Hydrogen Bonding in Polymer Thermodynamics: Fundamentals, Design, and Biomedical Applications

This article provides a comprehensive analysis of hydrogen bonding (H-bonding) and its profound influence on the thermodynamic and mechanical properties of polymer systems.

Hydrogen Bonding in Polymer Thermodynamics: Fundamentals, Design, and Biomedical Applications

Abstract

This article provides a comprehensive analysis of hydrogen bonding (H-bonding) and its profound influence on the thermodynamic and mechanical properties of polymer systems. Tailored for researchers and drug development professionals, it explores the fundamental principles of reversible H-bond networks, from rigid and flexible motifs to cooperative effects. The scope extends to advanced material design strategies, including supramolecular polymers and nanocomposites, highlighting their role in creating mechanically robust, self-healing, and stimuli-responsive biomaterials. The review further addresses critical challenges in tuning material properties and validates these approaches through computational and experimental studies. By synthesizing foundational knowledge with cutting-edge applications, this work serves as a guide for leveraging H-bond thermodynamics to innovate in drug delivery, tissue engineering, and medical devices.

The Fundamentals of Hydrogen Bonding: From Basic Interactions to Polymer Thermodynamics

Hydrogen bonding (H-bonding) represents a specific type of intermolecular attraction that is fundamental to the behavior of numerous chemical and biological systems, particularly in polymer science and thermodynamics research. In chemistry, a hydrogen bond is a specific type of molecular interaction that exhibits partial covalent character and cannot be described as a purely electrostatic force [1]. It occurs when a hydrogen (H) atom, covalently bonded to a more electronegative donor atom or group (Dn), experiences an attractive force with another electronegative atom bearing a lone pair of electrons—the hydrogen bond acceptor (Ac) [1]. The general notation for hydrogen bonding is Dn−H···Ac, where the solid line represents a polar covalent bond, and the dotted or dashed line indicates the hydrogen bond itself [1]. This interaction arises from a combination of electrostatics (multipole-multipole and multipole-induced multipole interactions), covalency (charge transfer by orbital overlap), and dispersion forces [1].

The essential prerequisite for hydrogen bond formation is the presence of a highly polar covalent bond where hydrogen is attached to a highly electronegative atom such as nitrogen (N), oxygen (O), or fluorine (F) [2]. This creates a significant difference in electronegativity, causing the hydrogen atom to bear a large partial positive charge (δ+) and the electronegative atom to bear a large partial negative charge (δ−) [2]. A hydrogen atom in one molecule then becomes electrostatically attracted to the N, O, or F atom in another molecule [2]. Although traditionally associated with N, O, and F, the definition of hydrogen bonding has broadened to include weaker interactions involving other acceptor atoms and even carbon in specific circumstances, especially when the carbon or its neighbors are electronegative [1].

Energy Range and Classification of Hydrogen Bonds

The strength of hydrogen bonds exhibits considerable variation, depending on the donor-acceptor pair, geometry, and chemical environment. This strength is most often evaluated through measurements of equilibria between molecules containing donor and/or acceptor units, typically in solution, or by studying conformational equilibria for intramolecular hydrogen bonds [1].

Quantitative Energy Classifications

Hydrogen bonds are typically stronger than van der Waals interactions but generally weaker than covalent or ionic bonds [1]. The following table summarizes the classification and typical energy ranges for hydrogen bonds.

Table 1: Classification and Energy Ranges of Hydrogen Bonds

| Bond Classification | Typical Energy Range (kJ/mol) | Typical Energy Range (kcal/mol) | Key Characteristics and Examples |

|---|---|---|---|

| Very Strong [3] | 63 – 167 [3] | 15 – 40 [3] | Exhibits significant covalent character; e.g., [F-H-F]⁻ bifluoride ion (161.5 kJ/mol) [1] [3]. |

| Strong [3] | 17 – 63 [3] | 4 – 15 [3] | Dominated by electrostatic interactions; e.g., O-H···O in water-water (21 kJ/mol) and O-H···N in water-ammonia (29 kJ/mol) [1] [3]. |

| Weak [3] | < 17 [3] | < 4 [3] | Includes non-traditional H-bonds involving donors/acceptors other than N,O,F; e.g., C-H···O interactions [1] [3]. |

Specific Donor-Acceptor Bond Energies

The strength of hydrogen bonds is highly dependent on the specific chemical identities of the donor and acceptor atoms. The table below provides representative bond enthalpies for specific donor-acceptor pairs, typically measured in the vapor phase [1].

Table 2: Representative Hydrogen Bond Enthalpies for Specific Donor-Acceptor Pairs

| Donor-Acceptor Pair (D-H···A) | Representative Enthalpy (kJ/mol) | Representative Enthalpy (kcal/mol) | Example System |

|---|---|---|---|

| F-H···F⁻ [1] | 161.5 [1] | 38.6 [1] | Bifluoride ion, [F-H-F]⁻ [1] |

| O-H···N [1] | 29 [1] | 6.9 [1] | Water-ammonia complex [1] |

| O-H···O [1] | 21 [1] | 5.0 [1] | Water-water, alcohol-alcohol [1] |

| N-H···N [1] | 13 [1] | 3.1 [1] | Ammonia-ammonia complex [1] |

| N-H···O [1] | 8 [1] | 1.9 [1] | Water-amide complex [1] |

Directionality and Structural Details

Directionality is a defining and key property of hydrogen bonds that separates it from more isotropic van der Waals forces [4]. This directionality arises from the electrostatic attraction between the donor hydrogen and the acceptor atom, coupled with the interaction between the lone pair of electrons on the acceptor and the σ-antibonding orbital of the X-H bond [5]. The hydrogen bond tends to become increasingly linear as its strength increases because this arrangement reaches an energy minimum [6].

Geometric Parameters

The geometry of a hydrogen bond, specifically the bond lengths and angles, directly correlates with its strength and stability.

Table 3: Geometric Parameters of Hydrogen Bonds

| Geometric Parameter | Typical Value or Range | Correlation with Bond Strength |

|---|---|---|

| X-H Bond Length (covalent) [1] [3] | ~110 pm [1] [3] | Lengthening of the covalent X-H bond indicates a stronger H-bond [3]. |

| H···A Bond Length (hydrogen bond) [1] [3] [7] | 160 - 200 pm [1] [3] | Shorter H···A distances indicate stronger H-bonds [7]. |

| X···A Distance [3] | 250 - 320 pm for strong H-bonds [3] | — |

| X-H···A Bond Angle [3] [7] | 130° - 180° [3] | Angles closer to 180° are associated with stronger, more stable bonds [7]. Strong H-bonds are typically between 170° and 180° [7]. |

The ideal bond angle depends on the nature of the hydrogen bond donor and the geometry of the acceptor. For instance, experimental determinations for hydrofluoric acid donors show acceptor-specific angles: linear (180°) with HCN, trigonal planar (120°) with H₂CO, and pyramidal (46°) with H₂O [1]. The directionality is particularly pronounced for acceptors like carbonyl groups, where the oxygen atom possesses a lone pair in its sp²-hybridized orbital, confining H-bond formation to the plane of the R₂C=O group [6].

