Molecular Dynamics Simulations in Polymer Electrolyte Membrane Fuel Cells: A Comprehensive Guide for Researchers

This article provides a detailed exploration of Molecular Dynamics (MD) simulations as a critical tool for advancing Polymer Electrolyte Membrane Fuel Cell (PEMFC) technology.

Molecular Dynamics Simulations in Polymer Electrolyte Membrane Fuel Cells: A Comprehensive Guide for Researchers

Abstract

This article provides a detailed exploration of Molecular Dynamics (MD) simulations as a critical tool for advancing Polymer Electrolyte Membrane Fuel Cell (PEMFC) technology. Targeted at researchers, scientists, and materials development professionals, it covers foundational principles, practical methodologies, common challenges, and validation techniques. The scope includes understanding nanoscale transport phenomena, optimizing membrane and catalyst materials, troubleshooting simulation pitfalls, and comparing MD results with experimental data to accelerate the rational design of next-generation PEMFC components.

Unlocking the Nanoscale: Foundational Principles of MD for PEMFCs

Application Notes: Core Insights from Recent Studies

Atomistic Molecular Dynamics (MD) simulations have become indispensable for polymer electrolyte membrane fuel cell (PEMFC) research, providing insights into nanoscale phenomena inaccessible to experimentation alone. These simulations elucidate the structure, dynamics, and transport properties of key components like hydrated Nafion membranes, catalyst layers, and catalyst-ionomer interfaces.

Table 1: Key Quantitative Insights from Recent MD Studies in PEMFCs (2023-2024)

| System Simulated | Primary Observables | Key Quantitative Finding | Impact on PEMFC Performance |

|---|---|---|---|

| Hydrated Nafion (SO3H-/H3O+) | Proton diffusivity, water network connectivity | Proton conductivity peaks at λ (H2O/SO3-) ~15-20, reaching ~0.25 S/cm. | Explains optimal hydration for membrane performance. |

| Pt(111)/Nafion interface | Oxygen adsorption energy, ionomer coverage | Ionomer adsorption reduces O2 adsorption energy by ~0.2 eV, increasing ORR overpotential. | Directly models catalyst poisoning at the interface. |

| Graphene-coated Pt catalysts in ionomer | O2 permeability near surface | Graphene overlayer can increase local O2 concentration by up to 300% vs. bare Pt/Nafion. | Informs design of corrosion-resistant, high-access catalysts. |

| Degraded Nafion (S=O formation) | Sulfonic acid group acidity (pKa), hydration shell | Mechanical stress can alter pKa by up to 2 units, reducing proton dissociation. | Models chemical degradation pathways under operation. |

Experimental Protocols for Validating MD Predictions

Protocol 2.1: Validating Simulated Proton Conductivity via Electrochemical Impedance Spectroscopy (EIS)

Objective: To experimentally measure the proton conductivity of a hydrated Nafion membrane under controlled conditions for comparison with MD-calculated diffusivity. Materials: Nafion 117 membrane, conductivity cell, potentiostat with EIS capability, temperature-controlled bath, deionized water.

- Membrane Pre-treatment: Boil Nafion in 3% H2O2, rinse in DI water, boil in 0.5M H2SO4, then rinse and store in DI water.

- Hydration Control: Place membrane in sealed chamber with saturated salt solutions or water vapor stream to achieve target water content (λ). Measure weight to confirm.

- EIS Measurement: Mount membrane in a 4-electrode conductivity cell. Apply a sinusoidal potential (10-100 mV) over a frequency range of 1 Hz to 1 MHz. Record impedance.

- Data Analysis: Extract the high-frequency resistance (R) from the Nyquist plot intercept. Calculate conductivity σ = L / (R * A), where L is electrode distance and A is membrane cross-sectional area.

- Comparison: Convert MD-calculated mean squared displacement (MSD) of hydronium ions to conductivity via the Nernst-Einstein relation for validation.

Protocol 2.2: Characterizing Pt/Ionomer Interface via X-ray Photoelectron Spectroscopy (XPS)

Objective: To characterize the chemical states and adsorption of ionomer components on a Pt catalyst surface, validating MD-predicted binding configurations. Materials: Pt catalyst thin film, Nafion ionomer solution, ultra-high vacuum XPS system, glove box.

- Sample Preparation: Sputter a clean Pt film on a conductive substrate. Drop-cast a dilute Nafion solution in a controlled environment (e.g., Ar glovebox). Anneal at 80°C for 1 hour.

- XPS Acquisition: Introduce sample into UHV chamber. Acquire survey scan, then high-resolution spectra for Pt 4f, C 1s, O 1s, F 1s, and S 2p regions.

- Data Analysis: Deconvolute the S 2p peak to identify signatures of sulfonate groups (SO3-, ~168-169 eV) and potential degradation products (e.g., SO2, ~167 eV). Analyze the Pt 4f shift to indicate electron interaction with adsorbed ionomer.

- Correlation: Compare the ratio of adsorbed species and Pt peak shifts with MD-predicted adsorption energies and coverage.

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 2: Essential Materials for MD-Informed PEMFC Experimental Research

| Item | Function/Description | Example Product/CAS |

|---|---|---|

| Perfluorosulfonic Acid (PFSA) Ionomer | Benchmark PEM material for simulation validation and membrane assembly. | Nafion NR211 membrane, 1100 EW. CAS: 66796-30-3. |

| Pt/C Catalyst | Standard cathode catalyst for studying ORR kinetics and ionomer/catalyst interfaces. | 40-60 wt% Pt on Vulcan XC-72R. |

| Quinoline Yellow Dye Analogs | Fluorescent probes for experimental mapping of local pH within operating PEMFCs. | 8-Hydroxypyrene-1,3,6-trisulfonic acid (HPTS), CAS: 6358-69-6. |

| Solid-State NMR Probeheads | For measuring dynamics of water and ions in membranes, directly comparable to MD trajectories. | MAS probeheads for 1H, 19F, 17O NMR. |

| Molecular Simulation Software | Platform for running atomistic and reactive MD simulations. | GROMACS, LAMMPS, CP2K (for ReaxFF). |

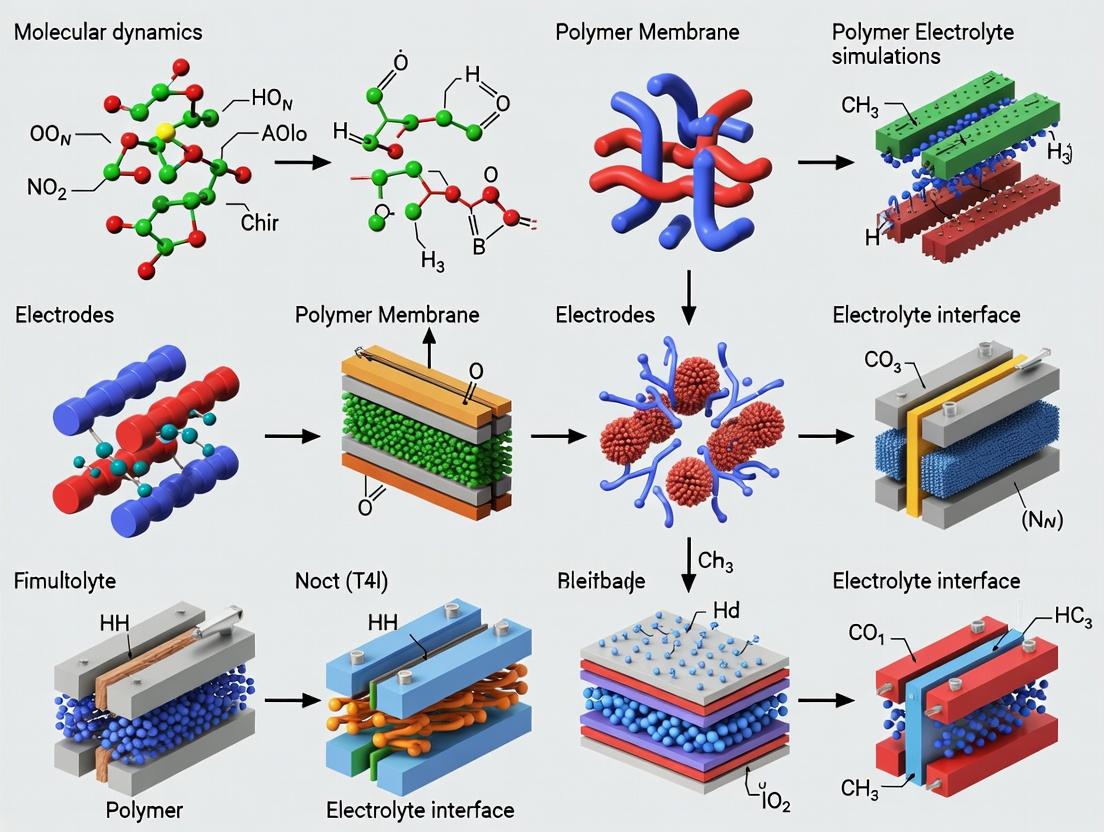

Visualization of Key Concepts and Workflows

Title: How MD Simulations Inform PEMFC Design

Title: MD Simulation and Experimental Validation Protocol

Molecular dynamics (MD) simulations are a cornerstone of modern computational materials science, providing atomistic insights into structure, dynamics, and transport phenomena. Within the broader thesis on MD for polymer electrolyte membrane fuel cells (PEMFCs), this document details application notes and protocols for simulating its core components: the perfluorosulfonic acid (PFSA) polymer membrane, ionomeric fragments within catalyst layers, water, and hydronium ions. Understanding their nanoscale interactions is critical for rational design of next-generation membranes with enhanced proton conductivity and durability at low hydration.

Application Notes & Quantitative Data

Recent MD studies focus on quantifying the interplay between polymer morphology, hydration level (λ = number of H₂O per sulfonic acid group), and ion transport. Key performance metrics are summarized below.

