Mastering MDSC for Tg Analysis: A Comprehensive Protocol for Pharmaceutical Formulation Stability

This article provides a detailed, step-by-step guide to Modulated Differential Scanning Calorimetry (MDSC) for the accurate determination of the glass transition temperature (Tg) in pharmaceutical formulations.

Mastering MDSC for Tg Analysis: A Comprehensive Protocol for Pharmaceutical Formulation Stability

Abstract

This article provides a detailed, step-by-step guide to Modulated Differential Scanning Calorimetry (MDSC) for the accurate determination of the glass transition temperature (Tg) in pharmaceutical formulations. Targeted at researchers and formulation scientists, it covers the fundamental principles of MDSC and Tg, a complete optimized experimental protocol, solutions to common analytical challenges, and validation strategies against other thermal analysis techniques. The content aims to empower professionals in selecting and implementing MDSC to characterize amorphous solid dispersions, lyophilized products, and other complex systems critical to drug stability and performance.

Understanding Tg and MDSC: Why This Analysis is Critical for Drug Product Stability

The glass transition temperature (Tg) is a critical material property in pharmaceutical science, defining the boundary between the glassy and rubbery states of an amorphous solid. Within the context of a broader thesis on Modulated Differential Scanning Calorimetry (MDSC) protocol development, precise Tg determination is paramount for predicting the physical stability, dissolution behavior, and shelf-life of amorphous solid dispersions, lyophilized products, and other amorphous formulations. A drop in storage temperature below Tg can lead to decreased molecular mobility and increased stability, while storage above Tg risks rapid physicochemical degradation.

Quantitative Data on Pharmaceutical Tg Ranges

The Tg of a pure active pharmaceutical ingredient (API) is influenced by its molecular structure and weight. Formulation with polymers is a standard strategy to elevate the Tg and enhance stability.

Table 1: Representative Tg Values for Common Pharmaceutical Materials

| Material Category | Example Compound/Polymer | Typical Tg Range (°C) | Key Stability Implication |

|---|---|---|---|

| Small Molecule APIs | Indomethacin | ~42 | Low Tg often requires stabilization. |

| Itraconazole | ~59 | ||

| Ritonavir | ~48 | ||

| Stabilizing Polymers | Polyvinylpyrrolidone (PVP) K30 | ~165 | High Tg polymer can elevate blend Tg. |

| Hydroxypropyl methylcellulose (HPMC) | ~170-180 | ||

| Copovidone (PVP-VA) | ~105 | ||

| Plasticizers | Water | -135 | Significantly lowers Tg; critical for lyophilisates. |

| Glycerol | -93 | ||

| Amorphous Solid Dispersions | Itraconazole / HPMC (30:70) | ~110 | Tg > typical storage T (25°C) enhances stability. |

| Ritonavir / PVP-VA (50:50) | ~85 |

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Tg Analysis via MDSC

| Item | Function & Importance |

|---|---|

| Hermetic Sealed DSC Pans (with lids) | Prevents volatile loss (e.g., water, solvent) during heating, which can artifact Tg measurement. Critical for hydrated or solvate samples. |

| Tzero Aluminum Pans & Lids (or equivalent) | Provides superior thermal contact and uniformity, especially important for precise MDSC heat capacity measurements. |

| Microbalance (μg precision) | Accurate sample mass (typically 5-10 mg) is essential for quantitative thermal analysis and reliable comparison. |

| Standard Reference Materials (Indium, Zinc) | Calibration of DSC temperature and enthalpy scales ensures accuracy and inter-laboratory reproducibility. |

| Dry Nitrogen Gas Supply | Inert purge gas prevents oxidative degradation during heating and ensures stable baseline. |

| Desiccator & Drying Agent | For storage of samples and pans to control moisture content, a known plasticizer. |

| Polymer Standards (e.g., Polystyrene) | Verified Tg standards for method validation and periodic performance checks of the MDSC. |

Core MDSC Experimental Protocol for Tg Analysis

This detailed protocol is framed within the thesis aim of standardizing MDSC for pharmaceutical formulation screening.

Protocol: Determination of Tg for an Amorphous Solid Dispersion

I. Sample Preparation

- Drying: Place the amorphous solid dispersion powder in a desiccator over phosphorus pentoxide (or similar) at room temperature for at least 48 hours to remove residual solvent.

- Weighing: Using a microbalance, accurately weigh 5-10 mg of the dried sample into a pre-tared, hermetic Tzero aluminum pan.

- Sealing: Carefully seal the pan with a Tzero lid using a manual or pneumatic press. Ensure the seal is complete to prevent pin-holes.

- Reference: Prepare an identical, empty sealed pan as the reference.

II. Instrument Calibration & Method Setup

- Calibration: Perform temperature and enthalpy calibration using pure Indium (Tm = 156.6°C, ΔHf ≈ 28.4 J/g). Perform heat capacity calibration using a sapphire standard according to the instrument manufacturer's protocol.

- MDSC Method Parameters:

- Temperature Range: Start at least 50°C below the expected Tg, end 30°C above.

- Underlying Heating Rate: 2-3 °C/min (ensures sufficient thermal resolution).

- Modulation Amplitude: ±0.5-1.0 °C (optimizes sensitivity for Cp change).

- Modulation Period: 60-100 seconds (must be appropriate for the heating rate).

- Purge Gas: Dry Nitrogen at 50 mL/min.

III. Data Acquisition & Analysis

- Run: Place the sample and reference pans in the DSC cell and execute the method.

- Deconvolution: Process the data to separate the total heat flow into Reversing Heat Flow (associated with Cp/Tg) and Non-Reversing Heat Flow (associated with enthalpic relaxation, crystallization, evaporation).

- Tg Determination: Identify the glass transition from the Reversing Heat Flow signal. The Tg is typically reported as the midpoint of the step change in heat capacity (inflection point), though onset and endpoint can also be noted.

- Enthalpic Relaxation: Observe the Non-Reversing Heat Flow signal for an endothermic peak just above the Tg, indicative of physical aging and molecular relaxation.

IV. Critical Reporting Parameters Report the sample history (preparation method, drying), exact MDSC parameters, pan type, and the specific Tg value (onset/midpoint/endpoint) from the reversing heat flow curve.

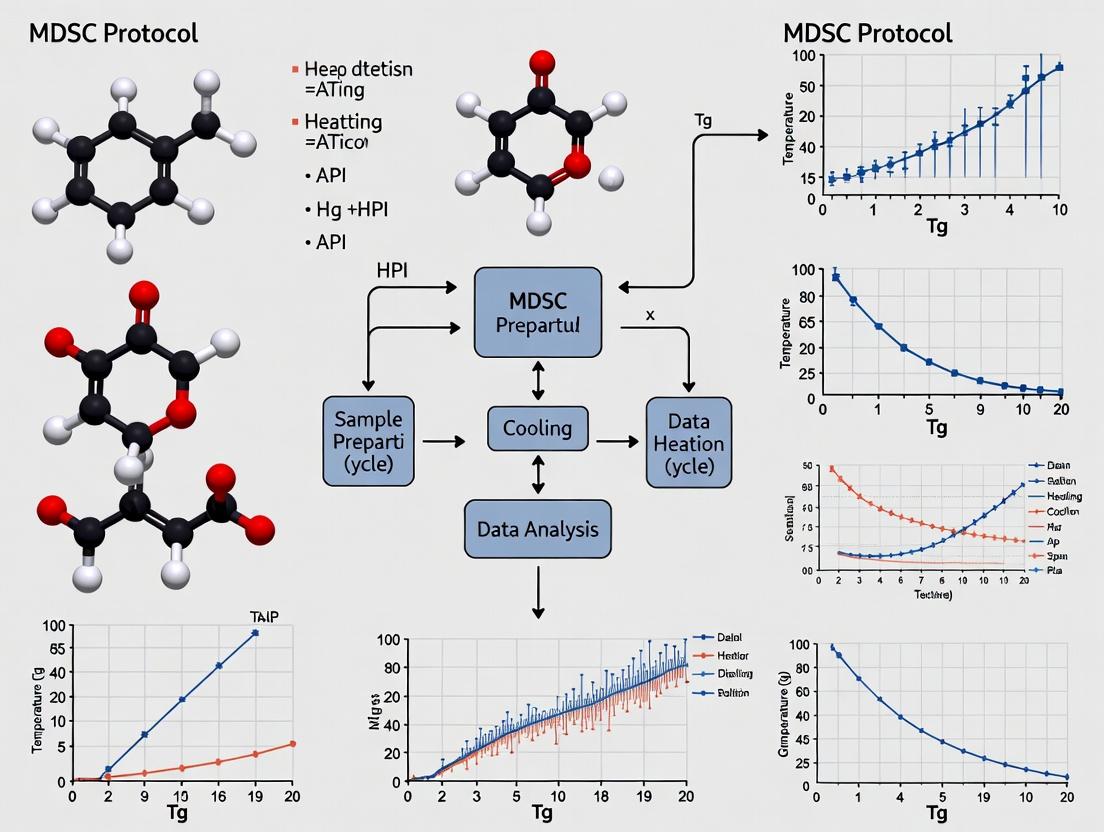

Conceptual and Workflow Visualizations

Tg and Pharmaceutical Stability Decision Logic

MDSC Workflow for Tg Determination

This document provides detailed Application Notes and Protocols for Modulated Differential Scanning Calorimetry (MDSC) as part of a broader thesis focusing on the analysis of glass transition temperatures (Tg) in amorphous solid dispersions and other complex pharmaceutical formulations. The enhanced resolving power of MDSC is critical for deconvoluting overlapping thermal events that conventional DSC cannot separate, thereby ensuring accurate characterization of stability and performance-critical parameters in drug development.

