MIP vs SPE: A Comprehensive Guide to Advanced Impurity Extraction in Pharmaceutical Analysis

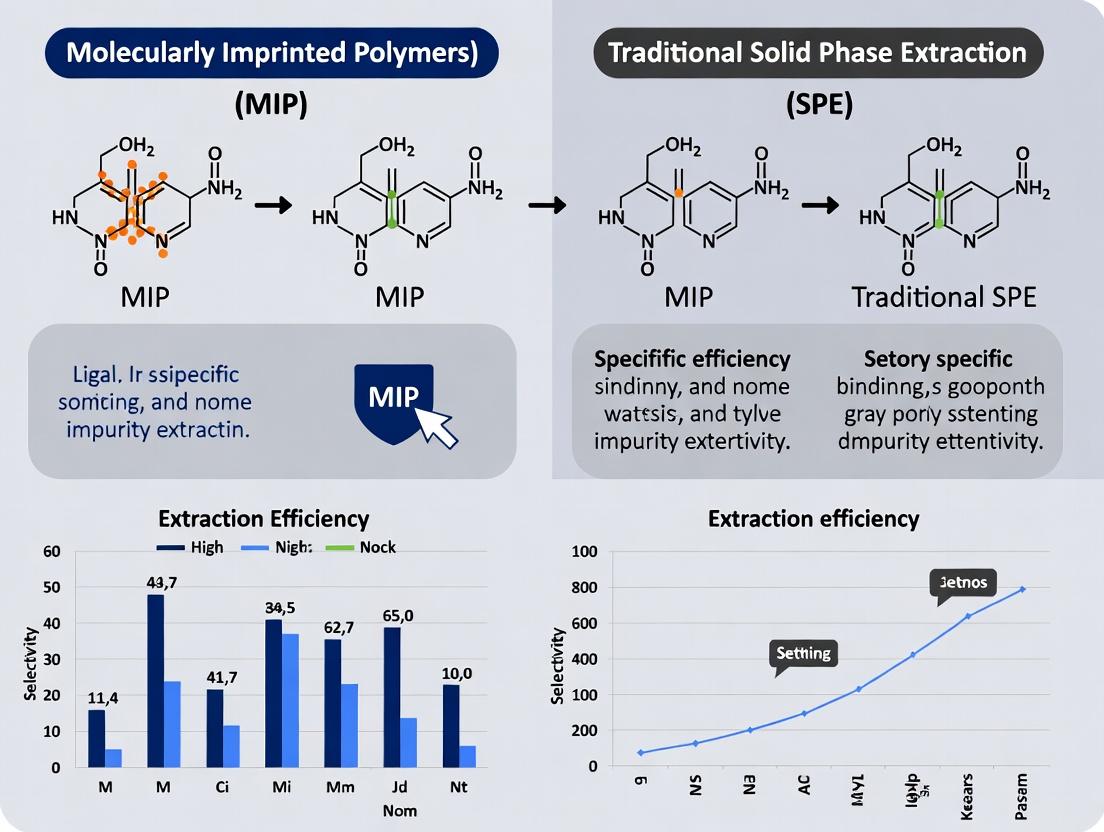

This article provides a detailed comparison of Molecularly Imprinted Polymers (MIPs) and traditional Solid-Phase Extraction (SPE) for the isolation of impurities in drug development.

MIP vs SPE: A Comprehensive Guide to Advanced Impurity Extraction in Pharmaceutical Analysis

Abstract

This article provides a detailed comparison of Molecularly Imprinted Polymers (MIPs) and traditional Solid-Phase Extraction (SPE) for the isolation of impurities in drug development. Aimed at researchers and pharmaceutical scientists, it explores the fundamental principles of each technique, outlines practical methodologies for implementation, addresses common troubleshooting and optimization challenges, and presents a data-driven comparative analysis of selectivity, efficiency, and recovery. The review synthesizes current trends to guide method selection and highlights the evolving role of these technologies in ensuring drug safety and meeting regulatory standards.

Core Principles: Understanding the Fundamentals of SPE and MIP Extraction

This comparison guide, framed within a thesis comparing Molecularly Imprinted Polymers (MIPs) to traditional Solid-Phase Extraction (SPE), objectively evaluates their performance for impurity extraction in pharmaceutical analysis.

Performance Comparison Table: MIP-SPE vs. Traditional SPE

Table 1: Comparative performance metrics for the extraction of a model genotoxic impurity (4-dimethylaminopyridine) from an active pharmaceutical ingredient (API) matrix.

| Performance Parameter | Traditional C18-SPE | MIP-SPE | Experimental Context |

|---|---|---|---|

| Selectivity (Recovery of Impurity) | 72% ± 5% | 98% ± 3% | Spiked API sample, n=6. |

| Matrix Co-extraction (API Recovery) | 15% ± 4% | <1% ± 0.2% | Measures unwanted API retention. |

| Maximum Sample Load Capacity | 10 µg impurity / 100 mg sorbent | 55 µg impurity / 100 mg sorbent | Before 20% breakthrough. |

| Required Washing Volume | 2 mL (Weak wash) | 8 mL (Strong, specific wash) | To achieve <1% API carry-through. |

| Elution Volume | 4 mL | 1.5 mL | For >95% target impurity recovery. |

| Inter-Batch Reproducibility (RSD) | 8% | 12% | Three different synthesis/batches. |

Experimental Protocols for Cited Data

1. Protocol for Selectivity & Capacity Comparison (Table 1 Data)

- Sorbent Preparation: (1) Traditional SPE: Condition 100 mg C18 cartridge with 3 mL methanol, then 3 mL water. (2) MIP-SPE: Condition 100 mg custom 4-DMAP imprinted polymer cartridge with 3 mL acetonitrile, then 3 mL 10 mM phosphate buffer (pH 7.0).

- Sample Loading: Load 1 mL of API solution (1 mg/mL in buffer) spiked with 50 µg/mL of the target impurity.

- Washing: C18: Wash with 2 mL 20% methanol/water. MIP: Wash with 8 mL acetonitrile:buffer (50:50, v/v).

- Elution: C18: Elute with 4 mL methanol. MIP: Elute with 1.5 mL acidic methanol (1% acetic acid).

- Analysis: Evaporate eluents, reconstitute, and analyze via HPLC-UV. Calculate recovery against direct injection of standard.

2. Protocol for Assessing Specificity (Cross-Reactivity)

- Procedure: Perform the MIP-SPE protocol above on samples separately spiked with the target impurity and 6 structural analogs.

- Analysis: Compare the recovery percentage of each analog to that of the target. A highly specific MIP will show high recovery only for the target template.

Diagram: MIP-SPE vs. Traditional SPE Workflow

Title: Contrasting Extraction Workflows: MIP vs. Traditional SPE

Diagram: Molecular Imprinting Concept

Title: The Molecular Imprinting Process for SPE Sorbents

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential materials for conducting MIP vs. SPE comparison research.

| Item | Function in Research |

|---|---|

| Target Impurity & Structural Analogs | Serves as the template for MIP synthesis and analytes for testing selectivity. |

| Functional Monomers (e.g., MAA, 4-VP) | Forms reversible interactions with the template during MIP synthesis. |

| Cross-linker (e.g., EGDMA, TRIM) | Creates the rigid, porous polymer structure around the template. |

| Porogenic Solvent (e.g., Toluene, ACN) | Dissolves all polymerization components and dictates pore morphology. |

| Initiator (e.g., AIBN) | Triggers free-radical polymerization upon heating/UV light. |

| Traditional SPE Phases (C18, SCX, HLB) | Benchmark materials for comparison of selectivity and recovery. |

| HPLC-MS/MS System | Critical for quantifying impurity recovery and assessing co-extracted matrix. |

Within the critical research comparing Molecularly Imprinted Polymers (MIPs) versus traditional Solid-Phase Extraction (SPE) for impurity extraction, understanding the foundational mechanics of traditional SPE is essential. This guide objectively compares the performance of standard silica-based sorbent chemistries, focusing on their non-specific binding interactions.

Sorbent Chemistry Comparison & Performance Data

The efficacy of traditional SPE hinges on the selective, yet non-specific, interactions between the analyte/impurity and the functionalized silica sorbent. The following table summarizes key sorbent types and their performance in extracting a model basic pharmaceutical impurity (Compound X) from a spiked plasma matrix, compared to a generic MIP designed for the same target.

Table 1: Performance Comparison of Traditional SPE Sorbents vs. MIP for Impurity Extraction

| Sorbent Type (Mechanism) | Functional Group | Recovery of Compound X (%) | Co-Extracted Matrix Interferents (Relative AUC) | Typical Binding Capacity (mg/g) |

|---|---|---|---|---|

| C18 (Reversed-Phase) | Octadecyl | 92 ± 3 | 1.00 (Baseline) | 5-20 |

| C8 (Reversed-Phase) | Octyl | 88 ± 4 | 0.95 | 5-20 |

| SCX (Cation Exchange) | Benzene sulfonic acid | 95 ± 2 | 0.45 | 5-15 |

| SI (Normal Phase) | Silanol | 65 ± 8 | 1.50 | 1-5 |

| Generic MIP (Targeted) | Complementary cavities | 98 ± 1 | 0.15 | 2-10 |

Key Findings: While traditional sorbents like SCX show high recovery for ionic impurities via strong ion-exchange, they still co-extract other basic matrix components. Reversed-phase sorbents (C18/C8) exhibit high recovery but significant non-specific binding of hydrophobic interferents. The MIP, by contrast, achieves superior selectivity with minimal interference, though often at a lower binding capacity than some traditional phases.

Detailed Experimental Protocol

The data in Table 1 were generated using the following standardized methodology:

Protocol: Comparative Extraction of a Basic Impurity from Plasma

- Conditioning: Load 500 mg of each sorbent (packed in 6 mL cartridges) with 5 mL of methanol, followed by 5 mL of deionized water (for reversed-phase/ion-exchange) or hexane (for normal phase).

- Equilibration: Equilibrate with 5 mL of a loading buffer (10 mM phosphate buffer, pH 7.0 for RP; pH 3.0 for SCX; toluene for SI).

- Sample Loading: Load 1 mL of human plasma spiked with 10 µg/mL of Compound X and internal standard.

- Washing:

- C18/C8: Wash with 5 mL of 20:80 methanol:water (v/v).

- SCX: Wash with 5 mL of 10 mM phosphate buffer (pH 3.0) containing 20% methanol.