Table 1: Key Quantitative Metrics from MD Simulations of PFSA Membranes (e.g., Nafion)

| Metric | Typical Range/Value | Hydration (λ) Dependence | Simulation Notes |

|---|---|---|---|

| Proton Diffusion Coefficient (D_H⁺) | 0.1 - 2.0 x 10⁻⁵ cm²/s | Increases exponentially with λ (λ=5 to λ=20) | Vehicle (H₃O⁺) and Grotthuss hopping mechanisms must be analyzed. |

| Water Diffusion Coefficient (D_H₂O) | 0.5 - 5.0 x 10⁻⁵ cm²/s | Increases linearly with λ | Lower than bulk water due to polymer confinement. |

| Mean Solvation Radius (H⁺ around SO₃⁻) | ~3.5 - 4.5 Å | Decreases with increasing λ | Indicates ion pair dissociation. |

| Water Clustering/Pore Diameter | 1 - 4 nm | Increases with λ | Percolated network forms at λ > ~6. |

| Membrane Density | ~1.6 - 2.0 g/cm³ | Slight decrease with λ | Validates force field against experimental data. |

Table 2: Essential Research Reagent Solutions & Materials for MD Studies

| Item Name/Type | Function in MD Research | Example (Specific) |

|---|---|---|

| Atomic Force Field | Defines potential energy functions for interatomic interactions. | OPLS-AA, COMPASS, ReaxFF (for bond breaking), specific PFSA parameters. |

| Polymer Topology File | Defines the initial connectivity, atom types, and bonds of the polymer. | Pre-equilibrated Nafion chain (e.g., (CF2-CF2)n-CF2-CF(OCF2CF(CF3)OCF2CF2SO3H)). |

| Simulation Software Suite | Engine for performing energy minimization, dynamics, and analysis. | GROMACS, LAMMPS, NAMD, Desmond. |

| Visualization & Analysis Tool | For trajectory inspection, rendering, and quantitative calculation. | VMD, PyMOL, MDAnalysis, in-house scripts. |

| Validation Dataset | Experimental data for validating simulation predictions. | XRD/SAXS spectra (d-spacing), QENS diffusion coefficients, NMR chemical shifts. |

Detailed Experimental Protocols

Protocol 3.1: Building and Equilibrating a Hydrated PFSA Membrane System

Objective: To construct a representative atomistic model of a hydrated ionomer membrane for subsequent production MD.

Materials: Polymer topology file, force field parameters, water model (e.g., SPC/E, TIP3P), neutralizing counterions (H₃O⁺/Na⁺).

Methodology:

- Initial Configuration: Use

PACKMOLor in-build tools to place 4-8 pre-equilibrated PFSA oligomers (DP~10-20) in a simulation box. Ensure random orientation to avoid bias. - Neutralization: Replace acidic H⁺ of SO₃H groups with hydronium ions (H₃O⁺) or other cations (e.g., Na⁺ for study of ion form).

- Hydration: Randomly insert water molecules into the box to achieve the target hydration level λ (e.g., λ=9, 16, 22). Use

GROMACSgmx insert-moleculesor equivalent. - Energy Minimization: Perform steepest descent or conjugate gradient minimization (force tolerance < 1000 kJ/mol/nm) to remove bad contacts.

- Stepwise Equilibration: a. NVT Ensemble (100 ps): Hold volume constant, gradually heat system from 10 K to target temperature (e.g., 353 K) using Berendsen thermostat. b. NPT Ensemble (5-10 ns): Apply isotropic (or semi-isotropic) barostat (Parrinello-Rahman) to achieve target density (~1.9 g/cm³ for Nafion). This is the critical phase for achieving experimental density.

- Validation: Check final density, potential energy stability, and radial distribution functions (RDFs) for key atom pairs (e.g., S-S for ion clustering).

Protocol 3.2: Calculating Transport Properties (Diffusion Coefficients)

Objective: To compute the mean squared displacement (MSD) and derived diffusion coefficients for water and ions from a production MD trajectory.

Materials: A fully equilibrated and stable production trajectory (≥50 ns), analysis software.

Methodology:

- Production Run: Perform extended MD simulation (50-200 ns) in the NPT ensemble at target T & P. Save trajectory frames every 10-100 ps.

- Trajectory Processing: Center system and remove periodic boundary jumps using

gmx trjconvor equivalent. - MSD Calculation: For species α (e.g., O of H₂O, O of H₃O⁺), calculate the MSD:

<r²(t)> = (1/N) * Σ [r_i(t + t0) - r_i(t0)]²Usegmx msdor a custom script. Use the linear regime of the MSD vs. time plot (typically after ~1 ns). - Diffusion Coefficient: Fit the MSD to the Einstein relation in 3D: D_α = (1/6) * slope of

<r²(t)>vs.t. - Error Estimation: Perform block-averaging by splitting the trajectory into 3-5 blocks and calculating standard deviation of the D values.

Mandatory Visualizations

Diagram 1: Core Components and Goals in PEMFC MD Thesis.

Diagram 2: MD Simulation Workflow for Membrane Systems.

Molecular dynamics (MD) simulations are a cornerstone of modern computational materials science for polymer electrolyte membrane fuel cells (PEMFCs). The accuracy of these simulations is fundamentally governed by the chosen force field—a mathematical model describing the potential energy of a system of atoms. This application note details the key classical force fields (AMBER, CHARMM, OPLS) and emerging reactive potentials, framing their use within a thesis focused on optimizing PEMFC components, such as hydronium ion diffusion in hydrated Nafion membranes, oxygen reduction reaction kinetics at catalyst surfaces, and membrane degradation mechanisms.

Key Force Fields: Comparison and Application

Classical Non-Reactive Force Fields

These force fields describe bonded and non-bonded interactions using fixed harmonic potentials and point charges. They are efficient for studying structure, dynamics, and thermodynamics at the nanoscale.

Table 1: Comparison of Key Classical Force Fields for PEMFC Simulations

| Force Field | Full Name | Primary Developer(s) | Key Functional Form Highlights | Common PEMFC Applications | Example Parameters for Nafion |

|---|---|---|---|---|---|

| AMBER | Assisted Model Building with Energy Refinement | Kollman et al. | E = Σ bonds kb(r-r0)² + Σ angles kθ(θ-θ0)² + Σ dihedrals Vn/2[1+cos(nφ-γ)] + Σ [Aij/Rij¹² - Bij/Rij⁶ + qiqj/εRij] | Hydrated membrane morphology, water channel formation, hydronium transport. | GAFF (General AMBER Force Field) with RESP charges for sulfonate groups. |

| CHARMM | Chemistry at HARvard Macromolecular Mechanics | Karplus et al. | Similar harmonic form. Distinguishes via detailed parameterization philosophy (condensed phase targets). Includes cross-term maps (CMAP). | Ionomer structure near Pt catalysts, water uptake studies, interfacial properties. | C36 lipid parameters adapted for fluorinated backbone, custom sulfonate parameters. |

| OPLS | Optimized Potentials for Liquid Simulations | Jorgensen et al. | Emphasis on accurate reproduction of liquid-state properties (densities, heats of vaporization). Unified atom/all-atom versions. | Diffusion coefficients of water/oxygen in membranes, solvation free energies of reactants. | OPLS-AA parameters for perfluoroether, tuned Lennard-Jones for SO₃⁻. |

Reactive Force Fields

Reactive force fields (ReaxFF) describe bond formation and breaking by making bond order a continuous function of interatomic distance, enabling the simulation of chemical reactions.

Table 2: Reactive Force Field (ReaxFF) for PEMFC Studies

| Feature | Description | Relevance to PEMFC |

|---|---|---|

| Bond Order | Calculated from interatomic distances, allowing bonds to form/break dynamically. | Simulating membrane chemical degradation (e.g., radical attack on polymer), ORR at Pt surfaces, Pt dissolution. |

| Polarization | Dynamic charge equilibration (e.g., QEq) at each step based on geometry. | Accurate modeling of proton transfer (Grotthuss mechanism) in water-filled channels. |

| Parameter Sets | Trained against quantum mechanical data for specific element sets (e.g., C/H/O, C/H/O/F/S, Pt/C/H/O). | Requires a parameter file specific to the chemical system (e.g., Nafion membrane, Pt catalyst). |

| Computational Cost | ~10-50x more expensive than classical non-reactive MD. | Typically limits systems to thousands of atoms and simulation times to nanoseconds. |

Application Protocols

Protocol: Simulating Hydronium Diffusion in Hydrated Nafion using AMBER/CHARMM

Objective: Calculate the diffusion coefficient (D_H3O+) of hydronium ions within a hydrated Nafion membrane at various water content levels (λ = H2O/SO3H).

Required Software: AMBER, GROMACS, or NAMD. Force Field: AMBER GAFF or CHARMM36.

Steps:

- System Building:

- Construct a Nafion oligomer (e.g., (CF2-CF2)n-CF-CF2-O-(CF2)2-SO3H) using polymerization tools.

- Place multiple oligomers in a simulation box using Packmol, ensuring periodic boundary conditions.

- Add water molecules (TIP3P/SPC/E) corresponding to the target λ value (e.g., λ = 5, 9, 15).

- Replace a stoichiometric number of water molecules with hydronium ions (H3O+) to achieve system neutrality.

- Parameterization:

- Assign classical force field parameters (GAFF/CHARMM36). Derive partial atomic charges for the sulfonate group using quantum chemistry (e.g., Gaussian) and RESP/HF methods.

- Equilibration (NPT ensemble):

- Minimization: 5000 steps of steepest descent to remove bad contacts.

- Heating: Gradually heat from 0 K to 353 K (typical PEMFC operating temperature) over 100 ps using a weak coupling thermostat (Berendsen/Langevin).

- Density Equilibration: Run a 2-5 ns simulation at 353 K and 1 atm (using Berendsen/Parinello-Rahman barostat) until box dimensions stabilize.

- Production Run (NVT ensemble):

- Perform a 50-100 ns MD simulation at 353 K, saving atomic coordinates every 1-10 ps.

- Analysis:

- Diffusion Coefficient: Calculate the Mean Squared Displacement (MSD) of hydronium oxygen atoms over time. Use the Einstein relation: D = (1/6) * lim_{t→∞} d(MSD)/dt. Perform this for each λ value.

Protocol: Simulating Membrane Degradation via Reactive Force Field (ReaxFF)

Objective: Observe initial chemical degradation events in a Nafion membrane under an oxidative environment.

Required Software: LAMMPS (with ReaxFF package).

Force Field: ReaxFF parameter set for C/H/O/F/S (e.g., Chenoweth2008_C/H/O.ff or similar, extended for F/S).