Core Principles and Comparative Advantages

Conventional DSC measures the total heat flow into or out of a sample as a function of temperature or time. MDSC superimposes a sinusoidal modulation onto the traditional linear heating ramp. This allows for the simultaneous measurement of total heat flow and the separation of its components into reversing (heat capacity-related, e.g., Tg) and non-reversing (kinetic, e.g., enthalpy relaxation, crystallization, evaporation) signals.

Key Advantages of MDSC for Pharmaceutical Tg Analysis:

- Separation of Overlapping Events: Distinguishes the glass transition from enthalpy recovery, drying, or decomposition.

- Improved Sensitivity: Enhances detection of weak or broad transitions.

- Direct Heat Capacity Measurement: Provides quantitative Cp data without a separate experiment.

- Resolution of Complex Events: Critical for analyzing multi-component systems like polymer-drug blends.

Quantitative Data Comparison

Table 1: Comparative Performance Metrics for Tg Analysis of a Model Amorphous Solid Dispersion (Itraconazole-HPMCAS)

| Parameter | Conventional DSC | Modulated DSC (MDSC) | Advantage/Explanation |

|---|---|---|---|

| Measured Tg Onset (°C) | 72.5 ± 1.2 | 74.8 ± 0.5 | MDSC minimizes interference from enthalpy relaxation, giving a more accurate Cp change point. |

| Detection of Enthalpy Relaxation | Obscured as an endothermic bump overlapping with Tg step change. | Clearly resolved as a separate peak in the Non-Reversing Heat Flow signal. | Enables quantitative study of physical aging. |

| Heat Capacity Change at Tg (J/g°C) | Not directly measurable. | 0.31 ± 0.02 | Directly measured from Reversing Heat Flow signal. Correlates with polymer content. |

| Signal-to-Noise Ratio for Tg Step | 1 : 8.5 | 1 : 22.3 | Modulation improves sensitivity for detecting weak transitions. |

| Analysis of Residual Solvent | Appears as a broad endotherm, can be mistaken for Tg. | Separated into Non-Reversing signal; Tg remains pure in Reversing signal. | Prevents misassignment of thermal events. |

Detailed Experimental Protocols

Protocol 1: MDSC for Tg Analysis of Amorphous Solid Dispersions

Objective: To accurately determine the glass transition temperature (Tg) and identify overlapping thermal events in a spray-dried amorphous dispersion.

Materials:

- TA Instruments Q2500 or equivalent MDSC-capable calorimeter.

- Tzero aluminum hermetic pans and lids.

- Analytical balance (µg precision).

- Dry box or glove bag for moisture-sensitive samples.

- Nitrogen purge gas (50 mL/min).

Procedure:

- Calibration: Perform temperature and heat capacity calibration using indium and sapphire standards under the same modulation conditions to be used for the experiment.

- Sample Preparation: a. Weigh 5-10 mg of the amorphous solid dispersion powder into a Tzero hermetic pan. b. Seal the pan with a lid using a crimper press inside a dry environment (<10% RH) to prevent moisture uptake. c. Prepare an empty, sealed reference pan.

- Method Design: a. Equilibrate at 25°C. b. Ramp temperature at an underlying heating rate of 2°C/min to 150°C. c. Apply a temperature modulation amplitude of ±0.5°C with a period of 60 seconds. d. Use a nitrogen purge flow of 50 mL/min.

- Data Analysis: a. Process the raw data using the manufacturer's software (e.g., TRIOS) to calculate Reversing and Non-Reversing Heat Flow. b. Identify the Tg onset and midpoint from the step change in the Reversing Heat Flow signal. c. Examine the Non-Reversing Heat Flow signal for any exothermic/endothermic peaks (e.g., enthalpy recovery, crystallization) overlapping the Tg region. d. Report Tg as the midpoint value ± standard deviation from triplicate runs.

Protocol 2: Conventional DSC for Comparative Analysis

Objective: To perform a standard DSC run on the same sample for direct comparison with MDSC data.

Procedure:

- Use the same sample preparation and instrument as in Protocol 1.

- Method Design: a. Equilibrate at 25°C. b. Ramp temperature at a constant linear rate of 2°C/min to 150°C (no modulation). c. Use identical purge gas flow.

- Data Analysis: a. Analyze the total heat flow signal. b. Attempt to identify Tg onset from the inflection point, noting any distortions or overlapping peaks.

Visualization of MDSC Signal Deconvolution

Title: MDSC Signal Deconvolution into Reversing and Non-Reversing Components

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for MDSC Analysis of Pharmaceutical Formulations

| Item | Function & Rationale |

|---|---|

| Tzero Hermetic Aluminum Pans | Provides superior thermal contact and seal integrity. Essential for preventing sample mass loss (e.g., solvent/water evaporation) during modulated runs, which would distort heat capacity measurements. |

| Calibration Standards (Indium, Sapphire) | Indium calibrates temperature and enthalpy scale. Sapphire disc calibrates heat capacity (Cp) scale, which is critical for quantitative MDSC analysis. |

| Dry Nitrogen Purge Gas | Inert atmosphere prevents oxidative degradation. Stable purge flow is required for consistent baseline in sensitive MDSC measurements. |

| Desiccant (e.g., Molecular Sieves) | For storing calibration standards and samples in a moisture-free environment. Moisture uptake by hygroscopic amorphous samples can drastically alter Tg. |

| Refrigerated Cooling Accessory | For sub-ambient temperature modulation experiments or for studying crystallization from the rubbery state above Tg. |

| Micro-balance (0.001 mg resolution) | Accurate sample mass (typically 5-10 mg) is required for precise quantitative Cp and heat flow calculations. |

The glass transition temperature (Tg) is a fundamental physicochemical property of amorphous solids and semi-crystalline materials. In pharmaceutical science, Tg is critical for predicting the physical stability, chemical degradation pathways, shelf-life, and optimal processing conditions of formulations, particularly those involving polymers and amorphous solid dispersions. Within the context of Modulated Differential Scanning Calorimetry (MDSC) protocol research, accurate Tg determination allows formulators to design robust drug products by identifying storage conditions below Tg to prevent molecular mobility-driven instabilities such as crystallization, chemical degradation, and changes in dissolution profile.

Table 1: Tg Correlations with Pharmaceutical Product Stability and Shelf-Life

| Formulation Type | Typical Tg Range (°C) | Critical Storage Condition (Relative to Tg) | Demonstrated Impact on Shelf-Life (Accelerated Studies) | Key Instability Mechanism Below/Above Tg |

|---|---|---|---|---|

| Amorphous Solid Dispersion (Polymer-based) | 50 - 120 °C | Store at T < Tg - 20°C | >24 months stability at 25°C/60% RH | Crystallization, phase separation |

| Lyophilized (Freeze-Dried) Proteins | 40 - 100 °C | Store at T < Tg | Up to 36 months at 2-8°C | Protein aggregation, loss of activity |

| Spray-Dried Dispersion (SDD) | 70 - 110 °C | Store at T < Tg - 10°C | 18-24 months at 25°C/60% RH | Moisture sorption, crystallization |

| Hot-Melt Extrudate | 60 - 130 °C | Process at T > Tg + 50°C | Shelf-life defined by T-Tg differential | Chemical degradation, physical aging |

Table 2: Tg-Based Processing Condition Guidelines

| Manufacturing Process | Target Temperature Relation to Tg | Rationale | Outcome of Deviation from Target |

|---|---|---|---|

| Hot-Melt Extrusion (HME) | T_process = Tg + 50 to 100°C | Ensures sufficient polymer plasticity for mixing & extrusion. | Too low: High torque, incomplete dispersion. Too high: Thermal degradation. |

| Spray Drying | T_outlet > Tg | Prevents stickiness and aggregation in cyclone. | T_outlet < Tg: Particle adhesion, low yield. |

| Film Casting | T_drying > Tg | Facilitates solvent evaporation and uniform film formation. | T_drying < Tg: Incomplete solvent removal, cracking. |

| Compression (Tableting) | For amorphous materials: T_compaction < Tg | Maintains amorphous state; prevents stress-induced plastic flow. | T_compaction > Tg: May induce crystallization or sticking. |

Experimental Protocols for MDSC-Based Tg Analysis

Protocol 1: MDSC Standard Operating Procedure for Tg Determination in Amorphous Formulations

Objective: To accurately determine the glass transition temperature (Tg) of a pharmaceutical solid dispersion using Modulated DSC.

Materials:

- Modulated Differential Scanning Calorimeter (e.g., TA Instruments Q series, Mettler Toledo DSC 3)

- Tzero or standard aluminum hermetic pans and lids

- Analytical balance (µg sensitivity)

- Desiccator

- Test sample (e.g., spray-dried amorphous dispersion, ~5-10 mg)

Procedure:

- Instrument Calibration: Calibrate the MDSC for temperature and enthalpy using indium and zinc standards. Perform baseline calibration with empty pans.

- Sample Preparation:

- Weigh 5-10 mg of sample accurately into a tared hermetic pan.

- Crimp the lid using a sealing press to ensure an airtight seal.

- For hygroscopic samples, perform this step in a dry box or glove bag under nitrogen.

- Method Programming:

- Equilibrate at 20°C.

- Ramp temperature at 2°C/min to a final temperature 30°C above the expected Tg.

- Apply a modulation amplitude of ±0.5°C with a period of 60 seconds.

- Use a purge gas (dry nitrogen) at 50 mL/min.

- Data Acquisition: Run the sample in triplicate.

- Data Analysis:

- Analyze the reversing heat flow signal.

- Identify the Tg as the midpoint of the step change in heat capacity.

- Report the onset, midpoint, and endpoint temperatures.

Interpretation: The Tg from the reversing heat flow minimizes interference from enthalpic relaxation, providing a more accurate representation of the true glass transition.