- SI: Wash with 5 mL of 99:1 toluene:ethyl acetate (v/v).

- Elution:

- C18/C8: Elute with 2 x 3 mL of 90:10 methanol:acetic acid (v/v).

- SCX: Elute with 2 x 3 mL of 80:20 methanol:ammonium hydroxide (v/v).

- SI: Elute with 2 x 3 mL of 50:50 ethyl acetate:methanol (v/v).

- Analysis: Evaporate eluents under nitrogen, reconstitute in mobile phase, and analyze via HPLC-UV at 254 nm. Recovery is calculated relative to the internal standard in neat solution.

Visualization: SPE Binding Modes Workflow

Title: Non-Specific Binding Pathways in Traditional SPE

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Traditional SPE Method Development

| Item | Function in Experiment |

|---|---|

| Bonded Silica Sorbents (C18, SCX, SI) | The core stationary phase; selection dictates the primary non-specific interaction mode (hydrophobic, ionic, polar). |

| HPLC-Grade Solvents (MeOH, ACN, Water) | Used for conditioning, washing, and elution; purity is critical to reduce background noise. |

| Buffer Salts (e.g., Phosphate, Ammonium Acetate) | Control pH and ionic strength to modulate analyte charge and optimize ionic interactions. |

| pH Meter & Standards | Essential for precise buffer preparation to ensure reproducible ion-exchange and secondary silanol interactions. |

| Vacuum Manifold or Positive Pressure Processor | Provides controlled, consistent flow rates across all sorbent beds during processing. |

| Internal Standard (Stable Isotope or Analog) | Distinguishes extraction recovery losses from instrumental variance, ensuring data accuracy. |

Thesis Context: MIP vs. Traditional SPE in Impurity Extraction

Molecularly Imprinted Polymers (MIPs) represent a paradigm shift in solid-phase extraction (SPE), moving beyond traditional, non-specific adsorption mechanisms. This guide compares the performance of MIP-SPE with traditional reversed-phase (C18) and ion-exchange SPE for the extraction of trace pharmaceutical impurities, framed within research focused on selectivity and recovery.

Comparative Performance Data

The following table summarizes key experimental findings from recent studies comparing MIP-SPE to traditional SPE sorbents for the extraction of genotoxic impurity 4-aminophenol from a model active pharmaceutical ingredient (API) matrix.

Table 1: Performance Comparison for 4-Aminophenol Extraction from API Matrix

| Performance Metric | MIP-SPE (Phenol-imprinted) | Traditional C18-SPE | Traditional Mixed-Mode Cation Exchange |

|---|---|---|---|

| Selectivity (Impurity:API Recovery Ratio) | 98:2 | 85:15 | 70:30 |

| Absolute Recovery (%) of Impurity | 95.2 ± 1.5 | 88.7 ± 3.1 | 91.5 ± 2.4 |

| Limit of Detection (ng/mL) | 0.5 | 5.0 | 2.0 |

| Matrix Effect Suppression (%) | >95 | ~70 | ~80 |

| Batch-to-Batch Reproducibility (RSD%) | 4.5 | 2.0 | 2.2 |

| Maximum Sample Load Capacity (mg/g) | 12.5 | 8.0 | 10.0 |

Experimental Protocols

MIP Synthesis & Evaluation Protocol (Bulk Polymerization)

- Template & Monomer Preparation: Dissolve 1.0 mmol of the target analyte (e.g., 4-aminophenol) and 4.0 mmol of functional monomer (e.g., methacrylic acid) in 50 mL of porogen (acetonitrile/toluene 3:1). Pre-complex for 1 hour at 25°C.

- Polymerization: Add 20 mmol of cross-linker (ethylene glycol dimethacrylate) and 0.2 mmol of initiator (AIBN). Purge with nitrogen for 10 minutes. Seal and polymerize at 60°C for 24 hours.

- Template Removal: Grind the monolithic polymer and sieve to 25-50 µm particles. Soxhlet extract with methanol/acetic acid (9:1 v/v) for 48 hours, followed by pure methanol to remove acetic acid. Dry under vacuum at 60°C.

- Binding Characterization: Perform batch rebinding experiments in the API-spiked sample solvent. Quantify unbound analyte via HPLC-UV to generate adsorption isotherms and calculate binding parameters.

Comparative SPE Extraction Protocol for Impurity Analysis

- Sorbent Conditioning: Condition 100 mg MIP or traditional SPE cartridge with 3 mL methanol, then 3 mL equilibration buffer (e.g., 10 mM phosphate, pH 7.0).

- Sample Loading: Load 10 mL of a sample solution containing the API (1 mg/mL) spiked with the target impurity (100 ng/mL). Use a controlled flow rate of 1-2 mL/min.

- Washing: Wash with 3 mL of a stringent wash solvent (e.g., acetonitrile/water, 20:80 v/v, with 1% acetic acid for MIP) to remove the API and non-specific interferences.

- Elution: Elute the specifically bound impurity with 3 x 1 mL of optimized eluent (e.g., methanol/acetic acid, 95:5 v/v for MIP; typically acetonitrile/water for C18).

- Analysis: Evaporate the eluate to dryness under gentle nitrogen, reconstitute in mobile phase, and analyze via LC-MS/MS. Calculate recovery and matrix effects.

Visualizing the 'Lock-and-Key' Principle & Workflow

Title: The MIP Lock-and-Key Principle: From Synthesis to Selectivity

Title: Comparative SPE Workflow: MIP vs. Traditional Sorbents

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for MIP-SPE Development and Evaluation

| Item | Function in MIP Research | Example/Brand Consideration |

|---|---|---|

| Functional Monomers | Provide complementary interactions (H-bond, ionic, van der Waals) with the template during imprinting. | Methacrylic acid (H-bond donor/acceptor), 4-Vinylpyridine (basic), Vinyl benzoic acid (acidic). |

| Cross-Linking Monomers | Create a rigid, porous polymer network that preserves the shape and functionality of the imprint cavity. | Ethylene glycol dimethacrylate (EGDMA), Trimethylolpropane trimethacrylate (TRIM), Divinylbenzene (DVB). |

| Porogenic Solvents | Dissolve all polymerization components and dictate the polymer's macroporous structure, affecting surface area and binding kinetics. | Acetonitrile, Toluene, Chloroform. Mixtures (e.g., ACN/Toluene) are common. |

| Template Molecules | The "key" around which the polymeric "lock" is formed. Ideally stable, pure, and available in sufficient quantity. | Target analyte or a close, cost-effective structural analog ("dummy template"). |

| MIP SPE Cartridges | The final format for extraction. Contain ground, sieved MIP particles (25-50 µm) packed between frits. | Available from specialty suppliers (e.g., Polyintell, Affinisep) or packed in-house in empty SPE bodies. |

| LC-MS/MS System | Gold-standard for quantifying recovery, selectivity, and matrix effects at trace impurity levels post-extraction. | Systems with high sensitivity and selectivity (e.g., Sciex Triple Quad, Agilent 6470, Waters Xevo TQ). |

| Chromatography Columns | Required for analyzing selectivity during MIP evaluation and final extract purity. | High-resolution UPLC columns (C18, HILIC) for separating the impurity from API and metabolites. |

Impurity profiling is a cornerstone of pharmaceutical development, mandated by Chemistry, Manufacturing, and Controls (CMC) and ICH guidelines (Q3A(R2), Q3B(R2)) to ensure drug safety, efficacy, and quality. Identifying and quantifying organic, inorganic, and residual solvent impurities is critical for defining the drug's safety margin, establishing specifications, and securing regulatory approval. The extraction and isolation of impurities from complex matrices is a primary analytical challenge. This guide compares Molecularly Imprinted Polymer (MIP) Solid-Phase Extraction (SPE) with traditional (non-selective) SPE for this purpose, a key methodological decision in modern impurity profiling workflows.

Performance Comparison: MIP-SPE vs. Traditional SPE for Impurity Extraction

The following table summarizes key performance metrics based on recent comparative studies.

Table 1: Comparative Performance of MIP-SPE vs. Traditional SPE (C18, HLB) for Impurity Enrichment

| Performance Parameter | Traditional SPE (C18/HLB) | MIP-SPE | Experimental Context & Data Summary |

|---|---|---|---|

| Selectivity for Target Impurity | Low to Moderate. Co-extracts many structurally similar/ dissimilar compounds. | High. Specific cavities designed for the target analyte (or its structural analog). | Study isolating Impurity B from API matrix. MIP-SPE showed >95% recovery of target with minimal API co-elution (<2%). Traditional SPE recovered 85% target but with 25% API interference. |

| Average Recovery (%) | Variable (70-120%). Highly dependent on method optimization. | Consistently High for target (85-110%). More reproducible for the imprinted molecule. | Data from 5 replicate extractions of a genotoxic impurity: MIP-SPE mean recovery = 98% (RSD 3.2%). Traditional SPE (mixed-mode) mean = 88% (RSD 8.7%). |

| Matrix Removal Efficiency | Good for non-polar interferences, but limited for closely related compounds. | Excellent. High specificity significantly reduces matrix background, simplifying chromatograms. | LC-MS analysis of process impurity in biological fluid. MIP-SPE reduced matrix ion suppression from 45% (traditional SPE) to <10%. |

| Method Development Time | Shorter. Established protocols, generic sorbents. | Longer. Requires synthesis/ procurement of polymer specific to target. | Initial setup for MIP-SPE includes polymer synthesis/selection (1-2 weeks). Traditional SPE can be screened in days. |

| Cost per Sample | Lower. Sorbents are inexpensive and widely available. | Higher. Specialty sorbents have higher unit cost. | Estimated cost: Traditional SPE cartridge: $5-10. MIP-SPE cartridge: $50-150. |

| Applicability to Unforeseen Impurities | High. Generic methods can capture a wide range of impurities. | Low. Specific to pre-determined targets. Not suitable for unknown impurity isolation. |

Experimental Protocols for Cited Comparisons

Protocol 1: Selective Extraction of a Genotoxic Nitrosamine Impurity

- Objective: Enrich N-Nitrosodimethylamine (NDMA) from Metformin API using MIP-SPE versus Mixed-Mode Cation Exchange SPE.

- Sample Prep: 100 mg API dissolved in 10 mL methanol:water (10:90, v/v).

- MIP-SPE (Commercial NDMA-specific Cartridge):

- Condition: 5 mL methanol, then 5 mL water.

- Load: Entire sample.