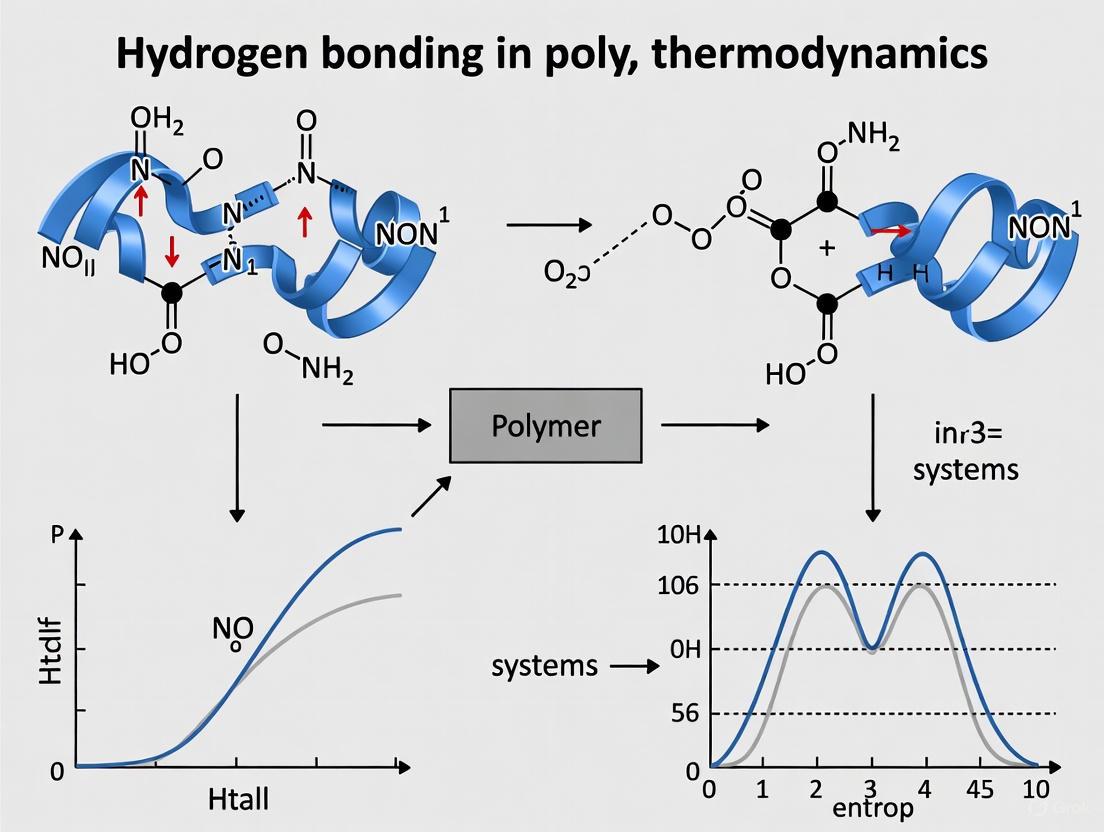

Figure 1: Schematic diagram illustrating the key geometric parameters of a hydrogen bond, including bond lengths and the critical X-H···A angle that defines its directionality.

Key Interactions and Theoretical Considerations

The fundamental nature of the hydrogen bond is complex and cannot be explained by electrostatic attraction alone. Modern understanding recognizes contributions from electrostatics, covalency (charge transfer by orbital overlap), and dispersion (London forces) [1]. A significant covalent component arises from charge transfer from the lone pair (n) of the acceptor to the antibonding orbital (σ) of the X-H bond in the donor (n→σ interaction) [1] [5]. This partial delocalization of electrons leads to the description of hydrogen bonding as a resonance-assisted interaction [1].

The frozen density interaction term, which encompasses electrostatics and Pauli repulsion, has been identified through density-based energy decomposition analysis (DEDA) as the dominant factor in determining the directional preference and orientation of hydrogen bonds at the acceptor atom [8]. Interestingly, the sum of polarization and charge-transfer components shows very little directional dependence, suggesting that the difficulty for classical non-polarizable force fields to describe HB directionality is not primarily due to the lack of these explicit terms, but rather stems from the inadequacy of simple atomic point charge models to represent the anisotropic electron density around the acceptor atom [8].

Hydrogen Bonding in Polymer Systems Thermodynamics

In the context of polymer thermodynamics research, hydrogen bonding plays a pivotal role in dictating material properties by serving as a reversible, dynamic cross-linking mechanism. The integration of multiple hydrogen-bonded networks into polymers is a key strategy for developing materials with exceptional mechanical performance, self-healing capabilities, and tailored thermodynamic properties [5].

"Rigid" vs. "Flexible" H-Bond Motifs

H-bond motifs in polymers can be broadly categorized based on their structural flexibility, which profoundly affects the resulting material's mechanoresponsive behavior and thermodynamics [6].

- Rigid Multiple H-Bonds: These are often characterized by π-conjugated units and structural complementarity, as seen in nucleobases and the 2-ureido-4[1H]-pyrimidinone (UPy) motif [6]. The UPy motif, for example, dimerizes through self-complementary quadruple H-bonds with a very high association constant (~10⁶ M⁻¹ in CHCl₃) [6]. This rigidity imparts strong directionality and association, leading to the formation of stable, long-lived cross-links that can significantly increase the elastic modulus, glass transition temperature (Tg), and relaxation time of the polymer [6]. The π-conjugation in these systems can also lead to π-bond cooperativity, where the overall bond energy of multiple H-bonds exceeds the sum of the individual bond energies due to resonance effects [6].

- Flexible Multiple H-Bonds: These motifs, such as aliphatic vicinal diol groups, lack strong π-conjugation and possess conformational freedom, allowing them to exhibit various stable H-bonding modes [6]. While individual bonds may be weaker or less directional, their collective, dynamic behavior can efficiently dissipate energy under strain and facilitate network restoration upon stress release, contributing to high toughness and stretchability [6].

Mechanical and Thermodynamic Effects

The reversible nature of hydrogen bonds makes them exceptional tools for enhancing mechanical properties. Under small strains, H-bonds act as apparent crosslinks, increasing the elastic modulus [6]. Under large strains, these relatively weak and reversible bonds can break and reform (exchange) before covalent bonds break, a process that dissipates energy and leads to high stretchability and toughness [5] [6]. When stress is released, the exchange of H-bonds facilitates the restoration of the polymer network and its mechanical strength [6]. This dynamic cross-linking directly influences thermodynamic properties such as the glass transition temperature (Tg). Introducing strong H-bonding cross-linkers can restrict chain mobility, thereby increasing the Tg, as observed in polyvinyl alcohol (PVA) systems with small molecule cross-linkers like HCPA [5]. The formation of multiple H-bonded networks can also be detected through rheological studies, which show a characteristic 'second plateau' in the storage modulus (G') at low frequencies, indicating a cross-linked network [5].

Experimental Protocols and Research Toolkit

Studying hydrogen bonds in polymer systems requires a multidisciplinary approach, combining synthesis, spectroscopic characterization, thermodynamic measurements, and mechanical testing.

Key Spectroscopic and Analytical Methods

- Infrared (IR) Spectroscopy: This is one of the most sensitive methods for detecting hydrogen bonding. The formation of an H-bond leads to a redshift (shift to lower frequency) and broadening of the X-H stretching vibration (e.g., O-H, N-H) due to a weakening of the X-H covalent bond [1] [5]. Variable-temperature IR can probe the dynamics of H-bonds during phase transitions [1].

- Nuclear Magnetic Resonance (NMR) Spectroscopy: Strong hydrogen bonds are revealed by downfield shifts (increased δH) in the ¹H NMR spectrum of the involved proton [1]. NMR can also demonstrate information transfer between H-bonded nuclei, providing evidence for the partial covalent character of the bond [1].

- Small-Angle X-Ray Scattering (SAXS): Used to investigate nanoscale structures and morphological changes under deformation. For example, in PVA/HCPA systems, SAXS can track the increase in the Guinier radius (Rg) of H-bonded nanodomains under tensile strain, revealing deformation mechanisms and energy dissipation [5].

- Dynamic Mechanical Analysis (DMA): Essential for measuring viscoelastic properties. DMA reveals the effect of H-bond cross-links on the storage modulus, loss modulus, and relaxation behavior of polymers, showing features like a rubbery plateau and substantially prolonged relaxation times in supramolecular polymers [6].