Steps:

- System Preparation:

- Build a small hydrated Nafion system (few oligomers, λ=3-5) in a periodic box.

- Introduce hydroxyl radicals (•OH) near sulfonate groups or polymer backbone (e.g., 5-10 radicals) to simulate radical attack.

- ReaxFF Simulation:

- Minimization: Use a conjugate gradient algorithm to minimize energy.

- NVT Dynamics: Run at elevated temperature (e.g., 2000-3000 K for tens of picoseconds) to accelerate reaction kinetics, or at operational temperature (353 K) for longer (ns) timescales.

- Trajectory Saving: Save trajectory frequently (every 5-10 fs) to capture bond-breaking events.

- Analysis:

- Bond Analysis: Use tools like

bondorder.reaxin LAMMPS or Python scripts to track the breaking of C-S, C-O, or C-F bonds over time. - Species Tracking: Monitor the formation of degradation products like SO4²⁻, HF, CO2, or smaller polymer fragments.

- Bond Analysis: Use tools like

Visualizations

Decision Workflow for PEMFC Force Field Selection

ReaxFF Protocol for Simulating Membrane Degradation

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Computational "Reagents" for PEMFC MD Simulations

| Item/Software | Type | Function in PEMFC Research |

|---|---|---|

| GROMACS | MD Simulation Engine | High-performance, open-source software for running classical MD simulations of hydrated membranes and calculating transport properties. |

| LAMMPS | MD Simulation Engine | Open-source engine with extensive support for reactive force fields (ReaxFF), essential for chemical degradation studies. |

| AmberTools | Simulation Suite | Provides tools for system preparation (tleap), parameterization (antechamber), and analysis for AMBER force field simulations. |

| CHARMM-GUI | Web-Based Interface | Facilitates the building of complex PEMFC membrane and interface systems with CHARMM force field parameters. |

| Packmol | Packing Tool | Fills simulation boxes with molecules (polymer, water, ions) to create initial configurations for membrane models. |

| VMD | Visualization/Analysis | Critical for visualizing MD trajectories, analyzing pore morphology, water channel networks, and creating publication-quality figures. |

| ReaxFF Parameter Set (e.g., C/H/O/F/S) | Force Field File | Contains all parameters (bond, angle, torsion, QEq) required to run a reactive simulation for a specific chemical system. |

| Quantum Chemistry Software (Gaussian, ORCA) | Electronic Structure | Used to generate target data (energies, charges, geometries) for training or validating force field parameters, especially for reactive studies. |

Application Notes

These application notes detail the investigation of critical phenomena—hydration, proton transport, and gas diffusion—within Polymer Electrolyte Membranes (PEMs) using Molecular Dynamics (MD) simulations. This work supports a broader thesis on MD for PEM Fuel Cell (PEMFC) research, providing atomistic insights critical for optimizing membrane materials.

Hydration: Water content, expressed as λ (number of H₂O molecules per sulfonic acid group, -SO₃H), fundamentally dictates membrane morphology (separation of hydrophilic/hydrophobic domains) and subsequent transport properties.

Proton Transport: Occurs via two primary mechanisms: the Vehicular mechanism (H₃O⁺ diffusion) and the Grotthuss mechanism (proton hopping via hydrogen bond networks). Their relative contribution is highly λ-dependent.

Gas Diffusion: Permeation of H₂ and O₂ through the membrane is a critical loss phenomenon. It occurs primarily through the hydrophobic polymer backbone domains and is influenced by hydration (swelling) and temperature.

Key Quantitative Relationships:

- Proton conductivity increases exponentially with λ up to saturation.

- Gas permeability (especially O₂) increases with membrane swelling at high λ but can be minimized with optimized polymer architecture.

- The balance between high proton conductivity (needs water) and low gas crossover (limited by water) defines the operational optimization window.

Table 1: Proton Conductivity & Transport Properties vs. Hydration Level (λ) for Nafion at 300K

| Hydration Level (λ) | Dominant Proton Transport Mechanism | Approx. Proton Conductivity (S/cm) | Mean Squared Displacement (H₃O⁺) (Ų/ps) | Hydronium Diffusion Coefficient (10⁻⁶ cm²/s) |

|---|---|---|---|---|

| λ = 3 | Vehicular | ~0.02 | 0.05 - 0.1 | 1.5 - 2.5 |

| λ = 5 | Mixed Vehicular/Grotthuss | ~0.05 | 0.1 - 0.3 | 3.0 - 5.0 |

| λ = 9 | Grotthuss-dominated | ~0.10 | 0.3 - 0.6 | 5.0 - 8.0 |

| λ = 15 | Extended Grotthuss Network | ~0.15 | 0.5 - 1.0 | 7.0 - 12.0 |

Table 2: Gas Solubility & Diffusion in Nafion at 353K (80°C)

| Gas Species | Solubility Coefficient (mol/m³Pa) [Dry] | Solubility Coefficient (mol/m³Pa) [λ=5] | Diffusion Coefficient (10⁻¹¹ m²/s) [Dry] | Diffusion Coefficient (10⁻¹¹ m²/s) [λ=5] | Permeability (Barrer) [λ=5] |

|---|---|---|---|---|---|

| H₂ | 1.2 x 10⁻⁶ | 1.0 x 10⁻⁶ | 150 - 200 | 80 - 120 | 50 - 80 |

| O₂ | 2.5 x 10⁻⁶ | 2.0 x 10⁻⁶ | 20 - 40 | 10 - 20 | 12 - 25 |

| N₂ | 1.1 x 10⁻⁶ | 0.9 x 10⁻⁶ | 10 - 20 | 5 - 10 | 3 - 7 |

Experimental Protocols

Protocol 1: MD Simulation of Hydration-Dependent Proton Transport

Objective: To calculate the proton diffusion coefficient and elucidate the transport mechanism as a function of water content (λ).

Methodology:

- System Building: Construct a simulation cell with a pre-equilibrated polymer matrix (e.g., Nafion, sulfonated poly(ether ether ketone) (SPEEK)). Randomly replace H⁺ on -SO₃H groups with hydronium ions (H₃O⁺) to maintain charge neutrality. Insert water molecules using packing algorithms (e.g., PACKMOL) to achieve target λ values (λ = 3, 5, 9, 15).

- Energy Minimization: Perform steepest descent/conjugate gradient minimization to remove bad contacts.

- Equilibration:

- NVT Ensemble: Equilibrate for 500 ps at target temperature (e.g., 300K, 353K) using a thermostat (e.g., Nosé-Hoover).

- NPT Ensemble: Equilibrate for 2-5 ns at target temperature and pressure (1 atm) using a barostat (e.g., Parrinello-Rahman) to achieve correct density.

- Production Run: Conduct an NPT simulation for 20-100 ns, saving trajectories every 1-10 ps.

- Analysis:

- Mean Squared Displacement (MSD): Calculate MSD of hydronium oxygens and water oxygens. Extract diffusion coefficients (D) via Einstein relation: D = (1/6) * slope(MSD vs. time).

- Proton Hopping Analysis: Identify Grotthuss events by tracking the reformation of H₃O⁺ from H₂O and the breaking/forming of O-H covalent bonds (e.g., using coordination number analysis).

- Conductivity Calculation: Use the Nernst-Einstein relation: σ = (ρ * e² / kBT) * Σ (zᵢ² * Dᵢ), where ρ is charge carrier density, or use Green-Kubo formalism for more accuracy.

Protocol 2: MD Simulation of Gas Solubility and Diffusion

Objective: To determine the solubility and diffusivity of O₂, H₂, and N₂ in hydrated PEMs.

Methodology:

- System Preparation: Start with an equilibrated, hydrated membrane system from Protocol 1 (λ=5).

- Gas Insertion: Use the Grand Canonical Monte Carlo (GCMC) method to insert gas molecules into the membrane at a specified chemical potential (related to gas pressure). Alternatively, insert a small number of gas molecules (5-10) randomly.

- Equilibration: Run a 5-10 ns NPT simulation to allow gas distribution within the polymer.

- Production Run: Perform a 50-200 ns NVT simulation for diffusion analysis.

- Analysis:

- Solubility Coefficient: From GCMC, it's directly obtained as s = ⟨N⟩ / (V * P), where ⟨N⟩ is average number of sorbed molecules, V is volume, P is pressure. From MD, use particle insertion methods (Widom's test particle method).

- Diffusion Coefficient: Calculate MSD of gas molecules' center of mass. Use D = (1/6) * slope(MSD vs. time) in the diffusive regime. Ensure gas molecules do not interact with their periodic images.

- Permeability: Calculate as P = s * D.

Visualizations

Diagram Title: MD Workflow for Proton Transport Analysis

Diagram Title: Hydration Dependence of Proton Transport Mechanisms

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for MD Studies of PEM Phenomena

| Item | Function in Research | Example/Note |

|---|---|---|

| Polymer Force Fields | Defines interactions (bonded/non-bonded) for polymer, water, and ions. Critical for accuracy. | OPLS-AA, DREIDING, COMPASS for polymers; SPC/E, TIP4P/2005 for water. |

| Specialized MD Software | Engine for running simulations with needed algorithms and analysis tools. | GROMACS (efficiency), LAMMPS (flexibility), NAMD (scalability), DESMOND (user-friendly). |

| Trajectory Analysis Tools | Post-processing of simulation data to extract diffusion, coordination, density profiles. | MDAnalysis (Python), VMD (visualization & scripting), MDTraj (Python), in-built tools. |

| Quantum Chemistry Software | Parameterizing force fields or performing QM/MM for proton hopping events. | Gaussian, ORCA, CP2K (for DFT-MD). |

| System Building Suites | Creates initial, solvated, and equilibrated molecular systems for simulation. | PACKMOL, CHARMM-GUI, Materials Studio, Polyply. |

| High-Performance Computing (HPC) Cluster | Essential for simulating large systems (10⁴-10⁵ atoms) over relevant timescales (>>100 ns). | Linux-based clusters with GPU acceleration (e.g., NVIDIA A100/V100). |

This application note provides the foundational protocol for constructing molecular dynamics (MD) simulation systems relevant to Polymer Electrolyte Membrane Fuel Cell (PEMFC) components. Within the broader thesis on MD for PEMFC research, this guide focuses on the initial, critical step of system assembly, encompassing membrane, hydronium ions, water, and catalyst surface models. Accurate system setup is paramount for subsequent studies of proton transport, water dynamics, and interfacial phenomena.