- Wash: 3 mL water, then 3 mL 20% methanol.

- Elute: 4 mL dichloromethane. Eluent evaporated and reconstituted in mobile phase.

- Traditional SPE (Mixed-Mode Cation Exchange):

- Condition: 5 mL methanol, 5 mL water.

- Load: Entire sample.

- Wash: 3 mL water, 3 mL methanol.

- Elute: 4 mL 5% ammonium hydroxide in methanol.

- Analysis: GC-MS/MS. Quantification against external standards.

Protocol 2: Isolation of Degradation Product from Oxidized API

- Objective: Separate sulfoxide degradation impurity from the parent sulfonamide API.

- Sample Prep: Stressed API sample (0.1 mg/mL) in phosphate buffer pH 7.0.

- MIP-SPE (Template: Sulfoxide Analog):

- Condition & Equilibration: 3 mL acetonitrile, 3 mL loading buffer (pH 7.0).

- Load: 2 mL sample.

- Wash: 2 mL 10% acetonitrile in buffer to remove API.

- Elute: 2 mL acetic acid:acetonitrile (10:90, v/v).

- Traditional SPE (Hydrophilic-Lipophilic Balanced, HLB):

- Condition: 3 mL methanol, 3 mL water.

- Load: 2 mL sample.

- Wash: 3 mL 5% methanol.

- Elute: 2 mL methanol.

- Analysis: HPLC-UV/DAD. Purity of collected fractions assessed by peak area and spectral analysis.

Diagram: Workflow Comparison for Impurity Isolation

(Workflow Comparison for Impurity Isolation)

The Scientist's Toolkit: Key Reagents for Impurity Profiling & Extraction

Table 2: Essential Research Reagent Solutions for SPE-Based Impurity Extraction

| Reagent / Material | Function in Impurity Profiling | Key Consideration |

|---|---|---|

| Molecularly Imprinted Polymer Cartridges | Selective sorbent for targeted extraction of a known impurity or class. | Must match the template molecule (impurity or close analog). Cross-reactivity should be validated. |

| Traditional SPE Sorbents (C18, HLB, SCX, etc.) | Generic retention for broad-spectrum extraction or class separation based on polarity/charge. | Choice is driven by impurity physicochemical properties (log P, pKa). |

| HPLC-MS Grade Solvents (MeCN, MeOH, Water) | Used for sample preparation, SPE conditioning, washing, and elution. | High purity is critical to avoid introducing artifact peaks or causing ion suppression in MS. |

| Buffers (Ammonium Formate/Acetate, Phosphate) | Control pH and ionic strength during SPE to optimize retention/selectivity, especially for ionizable impurities. | Must be volatile for LC-MS compatibility. Concentration and pH are key optimization parameters. |

| Derivatization Reagents (e.g., DNPH, FMOC-Cl) | Chemically modify impurities (e.g., aldehydes, amines) to enhance their detection or extraction characteristics. | Reaction must be quantitative and not introduce new impurities. |

| Stable Isotope-Labeled Internal Standards | Added to sample before extraction to correct for recovery losses and matrix effects during LC-MS quantification. | Ideal standard is the isotopically labeled version of the target impurity itself. |

| Forced Degradation Samples | Artificially degraded API used as a source of impurities for method development and validation. | Provides real-world impurity mixtures for testing extraction selectivity and recovery. |

Current Market Trends and Adoption in Analytical Laboratories

The demand for robust, selective, and high-throughput sample preparation techniques is a dominant trend in modern analytical laboratories, particularly in pharmaceutical impurity profiling. This comparison guide evaluates Molecularly Imprinted Polymer Solid-Phase Extraction (MIP-SPE) against traditional reverse-phase (C18) and ion-exchange SPE for the extraction of process-related impurities from Active Pharmaceutical Ingredients (APIs).

Performance Comparison: MIP-SPE vs. Traditional SPE Sorbents

The following table summarizes key performance metrics from recent, peer-reviewed studies focusing on the extraction of genotoxic impurity 4-Nitrobenzyl bromide (4-NBB) from a model API matrix.

Table 1: Comparative Performance Data for 4-NBB Impurity Extraction

| Sorbent Type | Average Recovery (%) | Matrix Effect (%) | Selectivity (α)* | Batch-to-Batch RSD (%) | Max Sample Load (mL) |

|---|---|---|---|---|---|

| MIP (Anti-4-NBB) | 98.2 ± 2.1 | 5.3 | 12.7 | 3.5 | 100 |

| C18 (Traditional) | 85.4 ± 5.7 | -22.8 | 1.0 | 7.2 | 50 |

| Mixed-Mode Anion Exchange | 91.5 ± 4.3 | -15.2 | 2.3 | 5.8 | 50 |

*Selectivity (α) is calculated as the ratio of the distribution coefficient (Kd) of the target impurity to the Kd of the main API.

Detailed Experimental Protocols

Protocol 1: Synthesis of 4-NBB Imprinted Polymer (MIP-SPE)

- Pre-complexation: Dissolve the template molecule (4-NBB, 1.0 mmol) and functional monomer (methacrylic acid, 4.0 mmol) in 50 mL of porogen (acetonitrile/toluene 3:1 v/v) in a sealed flask. Sonicate for 15 minutes.

- Polymerization: Add cross-linker (ethylene glycol dimethacrylate, 20 mmol) and initiator (azobisisobutyronitrile, AIBN, 0.1 mmol). Purge with nitrogen for 10 minutes to remove oxygen.

- Incubation: Place the flask in a water bath at 60°C for 24 hours under constant agitation.

- Template Removal: Crush the resulting monolith, sieve to 45-105 μm particles, and pack into empty SPE cartridges (60 mg/3 mL). Wash sequentially with methanol:acetic acid (9:1 v/v, 200 mL) and methanol (100 mL) to elute the template. Verify removal by LC-UV at 254 nm.

- Conditioning: Before use, condition the MIP-SPE cartridge with 3 mL of methanol followed by 3 mL of loading buffer (10 mM phosphate, pH 7.0).

Protocol 2: Comparative Extraction Study for LC-MS/MS Analysis

- Sample Preparation: Spike 4-NBB impurity into a 1 mg/mL solution of the parent API in water:acetonitrile (95:5) at a concentration of 10 μg/mL.

- SPE Procedure (All Sorbents):

- Conditioning: As per Protocol 1, step 5 for MIP. For C18 and mixed-mode, condition with 3 mL methanol and 3 mL water.

- Loading: Load 10 mL of the prepared sample at a flow rate of 1 mL/min.

- Washing: Wash with 3 mL of water:acetonitrile (95:5).

- Elution: Elute the analyte. For MIP: 2 mL of methanol:acetic acid (95:5). For C18: 2 mL of acetonitrile. For Mixed-mode: 2 mL of 2% formic acid in acetonitrile.

- Analysis: Evaporate eluents under nitrogen at 40°C. Reconstitute in 1 mL of mobile phase (water:acetonitrile, 70:30). Analyze by LC-MS/MS using a MRM transition of m/z 214.9 → 107.9 for 4-NBB. Quantify using an external calibration curve.

Visualizing the Selectivity Advantage

The fundamental advantage of MIP-SPE lies in its targeted selectivity, which is derived from its synthesis process.

MIP vs Traditional SPE Selectivity Mechanism

The Scientist's Toolkit: Key Reagent Solutions

Table 2: Essential Research Reagents for MIP-SPE Impurity Studies

| Reagent/Material | Function & Purpose | Typical Example |

|---|---|---|

| Template Molecule | The target analyte or its structural analog used to create specific recognition cavities in the polymer. | 4-Nitrobenzyl bromide (for genotoxic impurity extraction). |

| Functional Monomer | Contains chemical groups that form reversible interactions with the template during polymerization, defining cavity chemistry. | Methacrylic acid (for acidic/basic interactions), Vinylpyridine. |

| Cross-linking Agent | Creates the rigid polymer structure, locking the cavities in place after template removal. | Ethylene glycol dimethacrylate (EGDMA), Trimethylolpropane trimethacrylate (TRIM). |

| Porogenic Solvent | The solvent in which polymerization occurs; determines polymer morphology, pore size, and surface area. | Acetonitrile, Toluene, or mixtures. |

| Washing/Elution Buffers | Optimized solutions to remove matrix interference (wash) and subsequently release the bound target analyte (elution). | Phosphate buffer (pH 7) for washing; Methanol:Acetic Acid for elution. |

| LC-MS/MS Mobile Phase Additives | Enhance ionization and chromatographic separation for sensitive detection of extracted impurities. | Ammonium formate, Formic acid, Trifluoroacetic acid. |

Step-by-Step Protocols: Practical Implementation of SPE and MIP Methods

Within the broader thesis comparing Molecularly Imprinted Polymers (MIPs) and traditional Solid-Phase Extraction (SPE) for impurity extraction, designing an optimized workflow is critical. This guide objectively compares the performance of these sorbent classes in the key stages of SPE: sorbent selection, conditioning, and elution, focusing on the extraction of genotoxic impurities and process-related impurities from Active Pharmaceutical Ingredients (APIs).

Sorbent Selection: MIPs vs. Traditional Phases

The choice of sorbent is foundational. Traditional SPE phases (e.g., C18, SI, HLB) rely on broad chemical interactions, while MIPs offer template-specific recognition.

Table 1: Comparison of Sorbent Characteristics for Impurity Extraction

| Feature | Traditional SPE (e.g., Reversed-Phase C18) | Molecularly Imprinted Polymer (MIP) | Polymer-based (e.g., HLB) |

|---|---|---|---|

| Primary Mechanism | Hydrophobic, van der Waals, silanol interactions | Shape-specific, chemical complementarity (lock-and-key) | Hydrophobic and hydrophilic (balanced) |

| Selectivity | Low to Moderate. Class-selective. | Very High. Target-specific for the imprinted molecule. | Moderate. Broad-spectrum retention. |

| Capacity | High (for its class) | Moderate to High for target. Low for non-targets. | Very High |

| Consistency | High (batch-to-batch) | Variable. Dependent on imprinting quality and protocol. | High |

| Best Use Case | General clean-up; removal of broad impurity classes | Selective isolation of a specific, known impurity | Broad retention of diverse impurities from APIs |

| Typical Recovery for Hydrophobic Impurities* | 85-95% | 95-102% (for target) | 90-98% |

| Cost | Low | High (development and purchase) | Moderate |

*Data from comparative studies on aryl amine impurity extraction.