- Differential Scanning Calorimetry (DSC): Used to determine thermal transitions, particularly the glass transition temperature (Tg). An increase in Tg indicates restricted chain mobility due to strong H-bonding interactions, while complex effects can sometimes lead to Tg depression at high cross-linker concentrations due to disrupted interchain interactions [5].

Figure 2: A representative experimental workflow for characterizing hydrogen bonding and its effects in polymer systems, integrating structural, thermal, and mechanical analysis.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Key Research Reagents and Materials for Studying H-Bonding in Polymers

| Reagent/Material | Function/Role in Research | Example Application |

|---|---|---|

| UPy (2-ureido-4[1H]-pyrimidinone) Motif [6] | A strong, self-complementary quadruple H-bonding unit used as a side-chain or chain-end group to create reversible cross-links in supramolecular polymers. | Imparts high elasticity, toughness, and self-healing properties to poly(n-butyl acrylate) and other polymer backbones [6]. |

| HCPA (Hexa-Component Hydrogen-Bonding Cross-linker) [5] | A small molecule with six amino groups that acts as a physical cross-linker by forming multiple H-bonds with polymer chains. | Simultaneously toughens and strengthens polyvinyl alcohol (PVA) films, enabling a balance of high tensile strength and self-healing [5]. |

| Nucleobase-Functionalized Monomers | Utilizing adenine, thymine, uracil, etc., to incorporate specific, complementary multiple H-bonding arrays into polymer structures. | Creates polymers with programmable assembly, molecular recognition features, and tailored thermomechanical responses [6]. |

| Aliphatic Vicinal Diol Monomers [6] | Provide "flexible" multiple H-bonding sites without strong π-conjugation, allowing for various bonding modes and dynamic network reorganization. | Used to synthesize polymers where H-bond flexibility contributes to energy dissipation and restoration mechanisms under strain [6]. |

In polymer science and drug development, hydrogen bonds (H-bonds) are fundamental tools for engineering material properties and function. These noncovalent interactions, characterized by an electron-deficient hydrogen atom (donor) and an electronegative atom like oxygen or nitrogen (acceptor), possess bond energies typically ranging from 4 to 15 kJ/mol [6]. Their reversible nature and directionality allow them to act as dynamic cross-links, significantly enhancing mechanical properties such as elastic modulus, toughness, and stretchability [6]. A critical advancement in the field is the recognition that the structural flexibility of the H-bonding motif itself is a primary determinant of macroscopic material behavior. This has led to the classification of motifs into two distinct categories: "rigid" and "flexible" multiple H-bonds [6]. This guide provides an in-depth technical comparison of three quintessential motifs—2-ureido-4[1H]-pyrimidinone (UPy), nucleobases, and aliphatic diols—framed within the thermodynamics of polymer systems, to inform the rational design of next-generation materials and therapeutic agents.

Fundamental Concepts and Definitions

Rigid vs. Flexible H-Bond Motifs

The distinction between rigid and flexible H-bond motifs lies in their molecular structure and its implications for bonding and dynamics.

- Rigid H-Bond Motifs: These motifs are characterized by π-conjugated units and structural complementarity [6]. The conjugated systems, such as aromatic rings, lock the donor and acceptor atoms in a specific geometric arrangement. This confinement imparts strong directionality to the H-bonds. Furthermore, these systems often exhibit π-bond cooperativity, where the overall bond energy of multiple H-bonds exceeds the sum of the individual bonds due to resonance effects [6]. This results in strong, stable, and highly specific dimerization.

- Flexible H-Bond Motifs: These motifs lack extensive π-conjugation and possess conformational freedom due to aliphatic (carbon-chain) spacers [6] [9]. The absence of a rigid plane allows the functional groups to adopt various orientations, leading to a diversity of stable H-bonding modes [6]. This flexibility translates to a higher degree of dynamic behavior in polymeric systems.

Thermodynamic and Kinetic Parameters

The binding behavior of these motifs is quantified by key parameters:

- Association Constant (K): A higher K value indicates stronger and more stable complex formation.

- Binding Energy: The total energy stabilizing the H-bonded complex, influenced by cooperativity in rigid motifs.

- Dynamicity: The rate at which H-bonds dissociate and reassociate under thermal energy; a critical factor for self-healing and energy dissipation.

Analysis of Key H-Bond Motifs

Rigid Motifs: UPy and Nucleobases

Table 1: Characteristics of Rigid H-Bond Motifs

| Feature | UPy (2-ureido-4[1H]-pyrimidinone) | Nucleobases (e.g., Adenine-Thymine) |

|---|---|---|

| H-bond Pattern | Self-complementary quadruple H-bonds (DDAA) [10] | Specific-complementary multiple H-bonds (e.g., DDA for A-T) [6] |

| Association Constant (K) | ~10⁶ – 10⁷ M⁻¹ (in CHCl₃) [6] [10] | Varies by pair; generally very high due to complementarity [6] |

| Key Structural Feature | π-conjugated pyrimidinone core [6] | π-conjugated heterocyclic cores with precise donor/acceptor arrays [6] |

| Primary Role in Polymers | Strong, reversible cross-link to enhance modulus and create supramolecular polymers [6] | Molecular recognition, self-assembly, and creating smart, responsive materials [6] |

| Impact on Mechanics | Increases relaxation time, tensile strength, and toughness [6] | Imparts directionality and can be used to program specific interactions [6] |

UPy is a paradigmatic rigid motif. Its self-complementary DDAA sequence forms a dimer through quadruple H-bonds, leading to an exceptionally high association constant [6] [10]. When incorporated into polymer chains, UPy dimers act as powerful, reversible cross-links. This dramatically slows polymer chain relaxation, elevates the rubbery plateau modulus, and enhances tensile strength and fracture strain [6]. Under certain conditions, the planar, rigid UPy dimers can stack and form crystalline nanodomains, further reinforcing the material [6].

Nucleobases represent nature's approach to rigid, specific H-bonding. Their precise geometric and electronic complementarity (e.g., between adenine and thymine) allows for highly selective molecular recognition [6]. Incorporating these into synthetic polymers enables the creation of materials with bio-inspired self-assembly and responsive properties, leveraging the built-in code of base-pairing to control macromolecular architecture.

Flexible Motifs: Aliphatic Diols

Table 2: Characteristics of Flexible H-Bond Motifs

| Feature | Aliphatic Diols |

|---|---|

| H-bond Pattern | Variable; can form multiple stable bonding modes with donors/acceptors [6] [9] |

| Association Constant (K) | Lower and more distributed than UPy due to multiple modes [9] |

| Key Structural Feature | Aliphatic chain separating two hydroxyl groups; no π-conjugation [6] |

| Primary Role in Polymers | Dynamic cross-links that frequently dissociate/reassociate, enhancing toughness and self-recovery [9] |

| Impact on Mechanics | Superior energy dissipation at large strains and faster network restoration after stress release [6] [9] |

Aliphatic diols, such as vicinal diols, exemplify flexible H-bonding motifs. The aliphatic spacer grants the hydroxyl groups conformational freedom, enabling them to interact with partners in various geometries [6]. Quantum chemical calculations confirm the existence of diverse H-bonding structures for diol groups, contrasting with the single, well-defined structure of rigid amides [9]. This translates to a higher dynamicity in polymers. Compared to rigid motifs, diol-bearing polymers exhibit more frequent dissociation and reassociation of H-bonds under stress. This mechanism is highly effective at dissipating energy, leading to greater stress at large strains and superior self-recoverability after the load is removed [6] [9].