Protocol 2: Determination of Tg as a Function of Relative Humidity (Plasticization Study)

Objective: To evaluate the effect of moisture (a common plasticizer) on Tg for shelf-life prediction.

Materials:

- Dynamic Vapor Sorption (DVS) system or controlled humidity chambers

- MDSC (as in Protocol 1)

- Desiccators with saturated salt solutions for specific %RH.

Procedure:

- Conditioning: Expose separate samples of the amorphous formulation to controlled relative humidity environments (e.g., 0%, 30%, 60%, 75% RH) at 25°C for 72 hours in DVS or desiccators.

- Sealing: After conditioning, quickly transfer samples to the DSC pans and hermetically seal to lock in moisture content.

- MDSC Analysis: Immediately analyze each conditioned sample using the method from Protocol 1.

- Data Modeling: Plot Tg vs. %RH. Fit data to the Gordon-Taylor equation to predict Tg at any moisture content.

Interpretation: A significant decrease in Tg with increased %RH indicates high moisture sensitivity, necessitating robust packaging and storage below critical RH.

Diagrams and Workflows

Diagram Title: Tg-Driven Stability and Processing Decision Workflow

Diagram Title: MDSC Protocol for Tg Analysis (6-Step Workflow)

The Scientist's Toolkit: Key Research Reagents and Materials

Table 3: Essential Materials for Tg Analysis and Formulation Studies

| Item Name | Function/Application in Tg Research | Critical Specifications/Notes |

|---|---|---|

| Hermetic Tzero Aluminum Pans & Lids | Sealed containment for DSC samples to prevent mass loss (e.g., solvent/water evaporation) during heating, which is critical for accurate Tg. | Must be hermetically sealable. Tzero pans improve baseline stability in MDSC. |

| Calibration Standards (Indium, Zinc) | For temperature and enthalpy calibration of the DSC instrument to ensure measurement accuracy and inter-lab reproducibility. | High purity (99.999%). Certified melting point and enthalpy of fusion. |

| Dynamic Vapor Sorption (DVS) Instrument | To precisely condition samples at specific relative humidities for plasticization studies, linking moisture content to Tg depression. | Enables automated, gravimetric moisture sorption analysis. |

| Dry Nitrogen Gas Supply | Inert purge gas for the DSC cell to prevent oxidative degradation during heating and to maintain a dry, stable environment. | High purity (≥99.9%), moisture-free. Required flow rate: ~50 mL/min. |

| Saturated Salt Solutions | For creating controlled relative humidity environments in desiccators for sample conditioning (e.g., LiCl for 11% RH, MgCl2 for 33% RH, NaCl for 75% RH). | Must be prepared with excess solid salt to ensure saturated conditions at constant temperature. |

| Amorphous Polymer Carriers | Model polymers or commercial pharmaceutical polymers (e.g., PVP, HPMCAS, Soluplus) used to create solid dispersions for Tg-stability relationship studies. | Well-characterized, pharmaceutical grade. Individual Tg should be known. |

| Molecular Sieves (3Å or 4Å) | For maintaining a dry environment in desiccators used to store hygroscopic samples and standards prior to analysis. | Must be periodically regenerated by heating to remove adsorbed water. |

Application Notes for MDSC in Pharmaceutical Tg Analysis

Within the thesis on optimizing Modulated Differential Scanning Calorimetry (MDSC) protocols for glass transition temperature (Tg) analysis of amorphous solid dispersions and lyophilized formulations, decoding the heat flow components is paramount. The separation of total heat flow into its reversing and non-reversing constituents provides unparalleled insight into the physical stability and miscibility of pharmaceutical formulations, critical for predicting shelf-life and performance.

Total Heat Flow (HF~total~) is the average heat flow, equivalent to conventional DSC signal. Reversing Heat Flow (HF~reversing~) corresponds to heat capacity-related events, such as the glass transition, which are temperature-dependent and rate-independent. Non-Reversing Heat Flow (HF~non-reversing~) encompasses kinetic, time-dependent events like enthalpy relaxation, crystallization, evaporation, and curing reactions.

For amorphous APIs and polymers, the Tg, derived primarily from the reversing heat flow signal, is often more clearly resolved, free from confounding effects of relaxation endotherms or decomposition events that manifest in the non-reversing signal. The ratio and magnitude of these components are quantitative indicators of physical aging, plasticization by residual moisture, and drug-polymer interactions.

Table 1: Characteristic Thermal Events in Pharmaceutical Formulations and Their Primary Heat Flow Signature

| Thermal Event | Reversing Heat Flow | Non-Reversing Heat Flow | Pharmaceutical Significance |

|---|---|---|---|

| Glass Transition (Tg) | Primary Signature (Step change) | Minimal | Indicates molecular mobility; critical for stability. |

| Enthalpy Relaxation | Minimal or none | Primary Signature (Endothermic peak) | Measures physical aging of amorphous systems. |

| Melting (Crystalline) | Minor | Primary Signature (Endothermic peak) | Purity of crystalline API or recrystallization. |

| Cold Crystallization | None | Primary Signature (Exothermic peak) | Instability of amorphous form. |

| Evaporation (Solvent/Loss) | None | Primary Signature (Endothermic) | Residual solvent or water content. |

| Curing/Cross-linking | None | Primary Signature (Exothermic) | In situ polymer formation in implants. |

Table 2: Typical MDSC Experimental Parameters for Tg Analysis

| Parameter | Recommended Setting | Purpose & Impact |

|---|---|---|

| Underlying Heating Rate | 2-3 °C/min | Ensures sufficient modulation cycles for deconvolution. |

| Modulation Amplitude | ±0.5-1.0 °C | Must be large enough to detect heat capacity change at Tg. |

| Modulation Period | 60-100 seconds | Optimizes signal-to-noise; period should be 4-10x amplitude. |

| Purge Gas | Nitrogen, 50 ml/min | Prevents oxidative degradation. |

| Sample Mass | 5-15 mg | Balances signal strength and thermal homogeneity. |

Experimental Protocols

Protocol 1: Standard MDSC for Tg Determination of an Amorphous Solid Dispersion

Objective: To accurately determine the glass transition temperature of a spray-dried amorphous solid dispersion (API + Polymer) and identify contributions from enthalpy relaxation. Materials: Refer to "The Scientist's Toolkit" below. Method:

- Sample Preparation: Precisely weigh 8-10 mg of the homogeneous solid dispersion into a tared, vented Tzero aluminum pan. Crimp hermetically. Prepare an empty, crimped reference pan.

- Instrument Calibration: Perform temperature and heat capacity calibration using indium and sapphire standards under the planned experimental conditions.

- Method Programming: Equilibrate at 20°C. Ramp at 2.5 °C/min to 150 °C (above the expected Tg). Apply a modulation of ±0.8 °C every 80 seconds.

- Data Acquisition: Run the experiment in triplicate. Ensure the instrument records total, reversing, and non-reversing heat flow signals.

- Data Analysis:

- Plot total, reversing, and non-reversing heat flow (y-axis) vs. temperature (x-axis).

- On the reversing heat flow signal, identify the glass transition as a step change in heat capacity.

- Determine the Tg using the midpoint method (half-height).

- Examine the non-reversing heat flow signal for an endothermic peak overlapping the Tg region, indicating enthalpy relaxation.

- Report Tg ± standard deviation from replicates.

Protocol 2: Assessing Physical Aging via Non-Reversing Heat Flow

Objective: To quantify the enthalpy relaxation of an amorphous formulation after accelerated stability storage. Materials: As in Protocol 1. Method:

- Aging: Subject sealed samples to accelerated conditions (e.g., 40°C/75% RH) for 1, 2, and 4 weeks.

- MDSC Analysis: Analyze aged and fresh control samples per Protocol 1.

- Quantification:

- Integrate the area of the endothermic peak in the non-reversing heat flow signal that appears near or superimposed on the Tg step.

- This area (J/g) is the relaxation enthalpy (ΔH~relax~), a direct measure of physical aging.

- Plot ΔH~relax~ vs. aging time to model stability trends.

Visualizations

Title: MDSC Signal Deconvolution Workflow

Title: Heat Flow Components and Thermal Events

The Scientist's Toolkit: Essential MDSC Reagents & Materials

Table 3: Key Research Reagent Solutions for MDSC Analysis

| Item | Function & Importance in Protocol |

|---|---|

| Hermetic Tzero Aluminum Pans & Lids | Standard, low-mass pans for encapsulating samples. Vented lids are used for potential off-gassing. Essential for precise heat transfer. |

| Tzero Press | Tool for hermetically sealing pans, ensuring consistent thermal contact and preventing solvent escape. |

| High-Purity Inert Gas (N2) | Purge gas to establish a consistent, non-reactive atmosphere in the DSC cell, preventing oxidation. |

| Calibration Standards (Indium, Sapphire) | Indium (melting point, enthalpy) calibrates temperature and heat flow. Sapphire (heat capacity) calibrates the reversing heat flow signal. |

| Desiccants (e.g., Silica Gel) | For dry storage of pans and samples prior to analysis, as moisture significantly plasticizes amorphous materials. |

| Microbalance (0.01 mg precision) | For accurate sample weighing (5-15 mg range), crucial for quantitative heat flow results. |

| Amorphous Solid Dispersion Reference | A well-characterized in-house standard (e.g., API/PVP VA64) for method validation and periodic instrument performance verification. |

Within the broader thesis on the application of Modulated Differential Scanning Calorimetry (MDSC) for glass transition (Tg) analysis in pharmaceutical formulation research, selecting the correct formulation strategy is paramount. The physical stability of amorphous solid dispersions (ASDs), lyophilizates, and polymeric matrices hinges on their Tg, a critical indicator of molecular mobility and product shelf-life. This application note provides a structured guide for researchers on when to prioritize MDSC Tg analysis during formulation development, supported by current protocols and data.