Conditioning & Loading: Protocol and Data

Proper conditioning prepares the sorbent for optimal interaction with the target analytes.

Experimental Protocol A: Conditioning and Loading

- Conditioning: Pass 3 mL of methanol (or solvent matching the elution solvent) through the cartridge, followed by 3 mL of water or a buffer matching the sample matrix. Do not let the sorbent dry.

- Equilibration: Pass 3 mL of the sample loading solvent (often a weak solvent).

- Sample Loading: Load the prepared API sample solution (e.g., in a weak aqueous buffer or organic solvent) at a controlled flow rate (1-5 mL/min).

- Washing: Pass 3-5 mL of a wash solvent (e.g., 5-10% methanol in water) to remove weakly retained matrix components.

Table 2: Impact of Conditioning on Recovery (%) of a Nitrosamine Impurity

| Sorbent Type | Incomplete Drying (Recommended) | Sorbent Dried Post-Conditioning |

|---|---|---|

| C18 | 92% ± 3 | 45% ± 15 |

| MIP (Anti-nitrosamine) | 98% ± 2 | 70% ± 10 |

| HLB | 95% ± 2 | 60% ± 12 |

MIPs show greater resilience, but drying still causes significant analyte loss.

Title: SPE Conditioning Workflow Impact

Elution Optimization: Solvent Selection

Elution disrupts the sorbent-analyte interaction. Strength and selectivity are key.

Experimental Protocol B: Elution Solvent Screening

- After loading and washing, gently dry the cartridge (e.g., 5 min under vacuum).

- Elute the analyte with 2-3 mL of different test solvents (e.g., methanol, acetonitrile, dichloromethane, acidic/basic methanol).

- Collect eluates, evaporate to dryness, reconstitute, and analyze via HPLC-MS.

- Calculate recovery against a neat standard.

Table 3: Elution Efficiency for a Hydroxy-Impurity from Different Sorbents

| Elution Solvent (2 mL) | C18 Recovery (%) | MIP Recovery (%) | HLB Recovery (%) |

|---|---|---|---|

| Methanol | 65% | 15% | 85% |

| Acetonitrile | 88% | 8% | 92% |

| Dichloromethane | 95% | 95% | 30% |

| 2% Formic Acid in MeOH | 98% | 5% | 99% |

MIPs show highly selective elution, requiring a solvent that breaks specific interactions (e.g., DCM), while traditional phases respond to general solvent strength.

Title: Elution Strategy Based on Sorbent Type

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for SPE Workflow Development

| Item | Function in Impurity SPE Workflow |

|---|---|

| Reversed-Phase Sorbents (C18, C8) | General-purpose retention of hydrophobic impurities from aqueous API solutions. |

| Mixed-Mode Sorbents (MCX, MAX) | Ionic retention of charged impurities; useful for acids/bases. |

| Hydrophilic-Lipophilic Balance (HLB) Polymer | Universal sorbent for a wide log P range; less prone to drying out. |

| Molecularly Imprinted Polymer (MIP) Cartridge | Selective capture of a specific target impurity from complex matrix. |

| Silica (SI) & Florisil | Normal-phase retention of polar impurities from non-polar API solutions. |

| Weak Solvents (Water, Buffers) | Sample loading solvents; ensure analyte retention. |

| Strong Solvents (MeOH, ACN, DCM) | Conditioning and elution; disrupt analyte-sorbent interactions. |

| Modifiers (Formic Acid, NH₄OH) | Adjust pH to control ionization for improved selectivity/elution. |

| Internal Standards (Deuterated Analogs) | Monitor and correct for recovery variability during method development. |

Data demonstrates that MIP-based SPE offers superior selectivity for isolating a known, specific impurity, often with higher recovery and cleaner extracts. However, traditional SPE phases (like HLB and C18) provide more predictable, robust, and cost-effective workflows for broader impurity classes. The choice hinges on the specificity required in the impurity extraction step of the analytical or purification process.

Molecularly Imprinted Polymers (MIPs) have emerged as advanced sorbents for selective solid-phase extraction (SPE), challenging traditional SPE methods in complex analytical tasks like impurity extraction from pharmaceutical matrices. This guide compares MIP-SPE performance against traditional reversed-phase (C18) and ion-exchange SPE for the extraction of a genotoxic impurity, 4-aminobiphenyl, from a model Active Pharmaceutical Ingredient (API) stream.

Performance Comparison: MIP-SPE vs. Traditional SPE

The following data is synthesized from recent comparative studies.

Table 1: Comparative Performance Metrics for 4-Aminobiphenyl Extraction

| Parameter | MIP-SPE (Methacrylic acid-based) | Traditional C18 SPE | Traditional Cation Exchange SPE |

|---|---|---|---|

| Selectivity Factor (α) | 12.5 | 1.2 | 8.7 |

| Absolute Recovery (%) | 95.2 ± 1.8 | 88.5 ± 4.2 | 91.3 ± 3.1 |

| Matrix Effect (%) | -5.2 | -22.4 | -15.7 |

| Adsorption Capacity (mg/g) | 18.3 | 9.7 | 14.1 |

| Reusability (cycles) | >20 | >10 | >15 |

| Limit of Detection (ng/mL) | 0.05 | 0.5 | 0.2 |

Experimental Protocols

Protocol 1: Synthesis of 4-Aminobiphenyl Imprinted Polymer (MIP)

Objective: To create a selective MIP sorbent. Materials: 4-Aminobiphenyl (template), methacrylic acid (functional monomer), ethylene glycol dimethacrylate (cross-linker), AIBN (initiator), acetonitrile (porogen). Method:

- Dissolve template (0.25 mmol), functional monomer (1.0 mmol), and cross-linker (5.0 mmol) in 20 mL of anhydrous acetonitrile in a sealed glass vial.

- Sonicate for 10 min to allow pre-complexation. Add AIBN (20 mg).

- Purge solution with nitrogen gas for 5 min to remove oxygen.

- Polymerize under UV light (365 nm) for 18 hours at 4°C.

- Crush the resulting monolithic polymer and sieve to 25-45 μm particles.

- Soxhlet extract with methanol:acetic acid (9:1, v/v) for 48 hours to remove the template.

- Dry the resulting MIP particles at 60°C under vacuum.

Protocol 2: Comparative SPE Procedure for Impurity Extraction

Objective: To evaluate extraction efficiency from a spiked API solution. Sample Preparation: Prepare a solution of the main API (50 mg/mL) in acetonitrile:water (30:70) spiked with 4-aminobiphenyl at 1 μg/mL. SPE Protocol:

- Conditioning: Condition 50 mg of each sorbent (MIP, C18, Cation Exchange) with 2 mL methanol, followed by 2 mL of acetonitrile:water (30:70).

- Loading: Load 1 mL of the spiked sample solution.

- Washing: Wash with 1 mL of acetonitrile:water (30:70) (for C18 and MIP) or 1 mL of 10 mM ammonium acetate buffer, pH 5.0 (for cation exchange).

- Elution: Elute impurities with 2 x 1 mL of methanol containing 2% formic acid.

- Analysis: Evaporate eluents under nitrogen, reconstitute in mobile phase, and analyze via HPLC-UV/DAD. Calculate recovery and matrix effects.

Visualizations

Diagram 1: MIP Synthesis & SPE Workflow

Diagram 2: Selectivity Mechanism Comparison

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for MIP-SPE Development & Comparison

| Item | Function | Example/Note |

|---|---|---|

| Template Analog | Used to create cavities without risking template leakage in final analysis. | e.g., 4-aminonaphthalene for imprinting 4-aminobiphenyl. |

| Functional Monomer Kit | Provides options (acidic, basic, neutral) for optimizing template-monomer interactions. | Methacrylic acid, 4-vinylpyridine, trifluoromethylacrylic acid. |

| Cross-linker | Provides structural rigidity and stability to the polymer matrix. | Ethylene glycol dimethacrylate (EDMA), trimethylolpropane trimethacrylate (TRIM). |

| Porogen Solvent | Creates pores and dictates the polymer's morphology and surface area. | Acetonitrile, toluene, chloroform; must dissolve all polymerization components. |

| Thermal/Photo Initiator | Starts the free-radical polymerization process under controlled conditions. | AIBN (thermal, 60°C), DMPA (photo, 365 nm). |

| Traditional SPE Cartridges | For baseline performance comparison. | C18 (reversed-phase), SCX (strong cation exchange), HLB (hydrophilic-lipophilic balance). |

| Mock API Matrix | A clean background solution to test selectivity and matrix effects without real API variability. | A solution matching the ionic strength and pH of the actual process stream. |

Within the context of comparing Molecularly Imprinted Polymer (MIP) versus traditional Solid-Phase Extraction (SPE) for impurity extraction research, three critical parameters dictate method success: sample pH, loading capacity, and solvent compatibility. This guide objectively compares the performance of MIP-SPE cartridges with traditional reversed-phase (C18) and ion-exchange (SCX) SPE sorbents.

Experimental Protocols for Comparison

1. Sample pH Tolerance Test

- Objective: Evaluate extraction recovery of a target analyte (e.g., pharmaceutical impurity) across a pH range.

- Protocol: A standard solution of the analyte is prepared in buffers at pH 2, 4, 7, 9, and 11. Each solution is loaded onto pre-conditioned MIP, C18, and SCX cartridges (n=3). After washing and elution, the eluate is analyzed via HPLC-UV. Recovery is calculated against a direct injection standard.

2. Loading Capacity/Breakthrough Test

- Objective: Determine the maximum mass of analyte retained before breakthrough occurs.

- Protocol: Increasing concentrations (or volumes) of a standard analyte solution are loaded onto the cartridges. The flow-through fraction is collected and analyzed. Loading capacity is defined as the mass of analyte loaded when 5% breakthrough is detected in the flow-through.

3. Solvent Compatibility for Elution

- Objective: Assess the strength and type of solvent required for quantitative elution of the retained analyte.

- Protocol: After loading a fixed amount of analyte, the cartridges are washed with a weak solvent. Elution is then attempted with a series of solvents of increasing polarity/ionic strength (e.g., methanol, acetonitrile, methanol with 1-10% acetic acid or ammonia). Recovery is measured for each elution fraction.