Comparative Analysis of Mechanical and Thermodynamic Behavior

Quantitative Comparison of Material Properties

Table 3: Comparative Impact on Polymer Properties

| Property | Rigid H-Bond Motifs (UPy/Amide) | Flexible H-Bond Motifs (Aliphatic Diol) |

|---|---|---|

| Elastic Modulus | Significant increase [6] | Moderate increase [6] [9] |

| Tensile Strength (σmax) | High (e.g., ~4.5 MPa with 6 mol% UPy cross-links) [6] | Data specific to diols not provided in results, but generally high toughness [9] |

| Fracture Strain (εbreak) | High (e.g., ~0.8 with 6 mol% UPy cross-links) [6] | Effective at large strains [9] |

| Toughness | High, due to energy dissipation prior to covalent bond breakage [6] | Very high, due to frequent H-bond exchange dissipating energy [9] |

| Self-Recovery | Good, facilitated by H-bond exchange [6] | Superior, owing to faster dynamics of flexible motifs [9] |

| Relaxation Time | Substantially delayed [6] | Less delayed than rigid motifs, faster dynamics [9] |

Mechanoresponsive Behavior and Network Dynamics

The structural flexibility of the H-bonding motif profoundly affects how a polymer responds to mechanical stress.

- Under Small Strain: Both rigid and flexible H-bonds act as apparent cross-links, increasing the elastic modulus by restricting chain mobility [6].

- Under Large Strain: The behavior diverges. The strong, directional bonds of rigid motifs like UPy can lead to a simultaneous, cooperative rupture of multiple bonds at a critical stress. While this dissipates energy, the reassociation kinetics can be slower. In contrast, the multiple bonding modes of flexible diols allow for a sequential, asynchronous breaking and reformation of H-bonds [6] [9]. This results in more continuous energy dissipation and a smoother stress-strain profile, contributing to high toughness and stretchability.

- Upon Stress Release: The rapid dynamics of flexible H-bonds enable faster network restoration, leading to better self-recovery of initial properties compared to systems with rigid H-bonds [9].

Diagram 1: Mechanoresponse of rigid vs. flexible H-bond motifs in polymers.

Experimental Protocols and Characterization Techniques

Protocol 1: Synthesis of UPy-Functionalized Poly(n-butyl acrylate)

Objective: To synthesize a model elastomer with UPy as a reversible cross-linking unit and characterize its enhanced mechanical properties [6].

Materials and Workflow:

- Polymer Synthesis: Synthesize poly(n-butyl acrylate) with a controlled amount of a comonomer containing an isocyanate or amine functionality for subsequent UPy functionalization.

- UPy Incorporation: React the functionalized polymer with the UPy precursor, 2-amino-4-hydroxy-6-methylpyrimidine, and an aliphatic isocyanate (e.g., hexyl isocyanate) to covalently attach the UPy moiety to the polymer side chains [6].

- Film Preparation: Cast the polymer from a suitable solvent (e.g., tetrahydrofuran or chloroform) into a film and dry thoroughly under vacuum to remove residual solvent.

Key Characterization Techniques:

- Dynamic Mechanical Analysis (DMA): Measure the storage modulus (E'), loss modulus (E''), and tan δ as a function of temperature. Expect an increased glass transition temperature (Tg) and a pronounced rubbery plateau extending to higher temperatures, indicating the formation of a supramolecular network [6].

- Tensile Testing: Compare stress-strain curves with a control polymer without UPy. The UPy-functionalized polymer should show significantly higher tensile strength (σmax) and fracture strain (εbreak) [6].

- FT-IR Spectroscopy: Monitor the N-H and C=O stretching regions to confirm the presence of H-bonded UPy dimers.

Protocol 2: Comparing Diol vs. Amide Motifs in Random Copolymers

Objective: To directly compare the mechanical dynamics of flexible (diol) and rigid (amide) H-bonding motifs in an identical polymer backbone [9].

Materials and Workflow:

- Polymer Design: Synthesize two sets of random copolymers. One set incorporates a flexible aliphatic diol monomer, while the other incorporates a monomer with a rigid amide group.

- Quantum Chemical Calculation (Optional but Informative): Perform calculations (e.g., DFT) on model compounds to visualize and quantify the diversity of H-bonding structures accessible to the diol group versus the single, well-defined structure of the amide group [9].

- Sample Preparation: Process polymers into films or dog-bone specimens for mechanical testing.

Key Characterization Techniques:

- H-bonding Structure Analysis: Use FT-IR and the calculated models to identify the plurality of H-bonding modes in the diol polymer.

- Large-Strain Cyclic Tensile Tests: Load samples to a specified strain, unload, and immediately re-load. The diol-bearing polymer will exhibit a larger hysteresis loop in the first cycle and significantly better recovery of initial properties in subsequent cycles, demonstrating superior energy dissipation and self-recoverability [9].

- Stress-Relaxation Experiments: Monitor stress decay over time at a constant strain. The diol system will typically relax faster, confirming its higher dynamicity.

Diagram 2: Experimental workflows for characterizing H-bonded polymers.

The Scientist's Toolkit: Essential Reagents and Materials

Table 4: Key Research Reagent Solutions

| Reagent/Material | Function in Research | Application Context |

|---|---|---|

| UPy Monomer (e.g., UPy-NCO) | A telechelic linker or side-chain modifier to introduce strong, reversible cross-links into polymer chains [6]. | Synthesis of supramolecular polymers and elastomers with enhanced toughness and self-healing propensity. |

| Nucleobase-Functionalized Monomers (e.g., Adenine-/Thymine-acrylates) | To impart specific, complementary molecular recognition for directed self-assembly [6]. | Creating programmable polymers, hydrogels, and responsive drug delivery systems. |

| Aliphatic Diol Monomers (e.g., vicinal diol acrylamides) | To introduce dynamic, flexible H-bonding cross-links that promote energy dissipation [9]. | Developing highly tough, stretchable, and self-recoverable elastomers. |

| Poly(n-butyl acrylate) Backbone | A model soft, amorphous elastomeric backbone for studying the effects of H-bonding motifs [6] [9]. | A standard substrate for incorporating and testing various H-bonding comonomers. |

| Deuterated Chloroform (CDCl₃) | Solvent for NMR spectroscopy to study association constants and dimerization in solution [6]. | Determining the strength (K) of H-bonded complex formation for rigid motifs like UPy. |

The strategic selection between rigid and flexible H-bond motifs is a cornerstone of modern macromolecular engineering. Rigid motifs like UPy and nucleobases provide high binding strength, directionality, and thermal stability, making them ideal for creating robust supramolecular structures and enhancing modulus. In contrast, flexible motifs like aliphatic diols excel in applications requiring high dynamicity, superior energy dissipation, and rapid self-recovery, achieving an optimal balance between mechanical robustness and adaptability. The choice is not merely binary; emerging research focuses on hierarchical network topologies that combine both rigid and flexible H-bonds, or H-bonds with other dynamic interactions, to create sophisticated polymer systems with unparalleled property sets. Understanding these fundamental thermodynamics and structure-property relationships is essential for driving innovation in advanced materials, from wearable bioelectronics to next-generation therapeutics.

The Role of H-Bond Cooperativity and π-Conjugation in Network Formation

Hydrogen bond (H-bond) cooperativity and π-conjugation represent two pivotal, often synergistic, design principles in advanced polymer science. Cooperativity, where an initial H-bond enhances the strength of subsequent bonds, works in concert with the electron delocalization inherent to π-conjugated systems to direct supramolecular assembly, dictate thermodynamic stability, and ultimately define the macroscopic properties of polymeric networks. This whitepaper delineates the fundamental mechanisms by which these interactions govern network formation, presenting quantitative data on their energetic contributions, detailed protocols for their experimental characterization, and a toolkit of essential materials. Framed within broader research on polymer thermodynamics, this guide provides a foundation for the rational design of next-generation supramolecular materials with tailored mechanical, electronic, and responsive properties.

In polymer thermodynamics, the quest to overcome the classical trade-off between robust mechanical properties and processability or self-healing capabilities has directed research toward reversible non-covalent interactions. Among these, hydrogen bonds are particularly valued for their directionality, reversibility, and tunable strength [6] [11]. When integrated into polymer networks, H-bonds can act as reversible cross-links, enhancing elasticity at low strains and dissipating energy through reversible breaking and reformation at high strains, thereby improving toughness and stretchability [6].