Table 1: Typical Tg Ranges and MDSC Analysis Priority for Key Formulation Types

| Formulation Type | Typical Tg Range (°C) | Key Stability Risk | MDSC Analysis Priority (High/Med/Low) | Rationale for Priority |

|---|---|---|---|---|

| Amorphous Solid Dispersions (ASDs) | 50 - 150 (Drug-dependent) | Recrystallization, Phase Separation | High | Tg is the primary stability descriptor. MDSC deconvolutes overlapping events (enthalpy relaxation, crystallization). |

| Lyophilized Products | 40 - 120 (Depends on cake composition) | Collapse, Loss of Viability, Degradation | High | Residual moisture drastically lowers Tg. MDSC is essential for accurate measurement in fragile, low-mass cakes. |

| Polymeric Excipients/Matrices | 80 - 180 (e.g., PVP, HPMC) | Brittleness, Aging, Drug Release Change | Medium | Baseline Tg needed for formulation design. High-priority when polymer is the main stabilizing component. |

| Spray-Dried Powders | Similar to ASDs | Agglomeration, Sorption, Caking | High | High surface area amplifies moisture impact. Tg measurement critical for process and packaging design. |

| Hot-Melt Extrudates | Similar to ASDs/Polymers | Drug Degradation, Aging | Medium/High | Priority high for amorphous products; medium for crystalline-in-polymer systems. |

Table 2: Impact of Critical Factors on Measured Tg (MDSC Data)

| Factor | Direction of Tg Change | Typical Magnitude of Change* | MDSC Advantage |

|---|---|---|---|

| Increasing Plasticizer (e.g., Water) | Decrease | -10°C per 1% water (for sugars) | Reversing heat flow isolates Tg from moisture loss endotherm. |

| Higher Drug Loading (in ASD) | Increase or Decrease | ±5 - 30°C | Separates drug-polymer mixing effects from relaxation. |

| Increased Mw of Polymer | Increase | +2 to +15°C (per Mw step) | Clear resolution of Tg in highly viscous systems. |

| Annealing/Physical Aging | Apparent Tg Increase | +1 to +5°C | Non-reversing signal quantifies enthalpy recovery directly. |

*Magnitudes are formulation-dependent examples.

Experimental Protocols

Protocol 1: MDSC Tg Analysis for Amorphous Solid Dispersions (ASDs)

Objective: To accurately determine the glass transition temperature (Tg) of an ASD, free from interfering thermal events.

Materials: See "The Scientist's Toolkit" (Section 5).

Method:

- Sample Preparation: Precisely weigh 3-5 mg of ASD powder into a tared, vented Tzero aluminum pan. Hermetically seal the pan with a lid. Prepare an empty, sealed reference pan.

- Instrument Calibration: Calibrate the MDSC cell for temperature and enthalpy using indium and zinc standards. Perform baseline correction with empty pans over the method temperature range.

- Method Parameters:

- Temperature Range: 20°C below expected Tg to 30°C above.

- Heating Rate: 2-3°C/min (underlying).

- Modulation Amplitude: ±0.5°C.

- Modulation Period: 60 seconds.

- Purge Gas: Nitrogen at 50 ml/min.

- Run: Load sample and reference. Execute method.

- Data Analysis: In the analysis software:

- Plot the Reversing Heat Flow signal.

- Identify the glass transition as a step change in heat capacity.

- Use the midpoint method (half-height) to report Tg.

- Examine the Non-Reversing Heat Flow for exotherms (crystallization) or endotherms (enthalpy relaxation/water loss).

Protocol 2: MDSC Tg Analysis for Lyophilized Cakes

Objective: To measure the Tg of a delicate lyophilized formulation, minimizing the effect of residual moisture loss during the scan.

Materials: See "The Scientist's Toolkit." Use high-sensitivity DSC if available.

Method:

- Sample Preparation: Carefully remove a small, intact piece (~2-4 mg) from the center of the lyophilized cake using a fine spatula. Place it in a hermetically sealed pan to prevent moisture exchange. Weigh rapidly.

- Instrument Calibration: As per Protocol 1. Ensure excellent baseline stability.

- Method Parameters:

- Temperature Range: 25°C to 120°C (or as required).

- Heating Rate: 2°C/min.

- Modulation Amplitude: ±0.3°C (reduces sample perturbation).

- Modulation Period: 80 seconds.

- Purge Gas: Nitrogen at 50 ml/min.

- Run: Load sample and execute method promptly.

- Data Analysis:

- Analyze the Reversing Heat Flow signal. The Tg may be broad.

- The Non-Reversing signal will show a large endotherm from moisture loss; MDSC isolates Tg from this event.

- Report Tg onset and midpoint.

Decision Pathway & Workflow Visualizations

Diagram 1: Decision Tree for MDSC Tg Analysis Priority

Diagram 2: MDSC Signal Deconvolution Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for MDSC Tg Analysis of Formulations

| Item | Function/Benefit | Example Product/Category |

|---|---|---|

| Modulated DSC Instrument | Enables separation of reversible (Tg) and non-reversible events. | TA Instruments Q Series MDSC, Mettler Toledo DSC 3 with ADSC. |

| Tzero Aluminum Pans & Lids | Low-mass pans with superior thermal contact; required for Tzero technology. | TA Instruments Tzero Hermetic or Vented Pans. |

| Hermetic Sealing Press | Creates a secure, sealed environment for volatile or moisture-sensitive samples. | TA Instruments Tzero Sealing Press. |

| High-Purity Calibration Standards | For accurate temperature and enthalpy calibration of the MDSC. | Indium, Tin, Zinc (≥99.999% purity). |

| High-Precision Microbalance | Accurate weighing of small (1-10 mg) sample masses. | Sartorius Cubis MSA, Mettler Toledo XP6U. |

| Dry Nitrogen Gas Supply | Inert purge gas to prevent oxidation and ensure stable baseline. | Industrial grade nitrogen with moisture trap. |

| Desiccator & Drying Packs | For storage of pans and samples to prevent moisture uptake prior to analysis. | Glass desiccator with silica gel or P2O5. |

Step-by-Step MDSC Protocol: From Sample Prep to Tg Determination

Application Note AN-MDSC-101: Protocol for Glass Transition Analysis of Solid Dispersions

1. Introduction Within a broader thesis on Modulated Differential Scanning Calorimetry (MDSC) for glass transition (Tg) analysis of pharmaceutical amorphous solid dispersions, the selection of appropriate consumables and instrument parameters is critical. This protocol details the essential equipment, calibration standards, and parameter optimization required for precise, reproducible Tg determination, a key stability indicator for formulation development.

2. Research Reagent Solutions & Essential Materials The following table details the essential consumables and their specific functions for MDSC Tg analysis.

| Item | Function & Selection Rationale |

|---|---|

| Hermetic T-Pans (Aluminum, 40µL) | Standard pan for most pharmaceutical solids. Hermetic seal prevents mass loss from solvent/volatile evaporation, which can distort Tg signal. |

| Hermetic Tzero Pans & Lids | Required for Tzero DSC technology. Provides enhanced baseline flatness and improved heat capacity measurement accuracy. |

| High-Volume Stainless Steel Pans | Used for highly volatile samples or those requiring high pressure. Provides a more robust seal against decomposition gases. |

| Indium Calibrant (99.999% purity) | Primary temperature and enthalpy calibrant (Melting Point: 156.6 °C, ΔH: 28.45 J/g). Validates instrument calibration. |

| Liquid Nitrogen Cooling System (LNCS) | Enables sub-ambient temperature experiments. Essential for analyzing formulations with Tg values below room temperature. |

| Nitrogen Gas Supply (High Purity, 50 mL/min) | Inert purge gas to prevent oxidative degradation of samples and ensure stable baseline. |

| Calibrated Microbalance (±0.001 mg) | For accurate sample mass measurement (3-10 mg typical range). Critical for quantitative heat capacity comparisons. |

| Desiccator | For storage of pans, lids, and hygroscopic samples to prevent moisture absorption, which plasticizes the API and lowers Tg. |

3. Instrument Calibration & Validation Protocol

- Objective: To establish temperature, enthalpy, and heat capacity (Cp) accuracy.

- Procedure:

- Clean the DSC cell and install a new sensor if required.

- Create a method with a heating rate of 10 °C/min from 120 °C to 180 °C.

- Weigh 3-5 mg of Indium calibrant into a Tzero pan, hermetically seal it.

- Run the method with the indium sample and an empty reference pan.

- Analyze the melting peak onset temperature and enthalpy of fusion.

- Acceptance Criteria: Onset temperature must be within ±0.3 °C of 156.6 °C; enthalpy within ±2% of 28.45 J/g.

4. MDSC Parameter Optimization Protocol for Tg Analysis

- Objective: To separate reversing (Cp-related, e.g., Tg) from non-reversing (kinetic, e.g., relaxation, evaporation) heat flow for clear Tg identification.

- Sample Preparation: Pre-dry formulation. Accurately weigh 5-10 mg into a hermetic Tzero pan. Seal pan immediately.

- Method Setup: The following table summarizes the critical parameters and their typical optimized values for pharmaceutical Tg analysis.

| Parameter | Recommended Setting | Rationale & Impact |

|---|---|---|

| Temperature Range | Tg - 30°C to Tg + 30°C | Ensures sufficient baseline before and after transition. |

| Underlying Heating Rate | 2 °C/min | Slow rate enhances resolution of closely spaced thermal events. |

| Modulation Period | 60 seconds | Optimal for separating signals at the recommended heating rate. |

| Modulation Amplitude | ±0.5 °C | Sufficient to probe Cp without inducing kinetic thermal events. |

| Purge Gas (N₂) Flow | 50 mL/min | Standard inert atmosphere to prevent oxidation. |

| Sample Mass | 5-10 mg | Provides adequate signal; larger masses can cause thermal lag. |

- Data Analysis: Process data to plot Reversing Heat Flow vs. Temperature. Tg is identified as the midpoint of the step change in the reversing heat flow signal.