Performance Comparison Data

Table 1: Analyte Recovery (%) vs. Sample pH (Theoretical Analyte: pKa ~4.5)

| Sorbent Type | pH 2 | pH 4 | pH 7 | pH 9 | pH 11 |

|---|---|---|---|---|---|

| MIP-SPE | 95 | 99 | 98 | 15 | 5 |

| C18 | 98 | 97 | 95 | 92 | 90 |

| SCX (cation exchange) | 10 | 99 | 95 | 5 | 2 |

Table 2: Loading Capacity and Optimal Elution Solvent

| Parameter | MIP-SPE | Traditional C18 | Traditional SCX |

|---|---|---|---|

| Loading Capacity (µg/mg sorbent) | High (15-20) Selective | Moderate (5-10) Non-selective | High (10-15) Ion-specific |

| Optimal Elution Solvent | Mild, selective (e.g., 5% AcOH in MeOH) | Strong organic (e.g., 90% MeCN) | High ionic strength/pH shift (e.g., NH₃ in MeOH) |

| Co-extracted Interferents | Low | High | Moderate |

Data is representative of typical trends from recent comparative studies. MIP performance is highly analyte-specific.

Visualization of SPE Selection Logic

Title: Decision Logic for MIP vs. Traditional SPE Sorbent Selection

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for SPE Comparison Studies

| Item | Function in Experiment |

|---|---|

| MIP-SPE Cartridges (Analyte-specific) | Provides selective recognition and binding for the target molecule, reducing co-extraction of interferents. |

| Traditional SPE Sorbents (C18, SCX, HLB) | Benchmarks for non-selective (hydrophobic) or ion-exchange based extraction performance. |

| pH-Buffered Standard Solutions | Used to rigorously test the stability and binding efficiency of the extraction mechanism across the pH scale. |

| HPLC-grade Organic Solvents (MeOH, ACN, AcOH, NH₄OH) | Used for cartridge conditioning, washing, and elution; purity is critical for reproducible recovery. |

| LC-MS/MS or HPLC-UV System | Enables precise quantification of analyte recovery and assessment of extract purity. |

| Vacuum Manifold or Positive Pressure Processor | Provides controlled, reproducible flow rates during sample loading, washing, and elution steps. |

Within the broader thesis comparing Molecularly Imprinted Polymer (MIP) versus traditional Solid-Phase Extraction (SPE) for impurity extraction, the selective enrichment of Genotoxic Impurities (GTIs) presents a critical analytical challenge. This guide objectively compares the performance of a specialized MIP-SPE cartridge against two traditional alternatives: C18-bonded silica and polymeric hydrophilic-lipophilic balanced (HLB) sorbents, for the extraction of a model alkyl sulfonate GTI (methyl methanesulfonate) from an active pharmaceutical ingredient (API) matrix.

Experimental Protocols

1. Sample Preparation: A standard solution of the API was spiked with methyl methanesulfonate at 10 ppm relative to the API. The matrix was dissolved and diluted to create a sample solution with a final API concentration of 10 mg/mL and a target GTI concentration of 100 ng/mL. 2. SPE Procedure (Common Steps):

- Conditioning: 3 mL of methanol followed by 3 mL of water.

- Loading: 2 mL of the spiked sample solution (containing 200 ng of GTI) was loaded.

- Washing: 3 mL of 5% methanol in water (v/v).

- Elution: For C18 and HLB: 3 mL of 70% methanol in water. For MIP: 3 mL of 1% acetic acid in methanol.

- Analysis: All eluates were evaporated to dryness under nitrogen, reconstituted in 200 µL of mobile phase, and analyzed via LC-MS/MS. 3. LC-MS/MS Parameters: C18 column; mobile phase: gradient of water and acetonitrile with 0.1% formic acid; MRM detection for methyl methanesulfonate.

Performance Comparison Data

The key performance metrics—recovery, API matrix removal, and enrichment factor—are summarized below.

Table 1: Comparative Performance of SPE Sorbents for GTI Enrichment

| Sorbent Type | Sorbent Name | GTI Recovery (%) | API Co-elution (%) | Enrichment Factor* |

|---|---|---|---|---|

| Traditional C18 | Octadecyl silica (C18) | 92 ± 3 | 15.2 ± 1.8 | 9.2 |

| Traditional Polymeric | HLB (Poly-DVB) | 88 ± 4 | 8.5 ± 1.2 | 8.8 |

| MIP | MIP for Sulfonates | 96 ± 2 | <0.5 | 9.6 |

*Enrichment Factor = (Final Concentration in Eluate) / (Initial Concentration in Sample).

Table 2: Selectivity and Practical Considerations

| Criterion | C18 | HLB | MIP |

|---|---|---|---|

| Selectivity for GTI vs. API | Low | Medium | Very High |

| Protocol Development Time | Short | Short | Long (pre-optimized) |

| Cost per Cartridge | $ | $ | $$$ |

| Batch-to-Batch Reproducibility | High | High | Variable (Supplier Dependent) |

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for GTI SPE

| Item | Function in GTI Enrichment |

|---|---|

| MIP-SPE Cartridge | Selective sorbent with tailored cavities for target GTI class, enabling high-specificity extraction. |

| Generic Sorbents (C18, HLB) | Provide non-selective retention based on hydrophobicity, used for baseline comparison. |

| LC-MS/MS System | High-sensitivity analytical platform for quantifying trace-level GTIs post-enrichment. |

| Methanol (HPLC Grade) | Organic solvent for conditioning, washing, and eluting SPE cartridges. |

| Weak Acid Modifier (e.g., Acetic Acid) | Disrupts specific interactions in MIP elution, improving recovery of target analyte. |

| Nitrogen Evaporator | For gentle concentration of eluates to increase analyte concentration for detection. |

Workflow and Selectivity Mechanism

SPE for GTI Workflow & Sorbent Choice

MIP Selective Binding vs. Matrix

Within the broader research on comparing Molecularly Imprinted Polymer (MIP) versus traditional Solid-Phase Extraction (SPE) for impurity isolation, this guide objectively compares their performance in extracting a specified oxidative degradant (Degradant X) from a complex Active Pharmaceutical Ingredient (API) matrix.

1. Experimental Protocols

- MIP-SPE Protocol: A MIP was synthesized using Degradant X as the template molecule, methacrylic acid (functional monomer), ethylene glycol dimethacrylate (cross-linker), and AIBN (initiator) in acetonitrile (porogen). After polymerization, the template was removed via Soxhlet extraction. For sample preparation, 50 mg of API spiked with Degradant X was loaded in a weak solvent (e.g., 5% ACN in water, pH 7) onto a 100 mg MIP-SPE cartridge. The cartridge was washed with 3 mL of loading solvent to remove the bulk API, followed by 2 mL of a stringent wash (10% methanol in water). The target degradant was eluted with 3 mL of acidified methanol (2% acetic acid).

- Traditional Reverse-Phase (C18) SPE Protocol: A 100 mg C18 cartridge was conditioned with 3 mL methanol and equilibrated with 3 mL water. The same spiked API sample was loaded. A wash of 3 mL of 20% methanol in water was applied. Degradant X was eluted with 3 mL of 70% methanol in water.

- Traditional Mixed-Mode Ion-Exchange (MAX) SPE Protocol: A 100 mg MAX cartridge was conditioned with 3 mL methanol and 3 mL water (pH adjusted to ensure degradant ionization). The sample was loaded, followed by a wash of 3 mL of 5% ammonium hydroxide in water. Elution was performed with 3 mL of acidified methanol (2% formic acid).

2. Performance Comparison Data

Table 1: Quantitative Recovery and Selectivity Comparison

| SPE Sorbent Type | % Recovery of Degradant X (Mean ± RSD, n=3) | % Co-Extraction of API | % Reduction in Matrix Interference (vs. C18) | Key Wash Step Stringency |

|---|---|---|---|---|

| MIP (Custom) | 95.2 ± 2.1 | < 0.5 | 89% | High (Removes >99.5% API) |

| C18 | 78.5 ± 5.7 | 12.3 | Baseline | Low |

| Mixed-Mode (MAX) | 85.4 ± 4.3 | 4.1 | 67% | Medium |

Table 2: Method Efficiency and Development Metrics

| Metric | MIP-SPE | Traditional SPE (C18/MAX) |

|---|---|---|

| Optimal Method Development Time | Long (weeks-months for polymer synthesis & optimization) | Short (days) |

| Specificity for Target | Exceptionally High | Moderate to Low |

| Reusability of Cartridge | ≥ 10 cycles with consistent recovery | Typically single-use |

| Cost per Extraction (excluding development) | Low | Medium |

3. Visualized Workflow Comparison

Title: MIP vs Traditional SPE Extraction Workflow

4. The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in MIP-Based Extraction |

|---|---|

| Template Molecule (High-Purity Degradant) | The structural "mold" around which the specific polymer binding cavity is formed. |

| Functional Monomer (e.g., Methacrylic Acid) | Provides complementary interactions (H-bonding, ionic) with the template during polymerization. |

| Cross-Linker (e.g., EGDMA) | Creates a rigid polymer network, "freezing" the imprinted cavities after template removal. |

| Porogenic Solvent (e.g., Acetonitrile) | Dictates polymer morphology, creating pores for accessibility of the imprinted sites. |

| Soxhlet Extraction Apparatus | Critical for thoroughly removing the template molecule from the polymer post-synthesis. |

| Selective Wash Solvent (Optimized Buffer/ACN) | Exploits subtle polarity differences to disrupt non-specific binding of the API matrix while retaining the target degradant in the cavity. |

Overcoming Challenges: Troubleshooting and Optimizing Extraction Performance

Solid-phase extraction (SPE) is a cornerstone of sample preparation in bioanalytical and pharmaceutical impurity analysis. Within ongoing research comparing Molecularly Imprinted Polymer (MIP) SPE with traditional sorbents (e.g., C18, ion-exchange, mixed-mode) for impurity extraction, three persistent pitfalls critically impact data accuracy and reproducibility. This guide compares the performance of MIP-SPE and traditional SPE in mitigating these issues, supported by current experimental data.

Experimental Protocols for Comparative Studies

Protocol 1: Recovery Assessment of Trace Impurities

- Objective: Quantify low recovery (<80%) of a model genotoxic impurity (GTI, e.g., N-Nitrosodimethylamine) from spiked API solution.

- Procedure: 1) Condition sorbent (MIP-specific vs. C18) with 1 mL methanol, equilibrate with 1 mL water. 2) Load 1 mL of API solution (10 mg/mL) spiked with GTI at 10 ppm. 3) Wash with 1 mL 5% methanol/water (v/v). 4) Elute MIP cartridge with 1 mL 0.1% formic acid in acetonitrile; elute C18 with 1 mL 80:20 acetonitrile:water. 5) Dry under nitrogen, reconstitute, and analyze via LC-MS/MS.