Core System Components and Parameters

The initial simulation box must represent a trifecta of the PEMFC environment: the hydrated ionomer membrane, the ionomer/catalyst interface, and the aqueous phase. Key quantitative considerations are summarized below.

Table 1: Standard Initial System Parameters for PEMFC-Relevant MD Simulations

| Component / Parameter | Typical Value / Description | Rationale / Notes |

|---|---|---|

| Ionomer (e.g., Nafion) | 10-20 repeat units (SO3H terminated) | Balance between computational cost and representative behavior. |

| Hydration Level (λ) | λ = 3, 9, 15, 20 (H2O/SO3-) | Covers conditions from dry to well-hydrated. λ is a critical variable. |

| Charge Neutralization | H3O+ counterions (1 per SO3-) | Represents acidic environment. Often exchanged for other cations (e.g., Na+) for control studies. |

| Excess Water Molecules | Varies by λ; e.g., λ=9: ~180 H2O per 20-mer | Added to achieve target hydration level. Use TIP3P or SPC/E water model. |

| Catalyst Surface Model | Pt(111) slab, 3-5 atomic layers, ~ 40 Å x 40 Å | Common, stable face for Pt catalysts. Frozen bottom layers. |

| Simulation Box Dimensions | ~ 50 Å x 50 Å x 80-100 Å | Must accommodate ionomer, water, and vacuum/air gap for interface studies. |

| Force Field | OPLS-AA/COMPASS for ionomer; Interface FF (e.g., Pt parameters) | Consistency between organic, ion, and metal parts is critical. |

Protocol: Building a Hydrated Ionomer System

This protocol details the steps to create a simulation box containing a hydrated Nafion-like ionomer strand, a common starting point.

Step 1: Ionomer Construction and Preparation

- Build a short-side-chain perfluorosulfonic acid (PFSA) ionomer using chemical building software (e.g., Materials Studio, Packmol, or manually in VMD). A typical 20-mer with -CF2-CF(CF3)-O-CF2-CF2-SO3H side chains is standard.

- Assign protonation states: Each terminal sulfonic acid (-SO3H) group should be deprotonated to -SO3-.

- Energy-minimize the initial structure using a consistent force field (e.g., OPLS-AA with L*-type parameters for perfluoroether) in vacuum to remove bad contacts.

Step 4: Solvation and Neutralization

- Calculate the number of water molecules (Nwater) required for the target hydration level λ: Nwater = λ * NSO3, where NSO3 is the number of sulfonate groups.

- Add N_water molecules to the simulation box using a solvation algorithm (e.g.,

solvateplugin in VMD,Packmol). - Add hydronium ions (H3O+) to neutralize the system's net charge from the -SO3- groups. In practice, replace a corresponding number of water molecules with H3O+ ions to maintain the correct total water count for λ. Parameterize H3O+ using a validated model (e.g., the modified TIP3P-based model).

Step 5: System Assembly and Equilibration

- Place the ionomer, water, and ions in a rectangular simulation box with periodic boundary conditions.

- Perform a multi-stage equilibration using a MD engine (NAMD, GROMACS, LAMMPS):

- Stage 1 (Minimization): 5,000-10,000 steps of steepest descent/ conjugate gradient minimization.

- Stage 2 (NVT): Heat system from 1 K to target temperature (e.g., 353 K) over 100 ps, using a small timestep (0.5 fs) and heavy atom restraints on the ionomer.

- Stage 3 (NPT): Release restraints and run for 1-5 ns at target temperature and pressure (1 bar) using a Nosé–Hoover thermostat and Parrinello–Rahman barostat. Use a 1-2 fs timestep.

- Monitor density, potential energy, and temperature for convergence.

Protocol: Incorporating a Catalyst Interface

To model the catalyst-ionomer interface, a metal slab must be introduced.

Step 1: Catalyst Slab Creation

- Generate a Pt(111) slab using crystal building tools. A typical size is 4 nm x 4 nm with 3-5 atomic layers.

- Assign force field parameters. The "Pt/OPLS-AA" compatible parameters (from the literature) are often used, treating Pt as uncharged Lennard-Jones particles with specific σ and ε values.

- Fix the bottom 2-3 layers of Pt atoms in place to mimic the bulk catalyst support.

Step 2: Interface System Assembly

- Create a large simulation box (e.g., 5 nm x 5 nm x 12 nm). Place the Pt slab at the bottom (z=0).

- Position the pre-equilibrated, hydrated ionomer system (from Protocol 3) above the Pt slab, ensuring no initial covalent overlaps. An air/vacuum gap of 1-2 nm should be left at the top of the box.

- This creates a two-phase system: a dense ionomer/water phase near the Pt and a vapor phase. Alternatively, a fully solvated three-phase system (Pt | Ionomer/Water | Bulk Water) can be constructed for studying swelling.

Step 3: Equilibration of the Interface System

- Minimize the entire system with strong positional restraints on Pt atoms and backbone of the ionomer.

- Perform a staged NVT equilibration, gradually heating and releasing restraints on the ionomer side chains and water.

- Run a final NVT or NPT production simulation (10-50 ns). For interfacial studies, the semi-isotropic pressure coupling (xy independent from z) may be used to allow the interface to relax.

Workflow for PEMFC MD System Setup

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Computational Materials for PEMFC MD Simulations

| Item | Function / Description | Example / Note |

|---|---|---|

| Force Field for Ionomer | Defines potential energy terms for bonded/non-bonded interactions. Critical for accuracy. | OPLS-AA with L* params; COMPASS III; ReaxFF for reactive processes. |

| Water Model | Represents water molecules and their interactions with ions and polymer. | TIP3P, SPC/E. Polarizable models (e.g., SWM4-NDP) for higher accuracy at cost. |

| Hydronium Ion Model | Parameter set for H3O+ to simulate proton transport via Grotthuss mechanism. | Multistate Empirical Valence Bond (MS-EVB) is state-of-the-art. Modified rigid TIP3P is a simpler alternative. |

| Metal Catalyst Parameters | Lennard-Jones parameters for Pt, C, Au etc., compatible with the organic force field. | Common literature values: ε~0.5 kJ/mol, σ~2.4-2.5 Å for Pt. |

| Simulation Software | MD engine to perform energy minimization, equilibration, and production runs. | GROMACS (free), NAMD (free for academics), LAMMPS (free), Desmond (commercial). |

| System Building Tool | Software to construct initial molecular structures and assemble simulation boxes. | Packmol (free), Moltemplate, CHARMM-GUI, Materials Studio (commercial). |

| Visualization & Analysis Tool | For monitoring simulations, rendering structures, and calculating properties. | VMD (free), PyMol (commercial/free), MDANALYSIS (Python library). |

PEMFC Proton Transport and Reaction

From Theory to Practice: Methodologies and Cutting-Edge Applications

Application Notes

Within the broader thesis research on Molecular Dynamics (MD) simulations for polymer electrolyte membrane fuel cells (PEMFCs), the proper initialization and equilibration of the simulation system are critical for generating physically meaningful trajectories. This protocol outlines the essential three-stage workflow—energy minimization, equilibration, and production—specifically contextualized for simulating components like hydrated Nafion membranes, catalyst layers with platinum nanoparticles, or interfacial systems. This foundational procedure ensures the stability of the simulation, removes unrealistic atomic clashes from initial configuration, and gradually brings the system to the desired thermodynamic state before data collection for analyzing properties such as proton conductivity, water diffusion, or oxygen transport.

Protocols & Detailed Methodologies

Energy Minimization

Objective: Relieve severe steric clashes and high potential energy resulting from initial system construction (e.g., packing polymer chains, solvent molecules, and ions).

- System Setup: Construct the initial configuration (e.g., hydrated PEM membrane). Define the simulation box with periodic boundary conditions. Set the force field parameters (e.g., OPLS-AA, CHARMM, or specific polymer force fields).

- Minimization Algorithm: Use the steepest descent algorithm for the first 50-100 steps, followed by the conjugate gradient algorithm until convergence.

- Convergence Criteria: Terminate minimization when the energy change between steps is less than 1000 kJ/mol/nm (for steepest descent) and the maximum force on any atom is below 10.0 kJ/mol/nm (for conjugate gradient).

- Software Commands (GROMACS example):

System Equilibration

Objective: Gently relax the minimized system to the target temperature and pressure/density while restraining solute (e.g., polymer backbone, catalyst surface) positions.

- Protocol (NVT then NPT):

- Phase 1: NVT (Constant Number, Volume, Temperature)

- Duration: 100 ps.

- Thermostat: Berendsen or velocity rescale (V-rescale) thermostat, coupling polymer and solvent/ions separately.

- Target Temperature: 300 K.

- Position Restraints: Apply harmonic restraints to heavy atoms of the polymer membrane or catalyst nanoparticle (force constant 1000 kJ/mol/nm²).

- Phase 2: NPT (Constant Number, Pressure, Temperature)

- Duration: 1-5 ns (longer for dense polymer systems).

- Thermostat: V-rescale or Nosé-Hoover thermostat (300 K).

- Barostat: Berendsen (initial) followed by Parrinello-Rahman barostat for stable pressure coupling.

- Target Pressure: 1 bar.

- Restraints: Gradually reduce or remove position restraints in subsequent NPT steps.

- Phase 1: NVT (Constant Number, Volume, Temperature)

- Validation: Monitor potential energy, temperature, pressure, density, and system volume time series for stability.

Production MD Run

Objective: Conduct an unrestrained, microsecond-scale simulation for data collection and analysis of equilibrium and dynamic properties.

- Duration: 100 ns to 1 µs, dependent on property of interest (e.g., longer for polymer chain relaxation).

- Ensemble: NPT ensemble.

- Integration: Leap-frog algorithm with a time step of 2 fs. Use LINCS constraints for bonds involving hydrogen.

- Electrostatics: Particle Mesh Ewald (PME) method.

- Neighbor Searching: Verlet list, updated every 20 steps.

- Trajectory Output: Save coordinates every 10-100 ps (balance disk space and temporal resolution).