The concept of H-bond cooperativity elevates this paradigm. Cooperativity occurs when the formation of one H-bond polarizes the electron density within a functional group, thereby enhancing the strength of adjacent H-bonds in a network [12]. This non-linear, synergistic effect results in association constants and network stabilities that far exceed what would be expected from the simple sum of individual bonds.

Concurrently, π-conjugation—the delocalization of π-electrons across adjacent atomic p-orbitals in unsaturated molecules—imparts critical electronic and structural characteristics. π-Conjugated units not only enable semiconducting and optical properties but also enforce structural rigidity and planarity [6]. This rigidity confines H-bonds to specific planes, enhancing their directionality and often enabling π-bond cooperativity, where resonance effects further strengthen the multiple H-bonds within a motif [6]. The interplay between these two phenomena is a cornerstone of modern supramolecular polymer science, enabling precise control over material hierarchy from the molecular to the macroscopic scale.

Core Mechanisms and Energetics

The Synergy of Rigid H-Bonds and π-Conjugation

The most profound effects are observed when multiple H-bonds are integrated into rigid, π-conjugated motifs. These "rigid" H-bonding units, such as 2-ureido-4[1H]-pyrimidinone (UPy) and nucleobases, are characterized by structural complementarity and extensive π-delocalization.

- Enhanced Directionality and Strength: The planar structure of π-conjugated systems confines H-bond donors and acceptors to a specific geometry. For instance, the carbonyl group in a UPy unit has a lone pair in its sp²-hybridized orbital, which interacts with a donor H-atom within the molecular plane, reinforcing strong directionality [6].

- π-Bond Cooperativity: In multiple H-bonding motifs, the overall bond energy can exceed the sum of the individual bond energies due to resonance and depolarization effects. This additional stabilization arises from the partial delocalization of π-electrons within the H-bonding motif, establishing an interplay between π-delocalization and H-bond strengthening [6].

- Supramolecular Polymerization: Rigid, π-conjugated H-bonding motifs can drive the formation of supramolecular polymers with greatly extended contour lengths. UPy, with its self-complementary DDAA H-bonding sequence, dimerizes with an association constant as high as ~10⁶ M⁻¹ in chloroform, creating robust and dynamic networks [6].

Table 1: Characteristics of Rigid vs. Flexible Multiple H-Bond Motifs

| Feature | Rigid H-Bonds (e.g., UPy, Nucleobases) | Flexible H-Bonds (e.g., Aliphatic Vicinal Diols) |

|---|---|---|

| Structural Basis | π-Conjugated units, structural complementarity | Aliphatic chains, conformational freedom |

| Primary Effect | Strong, directional association; apparent crosslinks | Various stable H-bonding modes; energy dissipation |

| H-bond Cooperativity | Strong, via π-bond cooperativity | Weaker, limited by structural flexibility |

| Impact on Mechanics | Increases modulus, toughness, and stretchability | Enhances energy dissipation and restoration |

| Typical Association Constant | Very high (e.g., ~10⁶ M⁻¹ for UPy) | Not specified in search results |

Quantifying Cooperativity and π-Conjugation Effects

The thermodynamic impact of cooperativity and π-conjugation can be quantified through both experimental and theoretical means.

- Energetics of Cooperativity: A key study on a model system featuring an intramolecular H-bond between a pyridine and an amide NH group quantified how the H-bond acceptor strength of the amide carbonyl oxygen increased linearly with the H-bond acceptor parameter (β) of the pyridine. The measured cooperativity parameter (κ) was 0.2, meaning the H-bond acceptor strength of the amide increased by one-fifth of the pyridine's acceptor strength [12]. This polarizing effect is a direct manifestation of cooperativity, mediated through the amide's π-system.

- Impact of π-Linkers on Cooperativity: The nature of the π-conjugated linker is critical. Research on nucleobase-derived macrocycles revealed that introducing a rigid, linear π-conjugated acetylene linker between donor and acceptor sides could decrease cooperativity. The linker abstracts electron density, suppressing the donor-acceptor charge transfer interaction and ultimately hampering the cooperative stabilization of the H-bonded macrocycle [13]. This counter-intuitive finding highlights that not all π-conjugation enhances cooperativity; the specific electronic effect of the bridge must be considered.

- Cooperativity in Non-Canonical H-Bonds: Cooperativity is not limited to traditional N-H···O=C bonds. In glycine-rich polyproline II (PPII) helical bundles, networks of aligned non-canonical C=O···Hα-Cα H-bonds also exhibit cooperative strengthening, which is crucial for stabilizing assemblies that lack a hydrophobic core [14].

Table 2: Quantitative Measures of H-Bond Cooperativity and π-Effects

| System/Parameter | Quantitative Measure | Interpretation/Significance |

|---|---|---|

| Cooperativity Parameter (κ) | κ = 0.2 [12] | Strength of an amide carbonyl as an H-bond acceptor increases by 20% for every unit increase in the β parameter of an intramolecularly H-bonded pyridine. |

| UPy Dimerization Constant | K_a ~ 10⁶ M⁻¹ (in CHCl₃) [6] | Demonstrates the extremely strong self-association enabled by cooperative, quadruple H-bonds in a π-conjugated motif. |

| Energy of H-Bonds | 4 - 15 kJ/mol (general range) [6] | Contextualizes the strength of individual, non-cooperative H-bonds, which is exceeded in cooperative networks. |

Experimental Characterization and Protocols

Validating the presence and quantifying the impact of H-bond cooperativity and π-conjugation requires a multidisciplinary experimental approach. Below are detailed protocols for key characterization methods.

Dynamic Mechanical Analysis (DMA)

Purpose: To probe the viscoelastic properties and relaxation dynamics of supramolecular polymer networks, directly revealing the effect of H-bond crosslinks. Experimental Workflow:

- Sample Preparation: Prepare polymer films (e.g., via solvent casting) of controlled dimensions (e.g., 10mm x 5mm x 0.1mm).

- Instrument Setup: Load the film in a tension clamp. Set the initial strain to a low value (e.g., 0.1%) within the linear viscoelastic regime.

- Temperature Ramp: Run a temperature sweep from sub-T_g to above the polymer's flow temperature (e.g., -50°C to 150°C) at a constant heating rate (e.g., 3°C/min), frequency (e.g., 1 Hz), and strain.

- Data Analysis:

- Identify the glass transition temperature (T_g) from the peak in the tan δ curve.

- Observe the rubbery plateau in the storage modulus (E') curve. A higher and more extended plateau indicates a higher density of effective crosslinks, a signature of strong H-bonding motifs like UPy [6].

- Analyze the relaxation time; substantial delays in relaxation confirm that H-bonding motifs are acting as reversible, yet strong, crosslinks.

Nuclear Magnetic Resonance (NMR) Spectroscopy

Purpose: To confirm H-bond formation and probe association constants in solution. Experimental Workflow (¹H NMR in Non-Polar Solvent):

- Sample Preparation: Prepare a concentrated solution (e.g., 5-10 mM) of the H-bonding molecule in a deuterated non-polar solvent like n-octane or CDCl₃ to minimize solvent competition.

- Data Acquisition: Acquire a ¹H NMR spectrum at a controlled temperature (e.g., 298 K).

- Chemical Shift Analysis:

- Identify the proton(s) of interest, typically the amide N-H.

- A significant downfield shift (e.g., >2 ppm) of the N-H signal compared to a reference molecule without an intramolecular H-bond is strong evidence for H-bond formation [12].

- Titration for Association Constants:

- Titrate a strong H-bond donor (e.g., Perfluoro-tert-butanol, PFTB) into the solution.