5. Experimental Workflow for Tg Determination

MDSC Tg Analysis Workflow

6. Data Interpretation Pathway

MDSC Data Deconvolution & Tg ID

Within the broader thesis on optimizing Modulated Differential Scanning Calorimetry (MDSC) protocols for Glass Transition Temperature (Tg) analysis of amorphous solid dispersions and other complex pharmaceutical formulations, sample preparation is the critical, non-negotiable foundation. Inaccurate Tg determination, leading to flawed stability predictions, can almost invariably be traced to poor sample handling leading to moisture uptake or non-representative loading. This document provides detailed application notes and protocols to standardize this pivotal step.

The Impact of Moisture on Tg Analysis

Moisture acts as a potent plasticizer for most amorphous pharmaceutical systems, significantly depressing the observed Tg. Uncontrolled humidity during preparation can lead to irreproducible data, masking true formulation performance and stability.

Table 1: Effect of Moisture on Tg of Common Pharmaceutical Polymers

| Polymer/Formulation | Tg (Dry) (°C) | Tg at 3% Moisture (°C) | ΔTg Depression (°C) | Reference |

|---|---|---|---|---|

| PVP K30 | ~167 | ~90 | ~77 | (1) |

| HPMCAS | ~120 | ~80 | ~40 | (2) |

| Spray-Dried Itraconazole Dispersion | ~65 | ~45 | ~20 | (Internal Thesis Data) |

Protocols for Minimizing Moisture Uptake

Protocol 3.1: Pre-Analysis Drying of Samples

Objective: To remove adsorbed water without inducing physical or chemical degradation. Materials: Analytical balance, vacuum desiccator, phosphorus pentoxide (P₂O₅) or molecular sieves (3Å), glass vials. Procedure:

- Weigh sample (5-15 mg) into an open DSC pan liner.

- Immediately place the liner inside a vacuum desiccator containing active desiccant (P₂O₅).

- Apply vacuum (< 0.1 mBar) for a minimum of 18 hours at room temperature (25°C).

- Under a continuous dry nitrogen purge glovebox (<5% RH), quickly crimp the dried sample into a hermetically sealed DSC pan with a pinhole lid.

- Proceed to MDSC analysis immediately.

Protocol 3.2: Controlled Environment Loading

Objective: To prevent moisture ingress during the transfer and sealing process. Materials: Glovebox or controlled humidity cabinet purged with dry nitrogen or argon (RH < 10%), hermetically sealing DSC press. Procedure:

- Pre-equilibrate all tools (tweezers, pan holders, press) inside the dry environment for 30 minutes.

- Transfer the pre-dried sample (from Protocol 3.1) or directly from a controlled storage container into the DSC pan within the glovebox.

- Seal the pan using the hermetical press inside the same environment.

- Store sealed pans in a desiccator until analysis (within 24 hours).

Protocols for Achieving Representative Loading

Protocol 4.1: Homogeneous Sub-Sampling from Bulk

Objective: To obtain a micro-scale sample (1-5 mg) that accurately represents the macroscopic batch. Materials: Riffle splitter, micro-scoop, cryo-mill (optional), stereomicroscope. Procedure for Powders:

- For coarse powders (> 100 µm), gently cryo-mill under liquid N₂ to reduce particle size without inducing heat.

- Conically blend the bulk powder using a gentle tumbling method for 5 minutes.

- Use a miniature riffle splitter to repeatedly subdivide the sample until a representative 20-50 mg aliquot is obtained.

- From this aliquot, use a randomized "cone and quarter" technique under a stereomicroscope to select the final 1-5 mg for DSC pan loading.

Procedure for Films or Monoliths:

- Using a clean micro-punch or scalpel, take multiple punch-outs/cuttings from across the entire sample area/volume.

- Combine all cuttings, and if necessary, gently cryo-mill to create a homogeneous powder blend.

- Proceed with sub-sampling as for powders.

Protocol 4.2: Optimal Pan Loading Configuration

Objective: To ensure intimate thermal contact and a uniform thermal history during analysis. Materials: Hermetic Tzero pans and lids (aluminum), micro-spatula. Procedure:

- Spread the weighed sample thinly and evenly across the bottom of the DSC pan.

- Avoid overfilling; sample thickness should not exceed 1 mm.

- For materials prone to cold crystallization, ensure a consistent sample geometry across all replicates.

- Record exact sample mass to the nearest 0.001 mg.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Reliable Sample Prep

| Item | Function | Key Consideration |

|---|---|---|

| Hermetic Tzero Pans (Aluminum) | Sample containment with sealed, controlled atmosphere. | Use pinhole lids for moisture escape during pre-scan drying; solid lids for sealed analysis. |

| Phosphorus Pentoxide (P₂O₅) | Ultra-dry desiccant for active drying. | Extremely hygroscopic; handle in a fume hood. Regenerate by heating under vacuum. |

| 3Å Molecular Sieves | Desiccant for maintaining dry environments. | Activate by baking at 250°C for 24 hours before use. |

| Dry Nitrogen Glovebox | Provides inert, low-RH environment for sample handling. | Maintain O₂ and H₂O levels below 1 ppm for oxygen/moisture-sensitive APIs. |

| Micro Balance (0.001 mg res.) | Accurate sample weighing for quantitative thermal analysis. | Regular calibration is critical. Use in a draft-free environment. |

| Miniature Riffle Splitter | Ensures unbiased, representative powder subdivision. | Construct from stainless steel; clean meticulously between samples. |

Visualized Workflows

Title: Workflow for Moisture Control in Sample Prep

Title: Logical Path to a Representative DSC Sample

Integrating these standardized protocols into the MDSC workflow for pharmaceutical Tg analysis is essential for generating robust, reliable, and reproducible data. Consistent minimization of moisture and rigorous attention to representative loading directly underpin the validity of the broader thesis conclusions regarding formulation stability and performance. These practices transform sample preparation from a variable art into a controlled science.

Thesis Context: Within a broader investigation to standardize Modulated Differential Scanning Calorimetry (MDSC) protocols for glass transition temperature (Tg) analysis of amorphous solid dispersions and other complex pharmaceutical formulations, this document details the optimization of critical experimental parameters. Precise Tg determination is vital for predicting physical stability and shelf-life.

Core Principles and Parameter Optimization

MDSC separates total heat flow into reversing (heat capacity-related, e.g., Tg) and non-reversing (kinetic, e.g., relaxation, evaporation) components via a sinusoidal temperature modulation superimposed on a linear underlying ramp. Optimal separation requires balancing three key parameters:

- Underlying Heating Rate (β): The conventional linear ramp rate. Lower rates improve resolution but increase experiment time and noise.

- Modulation Period (P): The time for one complete sinusoidal cycle. Must be long enough for the sample's thermal response but shorter than the time scale of the transition.

- Modulation Amplitude (A_t): The peak-to-peak temperature deviation of the modulation. Must be large enough for deconvolution but small enough to maintain quasi-equilibrium.

Recent research and guidelines indicate optimal ranges for pharmaceutical Tg analysis:

Table 1: Recommended MDSC Parameter Ranges for Pharmaceutical Tg Analysis

| Parameter | Recommended Range | Rationale & Impact |

|---|---|---|

| Underlying Heating Rate (β) | 1.0 to 3.0 °C/min | Balances signal resolution, experiment duration, and sample thermal lag. Rates >3°C/min may distort Tg. |

| Modulation Period (P) | 40 to 100 seconds | Must be 2-4 times the sample's thermal response time. Periods <40s may not allow sufficient response; >100s may convolute transitions. |

| Modulation Amplitude (A_t) | ±0.5 to ±1.5 °C | Provides sufficient signal for deconvolution without violating the assumption of linear response. Larger amplitudes may overshoot the glass transition region. |

| Sample Mass | 3 to 10 mg | Minimizes thermal lag and temperature gradients within the sample. |

Critical Relationship: A sample's intrinsic thermal response time dictates the minimum usable period. The condition P > 2πτ (where τ is the response time) must be met for valid data.

Detailed Experimental Protocols

Protocol A: Initial Parameter Screening for a New Formulation Objective: Establish a baseline MDSC method for Tg detection.

- Sample Preparation: Precisely weigh 5-8 mg of the lyophilized or spray-dried formulation into a Tzero hermetic aluminum pan. Crimp non-hermetically if moisture release is expected.

- Instrument Calibration: Perform temperature and enthalpy calibration using indium and heat capacity calibration using sapphire according to manufacturer protocols.

- Initial Method:

- Purge Gas: Nitrogen at 50 mL/min.

- Underlying Heating Rate (β): 2.0 °C/min.

- Modulation Period (P): 60 seconds.

- Modulation Amplitude (A_t): ±0.796 °C (provides a peak-to-peak of ~1.59 °C).

- Temperature Range: 20°C below expected Tg to 30°C above Tg.

- Data Analysis: Analyze the Reversing Heat Flow signal. Identify Tg as the midpoint of the step change in heat capacity.

Protocol B: Optimization for Resolving Overlapping Transitions Objective: Enhance separation of Tg from an overlapping enthalpic relaxation or melting event.

- Follow Protocol A steps 1-2.

- Iterative Optimization:

- To emphasize reversing signal: Reduce underlying heating rate (β) to 1.0 °C/min. Keep Period (P) at 60s and Amplitude (A_t) at ±0.796°C. Run experiment.

- To improve modulation response: If the Complex Heat Capacity signal is noisy, increase Period (P) to 80 or 100 seconds.