- Software Commands (GROMACS example):

Data Presentation

Table 1: Summary of Key Simulation Parameters for PEMFC MD Protocols

| Stage | Ensemble | Duration | Thermostat/Barostat | Key Restraints | Primary Goal |

|---|---|---|---|---|---|

| Energy Minimization | N/A | Until convergence | None | None | Remove steric clashes, minimize energy |

| Equilibration (NVT) | NVT | 100 ps | V-rescale (τ_t = 0.1 ps) | Heavy atoms (fc=1000) | Reach target temperature |

| Equilibration (NPT) | NPT | 1-5 ns | V-rescale (τt=0.1 ps), Parrinello-Rahman (τp=2.0 ps) | Reduced/removed | Reach target density & pressure |

| Production | NPT | 100 ns - 1 µs | Nosé-Hoover (τt=1.0 ps), Parrinello-Rahman (τp=5.0 ps) | None | Sample equilibrium properties |

Visualization

Title: MD Simulation Protocol Workflow for PEMFC Research

Title: Key PEMFC Components and Simulated Properties

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions & Materials for PEMFC MD Simulations

| Item | Function/Description |

|---|---|

| Force Fields (e.g., OPLS-AA, CHARMM, ReaxFF) | Defines potential energy functions (bonded/non-bonded) for atoms in the system. Crucial for accurate modeling of polymers, water, ions, and metal surfaces. |

| Polymer Structure Files (e.g., Nafion.pdb) | Initial atomic coordinates for the polymer electrolyte, often built using polymer modeling tools (e.g., Materials Studio, PACKMOL). |

| Topology Files | Contains system-specific force field parameters, bond connections, and molecule definitions. Links structure to the force field. |

| Water Models (e.g., SPC/E, TIP4P/2005) | Explicit solvent molecules for simulating hydration effects. Choice impacts diffusion and hydrogen bonding network. |

| Ion Parameters (e.g., H3O+, SO3-, Pt) | Parameters for hydronium, sulfonate groups, and platinum atoms, essential for modeling proton transport and catalyst interfaces. |

| Simulation Software (e.g., GROMACS, LAMMPS, NAMD) | High-performance MD engine to execute energy minimization, equilibration, and production runs. |

| Trajectory Analysis Tools (e.g., VMD, MDAnalysis, in-house scripts) | For visualizing trajectories and calculating properties like Mean Squared Displacement (MSD), radial distribution functions (g(r)), and density profiles. |

| High-Performance Computing (HPC) Cluster | Necessary resource to run microsecond-scale simulations for adequately sampling polymer and transport phenomena. |

Within the broader thesis on Molecular Dynamics (MD) simulations for Polymer Electrolyte Membrane Fuel Cell (PEMFC) research, this application note details protocols for simulating three critical membrane properties: water uptake, proton conductivity, and methanol crossover. These properties are interdependent and fundamentally dictate the performance and efficiency of direct methanol fuel cells (DMFCs). MD simulations provide atomic-level insights into the underlying mechanisms, guiding the rational design of next-generation electrolyte membranes.

Core Simulation Protocols

Protocol A: Simulating Water Uptake and Swelling

Objective: To calculate the equilibrium water content (λ, H₂O/SO₃H) and volumetric swelling of a hydrated ionomer membrane (e.g., Nafion, sulfonated polyetheretherketone (SPEEK)).

System Construction:

- Build an atomistic model of a dry polymer chain (e.g., 10 repeating units) within a simulation box using tools like PACKMOL.

- Assign partial charges and force field parameters (e.g., OPLS-AA, COMPASS, GRASP).

- Insert a predetermined number of water molecules (corresponding to a target λ) randomly into the box.

Equilibration:

- Perform energy minimization using the steepest descent algorithm.

- Conduct an NVT ensemble simulation for 500 ps at 300 K (using a Nosé–Hoover thermostat) to equilibrate density.

- Perform an NPT ensemble simulation for 2-5 ns at 300 K and 1 atm (using a Parrinello–Rahman barostat) to achieve equilibrium box dimensions.

Production and Analysis:

- Run an NPT production simulation for 10-20 ns.

- Water Uptake (λ): Calculate the average number of water molecules within the first hydration shell of sulfonate groups or per polymer chain.

- Swelling Ratio: Compute as (Vhydrated / Vdry) from the average box volume of the hydrated and dry systems.

Protocol B: Calculating Proton Conductivity via the Vehicle and Grotthuss Mechanisms

Objective: To quantify proton diffusivity and estimate conductivity within the hydrated membrane.

System Preparation: Use the equilibrated hydrated system from Protocol A.

Charge Carrier Introduction: Replace a hydronium ion (H₃O⁺) for a water molecule to maintain system neutrality, or explicitly add excess protons.

Equilibration: Re-equilibrate the charged system in NPT for 1-2 ns.

Production Run: Perform a long-timescale NPT simulation (50-100 ns). Trajectories must be saved with high frequency (e.g., every 1 ps).

Analysis:

- Calculate the Mean Squared Displacement (MSD) of the center of mass of all hydronium ions (or of "tagged" protons based on coordination).

- Apply the Einstein relation to determine the proton diffusion coefficient (D_H⁺):

D_H⁺ = (1/6) * lim (t→∞) d(MSD)/dt - Estimate conductivity (σ) using the Nernst-Einstein relation:

σ = (ρ * (zF)² * D_H⁺) / (RT)where ρ is the charge carrier density, z is charge, F is Faraday's constant, R is the gas constant, and T is temperature.

Protocol C: Simulating Methanol Crossover

Objective: To model the transport of methanol and water from anode to cathode through the membrane.

System Setup: Construct a multilayer simulation cell: Water/Methanol mixture (anode) | Hydrated Membrane | Water (cathode).

Equilibration: Perform extensive NPT equilibration (5-10 ns) to establish a stable interface and realistic concentration gradients.

Non-Equilibrium MD (NEMD) or Equilibrium MD:

- NEMD Approach: Apply a chemical potential gradient or a pressure difference across the membrane. Monitor flux over 20-50 ns.

- Equilibrium Approach: Use a well-equilibrated system and calculate the permeability (P) from the solubility (S) and diffusivity (D):

P = S * D. Solubility is obtained from the concentration of permeant within the membrane, and diffusivity from its MSD.

Analysis:

- Track the number and position of methanol and water molecules as a function of time.

- Calculate the flux (J, molecules/ns/nm²) and the methanol crossover current density equivalent.

Table 1: Representative MD Simulation Results for Key PEM Properties

| Membrane Model | Water Uptake (λ, H₂O/SO₃H) | Proton Diffusivity (D_H⁺ x 10⁻⁵ cm²/s) | Estimated Conductivity (σ, S/cm) | Methanol Diffusivity (D_MeOH x 10⁻⁶ cm²/s) | Ref. (Example) |

|---|---|---|---|---|---|

| Nafion (λ=15) | 15.0 ± 1.2 | 2.5 ± 0.3 | 0.10 ± 0.02 | 8.2 ± 0.9 | [1] |

| SPEEK (30% sulfonation) | 8.5 ± 0.7 | 0.9 ± 0.2 | 0.04 ± 0.01 | 2.1 ± 0.5 | [2] |

| Cross-linked PEEK | 6.0 ± 0.5 | 0.5 ± 0.1 | 0.02 ± 0.005 | 0.7 ± 0.2 | [3] |

| Hybrid Organic-Inorganic | 12.0 ± 1.0 | 1.8 ± 0.3 | 0.08 ± 0.01 | 3.5 ± 0.6 | [4] |

Note: Data is illustrative, compiled from recent literature. Actual simulation parameters (FF, time, model size) influence absolute values.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials and Software for MD Simulations in PEM Research

| Item | Function/Description |

|---|---|

| Force Fields (e.g., OPLS-AA, COMPASS III, GAFF) | Defines potential energy functions (bonded/non-bonded interactions) for polymers, water, and ions. Critical for accuracy. |

| System Builder (e.g., PACKMOL, Moltemplate) | Software to create initial configurations of complex, multi-component molecular systems in a simulation box. |

| MD Engine (e.g., GROMACS, LAMMPS, NAMD) | High-performance software to perform the energy minimization, equilibration, and production MD simulations. |

| Trajectory Analysis Tools (e.g., MDAnalysis, VMD, in-house scripts) | Used to process simulation trajectories, calculate MSD, RDF, density profiles, and other key properties. |

| Polymer Libraries (e.g., PolyDAT, HSPiP) | Provide repeat unit structures and initial parameters for building various ionomer chains. |

| Ab Initio MD (AIMD) Software (e.g., CP2K, VASP) | For simulating bond breaking/forming (e.g., Grotthuss mechanism) where classical FF may be insufficient. |

Visualization of Workflows and Mechanisms

MD Simulation Workflow for PEM Property Analysis

Proton Transport Mechanisms in Hydrated Membranes

Application Notes

Understanding the dynamic interface between platinum (Pt) nanoparticles and the ionomer (typically Nafion) within the catalyst layer is critical for predicting catalyst degradation and oxygen reduction reaction (ORR) kinetics in polymer electrolyte membrane fuel cells (PEMFCs). Molecular Dynamics (MD) simulations provide atomic-scale insights into this complex interface, which is central to the broader thesis of using computational methods to design durable, high-performance PEMFC materials. These simulations elucidate how ionomer adsorption, water network formation, and local oxygen transport influence Pt dissolution, particle growth, and the ORR activity.

Key Quantitative Insights from Recent Studies

The following table summarizes critical quantitative findings from recent computational and experimental studies on the Pt-ionomer interface.