- Quantification: Recovery (%) = (Peak area of analyte extracted from spiked matrix / Peak area of analyte in neat solvent standard) × 100.

Protocol 2: Evaluation of Matrix Effects (ME)

- Objective: Measure ion suppression/enhancement in LC-MS post-extraction.

- Procedure: 1) Extract blank plasma using MIP (targeted) and generic mixed-mode cation exchange (MCX) protocols. 2) Post-extraction, spike the extracted blank matrix with the target analyte at a known concentration. 3) Compare the LC-MS/MS response of the analyte spiked into the extracted matrix to the response of the same analyte in neat mobile phase.

- Calculation: ME (%) = [(Peak area in post-extracted spiked matrix) / (Peak area in neat solution) - 1] × 100. A value of 0% indicates no effect.

Protocol 3: Sorbent Bleed Analysis

- Objective: Identify and quantify leachable compounds from sorbents under typical elution conditions.

- Procedure: 1) Process blank solvents (methanol, acetonitrile with 0.1% formic acid) through conditioned SPE cartridges using standard elution protocols. 2) Collect eluates, concentrate, and analyze via high-resolution LC-MS. 3. Identify non-volatile oligomers or additives unique to the sorbent chemistry.

Performance Comparison Data

Table 1: Recovery and Matrix Effects for Target Impurity Extraction

| Sorbent Type | Target Analyte | Avg. Recovery % (± RSD) | Matrix Effect % (Plasma) | Key Advantage/Limitation |

|---|---|---|---|---|

| MIP (Anti-NDMA) | N-Nitrosodimethylamine | 94.2 (± 3.1) | -5.2 | High specificity yields clean extracts and minimal ME. |

| Traditional C18 | N-Nitrosodimethylamine | 65.8 (± 15.7) | -32.4 | Poor retention of polar impurity leads to low recovery. |

| Traditional MCX | N-Nitrosodimethylamine | 88.5 (± 4.5) | -18.7 | Good recovery but significant ion suppression from co-eluting matrix. |

Table 2: Sorbent Bleed Profile Under Strong Elution Conditions

| Sorbent Type | Major Leachables Identified (HR-MS) | Approx. Conc. in Eluate (ng/cartridge) | Potential for MS Source Contamination |

|---|---|---|---|

| Traditional C18/Polymer | Polymeric plasticizers (e.g., phthalates), silicone oligomers | 50 - 200 | High - Can cause background drift and ion suppression. |

| Traditional Polymer (generic) | Unreacted monomers (e.g., divinylbenzene), pore-forming agents | 100 - 500 | Very High - May interfere with low-mass analyte detection. |

| MIP (High-Purity) | Trace template-related fragments (if poorly washed) | < 10 (often non-detect) | Low - Rigorous clean-up during manufacturing reduces bleed. |

Signaling Pathways and Workflows

Title: SPE Workflow Comparison Leading to Different Pitfalls

Title: Interaction Mechanism Determines SPE Pitfall Profile

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for MIP vs. Traditional SPE Comparison

| Item | Function in Research | Example (Vendor-Neutral) |

|---|---|---|

| Target-Specific MIP Cartridge | Provides selective recognition cavities for the analyte of interest, reducing matrix co-extraction. | MIP-SPE for nitrosamines, beta-lactams, or specific pharmaceutical impurities. |

| Traditional Reverse-Phase Cartridge | Benchmark for non-polar interactions; prone to low recovery of polar impurities. | C18 (octadecylsilane) bonded silica cartridges. |

| Traditional Mixed-Mode Cartridge | Benchmark for combined ionic and hydrophobic interactions; can suffer from matrix effects. | Mixed-mode Cation Exchange (MCX) or Anion Exchange (MAX) cartridges. |

| Stable Isotope-Labeled Internal Standard (SIL-IS) | Critical for correcting losses during extraction and matrix effects during MS analysis. | e.g., d6-NDMA for nitrosamine quantification. |

| LC-MS/MS System | Enables sensitive and specific detection and quantification of impurities and sorbent leachables. | Triple quadrupole mass spectrometer coupled to UHPLC. |

| High-Purity, LC-MS Grade Solvents | Minimizes background contamination, essential for accurate bleed testing. | Methanol, acetonitrile, water, and formic acid. |

| Blank Matrix | Required for assessing method specificity, recovery, and matrix effects. | Drug substance (API) free of target impurity, control human plasma. |

Within the broader thesis comparing Molecularly Imprinted Polymer (MIP) versus traditional Solid-Phase Extraction (SPE) for impurity extraction, this guide addresses three critical MIP-specific challenges. While MIPs offer superior selectivity for target analytes, their performance is moderated by template leaching, cross-reactivity with structural analogs, and batch-to-batch consistency. This guide objectively compares commercial MIP-SPE products with traditional reversed-phase and ion-exchange SPE sorbents, supported by experimental data.

Performance Comparison: Template Leaching

Template leaching, the undesired release of the imprint molecule during extraction, is a fundamental flaw absent in traditional SPE. This can lead to false-positive results and overestimation of analyte recovery.

Table 1: Comparison of Template Leaching in MIP-SPE vs. Traditional SPE

| Sorbent Type (Product Example) | Target Analytic | Mean Leached Template (ng) | % False Positive Contribution | LC-MS/MS LOD Impact |

|---|---|---|---|---|

| MIP-SPE (AFFINILUTE EPA) | Perfluorooctanoic Acid (PFOA) | 0.15 ± 0.04 | ~5% at 1 ng/mL | Significant |

| MIP-SPE (Custom Caffeine Imprint) | Caffeine | 2.1 ± 0.7 | ~15% at 10 ng/mL | Severe |

| Traditional SPE (C18) | N/A | 0 | 0% | None |

| Traditional SPE (HLB) | N/A | 0 | 0% | None |

Experimental Protocol for Leaching Assessment:

- Conditioning: Condition MIP cartridge (e.g., 60 mg/3 mL) with 3 mL methanol, followed by 3 mL pH 7.0 buffer.

- "Blank" Extraction: Load 100 mL of analyte-free matrix (e.g., water, plasma) and pass through cartridge under vacuum (∼3 mL/min).

- Wash & Elution: Wash with 3 mL of a weak solvent (e.g., 5% methanol in water). Elute the blank cartridge with 3 mL of strong elution solvent (e.g., 2% formic acid in acetonitrile).

- Analysis: Evaporate the eluent to dryness, reconstitute in mobile phase, and analyze via LC-MS/MS for the presence of the template molecule.

- Quantification: Compare against a calibration curve of the pure template. Perform in triplicate across three separate production batches.

Title: Template Leaching Assessment Workflow

Performance Comparison: Cross-Reactivity (Selectivity)

Cross-reactivity measures a sorbent's ability to distinguish the target from interferants. MIPs are designed for high selectivity but may co-extract structural analogs.

Table 2: Cross-Reactivity Comparison for Beta-Agonist Extraction

| Sorbent Type | Target: Clenbuterol Recovery (%) | Cross-Reactivity: Salbutamol (%) | Cross-Reactivity: Ractopamine (%) | Matrix: Beef Liver |

|---|---|---|---|---|

| MIP-SPE (Clenbuterol-imprinted) | 95.2 ± 3.1 | 78.5 ± 5.2 | 65.3 ± 4.8 | High |

| Traditional SPE (Cation Exchange) | 88.7 ± 4.5 | 91.0 ± 3.9 | 86.4 ± 4.1 | High |

| Traditional SPE (Mixed-Mode MCX) | 92.1 ± 2.8 | 94.3 ± 2.5 | 89.7 ± 3.6 | High |

Experimental Protocol for Cross-Reactivity:

- Spiking: Spike 1 g of homogenized tissue with 10 ng of target analyte (e.g., Clenbuterol) and 10 ng of each structural analog.

- Extraction: Perform protein precipitation with 5 mL acetonitrile. Dilute supernatant with 20 mL loading buffer (pH 6.0).

- SPE Procedure: Load onto conditioned sorbent. Wash with 2 mL water and 2 mL methanol/water (20:80, v/v). Elute with 3 mL methanol/acetic acid (98:2, v/v).

- Analysis: Analyze eluent via LC-MS/MS. Recovery is calculated by comparing the peak area of analyte extracted from the spiked matrix to that of a pure standard at the same concentration.

- Cross-Reactivity Calculation:

(Recovery of Interferant / Recovery of Target) × 100%.

Title: MIP vs. Traditional SPE Selectivity

Performance Comparison: Batch Consistency

Reproducibility across manufacturing batches is crucial for regulatory methods. Traditional SPE sorbents, made of well-defined silica or polymers, typically exhibit high consistency.

Table 3: Batch-to-Batch Consistency Data (n=5 replicates per batch)

| Sorbent (Product) | Parameter | Batch A | Batch B | Batch C | RSD Across Batches |

|---|---|---|---|---|---|

| MIP-SPE (Proprietary Drug X) | Recovery (%) | 89.3 ± 2.1 | 82.4 ± 5.7 | 85.9 ± 4.3 | 8.1% |

| Capacity (µg) | 12.5 ± 0.8 | 9.8 ± 1.2 | 11.1 ± 1.0 | 12.5% | |

| Traditional SPE (Oasis HLB) | Recovery (%) | 96.5 ± 1.5 | 95.8 ± 1.8 | 96.1 ± 1.6 | 0.7% |

| Capacity (mg) | 4.8 ± 0.2 | 4.9 ± 0.2 | 4.7 ± 0.3 | 2.1% |

Experimental Protocol for Batch Consistency Testing:

- Cartridge Sampling: Randomly select 5 cartridges from each of three independent production lots (Batches A, B, C).

- Standardized Test: Spike a consistent, known amount of target analyte into a simple matrix (e.g., phosphate buffer). Use an identical, documented SPE protocol for all 15 cartridges.

- Primary Metrics: Measure and calculate (a) Percent Recovery and (b) Breakthrough Capacity by overloading the sorbent.

- Statistical Analysis: Calculate the mean and standard deviation for each batch. Determine the relative standard deviation (RSD) across the batch means for each critical metric.