- Monitor the chemical shift of the proton.

- Fit the change in chemical shift versus donor concentration to a 1:1 binding isotherm to determine the association constant (K_a) [12].

UV-Vis Absorption Titrations

Purpose: To measure the strength of intermolecular H-bonding interactions with chromophores, particularly in π-conjugated systems. Experimental Workflow:

- Baseline Measurement: Record the UV-Vis absorption spectrum of the H-bond acceptor (e.g., a π-conjugated molecule with a carbonyl group) in a non-polar solvent (n-octane) at a fixed concentration.

- Titration: Incrementally add small volumes of a concentrated stock solution of the H-bond donor (e.g., PFTB).

- Spectral Monitoring: After each addition, record the full absorption spectrum. Observe isosbestic points, which indicate a clean conversion between two species (free and bound).

- Data Fitting: Plot the change in absorbance at a specific wavelength (e.g., a blue-shifting peak) against the concentration of the donor. Fit the data to a 1:1 binding model to extract the association constant (K_a) [12].

The logical relationship between the core concepts, experimental techniques, and the material properties they inform is summarized in the following workflow:

The Scientist's Toolkit: Essential Research Reagents and Materials

The design of advanced polymer networks relies on a repertoire of well-characterized H-bonding functional groups and π-conjugated building blocks.

Table 3: Key Research Reagents for H-Bonded/π-Conjugated Networks

| Reagent/Motif | Chemical Nature | Function in Network Formation |

|---|---|---|

| UPy Motif | Self-complementary quadruple H-bonding unit with strong π-conjugation [6]. | Serves as a high-fidelity, reversible crosslinker. Imparts high toughness and stretchability; can form nanofibrillar structures [6]. |

| Nucleobases (e.g., Guanine, Cytosine) | Biological moieties with specific-complementary multiple H-bonding patterns [11]. | Enable molecular recognition and controlled self-assembly via specific base-pairing (e.g., G-C), mimicking DNA. |

| Amide Functional Group | Common, robust H-bond donor (N-H) and acceptor (C=O) [12] [11]. | Provides strong, directional H-bonds. Exhibits measurable cooperativity. Used in side chains or main chain to enhance mechanical reliability and electronic performance [11]. |

| Hydroxyl Functional Group | Simple H-bond donor and acceptor [11]. | Increases hydrophilicity and aqueous solubility of conjugated polymers. Often introduced via post-polymerization functionalization. |

| Perfluoro-tert-butanol (PFTB) | Exceptionally strong H-bond donor, weak acceptor [12]. | Analytical reagent used in titrations (NMR, UV-Vis) to quantify the H-bond acceptor strength of a molecule without interference. |

| Aliphatic Vicinal Diols | Flexible multiple H-bonding motif without strong π-conjugation [6]. | Provides various H-bonding modes for energy dissipation and network restoration; a model "flexible" H-bond. |

The strategic integration of cooperative H-bonds and π-conjugation presents a powerful pathway for engineering sophisticated polymer networks with programmable thermodynamics and properties. The understanding that rigid, π-conjugated motifs like UPy impart directionality and ultra-strong association, while flexible motifs offer versatile energy dissipation, provides a nuanced design framework. Quantitative relationships, such as the cooperativity parameter κ, offer predictive power in tailoring interaction strengths.

Future research will likely focus on several frontiers:

- Decoupling Interactions: Further refining our understanding of how specific π-linkers (e.g., acetylene vs. phenylene) electronically influence cooperativity, moving beyond simple structural rigidity to precise electronic control [13].

- Dynamic and Adaptive Networks: Exploiting these design principles to create materials that can adapt their properties in response to external stimuli (heat, light, mechanical force) for applications in recyclable plastics and soft robotics [6].

- Biological and Electronic Interfaces: Designing H-bonded/π-conjugated polymers that seamlessly interface with biological systems for sensing and drug delivery, or that combine excellent mechanical durability with high electronic performance in stretchable organic electronics [11].

By leveraging the synergistic effects of H-bond cooperativity and π-conjugation, researchers can continue to push the boundaries of supramolecular materials science, creating systems of increasing complexity and functionality that are firmly grounded in thermodynamic principles.

In the broader context of polymer system thermodynamics, the integration of dynamic non-covalent interactions represents a paradigm shift toward intelligent, adaptive materials. Hydrogen bonds (H-bonds), with their unique combination of directionality, reversibility, and tunable strength, serve as exemplary tools for engineering polymer networks with precisely controlled thermal and mechanical responses [10]. When incorporated into polymer architectures, H-bonds function as reversible crosslinks that profoundly influence two fundamental thermodynamic properties: the glass transition temperature (Tg) and the entropic elasticity governing rubbery plateau behavior [6] [10]. This whitepaper delineates the mechanistic role of H-bonds in modulating these properties, providing a technical guide for researchers and scientists engaged in the development of advanced polymeric materials for pharmaceutical, biomedical, and industrial applications. The thermodynamic framework presented herein establishes H-bonding as a critical design element for manipulating energy dissipation pathways, relaxation dynamics, and network recovery within solvent-free polymer systems [6].

Theoretical Foundation: H-Bonds as Thermodynamic Elements in Polymer Networks

Hierarchy and Energy of Hydrogen Bonds

H-bonds are electrostatic interactions between an electron-deficient hydrogen atom (donor) and an electronegative atom (acceptor), such as oxygen or nitrogen [6]. Their bond energies typically range from 4 to 15 kJ/mol, situating them between covalent bonds and weaker van der Waals forces [6]. This intermediate strength is crucial for their function as reversible crosslinks.

- Single H-Bonds: Possess limited directionality and relatively low dissociation energy, making them highly dynamic but mechanically weak.

- Multiple H-Bonds: When arranged in complementary arrays (e.g., double, triple, or quadruple H-bonds), their collective binding energy can surpass the sum of individual bonds due to π-bond cooperativity and resonance effects within conjugated systems [6].

- Rigid vs. Flexible H-Bonds: A critical structural distinction governs their thermodynamic impact.

- Rigid Multiple H-Bonds: Found in π-conjugated, structurally complementary motifs like 2-ureido-4[1H]-pyrimidinone (UPy) or nucleobases. Their planar geometry confines H-bonds to a specific plane, imparting strong directionality and high association constants (Kdim for UPy ~10⁷–10⁸ M⁻¹ in chloroform) [6] [10].

- Flexible Multiple H-Bonds: Found in motifs like aliphatic vicinal diols, these lack strong π-conjugation and possess conformational freedom. This allows for multiple, dynamically interchanging bonding modes, leading to efficient energy dissipation and network restoration under strain [6].

Governing Thermodynamic Principles

The incorporation of H-bonds influences polymer thermodynamics through several key mechanisms:

- Apparent Crosslinking: Under small strains, reversible H-bonds act as temporary, physical crosslinks, increasing the elastic modulus by restricting chain mobility [6].

- Energy Dissipation: Under large strains, H-bonds reversibly break before covalent bonds fail. This dissociation process dissipates energy, enhancing toughness and stretchability [6] [15].

- Network Restoration: Upon stress release, the dynamic exchange and reformation of H-bonds facilitate the recovery of the polymer network and its mechanical properties [6] [10].

Table 1: Classification and Characteristics of Hydrogen-Bonding Motifs in Polymers.

| H-Bond Motif Category | Representative Examples | Association Constant (K_dim) | Key Characteristics | Primary Impact on Polymer Properties |

|---|---|---|---|---|

| Rigid Multiple H-Bonds | UPy, Nucleobases (e.g., Adenine-Thymine) | 10⁶ – 10⁸ M⁻¹ [6] [10] | Strong directionality, π-conjugation, planar structure, high cooperativity. | Increased elastic modulus, elevated Tg, slowed relaxation, high strength. |

| Flexible Multiple H-Bonds | Aliphatic vicinal diols | Not Specified (Lower than rigid motifs) | Conformational freedom, multiple binding modes, absence of strong π-conjugation. | Enhanced energy dissipation, superior dynamic recovery, high toughness. |

| Single H-Bonds | Urethane, Urea, Amide groups | < 10² M⁻¹ (Estimated) | Low directionality, fast dynamics, low dissociation energy. | Moderate increase in Tg and modulus, often used in concert with other bonds. |

Quantitative Effects on Key Polymer Properties

Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is a key thermodynamic property signifying the onset of cooperative chain motion. H-bonds elevate Tg by introducing transient physical crosslinks that restrict segmental mobility.