Table 1: Key Parameters and Findings from Catalyst-Ionomer Interface Studies

| Parameter / Phenomenon | Typical Value / Observation | Impact on Pt Degradation & ORR | Source Method |

|---|---|---|---|

| Ionomer Sidechain (SO₃⁻) Adsorption Energy on Pt(111) | -0.8 to -1.5 eV | Strong adsorption blocks ORR active sites; can stabilize Pt atoms under potential. | DFT Calculation |

| Diffusion Coefficient of H₂O in interfacial region (vs. bulk) | Reduced by ~50-70% | Alters local proton conductivity and hydration, affecting ORR kinetics. | MD Simulation |

| Oxygen Permeability at Interface | 1-2 orders magnitude lower than in bulk ionomer | Limits O₂ transport to catalyst surface, a key factor in mass transport losses. | MD Simulation |

| Pt²⁺ Dissolution Rate under Potential (with ionomer) | Reduced by factor of 2-4 vs. aqueous electrolyte | Ionomer adsorption can mitigate Pt dissolution by stabilizing surface atoms. | Combined DFT/MD |

| Ionomer Film Thickness on Pt nanoparticle | ~1-2 nm (approx. 5-10 monomer units) | Defines the confined nanoscale environment for all interfacial reactions. | Experimental (XPS, SANS) & MD |

| Local Proton Concentration at Interface (pH) | Estimated pH 1-3, lower than bulk membrane | Highly acidic environment accelerates Pt dissolution and oxide formation. | Continuum Modeling |

Experimental Protocols for Supporting and Validating MD Simulations

Protocol 1: Characterization of the Pt-Ionomer Interface via X-ray Photoelectron Spectroscopy (XPS)

Objective: To determine the chemical states of Pt and the nature of ionomer adsorption on catalyst surfaces ex situ.

- Sample Preparation: Deposit a thin, uniform layer of high-surface-area carbon-supported Pt nanoparticles (e.g., Pt/Vulcan) onto a conductive substrate. Apply a dilute Nafion ionomer solution via spray-coating or drop-casting to achieve a controlled ionomer-to-carbon ratio (I/C) of 0.5-1.0. Dry under inert atmosphere.

- XPS Analysis:

- Load sample into ultra-high vacuum (UHV) chamber.

- Acquire survey scan to identify all elements present.

- Perform high-resolution scans for Pt 4f, S 2p, C 1s, O 1s, and F 1s regions.

- Use a monochromatic Al Kα X-ray source (1486.6 eV).

- Apply charge neutralization for non-conductive samples.

- Data Processing: Fit Pt 4f peaks to identify contributions from Pt(0), Pt(II) (e.g., PtO, Pt(OH)₂), and Pt(IV) (e.g., PtO₂). Analyze S 2p peak to confirm presence of sulfonate groups (-SO₃⁻) from ionomer.

Protocol 2: In Situ Electrochemical Quartz Crystal Microbalance (EQCM) Measurement of Pt Dissolution

Objective: To quantify Pt mass loss under potential cycling, simulating PEMFC cathode conditions.

- Electrode Preparation: Sputter a thin Pt film (~100 nm) onto a gold-coated quartz crystal microbalance sensor. The crystal's resonant frequency is sensitive to mass changes.

- Electrochemical Setup: Assemble a three-electrode cell with the Pt-coated crystal as working electrode, Pt mesh counter electrode, and reversible hydrogen electrode (RHE) reference. Use 0.1 M perchloric acid (HClO₄) or a dilute Nafion-containing electrolyte at 80°C.

- Potential Cycling: Apply a potential cycling protocol (e.g., 0.6 V to 1.0 V vs. RHE, 500 mV/s) for hundreds or thousands of cycles to accelerate degradation.

- Data Acquisition: Simultaneously record electrochemical current and the resonant frequency shift (Δf) of the quartz crystal.

- Data Analysis: Convert Δf to mass change using the Sauerbrey equation. Correlate mass loss with charge passed during oxide formation/reduction to derive dissolution rates.

Protocol 3: Molecular Dynamics Simulation of the Pt-Nafion-Water Interface

Objective: To simulate the atomistic structure, dynamics, and transport properties at the catalyst-ionomer interface.

- System Setup:

- Force Field: Use a classical force field (e.g., OPLS-AA for Nafion, SPC/E or TIP4P for water, Pt described by a fixed lattice or a suitable metal potential).

- Initial Configuration: Construct a Pt(111) slab. Place a pre-equilibrated Nafion film (e.g., 10-20 polymer chains) with equilibrated water molecules above the Pt surface. Ensure sufficient water content (λ = H₂O/SO₃⁻ ~ 5-20).

- Simulation Box: Apply periodic boundary conditions in x and y directions; a vacuum or inert layer in the z-direction.

- Simulation Procedure:

- Perform energy minimization using steepest descent/conjugate gradient algorithm.

- Conduct an NVT equilibration (300-353 K) for 1-2 ns with position restraints on Pt atoms.

- Run a production NPT simulation (1 atm, target temperature) for 50-200 ns. Use a time step of 1-2 fs.

- Analysis:

- Density Profiles: Plot number density of water, sulfonate groups, backbone, and hydronium ions along the z-axis (normal to Pt).

- Radial Distribution Functions (RDFs): Calculate g(r) for key pairs (e.g., S (SO₃⁻) - Pt, O (H₃O⁺) - Pt).

- Mean Squared Displacement (MSD): Compute MSD of water and hydronium ions to determine diffusion coefficients in the interfacial region vs. bulk-like region.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Catalyst-Ionomer Interface Studies

| Item | Function in Experiments |

|---|---|

| Nafion Dispersion (e.g., 5 wt% in aliphatic alcohols/water) | Provides the perfluorosulfonic acid (PFSA) ionomer for creating the catalyst layer and modeling the interface. |

| High-Surface-Area Carbon-Supported Pt Catalyst (e.g., Pt/Vulcan XC-72, 20-40 wt% Pt) | Standard catalyst material for preparing membrane electrode assemblies (MEAs) or thin-film electrodes. |

| Perchloric Acid (HClO₄, Ultrapure, 0.1 M Solution) | Model aqueous acidic electrolyte for fundamental electrochemistry studies (e.g., RDE, EQCM) with minimal anion adsorption. |

| Deuterated Water (D₂O) and Deuterated Solvents | Essential for Neutron Scattering techniques (SANS, NR) to probe the interface structure due to contrast matching capabilities. |

| Quartz Crystal Microbalance (QCM) Sensor with Sputtered Pt | Enables in situ mass change measurements during electrochemical potential cycling to track dissolution. |

| Classical Force Field Software (e.g., GROMACS, LAMMPS, AMBER) | MD simulation packages equipped with force fields for polymers, water, and metals to model the interface. |

| Density Functional Theory (DFT) Code (e.g., VASP, Quantum ESPRESSO) | For calculating adsorption energies of ionomer components, reaction barriers for ORR and Pt dissolution. |

Visualizations

Title: MD Simulation Workflow for Pt-Ionomer Interface

Title: Interlinked Pathways of Pt Degradation and ORR Hindrance

Coarse-grained molecular dynamics (CGMD) is an indispensable computational technique for simulating polymer electrolyte membranes (PEMs) and other fuel cell components at experimentally relevant spatiotemporal scales. Within the broader thesis of MD simulations for PEM fuel cell research, CGMD bridges the gap between atomistic detail and system-scale phenomena. It enables the study of mesoscale structure, ion transport mechanisms, water network percolation, and polymer morphology evolution over microseconds and across hundreds of nanometers—scales critical for understanding membrane durability, conductivity, and interfacial properties.

Key CGMD Methodologies & Application Notes

The selection of a CG mapping scheme and force field is paramount. Below is a comparison of prevalent approaches for PEM materials, particularly perfluorosulfonic acid (PFSI) ionomers like Nafion.

Table 1: Comparison of CG Mapping Schemes for PFSI Ionomers

| Mapping Scheme | Resolution (Atoms per Bead) | Key Interactions Modeled | Typical System Size | Max Simulatable Time | Primary Application in PEMs |

|---|---|---|---|---|---|

| MARTINI-like | ~4-6 heavy atoms | Electrostatics, LJ, bonds/angles | 20-50 nm box, 100+ chains | >10 µs | Phase segregation, water domain formation |

| SDK (Shinoda-DeVane-Klein) | 2-3 heavy atoms | Bonded, LJ, explicit charges | 10-20 nm box | 1-5 µs | Hydration structure, ion clustering |

| Ultra-Coarse (1 bead per monomer) | 10+ heavy atoms | Elastic network, density fields | 100+ nm box, bulk morphology | 10-100 µs | Mechanical properties, interfacial effects |

| Hybrid AA/CG | Variable | Polarizable/atomic at interface | 15-30 nm box | 100s ns | Catalyst-ionomer interface, detailed local transport |

Table 2: Quantitative Insights from CGMD Studies on Nafion (Recent Examples)

| Study Focus | CG Model Used | Key Quantitative Finding | Simulated Scale |

|---|---|---|---|

| Hydration Dynamics | SDK with polarizable water | Diffusion coefficient of H3O+ increases 5-fold from λ=5 to λ=15 | 20 nm, 2 µs |

| Morphology under Strain | Ultra-Coarse Elastic Network | 15% tensile strain increases hydrophilic channel connectivity by 40% | 100 nm, 50 µs |

| Ionomer/Platinum Interface | Hybrid AA/CG | Average O-Pt binding distance stabilizes at 2.3 Å in hydrated state | 15 nm, 500 ns |

| Water Percolation | MARTINI-style | Percolation threshold observed at λ=6 for 100 nm thin film | 50 nm, 10 µs |

Detailed Experimental Protocols

Protocol 3.1: Setting up a CGMD Simulation for Nafion Morphology Analysis

Objective: To simulate the self-assembled morphology of Nafion at varying hydration levels (λ = H2O/SO3H). Software: GROMACS, LAMMPS, or ESPResSo. Step-by-Step:

- Initial Structure Generation:

- Use

polymertoolsorpackmolto create an initial configuration of 50-200 CG Nafion chains (e.g., 12-mer per chain) in a large, low-density box. Common mapping: 1 bead for backbone CF2 unit, 1 bead for side chain, 1 charged bead for sulfonate.

- Use

- Force Field Parameterization:

- Import parameters from published MARTINI or SDK-based ionomer force fields.

- Define non-bonded interactions: Lennard-Jones (LJ) potentials for all beads, plus Coulomb interactions for charged sulfonate and hydronium/water beads. Use reaction-field or Particle-Particle Particle-Mesh (PPPM) for long-range electrostatics.

- Define bonded interactions: Harmonic potentials for bonds and angles based on reference atomistic simulations or quantum chemistry data.

- System Hydration:

- Randomly replace water beads (representing 3-4 H2O molecules each) in the simulation box to achieve target hydration levels (λ = 4, 9, 15).

