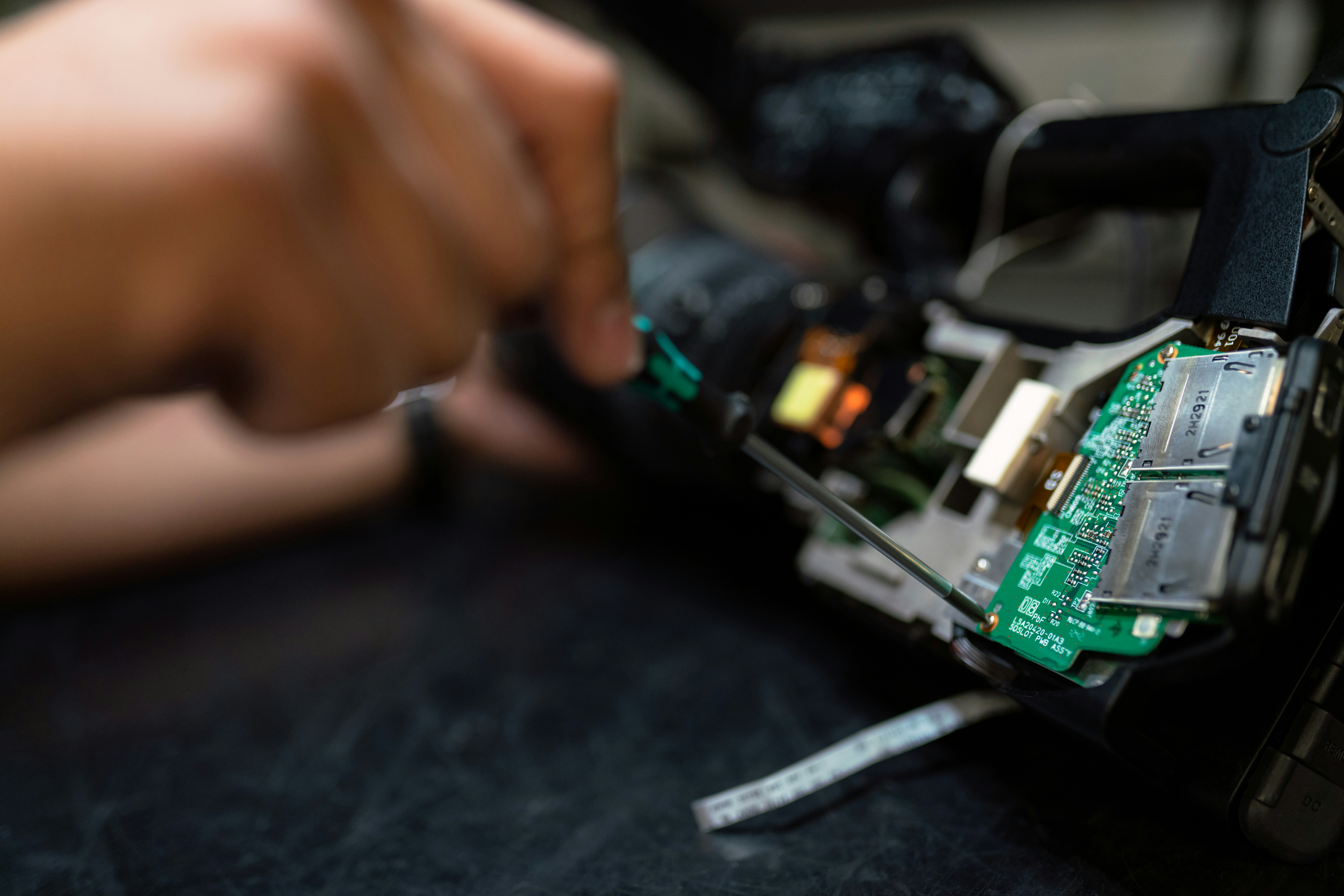

Compression Testing

Hydraulic machines measure the ultimate strength of concrete samples under crushing forces.

XRD Analysis

X-ray Diffraction helps identify the crystalline phases in cement paste and their modifications.

Conclusion: A Foundation for a Sustainable Future

The Future of Construction

The fusion of recycled PET plastic and high-tech carbon nanotubes represents more than just incremental improvement in concrete. It's a paradigm shift. By transforming waste plastic into a valuable reinforcement and leveraging the incredible power of nanotechnology, we are developing a new generation of concrete that is significantly stronger, potentially lighter, and far more sustainable.

Key Achievement

The impressive 28% boost in compressive strength seen in hybrid samples is just the beginning.

Environmental Impact

This research tackles the twin environmental challenges of construction emissions and plastic pollution head-on.

While challenges remain – particularly in scaling up CNT dispersion economically and ensuring long-term durability – the path forward is clear. The concrete jungles of tomorrow might just be built, in part, from the plastic bottles of today, reinforced by the invisible strength of carbon nanotubes, creating a literally stronger foundation for our planet.