- Impact of Rigid H-Bonds: Incorporating 5 mol% of UPy into poly(n-butyl acrylate) elevated its Tg to approximately -39°C, comparable to the effect of 5 mol% acrylic acid. However, the UPy-containing system exhibited a far more significant suppression of relaxation in Dynamic Mechanical Analysis (DMA), underscoring the profound effect of strong, directional H-bonding on segmental dynamics [6].

- Synergistic Effects: In poly(boron-urethane) elastomers, the combination of hierarchical H-bonding and π-π stacking creates dynamic nanostructured domains. These domains act as rigid fillers that further restrict chain motion, contributing to the exceptional low-temperature performance and high Tg of the material [15].

Table 2: Experimental Data on the Effects of H-Bond Crosslinks on Thermal and Mechanical Properties.

| Polymer System | H-Bonding Motif & Concentration | Glass Transition Temp (Tg) | Tensile Strength | Fracture Toughness | Key Experimental Method |

|---|---|---|---|---|---|

| Poly(n-butyl acrylate) [6] | 5 mol% UPy | ≈ -39 °C | Not Specified | Not Specified | Dynamic Mechanical Analysis (DMA) |

| Poly(n-butyl acrylate) network [6] | 6 mol% cyclic UPy crosslink | 0 to 15 °C | 4.5 MPa | Not Specified | Tensile Testing |

| Poly(boron-urethane) Elastomer (PTPU-ABA) [15] | Hierarchical H-bonds & π-π stacking | Low Tg (specific value not given) | ~70.1 MPa (RT) ~100.6 MPa (-40°C) | ~437.5 MJ/m³ (RT) ~237.5 MJ/m³ (-40°C) | Tensile Testing, Fracture Mechanics |

| Control Network (Covalent Crosslinks) [6] | Irreversible covalent bonds | Not Specified | 0.63 MPa | Not Specified | Tensile Testing |

Entropic Elasticity and the Rubbery Plateau

In the rubbery state (T > Tg), polymer elasticity is primarily entropic in nature. The introduction of H-bond crosslinks directly impacts this regime by increasing the density of network junctions.

- Prolonged Relaxation Times: H-bond crosslinks, particularly strong multiple H-bonds, create a transient network that resists flow. For instance, UPy-end-capped polymers exhibit a distinct rubbery plateau in DMA and "substantially prolonged relaxation times" compared to their non-functionalized counterparts [6].

- Enhancement of Storage Modulus: The storage modulus (E') in the rubbery plateau region is directly elevated by higher loadings of H-bonding units, as demonstrated in random polyacrylate copolymers bearing UPy side chains [6].

- Strain-Induced Effects: Under large deformation, the dissociation of H-bonds releases "hidden lengths" of polymer chains. This mechanism allows for high extensibility while maintaining network integrity, a principle exemplified in titin-inspired cyclic UPy crosslinks [6]. Furthermore, in systems like poly(boron-urethane), strain-induced crystallization (SIC) of soft segments like PTMEG can be triggered, further enhancing strength and toughness during elongation [15].

Diagram 1: H-bond response to mechanical strain.

Experimental Protocols for Characterizing H-Bond Effects

Dynamic Mechanical Analysis (DMA)

Purpose: To quantitatively measure the viscoelastic properties of H-bonded polymers, specifically Tg, storage modulus (E'), loss modulus (E''), and relaxation behavior.

Detailed Protocol:

- Sample Preparation: Prepare polymer films or molded specimens with precise dimensions (e.g., 20 mm x 5 mm x 0.5 mm for tension film clamps).

- Instrument Calibration: Calibrate the DMA instrument for force and displacement according to manufacturer specifications. Select appropriate clamps (e.g., tension, compression, or shear).

- Temperature Ramp Experiment:

- Mode: Use a controlled strain amplitude (e.g., 0.1%) within the linear viscoelastic region, determined by a prior strain sweep.

- Frequency: Set a fixed oscillatory frequency (commonly 1 Hz or 10 Hz).

- Temperature Range: Typically from -100°C to 150°C or beyond the polymer's flow region, at a heating rate of 3°C/min.

- Data Analysis:

- Tg Determination: Identify the peak of the tan δ (E''/E') curve or the onset of the rapid drop in E' as the Tg.

- Rubbery Plateau Analysis: Examine the storage modulus (E') in the temperature region above Tg. A higher and more extended plateau indicates effective H-bond crosslinking.

- Relaxation Time: Perform time-temperature superposition or analyze the breadth of the tan δ peak to infer changes in relaxation dynamics.

Synthesis of UPy-Functionalized Poly(n-butyl acrylate)

Purpose: To incorporate strong, reversible H-bond crosslinks into a model elastomer for structure-property studies [6].

Detailed Protocol:

- Materials:

- n-Butyl acrylate (nBA) monomer, purified by passing through a basic alumina column.

- UPy-functionalized initiator or chain transfer agent (e.g., UPy-methacrylate).

- Standard free-radical initiator (e.g., AIBN).

- Anhydrous solvent (e.g., toluene).

- Procedure:

- Copolymerization: Charge a Schlenk flask with nBA, the UPy monomer (e.g., 5 mol%), and AIBN (0.5 mol%) in anhydrous toluene. Purge the solution with nitrogen or argon for 30 minutes to remove oxygen.

- Reaction: Immerse the flask in an oil bath pre-heated to 65°C and stir for 12-24 hours under an inert atmosphere.

- Precipitation & Purification: After cooling, precipitate the polymer into a large excess of cold methanol/water (10:1 v/v). Filter the resulting polymer and re-dissolve in toluene. Repeat the precipitation process twice to remove unreacted monomers.

- Drying: Dry the purified polymer under vacuum at 40°C until a constant weight is achieved.

- Characterization:

- Verify UPy incorporation and copolymer composition using ( ^1H ) NMR spectroscopy.

- Determine molecular weight and distribution via Gel Permeation Chromatography (GPC).

Tensile Testing of H-Bonded Elastomers

Purpose: To evaluate the mechanical performance (strength, extensibility, toughness) under uniaxial deformation.

Detailed Protocol:

- Sample Preparation: Prepare dog-bone shaped specimens (e.g., ASTM D412 Type V) by compression molding or laser cutting from solution-cast films.

- Instrument Setup: Calibrate the universal tensile testing machine and select an appropriate load cell. Set the gauge length and initialize the extensometer.

- Testing Parameters:

- Conduct tests at room temperature (e.g., 23°C) and a constant crosshead speed (e.g., 50 mm/min).

- Record the force and displacement data until sample fracture.

- Data Analysis:

- Tensile Strength (σmax): Calculate as the maximum stress sustained by the sample.

- Fracture Strain (εbreak): The elongation at break.

- Toughness: Calculate the area under the stress-strain curve, representing the energy required to fracture the material.