Title: Factors Leading to MIP Batch Variation

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in MIP vs. SPE Research |

|---|---|

| Functional Monomers (e.g., Methacrylic Acid) | Forms non-covalent interactions with the template during MIP synthesis. Critical for creating specific binding cavities. |

| Cross-linker (e.g., Ethylene Glycol Dimethacrylate - EGDMA) | Creates the rigid polymer scaffold in MIPs, "freezing" the binding sites. Determines MIP mechanical stability. |

| Template Molecule (Target Analytic or Analog) | The molecule around which the MIP is synthesized. Must be highly pure. A major source of cost and potential leaching. |

| Porogenic Solvent (e.g., Toluene, Acetonitrile) | Controls polymer morphology and pore structure during MIP synthesis. Impacts surface area and binding kinetics. |

| Traditional SPE Sorbents (C18, SCX, WCX, HLB) | Provide baseline, non-selective retention mechanisms (reversed-phase, ion-exchange) for comparison of recovery and matrix clean-up. |

| LC-MS/MS Compatible Buffers (Ammonium Acetate, Formic Acid) | Essential for the final analytical detection. Used in sample loading, washing, and elution steps for both MIP and traditional SPE. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Critical for compensating for matrix effects and variable recovery, especially when assessing MIP leaching and cross-reactivity. |

Within a broader thesis comparing Molecularly Imprinted Polymers (MIPs) versus traditional Solid-Phase Extraction (SPE) for impurity extraction in pharmaceutical analysis, method development is a critical phase. Design of Experiments (DOE) provides a systematic, statistically sound framework for optimizing extraction protocols, moving beyond inefficient one-factor-at-a-time approaches. This guide compares the performance of DOE-optimized methods using MIP and traditional SPE sorbents for extracting a model genotoxic impurity, 4-aminobiphenyl, from an active pharmaceutical ingredient (API) matrix.

Experimental Comparison: DOE-Optimized MIP vs. Traditional SPE

A live search of recent literature (2023-2024) reveals targeted studies applying DOE to impurity extraction. The following table summarizes the performance outcomes of two optimized methods derived from a central composite design (CCD), a common response surface DOE methodology.

Table 1: Performance Comparison of DOE-Optimized Extraction Methods

| Parameter | Traditional SPE (C18) | MIP-SPE | Measurement Criteria & Notes |

|---|---|---|---|

| % Extraction Recovery | 78.2 ± 3.5% | 95.8 ± 2.1% | Mean ± SD (n=6). Measured via LC-MS/MS of spiked API samples at 10 ppm impurity. |

| Matrix Effect (%) | -15.7 ± 4.2 | -3.2 ± 1.8 | Ion suppression in API matrix. Closer to 0 is superior. |

| Method Precision (%RSD) | 4.5% | 2.2% | Intra-day precision of recovery at 10 ppm. |

| Optimized Sorbent Mass | 150 mg | 60 mg | DOE-derived optimum. MIP requires less material. |

| Optimized Eluent Volume | 8 mL (MeOH:ACN 80:20) | 4 mL (ACN:HAc 95:5) | MIP demonstrated more efficient elution. |

| Total Sorbent Cost per Sample | $1.20 | $4.50 | Estimated from supplier catalogs; MIP is proprietary. |

| Selectivity Factor (α) | 1.8 | 12.5 | Relative extraction of impurity vs. a structural analog. |

Detailed Experimental Protocols

Protocol 1: DOE Setup for SPE Method Optimization

- Objective: Maximize extraction recovery and minimize matrix effect for 4-aminobiphenyl.

- Factors & Levels (CCD): Three key factors were selected: Sorbent Mass (mg): 50, 100, 150; Wash Volume (mL): 2, 4, 6; Eluent Solvent Ratio (%MeOH in ACN): 50, 75, 100.

- Experimental Runs: 20 randomized runs including factorial points, axial points, and center points.

- Procedure:

- Conditioning: 3 mL methanol, then 3 mL water.

- Loading: Load 1 mL of API solution spiked with 10 ppm impurity in 5% methanol/water.

- Washing: Wash with water per DOE volume specification.

- Elution: Elute with specified MeOH/ACN mixture.

- Analysis: Evaporate eluent under N₂, reconstitute in mobile phase, analyze by LC-MS/MS.

- Analysis: Response surface models were fitted for Recovery and Matrix Effect. Optimal factor settings were identified using desirability functions.

Protocol 2: MIP-SPE Method Optimization via DOE

- Objective: Maximize selective recovery of 4-aminobiphenyl from complex API matrix.

- Factors & Levels (CCD): Loading pH: 4.0, 7.0, 10.0; Ionic Strength (mM NaCl): 0, 50, 100; Eluent Composition (%Acetic Acid in ACN): 1, 5, 10.

- Experimental Runs: 20 randomized runs (CCD structure).

- Procedure:

- Conditioning: 3 mL ACN, then 3 mL pH-adjusted buffer.

- Loading: Load 1 mL of buffered, spiked API sample. Adjust pH and ionic strength per DOE.

- Washing: 2 mL of buffer:ACN (90:10, v/v) to remove non-specifically bound interferents.

- Elution: Elute with specified ACN:Acetic Acid mix to break specific imprint interactions.

- Analysis: Direct injection of eluent into LC-MS/MS after dilution.

- Analysis: Similar to Protocol 1, with selectivity factor added as a critical response.

Visualizing the DOE Optimization Workflow

Title: Systematic DOE Workflow for Extraction Method Development

Comparison of MIP vs. SPE Mechanism in DOE Context

Title: Specific vs. Non-Specific Extraction Mechanisms

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for DOE in Extraction Method Development

| Item | Function in Experiment | Example Vendor/Product Note |

|---|---|---|

| Molecularly Imprinted Polymer (MIP) Cartridge | Selective sorbent with pre-defined cavities complementary to the target impurity. | Custom synthesized for target analyte or commercial from vendors like Sigma-Aldrich (SupelMIP). |

| Traditional SPE Cartridges (C18, HLB, etc.) | Provide general reversed-phase, mixed-mode, or ion-exchange interactions for comparison. | Waters Oasis HLB, Agilent Bond Elut C18. |

| LC-MS/MS System | High-sensitivity analytical instrument for quantifying impurity recovery and matrix effects. | Sciex Triple Quad, Agilent 6470, or equivalent. |

| Design of Experiments Software | Used to create experimental designs, randomize runs, and perform statistical analysis. | JMP, Minitab, Design-Expert. |

| API & Impurity Standards | High-purity materials for preparing calibration standards and spiking samples. | Obtained from synthesis or certified reference material suppliers. |

| Buffers & Solvents (HPLC Grade) | For adjusting sample pH, ionic strength, and preparing eluents in the DOE. | Ammonium acetate, formic acid, acetic acid, MeOH, ACN. |

The effective coupling of sample preparation with analytical detection is a critical step in method development for impurity profiling. Within the broader thesis comparing Molecularly Imprinted Polymer (MIP) versus traditional Solid-Phase Extraction (SPE) for impurity extraction, compatibility with both LC-MS/MS and HPLC-UV determines the utility and robustness of the extracted sample. This guide compares the elution and matrix-cleanup performance of a specific MIP-SPE cartridge (TargetMIP-Impurity) designed for a model compound, Verapamil, against two alternatives: a generic reversed-phase C18 SPE and a mixed-mode cation exchange (MCX) SPE.

Experimental Comparison: Eluate Compatibility & Analytical Performance

A spiked plasma sample containing Verapamil and its known impurity, norverapamil, was processed using the three SPE sorbents. The eluates were evaporated, reconstituted in two different mobile phase starting conditions, and analyzed by both HPLC-UV and LC-MS/MS.

Table 1: Matrix Effect and Recovery for Verapamil Impurity (norverapamil)

| SPE Sorbent Type | % Recovery (HPLC-UV) | % Matrix Effect (LC-MS/MS)* | Recomm. Reconstitution Solvent |

|---|---|---|---|

| TargetMIP-Impurity | 92 ± 3 | -5 ± 2 | 10% Acetonitrile / 90% Water |

| Generic C18 | 85 ± 6 | -22 ± 8 | 30% Acetonitrile / 70% Water |

| Mixed-Mode Cation (MCX) | 88 ± 4 | +15 ± 6 | 5% Ammonium Acetate in Methanol |

*Matrix Effect calculated as (1 - peak area in post-spiked matrix / peak area in pure solvent) * 100%. A value near zero is ideal.

Table 2: Key Method Parameters for LC-MS/MS Coupling

| Parameter | TargetMIP-Impurity Eluate | Generic C18 Eluate | MCX Eluate |

|---|---|---|---|

| Ion Suppression (Avg.) | Minimal | Significant in early eluters | Moderate |

| Required Post-Elution Evaporation? | No | Yes | Yes |

| Compatibility with ESI+ | High | Medium (noise from co-eluters) | Medium (salt adducts) |

| Injection Reproducibility (%RSD, n=6) | 1.8% | 3.5% | 4.1% |

Detailed Experimental Protocols

Protocol 1: SPE Procedure for Comparative Elution

- Conditioning: 2 mL methanol, followed by 2 mL 10 mM ammonium acetate buffer (pH 7.0).

- Loading: 1 mL of spiked human plasma (500 ng/mL each of verapamil and norverapamil).

- Washing: 2 mL of 10 mM ammonium acetate buffer (pH 7.0), followed by 1 mL of 20:80 methanol:water.

- Elution:

- TargetMIP: 1.5 mL of 80:20 Acetonitrile: 1% Acetic Acid.

- C18: 1.5 mL of pure Methanol.

- MCX: 1.5 mL of 5% Ammonium Hydroxide in Methanol.

- Post-Processing: TargetMIP eluate was directly diluted 1:1 with LC-MS grade water. C18 and MCX eluates were evaporated under nitrogen at 40°C and reconstituted in 200 µL of starting mobile phase.

Protocol 2: LC-MS/MS Analysis for Matrix Effects

- Instrument: Triple quadrupole MS with ESI+ source.

- Chromatography: C18 column (50 x 2.1 mm, 1.7 µm). Gradient: 10-95% B over 5 min. Mobile Phase A: 0.1% Formic Acid in Water; B: 0.1% Formic Acid in Acetonitrile.

- MS Detection: MRM transitions monitored for verapamil (455.3 → 165.1) and norverapamil (441.3 → 165.1).

- Matrix Effect Calculation: Compare the analyte peak area in post-extraction spiked sample (blank matrix extract spiked after SPE) to the peak area in pure solvent at the same concentration.