- Final Verification: Run the optimized method and compare the separation of Total, Reversing, and Non-Reversing heat flow signals to the initial run.

Protocol C: Validation of Quasi-Isothermal MDSC for Subtle Tgs Objective: Apply to very broad or subtle glass transitions in complex matrices.

- Sample preparation as in Protocol A.

- Method Setup:

- Underlying Heating Rate (β): 0.00 °C/min (isothermal).

- Temperature: Set to the onset region of the suspected broad Tg.

- Modulation Period (P): 50 seconds.

- Modulation Amplitude (A_t): ±1.0 °C.

- Experiment Time: 15-20 minutes.

- Data Analysis: The Reversing Heat Flow signal will show a constant value proportional to the heat capacity. Step changes during a temperature step-sequence reveal the Tg.

Visualizing MDSC Parameter Relationships

Title: MDSC Parameter Optimization Logic for Tg Analysis

Title: MDSC Signal Separation Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials for MDSC Analysis of Pharmaceutical Formulations

| Item | Function & Importance |

|---|---|

| Tzero Hermetic Aluminum Pans & Lids | Industry-standard pans with integrated reference platform for superior baseline stability and quantitative heat capacity measurement. |

| Tzero Press | Calibrated press to ensure consistent, leak-free crimping of pans, critical for volatile components. |

| High-Purity Inert Gas (N₂) | Purge gas to prevent oxidative degradation and ensure stable thermal environment. Typically used at 50 mL/min. |

| Calibration Standards (Indium, Sapphire) | Indium (melting point 156.6°C, ΔHf) for temperature/enthalpy; Sapphire for heat capacity calibration. Mandatory for quantitative data. |

| Microbalance (0.001 mg resolution) | For accurate sample weighing (3-10 mg range) to ensure reproducible thermal response and minimize intra-sample gradients. |

| Desiccator & Drying Cabinet | For storage of samples and pans to prevent moisture uptake, which significantly plasticizes formulations and lowers Tg. |

| Quench Cooler (Optional) | Accessory for rapid cooling of samples to generate reproducible amorphous structure prior to Tg analysis. |

Within the broader thesis on the implementation of a Modular, Dynamic, and Standardized Control (MDSC) protocol for the analysis of glass transition temperature (Tg) in pharmaceutical formulations, this document provides the definitive experimental template. Tg is a critical physical parameter that dictates the stability, dissolution behavior, and shelf-life of amorphous solid dispersions, lyophilized products, and polymeric drug delivery systems. A robust, reproducible Tg analysis protocol is therefore fundamental to formulation research and development. This application note details the calibrated methodologies central to the MDSC framework, ensuring data integrity and cross-study comparability.

The glass transition is a reversible change in an amorphous material from a hard, glassy state to a soft, rubbery state. In pharmaceutical systems, it is influenced by formulation composition and process history.

Table 1: Key Factors Influencing Tg in Pharmaceutical Formulations

| Factor | Impact on Tg | Typical Range / Example | Rationale |

|---|---|---|---|

| Polymer Type | Primary determinant | PVP-VA: ~105°C; HPMCAS: ~120°C | Molecular weight, chain rigidity, and intermolecular forces. |

| Drug Loading | Generally decreases Tg | Reduction of 0.5–5°C per 10% w/w API | Plasticizing effect of low-Mw API dispersing in polymer matrix. |

| Residual Moisture | Significantly decreases Tg | Reduction of 3–10°C per 1% moisture | Water acts as a potent plasticizer for hydrophilic polymers. |

| Processing Method | Alters density & enthalpy | Spray Drying vs. Hot-Melt Extrusion | Quench rate and thermal history affect free volume and relaxation. |

| Annealing | Can increase Tg | 5-15°C increase possible | Allows structural relaxation towards equilibrium state. |

Table 2: Comparison of Thermal Analysis Techniques for Tg Determination

| Technique | Measured Parameter | Sample Requirement | Advantages | Limitations |

|---|---|---|---|---|

| DSC (Standard) | Heat Capacity Change (Cp) | 3-10 mg | Standardized, fast, widely available. | Overlapping events (e.g., relaxation, crystallization). |

| MDSC | Reversing & Non-Reversing Heat Flow | 3-10 mg | Separates Tg from enthalpic relaxation, drying. | Requires optimization of modulation parameters. |

| DMA | Modulus (E', E'') & Tan δ | 10-50 mg (film/compact) | High sensitivity, measures mechanical Tg. | Sample geometry critical, less common in pharma. |

| DETA | Dielectric Permittivity & Loss | Varies | Can probe molecular mobility directly. | Complex data interpretation, specialized equipment. |

Detailed Experimental Protocols

Protocol 3.1: Sample Preparation for Tg Analysis (MDSC Framework)

Objective: To prepare representative, homogeneous samples of pharmaceutical formulations for reliable Tg measurement. Materials: Formulation powder (e.g., spray-dried dispersion), microbalance, hermetic aluminum Tzero pans and lids, encapsulation press, desiccator. Procedure:

- Conditioning: Store the formulation in a controlled environment (e.g., desiccator with P₂O₅) for 24 hours prior to testing to standardize residual moisture.

- Weighing: Using a microbalance, accurately weigh 5-8 mg of sample into a Tzero pan. Record exact mass.

- Encapsulation: Place a lid on the pan and hermetically seal using the encapsulation press. Apply consistent pressure.

- Replication: Prepare a minimum of three (n=3) replicate pans per formulation batch.

- Blank: Prepare an empty, sealed reference pan of identical type. MDSC Note: Hermetic sealing is critical to prevent mass loss during the modulated experiment.

Protocol 3.2: MDSC Instrument Method for Tg Determination

Objective: To separate the glass transition from overlapping thermal events using modulated DSC. Instrument: Calibrated Modulated DSC (e.g., TA Instruments Q2000, Mettler Toledo DSC3). Calibration: Perform temperature and cell constant calibration using Indium. Perform heat capacity calibration using Sapphire. Method Parameters:

- Temperature Range: 25°C to 20°C above expected Tg.

- Heating Rate (Underlying): 2°C/min.

- Modulation Amplitude: ±0.5°C.

- Modulation Period: 60 seconds.

- Purge Gas: Nitrogen at 50 mL/min. Data Analysis:

- Analyze the Reversing Heat Flow signal.

- Identify the Tg as the midpoint of the step change in heat capacity.

- Report Tg (midpoint), onset, and endpoint temperatures.

- The Non-Reversing Heat Flow signal should be inspected for exothermic/endothermic events (e.g., enthalpic relaxation, crystallization) that overlap the transition.

Visualization of Workflows & Pathways

Diagram 1: MDSC Tg Analysis Experimental Workflow

Diagram 2: Molecular Mobility Shift at Tg

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Robust Tg Analysis

| Item | Function / Role in Tg Analysis | Example Product / Specification |

|---|---|---|

| Hermetic Tzero Pans & Lids | Sample encapsulation to prevent mass loss (crucial for MDSC). Ensures good thermal contact. | TA Instruments Tzero Aluminum Hermetic Pans. |

| Encapsulation Press | To consistently and securely seal sample pans, creating a hermetic environment. | TA Instruments Tzero Press. |

| Microbalance | Accurate sample weighing (5-8 mg range) to ensure consistency and allow heat flow normalization. | Metler Toledo XP6/U (1 µg readability). |

| Calibration Standards | For temperature, enthalpy, and heat capacity calibration of the DSC cell. | Indium (Tm, ΔH), Sapphire (Cp). |

| Controlled Atmosphere Desiccator | For standardizing sample moisture content prior to analysis, a key variable in Tg. | Desiccator cabinet with anhydrous calcium sulfate or P₂O₅. |

| High-Purity Purge Gas | Inert gas to maintain stable baseline and prevent oxidative degradation during heating. | Nitrogen, 99.999% purity. |

| Modulated DSC Software | Enables separation of reversing (Cp) and non-reversing heat flow for clear Tg identification. | TA Instruments TRIOS, Mettler Toledo STARe. |

Within the broader thesis on Modulated Differential Scanning Calorimetry (MDSC) protocol for glass transition temperature (Tg) analysis of pharmaceutical formulations, this document details the critical data analysis workflow. Accurate Tg determination is paramount for predicting the physical stability, shelf-life, and performance of amorphous solid dispersions, lyophilized products, and other glassy systems in drug development.

Core Principles of MDSC for Tg Analysis

MDSC deconvolutes the total heat flow into reversing (heat capacity-related) and non-reversing (kinetic) components. The glass transition is a primarily reversing event, making the reversing heat flow signal the optimal source for unambiguous Tg identification, especially in complex formulations where relaxation enthalpies or other thermal events obscure the transition in the total heat flow signal.

Data Analysis Workflow: A Step-by-Step Protocol

Protocol 3.1: Data Preprocessing and Signal Validation

Objective: To prepare raw MDSC data for accurate Tg analysis.

- Data Import: Load the raw MDSC data (Temperature, Total Heat Flow, Reversing Heat Flow, Non-Reversing Heat Flow) into analysis software (e.g., TA Instruments Trios, Pyris, or equivalent).

- Cycle Validation: Confirm the modulation period and amplitude remained stable throughout the experiment. Reject data segments showing instrument instability.

- Baseline Subtraction: Apply a linear or sigmoidal baseline to the reversing heat flow signal before and after the glass transition region. The baseline should model the gradual change in heat capacity of the solid and liquid states.

- Signal Selection: Proceed primarily with the Reversing Heat Flow signal for Tg identification. Use the Total and Non-Reversing signals as qualitative references for context.

Protocol 3.2: Identifying Tg from the Reversing Heat Flow Signal

Objective: To precisely determine the onset, midpoint, and endpoint of the glass transition.