- Add counter-ions (e.g., H3O+ beads) to maintain system neutrality.

- Equilibration:

- Step A (Energy Minimization): Run steepest descent minimization for 5000 steps to remove bad contacts.

- Step B (NVT Ensemble): Simulate for 5 ns with a stochastic thermostat (e.g., V-rescale) at 300 K.

- Step C (NPT Ensemble): Simulate for 20-50 ns with a Parrinello-Rahman barostat at 1 bar to achieve correct density.

- Production Run:

- Run simulation in NPT ensemble for 1-5 µs, saving coordinates every 10,000 steps.

- Analysis:

- Morphology: Calculate radial distribution functions (RDFs) between sulfonate beads.

- Connectivity: Use clustering algorithms to analyze percolation of water beads.

- Transport: Compute mean-squared displacement (MSD) of hydronium beads to derive diffusivity.

Protocol 3.2: Analyzing Water Channel Networks

Objective: To quantify the percolation and tortuosity of water networks within equilibrated CG structures. Software Tools: MDAnalysis, VMD, in-house Python scripts. Step-by-Step:

- Trajectory Preparation: Align all production run frames to a reference to remove global rotation/translation.

- Grid Construction: Discretize the simulation box into a 3D voxel grid (e.g., 1 Å resolution).

- Network Identification: For each frame, mark a voxel as "water-occupied" if any water bead center lies within it.

- Clustering Analysis: Apply a connected-components algorithm to identify contiguous clusters of occupied voxels.

- Percolation Check: Determine if a cluster spans the box in all three dimensions (bulk) or just in-plane (thin film).

- Geometric Analysis: For the spanning cluster, calculate the pore size distribution and tortuosity factor (ratio of actual path length to Euclidean distance).

Visualization of Methodologies

Title: CGMD Model Development and Application Workflow

Title: CG Mapping Scheme for a Nafion Ionomer

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Tools for CGMD in PEM Research

| Item | Function in CGMD Study | Example/Note |

|---|---|---|

| Reference Atomistic Trajectories | Source data for deriving CG bonded distributions and non-bonded potentials. | All-atom simulations of Nafion oligomers in water. |

| CG Force Field Files (.itp, .xml) | Define bead types, masses, charges, bonded parameters, and non-bonded interaction matrices. | MARTINI 3.0 ionomer parameters, SDK water models. |

| Initial Structure Generator | Creates starting configurations of polymers, water, and ions at target density. | packmol, polymertools, Moltemplate. |

| High-Performance Computing (HPC) Cluster | Enables µs-scale simulations of large systems (10^5-10^6 beads). | GPU-accelerated nodes for running GROMACS/LAMMPS. |

| Trajectory Analysis Suite | Processes simulation output to compute RDFs, MSD, cluster analysis, etc. | MDAnalysis, VMD, GROMACS built-in tools. |

| Visualization Software | Renders 3D structures and animates dynamics for qualitative assessment. | VMD, PyMol, OVITO. |

| Percolation/Network Analysis Code | Custom scripts to quantify connectivity and tortuosity of water/ion networks. | Python with scikit-image/NetworkX libraries. |

This application note is framed within a broader thesis investigating the use of Molecular Dynamics (MD) simulations to guide the design of advanced polymer electrolyte membranes (PEMs) for fuel cells. The study compares two primary material classes: state-of-the-art perfluorinated sulfonic acid (PFSA) ionomers (e.g., Nafion) and emerging hydrocarbon-based (HC) alternatives. MD simulations provide atomic-level insights into morphology, hydration, and ion transport, which are critical for optimizing proton conductivity and durability under operational conditions.

Quantitative Comparison of Membrane Properties from MD Studies

The following tables summarize key quantitative findings from recent MD simulation studies and experimental validations relevant to PEM design.

Table 1: Simulated Structural and Hydration Properties

| Property | Perfluorinated (e.g., Nafion) | Hydrocarbon-Based (e.g., sPEEK, sPAEK) | Simulation Conditions (Typical) |

|---|---|---|---|

| Water Uptake (λ, H₂O/SO₃H) | 6-12 (moderate) | 10-25 (highly variable) | 300-360 K, Hydration levels |

| Hydrophobic Domain Size | ~3-5 nm (well-defined) | ~2-4 nm (less defined) | Dry/Equilibrated state |

| Hydrated Proton Diffusivity (10⁻⁶ cm²/s) | 1.5 - 4.0 | 0.8 - 3.5 | 353 K, Fully hydrated |

| Mean Separation of Ionic Groups (Å) | ~10-12 | ~7-10 (denser) | Hydrated, λ~15 |

| Hydration Energy (kJ/mol SO₃H) | -450 to -500 | -480 to -550 (more negative) | With explicit water |

Table 2: Key Performance Indicators from Combined MD/Experimental Studies

| Indicator | PFSA Membranes | HC Membranes | Notes |

|---|---|---|---|

| Proton Conductivity (S/cm) @ 80°C, 95% RH | 0.10 - 0.15 | 0.08 - 0.14 (optimized) | Experiment |

| Predicted Methanol Crossover (rel. to Nafion) | 1.0 (Baseline) | 0.3 - 0.8 | MD Permeation Simulation |

| Glass Transition Temp, Tg (K) (Dry) | ~380 | 420 - 480 | MD & DSC |

| Morphological Stability under Hydration | High (Teflon backbone) | Moderate (Backbone dependent) | RMSD analysis from MD |

Research Reagent Solutions Toolkit

Table 3: Essential Materials and Reagents for MD Studies of PEMs

| Item | Function in MD Study |

|---|---|

| PFSA Atomistic/Coarse-Grained Force Fields (e.g., DREIDING, OPLS-AA variants) | Defines bonded/non-bonded parameters for perfluorinated backbone and sulfonic acid groups. |

| Hydrocarbon Polymer FF (e.g., GAFF2 for sulfonated aromatics) | Defines parameters for aromatic HC backbones and ionic moieties. |

| Explicit Water Model (e.g., SPC/E, TIP4P/2005) | Solvates the system, critical for modeling hydration and proton transport. |

| Hydronium Ions (H₃O⁺) | The primary charge carrier; concentration set by sulfonation degree. |

| Neutralization/Typing Software (e.g., MATCH, LigParGen) | Generates missing FF parameters for novel HC monomer units. |

| High-Performance Computing (HPC) Cluster | Runs MD simulations (often >100,000 atoms, microsecond scales). |

Experimental Protocols

Protocol 1: MD Workflow for Comparing Hydrated Morphology

- Model Construction:

- Build a polymer chain (e.g., 10-20 repeating units for PFSA; similar for HC).

- Replicate chains in an amorphous cell to achieve target density (~1.8-2.0 g/cm³ dry).

- Assign partial charges and force field parameters (see Table 3).

- System Preparation and Equilibration:

- Solvate the system with explicit water molecules. The number is determined by the target hydration level, λ (H₂O/SO₃H).

- Replace random water molecules with hydronium ions to maintain system neutrality.

- Perform energy minimization using steepest descent/conjugate gradient.

- Conduct stepwise equilibration in the NVT and NPT ensembles (e.g., 310-363 K, 1 bar) for 2-10 ns using a weak coupling algorithm (Berendsen) followed by a Parrinello-Rahman barostat.

- Production Run & Analysis:

- Run a production MD simulation for 50-200 ns in the NPT ensemble.

- Analyze the last 50% of the trajectory for:

- Radial Distribution Function (RDF): g(r) between sulfur atoms (ionic clusters) and water oxygen.

- Water Cluster Analysis: Use a clustering algorithm (e.g., DCCA) on water/ion percolation networks.

- Domain Size: Calculate the structure factor or perform pair correlation analysis on hydrophobic backbone atoms.

Protocol 2: MD Protocol for Calculating Proton Diffusivity

- Follow Protocol 1 to generate a well-equilibrated, hydrated system.

- Extend Production Run: For transport properties, a longer production run (≥100 ns) is recommended.

- Trajectory Analysis for Conductivity:

- Track the mean squared displacement (MSD) of hydronium ions (or proton-vectoring via the "center of excess charge" method).

- Apply the Einstein relation: D = (1/6) * lim_{t→∞} d(MSD)/dt, where D is the diffusion coefficient.

- Estimate proton conductivity (σ) using the Nernst-Einstein relation: σ = (ρ * z² * F² * D)/ (RT), where ρ is charge carrier density, z is charge, F is Faraday's constant, R is gas constant, and T is temperature. Note: This provides an upper-bound estimate.

Protocol 3: Validating MD Predictions with Experimental Membrane Fabrication

- Membrane Casting (Solution Casting Method):

- Dissolve purified hydrocarbon polymer (e.g., sulfonated poly(ether ether ketone), sPEEK) or commercial PFSA (e.g., Nafion) in appropriate solvent (e.g., DMSO for sPEEK, water/alcohol for Nafion) to form a 5-10 wt% solution.

- Filter the solution through a 0.45 μm PTFE syringe filter to remove particulates.

- Pour the solution onto a clean, level glass Petri dish.

- Dry in an oven at 60°C for 48 hours, followed by vacuum drying at 80°C for 24 hours to remove residual solvent.

- Post-Treatment (Acidification/Hydration):

- For HC membranes, acidify by immersion in 1.0 M sulfuric acid at 80°C for 1 hour.

- Rinse repeatedly in deionized water until the rinse water is neutral.

- Store membranes in DI water prior to testing.

- Ex Situ Validation Measurements:

- Water Uptake: Measure weight change between dry and wet (blotted) membrane.

- Proton Conductivity: Use 4-point probe AC impedance spectroscopy on a membrane strip in a humidity-controlled cell.

- Small-Angle X-ray Scattering (SAXS): Compare measured ionomer peak (q ~ 1-2 nm⁻¹) with simulated electron density maps from MD.

Visualization Diagrams

Title: MD Simulation Workflow for PEM Analysis

Title: Key Analysis Pathways from MD Trajectory

Title: Case Study Context in Thesis Framework

Navigating Challenges: Troubleshooting and Optimizing PEMFC MD Simulations

Application Notes and Protocols for Molecular Dynamics Simulations in Polymer Electrolyte Membrane Fuel Cell Research

Within the broader thesis on advancing polymer electrolyte membrane (PEM) fuel cell technology through molecular dynamics (MD) simulations, a rigorous methodology is paramount. This document outlines critical pitfalls and provides protocols to ensure the reliability of simulations studying hydrated Nafion membranes, ionomer structure, proton transport, and reactant permeation.