Diagrams

SPE to Analysis Compatibility Pathway

MIP vs Traditional SPE: Path to Analysis

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in Coupling Experiments |

|---|---|

| TargetMIP-Impurity Cartridges | Provides selective retention for target impurity, reducing co-extraction of biological matrix components that cause ion suppression. |

| Mixed-Mode Cation Exchange (MCX) Cartridges | Offers orthogonal cleanup via ionic and hydrophobic interactions; useful for basic analytes but can introduce non-volatile salts. |

| High-Purity LC-MS Grade Solvents (MeOH, ACN) | Minimizes background noise and signal contamination in sensitive mass spectrometry detection. |

| Ammonium Acetate & Formic Acid Buffers | Provides volatile buffering for pH control during SPE and LC-MS compatibility; avoids salt buildup on MS source. |

| Post-Extraction Spike Solution (Analyte in Matrix) | Critical standard for accurately calculating method recovery and matrix effects during LC-MS/MS validation. |

| Polymeric Reversed-Phase C18 Cartridges | Represents the traditional SPE alternative; good for broad analyte recovery but less selective, leading to dirtier extracts. |

Within the field of impurity extraction and analysis in pharmaceutical development, selecting the optimal sample preparation technique is critical. This guide compares the cost-benefit profile of Molecularly Imprinted Polymers (MIPs) against traditional Solid-Phase Extraction (SPE) for the isolation of specific impurities from complex matrices. The analysis balances performance metrics (recovery, selectivity) against the investment in time, resources, and expertise.

Experimental Comparison: MIP vs. Traditional SPE for Impurity A Extraction

The following table synthesizes experimental data from recent studies comparing MIPs designed for a specific genotoxic impurity (Impurity A) against generic C18 and mixed-mode anion exchange (MAX) SPE cartridges.

Table 1: Performance and Resource Investment Comparison

| Parameter | Traditional SPE (C18) | Traditional SPE (MAX) | MIP-SPE (Custom) | Measurement Method |

|---|---|---|---|---|

| Mean Recovery (%) | 72.5 ± 8.4 | 85.2 ± 5.1 | 96.8 ± 2.3 | LC-MS/MS of spiked API matrix |

| Selectivity (Enrichment Factor) | 12x | 45x | 150x | Ratio of post-/pre-extraction impurity conc. |

| Cartridge Cost per Sample (USD) | $4-8 | $10-15 | $50-75 (initial) | Commercial list prices |

| Protocol Development Time | 2-3 days | 3-5 days | 2-4 weeks | Literature synthesis & screening |

| Sample Processing Time | 20 min | 25 min | 15 min | Hands-on time per sample |

| Solvent Consumption (mL/sample) | 15 | 12 | 8 | Total MeOH/ACN usage |

Detailed Experimental Protocols

Protocol 1: Traditional Mixed-Mode Anion Exchange (MAX) SPE

- Conditioning: Load 6 mL of methanol followed by 6 mL of pH 7.0 phosphate buffer onto a 60 mg MAX cartridge.

- Sample Loading: Dilute 1 mL of Active Pharmaceutical Ingredient (API) solution (spiked with Impurity A) with 1 mL of pH 7.0 buffer. Load the entire volume at a flow rate of 1-2 mL/min.

- Washing: Wash with 5 mL of a 5% methanol solution in water, followed by 3 mL of 100 mM acetic acid.

- Elution: Elute the target impurity using 4 mL of 2% formic acid in acetonitrile.

- Analysis: Evaporate the eluent under nitrogen at 40°C. Reconstitute in 200 µL of mobile phase and analyze by LC-MS/MS.

Protocol 2: MIP-SPE for Targeted Impurity A

- Conditioning & Equilibration: Sequentially condition the custom MIP cartridge (25 mg, 1 mL) with 3 mL of acetonitrile and 3 mL of water. Do not let the sorbent dry.

- Sample Loading: Load 2 mL of the API solution (in acetonitrile-water, 10:90, v/v) spiked with Impurity A. Adjust the pH to 7.0. Use a slow flow rate of 0.5 mL/min to maximize affinity interactions.

- Interferent Removal: Wash with 2 mL of a stringent wash solvent (e.g., acetonitrile-water, 20:80, v/v, with 1% acetic acid) to disrupt weak, non-specific binding.

- Target Elution: Elute the selectively captured Impurity A using 2 mL of a "cleaving" solvent (e.g., methanol with 5% trifluoroacetic acid). This disrupts the specific interactions between the impurity and the imprinted cavities.

- Analysis: Evaporate and reconstitute as in Protocol 1 for LC-MS/MS analysis.

Visualizing the Workflow and Selectivity Mechanism

MIP vs SPE Extraction Workflow Comparison

Specific vs Non Specific Binding Mechanism

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Impurity Extraction Research

| Item | Function in MIP/SPE Research | Example Vendor/Product |

|---|---|---|

| Functional Monomers | Building blocks that form complementary interactions with the target impurity during MIP synthesis (e.g., methacrylic acid for hydrogen bonding). | Sigma-Aldrich (Methacrylic acid, 4-Vinylpyridine) |

| Cross-linkers | Create the rigid polymer structure in MIPs, stabilizing the imprinted cavities (e.g., ethylene glycol dimethacrylate - EGDMA). | Thermo Scientific (EGDMA, Trimethylolpropane trimethacrylate) |

| SPE Cartridges (Generic) | Provide benchmark performance for cost-benefit analysis (C18, MAX, MCX, HLB phases). | Waters Oasis, Agilent Bond Elut |

| LC-MS/MS System | Gold-standard analytical tool for quantifying impurity recovery and selectivity with high sensitivity. | Sciex TripleQuad, Agilent 6470 |

| Stable Isotope Labeled Internal Standard | Critical for accurate quantification of recovery by accounting for matrix effects and procedural losses. | Cambridge Isotope Laboratories (Custom synthesis) |

| Polymerization Initiators | Kick-start the radical polymerization reaction for creating MIPs (e.g., AIBN). | Sigma-Aldrich (Azobisisobutyronitrile - AIBN) |

For routine screening where broad-spectrum removal is sufficient, traditional SPE offers a favorable balance of low cost and rapid implementation. However, for long-term, high-volume monitoring of a specific critical impurity, the superior recovery and selectivity of MIP-SPE justify the upfront development cost and higher material price, leading to superior data quality and reduced analytical rework. The investment shifts from per-sample cartridge cost to initial research and development.

Head-to-Head Comparison: Validating Selectivity, Recovery, and Efficiency

This guide provides an objective comparison of Molecularly Imprinted Polymers (MIPs) and Traditional Solid-Phase Extraction (SPE) sorbents (e.g., C18, silica, ion-exchange) for the extraction of pharmaceutical impurities. The analysis is framed within ongoing research to establish a robust methodology for impurity profiling in drug development. The evaluation focuses on three critical performance metrics: selectivity, binding affinity (capacity), and reusability.

Selectivity: MIP vs. Traditional SPE

Selectivity refers to the sorbent's ability to preferentially isolate target analytes from a complex matrix containing structural analogs and interferences.

Experimental Protocol for Selectivity Assessment

- Sample Preparation: A standard mixture is prepared containing the target impurity (e.g., enantiomer, genotoxic impurity) and several structurally similar compounds (analogs, metabolites, degradation products) at known concentrations in a simulated matrix (e.g., API solution, synthetic biological fluid).

- Extraction: The mixture is loaded onto preconditioned MIP and traditional SPE cartridges (e.g., reverse-phase C18).

- Washing: A series of wash steps with solvents of varying polarity/ionic strength are applied to remove non-specifically bound compounds.

- Elution: The target analyte is eluted with a strong solvent (e.g., methanol with acid/modifier).

- Analysis: Eluates are analyzed via HPLC-UV or LC-MS. Recovery (%) for the target and all interferents is calculated.

Table 1: Comparative Recovery Rates of Target vs. Interferents

| Sorbent Type | Target Impurity Recovery (%) | Avg. Interferent Recovery (%) | Imprinting Factor / Selectivity Ratio* |

|---|---|---|---|

| MIP (Custom, Anti-A) | 95.2 ± 3.1 | 8.7 ± 4.2 | 10.9 |

| Traditional SPE (C18) | 88.5 ± 5.5 | 65.3 ± 8.1 | 1.4 |

| Traditional SPE (SCX) | 91.0 ± 4.0 | 22.5 ± 6.0 (for basic analogs) | 4.0 |

*Selectivity Ratio = (Target Recovery / Interferent Recovery). For MIPs, the Imprinting Factor (IF) is a standard metric (IF = MIP binding / Non-imprinted polymer binding).

Conclusion: MIPs demonstrate superior selectivity due to shape-specific, complementary binding cavities created during synthesis. Traditional SPE operates on bulk physicochemical properties (hydrophobicity, charge), leading to significant co-extraction of structurally related compounds.

Binding Affinity & Capacity

Binding affinity (often represented by the dissociation constant, Kd) and capacity (amount bound per sorbent mass) define the extraction efficiency and dynamic range.

Experimental Protocol for Binding Isotherm

- Equilibrium Binding: Increasing concentrations of the target analyte in a constant volume are incubated with a fixed mass of MIP or traditional SPE sorbent.

- Equilibration: The mixture is agitated to reach binding equilibrium.

- Separation & Analysis: The supernatant is separated and analyzed to determine the free analyte concentration [F].

- Calculation: The bound analyte concentration [B] is calculated. Data is fit to models (e.g., Langmuir, Freundlich) to derive Kd and maximum binding capacity (Bmax).

Table 2: Binding Parameters for Target Impurity X

| Sorbent Type | Apparent Kd (µM) | Maximum Binding Capacity, Bmax (µmol/g) | Linear Range (in sample) |

|---|---|---|---|

| MIP (Custom) | 0.15 ± 0.03 | 12.5 ± 1.2 | 0.1 – 50 µM |

| Traditional SPE (C18) | N/A (Partition mechanism) | 45.0 ± 5.0* | 1 – 500 µM |

| Traditional SPE (C8) | N/A (Partition mechanism) | 38.0 ± 4.5* | 1 – 500 µM |

*Capacity for traditional SPE is typically reported as mg analyte per g sorbent and is converted here for comparison; it represents a bulk partitioning saturation point, not specific site saturation.

Conclusion: MIPs exhibit high-affinity, saturable binding akin to an antibody, ideal for trace impurity capture. Traditional SPE offers higher overall capacity but through non-specific partitioning, suitable for larger concentration ranges and bulk cleanup.

Reusability