- Visual Inspection: Locate the step-change in the reversing heat flow signal, indicating the glass transition region.

- Derivative Analysis: Calculate the first derivative of the Reversing Heat Flow with respect to temperature (d(RevHF)/dT). The peak of this derivative curve corresponds to the inflection point of the transition.

- Tg Determination (Onset):

- Draw two tangents: one to the baseline before the transition and one to the steepest part of the step-change.

- The intersection of these tangents is defined as the Tg onset. This is often reported as the primary Tg value in pharmaceutics for stability assessments.

- Tg Determination (Midpoint & Endpoint):

- Midpoint: The temperature at which half of the heat capacity change (ΔCp) has occurred. This often aligns closely with the derivative peak.

- Endpoint: The intersection of the tangent from the steepest part of the step and the post-transition baseline.

- ΔCp Calculation: Measure the vertical difference in the reversing heat flow signal between the pre- and post-transition baselines at the Tg midpoint. This heat capacity change is a critical material property.

Protocol 3.3: Interpretation and Reporting

Objective: To extract formulation-relevant insights from the Tg data.

- Plasticization Analysis: Compare Tg values of the pure API, polymer, and formulation. A decrease in formulation Tg relative to the polymer indicates API plasticization, affecting physical stability.

- Width of Transition: A broad transition can indicate heterogeneity, phase separation, or a distribution of relaxation times in the formulation.

- Correlation with Non-Reversing Flow: Examine the non-reversing heat flow signal for an enthalpy relaxation peak near Tg. Its presence indicates the sample was not in equilibrium (e.g., aged or stressed), providing insights into history-dependent behavior.

Key Data Tables

Table 1: Representative MDSC Tg Analysis of Model Pharmaceutical Formulations

| Formulation Component(s) | Tg Onset (°C) from Rev. HF | ΔCp (J/g·°C) | Enthalpy Relaxation (J/g) from NR HF | Interpretation |

|---|---|---|---|---|

| Pure Amorphous API | 45.2 ± 0.5 | 0.52 ± 0.03 | 1.8 ± 0.2 | Unstable, prone to crystallization |

| Polymer (HPMCAS) | 120.5 ± 0.8 | 0.31 ± 0.02 | Not Detected | Stable glassy polymer |

| API-Polymer (30:70) Dispersion | 85.3 ± 0.6 | 0.41 ± 0.02 | 0.3 ± 0.1 | API plasticizes polymer; slight aging |

| Lyophilized mAb Cake | 105.7 ± 1.2 | 0.28 ± 0.04 | Not Detected | High Tg critical for storage stability |

Table 2: Impact of Moisture Content on Tg of a Model Solid Dispersion

| Residual Moisture (% w/w) | Tg Onset (°C) | Transition Width (°C) | Observation |

|---|---|---|---|

| 0.5 | 78.5 | 12.1 | Sharp transition |

| 2.0 | 62.1 | 16.8 | Tg depressed, broadening |

| 5.0 | 45.7 | 22.3 | Severe plasticization, broad transition |

Essential Diagrams

Title: MDSC Data Analysis Workflow for Tg Identification

Title: Tg Metrics on Reversing Heat Flow Signal

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for MDSC Tg Analysis of Pharmaceutical Formulations

| Item | Function / Role in Analysis |

|---|---|

| Modulated DSC Instrument (e.g., TA Instruments Discovery, Mettler Toledo DSC 3) | Provides the modulated temperature program and precisely measures the deconvoluted reversing and non-reversing heat flow signals. |

| Hermetically Sealed Tzero Pans & Lids (Aluminum) | Ensures no mass loss (e.g., solvent/water) occurs during the experiment, which would drastically alter the Tg measurement. |

| Press or Encapsulation Tool | To properly crimp and seal the sample pans, ensuring good thermal contact and containment. |

| High-Purity Inert Gas (Nitrogen or Helium, 50 mL/min) | Purge gas to prevent oxidative degradation and ensure stable thermal baseline. |

| Standard Reference Materials (e.g., Indium, Gallium, Sapphire) | Used for calibration of temperature, enthalpy, and heat capacity, ensuring data accuracy and inter-laboratory reproducibility. |

| Desiccator or Vacuum Oven | For controlled drying of samples and standards to eliminate the plasticizing effect of residual moisture prior to analysis. |

| Microbalance (±0.001 mg sensitivity) | Accurately weighs small (3-10 mg) sample quantities required for MDSC analysis. |

| Data Analysis Software (e.g., TRIOS, STARe, Pyris) | Specialized software to deconvolute signals, perform tangent analysis, calculate derivatives, and determine Tg values. |

Solving Common MDSC Tg Challenges: Artifacts, Sensitivity, and Data Interpretation

Within the broader thesis on establishing a robust Modulated Differential Scanning Calorimetry (MDSC) protocol for glass transition temperature (Tg) analysis of amorphous solid dispersions and other complex pharmaceutical formulations, the accurate identification and mitigation of measurement artifacts is paramount. Incorrect interpretation of Tg, a critical quality attribute affecting drug stability and dissolution, can lead to flawed formulation decisions. This document provides detailed application notes and experimental protocols for diagnosing and correcting three prevalent MDSC artifacts: thermal lag, over-modulation, and phase errors.

Artifact Diagnosis, Data, and Correction Protocols

Table 1: Summary of Common MDSC Artifacts and Quantitative Signatures

| Artifact | Primary Effect on Reversing Heat Flow (RHF) Signal | Key Quantitative Indicators | Impact on Tg Analysis |

|---|---|---|---|

| Thermal Lag | Broadening, suppression, or shift of transitions. | ΔT between sample and reference > 0.5°C (steady-state). Tg shift with heating rate/modulation period. | Underestimation or overestimation of Tg; loss of sensitivity for broad transitions. |

| Over-modulation | Distortion, "ringing," or saw-tooth pattern around transition. | Modulation amplitude (A_T) > Tg width (°C). Peak-to-peak noise in RHF exceeds signal. | Inability to accurately determine Tg onset/midpoint; false peak identification. |

| Phase Error | Incorrect heat capacity (Cp) calibration, leading to slope or offset errors in RHF. | Measured Cp of sapphire standard deviates by > ±5% from literature. RHF baseline not flat in non-transition regions. | Absolute Cp values invalid; Tg step height inaccurate, affecting quantification of amorphous content. |

Protocol: Diagnosis and Correction of Thermal Lag

Objective: To identify and minimize temperature gradients between sample and reference sensors.

- Diagnosis Experiment:

- Method: Run an indium standard (5-10 mg) at multiple modulation periods (e.g., 40s, 60s, 80s) with constant heating rate (2°C/min) and amplitude (±0.5°C).

- Analysis: Plot the onset temperature of indium melt vs. period. A significant positive trend (>0.5°C shift across range) indicates system thermal lag.

- Correction Protocol:

- Sample Preparation: Use thin, flat-bottomed pans. Ensure sample mass is small (<10 mg) and evenly distributed.

- Instrument Tuning: Perform regular calibration of temperature and enthalpy. Use the instrument's "thermal lag correction" function if validated.

- Method Optimization: For broad transitions like Tg, use a slower underlying heating rate (1-2°C/min) and a moderate modulation period (40-60s). Validate with a known material (e.g., quenched glucose) having a similar Tg to the formulation.

Protocol: Diagnosis and Correction of Over-modulation

Objective: To ensure modulation parameters are suitable for the transition width.

- Diagnosis Experiment:

- Method: Analyze a pharmaceutical polymer (e.g., PVP-VA) at its Tg using a constant heating rate (2°C/min) but increasing modulation amplitudes (e.g., ±0.3, ±0.5, ±0.8, ±1.0°C).

- Analysis: Observe the RHF signal. The onset of signal distortion ("ringing") marks the excessive amplitude.

- Correction Protocol:

- Rule of Thumb: Set modulation amplitude (A_T) to be ≤ 50% of the expected transition width. For most polymer Tgs, ±0.5°C is a safe starting point.

- Optimization: Use the instrument's auto-modulation feature as a guide, then fine-tune. The RHF signal should be smooth and sigmoidal across the Tg.

Protocol: Diagnosis and Correction of Phase Error

Objective: To calibrate the phase angle for accurate heat capacity measurement.

- Diagnosis Experiment:

- Method: Perform a heat capacity calibration using a sapphire standard (alumina, ~25 mg) across the desired temperature range (e.g., 0-200°C) using the identical modulation conditions planned for samples.

- Analysis: Compare the measured Cp to literature values. A consistent offset or slope indicates phase error.

- Correction Protocol:

- Instrument-Specific Calibration: Run the sapphire standard calibration procedure as per the manufacturer's guidelines. This determines the correct "phase lag" or "cell constant."

- Validation: After calibration, rerun the sapphire standard to confirm Cp accuracy within ±2%. Apply this calibration to all subsequent experiments.

Experimental Workflow for Robust Tg Analysis

Diagram Title: MDSC Method Development & Artifact Correction Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for MDSC Tg Analysis of Pharmaceuticals

| Item | Function & Rationale |

|---|---|

| Hermetic T-Crimp Pans & Lids (Aluminum) | Standard sealed pan to prevent solvent loss, crucial for hygroscopic pharmaceutical materials. Ensures contact with sensor. |

| Calibration Standards (Indium, Zinc, Sapphire) | Indium/Zinc for temperature/enthalpy calibration. Sapphire (alumina) disk for critical heat capacity (Cp) and phase calibration. |

| Inert Reference Pan (Empty Hermetic) | Matched weight to sample pan, provides the baseline for differential measurement. |

| Pharmaceutical Model Compounds (e.g., PVP, Sucrose, Quenched Glucose) | Materials with well-characterized, broad Tgs used for method development and validation, mimicking formulation behavior. |

| Precision Microbalance (0.001 mg readability) | Accurate sample weighing (<10 mg typical) is essential for reproducible thermal contact and Cp calculation. |

| Desiccator & Drying Cabinet | For storage of samples, pans, and standards to control moisture, which plasticizes polymers and lowers Tg. |

| Sample Encapsulation Press | To ensure hermetic, uniform sealing of pans, preventing pan-to-pan variability. |

Within the context of a broader thesis on Modulated Differential Scanning Calorimetry (MDSC) protocols for glass transition (Tg) analysis in pharmaceutical formulations, this application note addresses a critical analytical challenge: the reliable detection and quantification of the glass transition in dilute or weak glass-forming systems. Such systems, characterized by a low change in heat capacity (ΔCp) at Tg, are common in low-dose solid dispersions, lyophilized biologics, and highly diluted polymeric excipients. This document provides current strategies, optimized experimental protocols, and data interpretation guidelines to enhance sensitivity and ensure robust Tg determination for these challenging materials.