Pitfall: System Size Limitations

Simulating a representative volume element (RVE) of a hydrated Nafion membrane is challenging. Too small a system misrepresents the long-range connectivity of hydrophilic domains and overestimates confinement effects.

Protocol 1.1: Determining Minimum System Size for Nafion RVE

- Initial Construction: Build a system with a target hydration level (λ = H₂O/SO₃⁻). A starting point is 3-5 Nafion oligomers (EW ~1100 g/mol) with periodic boundary conditions.

- Equilibration: Run an extended NPT equilibration (see Protocol 3.1).

- Analysis of Domain Size: Calculate the radial distribution function (RDF) for sulfur atoms (SO₃⁻ groups). Determine the first coordination shell distance (r₁).

- Convergence Test: Replicate the system by increasing the number of oligomers (e.g., 5, 10, 20). For each size, compute the structure factor S(q) or the persistence length of hydrophilic domains via cluster analysis.

- Criterion: The minimum system size is reached when the calculated domain morphology metrics (peak position in S(q), cluster size distribution) converge to within 5% deviation between successive doublings.

Table 1: Representative System Sizes and Observed Properties from Literature

| Membrane Type (Hydration λ) | Number of Chains | Atoms | Box Size (nm³) | Key Property Studied | Observed Artifact if Too Small |

|---|---|---|---|---|---|

| Nafion (λ=5) | 5 | ~15k | 6x6x6 | Water Diffusion Coeff. | Overestimation by ~40% |

| Nafion (λ=16) | 10 | ~50k | 8x8x8 | Hydrated Channel Diameter | Lack of percolation, isolated clusters |

| Hydroxyl-functionalized PEM | 15 | ~35k | 7x7x7 | Proton Hopping Rate | Underestimation of vehicular transport |

Pitfall: Sampling Issues

Adequate sampling is required to capture rare events like proton hopping (Grotthuss mechanism) and oxygen diffusion through the membrane.

Protocol 2.1: Enhanced Sampling for Proton Transport Method: Weighted Histogram Analysis Method (WHAM) with Umbrella Sampling.

- Reaction Coordinate: Define as the distance between the donating hydronium ion oxygen (Od) and the accepting water molecule oxygen (Oa).

- Sampling Windows: Create 20-30 simulation windows along the reaction coordinate, spaced 0.1 Å apart, covering 1.0 to 3.0 Å.

- Restraint: Apply a harmonic biasing potential (force constant 20-30 kcal/mol/Ų) in each window.

- Production Runs: Run each window for 2-5 ns in the NVT ensemble.

- Analysis: Use WHAM to unbias the data and compute the potential of mean force (PMF) for the proton transfer event.

Protocol 2.2: Long-timescale Sampling for Morphology Method: Hamiltonian Replica Exchange MD (HREMD).

- Parameter Scaling: Prepare 16-32 replicas. Scale the non-bonded interaction parameters (Lennard-Jones and Coulomb) for the polymer backbone and sidechains by a factor λ (λ ranging from 1.0 [fully interacting] to ~0.6 [softened]).

- Simulation: Run each replica in parallel. Attempt exchanges between neighboring replicas every 1-2 ps based on the Metropolis criterion.

- Analysis: Ensure a swap acceptance rate of 20-30%. Pool data from replicas with λ=1.0 for analysis. This accelerates the exploration of polymer chain configurations and phase separation.

Pitfall: Equilibration Errors

Insufficient equilibration leads to analysis of non-equilibrium, high-energy states, distorting predictions of density, water network formation, and mechanical properties.

Protocol 3.1: Comprehensive Multi-Stage Equilibration for Hydrated Nafion Stage 1: Energy Minimization

- Algorithm: Steepest Descent, followed by Conjugate Gradient.

- Termination: Maximum force < 1000 kJ/mol/nm.

Stage 2: Solvent and Ion Relaxation (NVT)

- Duration: 100-200 ps.

- Temperature: 300 K, coupled with v-rescale.

- Constraints: Apply position restraints on all heavy atoms of the polymer (force constant 1000 kJ/mol/nm²). Allow water and ions to relax.

Stage 3: Density Equilibration (NPT)

- Duration: 2-5 ns.

- Temperature: 300 K, v-rescale.

- Pressure: 1 bar, Parrinello-Rahman barostat.

- Constraints: Remove position restraints. Use semi-isotropic coupling for slab systems.

- Monitoring: Plot system density, box volume, and potential energy vs. time. Equilibrium is reached when these properties plateau and show no drift over the last 1 ns.

Stage 4: Production Equilibration (NPT)

- Duration: 5-10 ns.

- Conditions: Same as Stage 3.

- Key Check: Calculate the mean squared displacement (MSD) of the polymer center of mass. It should show normal diffusion (linear in time). A sub-diffusive or arrested MSD indicates the polymer is still relaxing.

Table 2: Equilibration Sufficiency Metrics

| Metric | Target for Equilibration | Sampling Frequency | Tool/Method |

|---|---|---|---|

| System Density | < ±0.5% fluctuation | Every 10 ps | GROMACS energy |

| Potential Energy | < ±0.1% fluctuation | Every 10 ps | GROMACS energy |

| Polymer CoM MSD Slope | > 0 (linear regime) | Every 100 ps | MDAnalysis |

| RDF(g(Owater-Owater)) | Stable peak heights | Every 1 ns | VMD/gmx rdf |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in PEM-MD Simulations |

|---|---|

| Force Field (e.g., OPLS-AA, COMPASS III) | Defines all interatomic potentials. Critical for accurate ionomer/water interaction energies. |

| Hydronium Ion (H₃O⁺) Parameters | Specialized parameters for simulating excess protons in water networks within pores. |

| Polarizable Water Model (e.g., SPC/E, TIP4P/2005) | More accurately captures hydrogen bonding and proton transfer dynamics than non-polarizable models. |

| Polymer Builder (e.g., POLYMRT, Maestro) | Software to generate initial, chemically accurate configurations of Nafion or other ionomers. |

| Enhanced Sampling Plugin (PLUMED) | Integrated library for implementing meta-dynamics, umbrella sampling, and replica exchange. |

| Trajectory Analysis Suite (MDAnalysis, VMD) | For calculating diffusion coefficients, RDFs, cluster analysis, and visualizing morphology. |

Diagram 1: Multi-Stage Equilibration Workflow

Equilibration Protocol for Reliable PEM MD

Diagram 2: Enhanced Sampling for Proton Hopping

Umbrella Sampling for Proton Transfer

Within the broader thesis on Molecular Dynamics (MD) simulations for Polymer Electrolyte Membrane Fuel Cell (PEMFC) research, the selection of an appropriate force field (FF) is a critical foundational step. The membrane, typically a hydrated perfluorosulfonic acid (PPSA) ionomer like Nafion, operates in a complex multiphase environment. Simulating its morphology, water and proton transport, and interaction with catalysts demands a FF that accurately captures quantum-mechanical (QM) realities while remaining computationally tractable for systems exceeding 100,000 atoms over nanosecond timescales. This document provides application notes and protocols for selecting and validating FFs, focusing on the trade-off between accuracy (in representing interactions, diffusion coefficients, and microstructure) and computational cost (simulation time, required resources).

Core Force Field Comparison for PEM Materials

The table below summarizes key force fields used in PEM research, their parameters, typical applications, and associated computational cost indicators.

Table 1: Comparison of Force Fields for PEMFC MD Simulations

| Force Field | Year/Version | Key Parameters for PEM | Typical Application in PEM | Accuracy Considerations | Computational Cost (Relative) |

|---|---|---|---|---|---|

| Class I: Generic (Fixed-Charge) | |||||

| OPLS-AA | 2001/2021 | Lennard-Jones (LJ), fixed charges, harmonic bonds/angles. Optimized for liquids & org. | Hydrated Nafion morphology, water diffusion. | Good for structural properties; poor for polarization, proton transfer. | Low (Baseline) |

| CHARMM36 | 2015/2022 | LJ, fixed charges, CMAP for backbone torsions. | Lipid bilayers, protein-membrane interfaces, hydrated polymers. | Excellent for biomolecules; PFSA parameters may be derived. | Low-Medium |

| AMBER (ff14SB, GAFF2) | 2016 | LJ, fixed charges, specific torsional potentials. | Combining PFSA with organic additives, composite membranes. | Relies on derived parameters for PFSA; good for mixed organic systems. | Low-Medium |

| Class II: Polarizable | |||||

| DRUDE (CHARMM) | 2023 | Classical Drude oscillators for induced dipoles. | Water structure in nanochannels, ion-polymer dynamics. | Superior for dielectric properties, ion hydration; captures polarization. | High (10-15x Class I) |

| AMOEBA | 2020 | Atomic multipoles (dipole, quadrupole), polarization. | Precise interaction energies, proton hopping mechanisms. | High QM agreement; parameterization complex. | Very High (20-30x Class I) |

| Class III: Reactive | |||||

| ReaxFF | 2023 (v2023) | Bond-order potentials, dynamic bonding. | Chemical degradation of membrane (radical attack), catalyst interface reactions. | Can model bond breaking/formation; parameter set dependent. | Extremely High (50-100x Class I) |

| Specialized for PFSA | |||||

| DREIDING (mod.) | N/A | Generic with tailored LJ σ/ε for CF2/SO3H groups. | Early studies of Nafion self-assembly. | Limited accuracy; historical baseline. | Low |

| COMPASS III | 2019 | Ab initio derived, validated for polymers & inorganics. | Hydrated PFSA, mechanical properties, glass transition. | High accuracy for condensed phase polymers; commercial. | Medium |

Note: Computational cost is relative to a standard OPLS-AA simulation of a 50k atom system for 10 ns on a 24-core CPU node. Polarizable and reactive FFs often require GPU acceleration for feasibility.

Validation Protocols and Workflows

Selecting a FF requires rigorous validation against experimental or high-level QM data. The following protocols detail key validation experiments.

Protocol 3.1: Validation of Hydration Structure and Water Diffusion