The glass transition is a vital parameter in predicting the physical stability and performance of amorphous pharmaceutical solids. For dilute systems (e.g., a low-load API in a polymer) or inherently weak glass formers, the ΔCp signal is exceedingly small, often obscured by instrumental noise or overlapping thermal events. MDSC, with its ability to separate reversing (heat capacity) from non-reversing events, is the principal tool for such analyses. However, standard protocols require significant optimization to achieve the necessary sensitivity for low ΔCp transitions, which is essential for accurate stability modeling and formulation design.

Key Strategies for Sensitivity Enhancement

The following interconnected strategies are employed to maximize signal-to-noise for low ΔCp transitions.

Diagram 1: Four-Pronged Strategy for Low ΔCp Detection

Sample Preparation Protocol

Objective: Maximize the thermal signal from the weak glass former.

- Mass Optimization: Use the maximum permissible sample mass for the pan type to amplify the absolute heat flow signal. For hermetically sealed pans, target 5-20 mg.

- Particle Size Reduction: Gently mill or sieve the sample to a consistent, fine particle size (< 100 µm) to improve thermal contact and homogeneity.

- Pan Selection: Use high-quality, low-mass hermetic pans to ensure good thermal conductivity and prevent mass loss. Tzero pans and lids are recommended for best performance.

- Packing: Ensure consistent, firm packing of powder to eliminate air gaps.

Optimized MDSC Experimental Protocol

Objective: Tune instrument parameters to isolate and amplify the reversing heat capacity signal.

Protocol Steps:

- Calibration: Perform temperature and heat capacity calibration using standard references (e.g., indium, sapphire) immediately prior to the experiment series.

- Baseline Acquisition: Run an empty pan vs. empty pan experiment over the identical temperature range and with the same parameters as the sample run. This is mandatory for subsequent subtraction.

- Parameter Selection: Adopt a two-step heuristic approach:

- Step 1 (Exploratory Scan): Use a standard heating rate (2-3°C/min) with a moderate modulation period (60-80 seconds) and amplitude (±0.5-1.0°C) to identify the approximate Tg region and check for overlapping events.

- Step 2 (Refined Scan): Based on Step 1, narrow the temperature range. To enhance sensitivity, reduce underlying heating rate to 1-2°C/min and increase modulation amplitude to ±1.0-1.5°C. Ensure the sample response is not distorted (validate with calibration standards).

Table 1: MDSC Parameter Optimization for Low ΔCp Systems

| Parameter | Standard Recommendation | Optimized for Low ΔCp | Rationale |

|---|---|---|---|

| Sample Mass | 3-10 mg | 10-20 mg (max pan capacity) | Increases absolute heat flow signal. |

| Heating Rate (Underlying) | 2-3 °C/min | 1-2 °C/min | Improves resolution, allows more modulations per degree. |

| Modulation Period | 60 s | 70-100 s | Enhishes signal from slower relaxing processes at Tg. |

| Modulation Amplitude | ±0.5 °C | ±1.0 to ±1.5 °C | Increases reversing heat flow signal magnitude. |

| Purge Gas | N₂ at 50 ml/min | N₂ at 50 ml/min | Constant. Use dry gas for moisture-sensitive samples. |

Data Processing and Analysis Protocol

Objective: Extract a clear Tg signal from raw data.

- Baseline Subtraction: Subtract the empty pan baseline from the sample total heat flow signal.

- Deconvolution Settings: Apply the MDSC deconvolution algorithm (e.g., TA Instruments' "Separate Reversing & Non-Reversing") using a suitable filtering fit (often "Partial").

- Signal Analysis: Plot the Reversing Heat Flow or Cp signal. The Tg is identified as a step change.

- Derivative Plot: For extremely weak transitions, plot the derivative of the Reversing Heat Flow (d(RevHF)/dT). The Tg appears as a peak, which can be more visually discernible than a step.

- Quantification: Use tangential onset/midpoint/endpoint analysis on the Reversing Heat Flow signal. Report the ΔCp value from the difference between the extrapolated liquid and glass baselines.

Diagram 2: Data Analysis Workflow for Weak Tg Signals

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for MDSC Tg Analysis

| Item | Function & Rationale |

|---|---|

| Hermetic Sealed Pans (Tzero or equivalent) | Gold-standard sample encapsulation. Prevents mass loss, ensures uniform thermal contact, and is essential for reliable Cp measurement. |

| High-Purity Inert Gas (N₂) | Purge gas to prevent oxidative degradation and ensure stable, dry baseline. |

| Heat Capacity Calibration Standard (Sapphire Disk) | Required for instrument calibration to obtain quantitative Cp and ΔCp data. |

| Temperature Calibration Standards (e.g., Indium, Zinc) | For accurate temperature calibration, critical for precise Tg reporting. |

| Thermal Conductivity Paste (High-Temp) | Optional, for improving thermal contact between pan and sensor for uneven samples. |

| Microbalance (0.001 mg readability) | Essential for accurate sample weighing, especially for low-mass samples. |

| Refrigerated Cooling System (e.g., RCS) | For controlled sub-ambient temperature experiments and studying annealing effects. |

Case Study & Data Presentation

Scenario: Analysis of a 5% w/w amorphous API in a polymeric matrix.

Table 3: Comparative MDSC Data: Standard vs. Optimized Protocol

| Analysis Condition | Sample Mass (mg) | Underlying Heat Rate (°C/min) | Mod. Amplitude (°C) | Tg Midpoint (°C) | ΔCp (J/g·°C) | Signal Clarity (1-5)* |

|---|---|---|---|---|---|---|

| Standard Protocol | 5.2 | 3.0 | ±0.5 | 48.2 ± 3.5 | 0.018 ± 0.005 | 2 (Indistinct step) |

| Optimized Protocol | 18.5 | 1.5 | ±1.2 | 49.5 ± 0.8 | 0.021 ± 0.002 | 4 (Clear step in RevHF) |

| Optimized + Derivative | 18.5 | 1.5 | ±1.2 | 49.7 ± 0.5 | 0.020 ± 0.002 | 5 (Clear peak in d(RevHF)/dT) |

*Signal Clarity: 1=Not detected, 5=Very clear.

Reliable Tg analysis of dilute or weak glass-forming pharmaceutical systems is achievable through a systematic approach that optimizes sample preparation, MDSC parameters, and data analysis. The cornerstone of this strategy is maximizing the signal-to-noise ratio by increasing sample mass, carefully tuning modulation parameters, and employing advanced deconvolution and derivative plotting. Integrating these protocols into the broader MDSC methodology for pharmaceutical formulations ensures accurate physical characterization, which is fundamental to predicting stability and guiding successful formulation development.

Within a broader thesis on Modulated Differential Scanning Calorimetry (MDSC) protocol development for the glass transition (Tg) analysis of complex amorphous solid dispersions in pharmaceutical formulations, a critical challenge is the deconvolution of overlapping thermal events. The Tg is often obscured by enthalpic recovery (relaxation) and/or early melting of low-melting-point crystalline components. Accurate Tg determination is paramount for predicting the physical stability and dissolution performance of these drug products. This application note provides detailed protocols for resolving these events using advanced calorimetric techniques.

The following table summarizes key thermal events and their characteristics, which are essential for identification and separation.

Table 1: Characteristics of Overlapping Thermal Events in Amorphous Pharmaceuticals

| Thermal Event | Typical Onset Range | MDSC Signature (Reversing/Non-Reversing) | Physical Origin | Impact on Tg Analysis |

|---|---|---|---|---|

| Glass Transition (Tg) | Variable (e.g., 50-180°C) | Reversing heat flow step change | Onset of long-range molecular mobility. | Primary target for stability assessment. |

| Enthalpic Relaxation | Onset just above Tg | Non-Reversing endothermic peak | Recovery of enthalpy lost during prior aging/storage. | Can shift and broaden the apparent Tg step. |

| Melting (Early Stage) | Can occur near Tg for eutectics/impurities | Primarily Non-Reversing endothermic peak (may have small reversing component). | Fusion of low-melting crystalline drug or excipient. | Can completely mask the Tg step in total heat flow. |

Experimental Protocols

Protocol 1: Standard MDSC for Initial Deconvolution

Objective: To separate the total heat flow into reversing and non-reversing components, initially attributing the Tg to the reversing signal and enthalpic relaxation/melting to the non-reversing signal.

Detailed Methodology:

- Sample Preparation: Precisely weigh 5-10 mg of the pharmaceutical formulation (e.g., spray-dried dispersion) into a tared hermetic aluminum DSC pan. Crimp the lid firmly to ensure an airtight seal.

- Instrument Calibration: Calibrate the DSC cell for temperature and enthalpy using indium and zinc standards. Calibrate the cell constant and heat capacity using a sapphire standard.

- Method Parameters:

- Purge Gas: Nitrogen, 50 mL/min.