Table 3: The Scientist's Toolkit: Essential Research Reagents and Materials.

| Reagent/Material | Function/Application | Key Characteristics & Notes |

|---|---|---|

| UPy (2-ureido-4[1H]-pyrimidinone) Monomer | Incorporating rigid, quadruple H-bonding motifs with high association constant into polymer chains. | Can be functionalized as a methacrylate for copolymerization or as an end-group for post-polymerization modification. Kdim ~10⁷–10⁸ M⁻¹ [6] [10]. |

| Aliphatic Vicinal Diol Monomers | Introducing flexible, multiple H-bonding motifs with conformational diversity. | Provides dynamic, efficient energy dissipation pathways. Less studied than rigid motifs but crucial for network restoration [6]. |

| Poly(tetramethylene ether) glycol (PTMEG) | Flexible soft segment in polyurethanes/elastomers. | Enables low Tg and facilitates strain-induced crystallization (SIC) under large deformation, enhancing strength [15]. |

| Arylboronic Acids (e.g., 4-Acetophenylboronic Acid) | Chain extenders that introduce dual dynamic bonds (B-urethane) and π-π stacking interactions. | Used in synthesizing poly(boron-urethane) elastomers for synergistic enhancement of strength and toughness [15]. |

| Dynamic Mechanical Analyzer (DMA) | Characterizing viscoelastic properties, Tg, and relaxation behavior of H-bonded networks. | Essential for measuring the thermodynamic and mechanical effects of reversible crosslinking [6]. |

Advanced Network Topologies and Synergistic Effects

Moving beyond single networks, the strategic combination of H-bonds with other interactions in complex topologies represents the cutting edge of material design.

- Dual/Triple Networks: Integrating H-bonds with covalent networks, ionic interactions, or metal-ligand coordination creates synergistic effects. The H-bond network provides efficient energy dissipation, while the other network(s) maintain integrity and prevent catastrophic failure [10].

- Woven and Interpenetrating Networks: These architectures facilitate load sharing and damage delocalization, significantly enhancing toughness and fatigue resistance. The slide of movable crosslinks and the reversibility of H-bonds are key to these mechanisms [16] [10] [17].

Diagram 2: Material design logic map.

Hydrogen bonds, functioning as reversible crosslinks, provide an unparalleled toolset for the thermodynamic engineering of polymers. By carefully selecting between rigid and flexible H-bond motifs and designing advanced network topologies, researchers can precisely tailor a material's glass transition, entropic elasticity, and overall mechanical performance. The experimental data and protocols outlined in this whitepaper provide a foundational guide for leveraging these dynamic interactions. As polymer thermodynamics research progresses, the rational design of H-bonded systems will continue to enable the development of next-generation materials with bespoke, adaptive, and robust properties for demanding applications in drug delivery, regenerative medicine, and flexible electronics.

Material Design and Biomedical Applications of H-Bonded Polymers

Supramolecular polymers are polymeric arrays of repeating units connected by reversible and highly directional non-covalent bonds, with hydrogen bonds representing one of the most essential and widely utilized interactions [18] [19]. Unlike conventional covalent polymers, supramolecular polymers are characterized by their dynamic nature, which confers unique properties such as self-healing, recyclability, and responsiveness to external stimuli [20] [18]. The field, rooted in the foundational work of researchers like Lehn and Meijer, has evolved to encompass sophisticated materials with tailored mechanical, thermal, and functional characteristics [21] [22]. Hydrogen bonds (H-bonds) are electrostatic interactions between an electron-deficient hydrogen atom (donor) and an electronegative atom like oxygen or nitrogen (acceptor) [22]. Their strength, typically ranging from 4 to 15 kJ/mol, is influenced by factors such as the electronegativity of the atoms involved, environmental conditions, and, critically, their directionality and potential for cooperativity in multiple H-bonding arrays [22]. When incorporated into polymer systems, these reversible interactions can act as transient crosslinks or chain extenders, profoundly influencing material properties and enabling precise control over polymer thermodynamics and assembly behavior [23] [24].

This review delineates the design principles for supramolecular polymers, focusing on main-chain and side-chain strategies mediated by hydrogen bonding. It examines how these design choices impact the thermodynamic landscape of polymer systems, with particular emphasis on the role of binding constant, reversibility, and interaction fidelity. The discussion is framed within contemporary research aimed at developing functional materials for demanding applications, including biomedicine, environmental remediation, and advanced elastomers.

Fundamental Thermodynamics of Supramolecular Polymerization

The formation and properties of supramolecular polymers are governed by the thermodynamics and kinetics of their non-covalent interactions [23] [25]. Unlike covalent polymerization, supramolecular polymerization is an equilibrium process, and the degree of polymerization is highly dependent on external conditions such as concentration and temperature [18]. Two primary mechanistic models describe most supramolecular polymerizations.

Isodesmic (Step-Growth) Polymerization

In the isodesmic, or equal-K model, the addition of a monomer to a growing polymer chain occurs with the same association constant (K) regardless of the chain length [18]. This mechanism is the supramolecular equivalent of step-growth polymerization. In such systems, there is no critical temperature or concentration for polymerization to begin. The average degree of polymerization increases gradually with increasing monomer concentration or decreasing temperature [18]. Supramolecular polymers based on strong, self-complementary motifs like the ureidopyrimidinone (UPy) dimer often follow this mechanism, achieving high molecular weights at moderate concentrations [20] [22].

Nucleation-Elongation (Chain-Growth) Polymerization

In the nucleation-elongation model, also known as the cooperative model, the initial formation of a nucleus (involving a small number of monomers) is less favored than subsequent elongation steps [20] [18]. This mechanism is characterized by a critical concentration below which polymerization does not occur appreciably. Once a stable nucleus forms, the addition of further monomers becomes highly favored, leading to rapid growth into long, often highly ordered, supramolecular polymers [20]. This mechanism is frequently observed in the assembly of structurally complex monomers, such as peptide amphiphiles, which form nanofibers with a high degree of internal order [20] [25].

Table 1: Comparison of Supramolecular Polymerization Mechanisms

| Feature | Isodesmic (Equal-K) Model | Nucleation-Elongation Model |

|---|---|---|

| Mechanism Analogy | Supramolecular step-growth polymerization | Supramolecular chain-growth polymerization |

| Association Constant | Constant for all addition steps | Lower for nucleation, higher for elongation |

| Critical Concentration | Not present; polymerization occurs at any concentration | Present; polymerization occurs above a threshold concentration |

| Structural Outcome | Random coil polymers with low internal order | Often shape-persistent, highly ordered filaments |

| Example Systems | Ureidopyrimidinone (UPy)-based polymers [22] | Peptide amphiphile nanofibers [20] |

The lifetime of the hydrogen bonds is a crucial parameter in the dynamic behavior of these materials. An intermediate range of bond lifetimes (e.g., milliseconds to seconds) is often targeted to create materials that are robust yet adaptive, enabling properties such as self-repair and unique processing options [20] [23].

Main-Chain Supramolecular Polymer Strategies

Main-chain supramolecular polymers are constructed by linking monomer units through directional hydrogen bonds positioned at the termini of the molecular building blocks. This approach effectively creates long, linear chains whose integrity and degree of polymerization are directly governed by the strength and fidelity of the terminal H-bonding motifs.

Key Hydrogen Bonding Motifs and Their Energetics

The design of main-chain supramolecular polymers has progressed from simple, single H-bonds to complex, high-fidelity multiple H-bonding arrays.

- Single and Double H-Bonds: Early systems utilized single hydrogen bonds (e.g., carboxylic acid dimers) or double H-bonds. However, these typically possess relatively low association constants (K < 10² M⁻¹ in organic solvents), resulting in limited degrees of polymerization and mechanical strength [21] [22].

- Triple H-Bonds: A significant advancement came with the use of triple H-bonding motifs, such as the complex between diaminopyridine and thymine. These systems offer improved directionality and association constants (K ≈ 10³ M⁻¹) [21]. Lehn and colleagues demonstrated this in 1989 by creating liquid crystalline supramolecular polymers from monomers functionalized with complementary triple H-bonding units [22].

- Quadruple H-Bonds: The development of the ureidopyrimidinone (UPy) motif by Meijer and coworkers represented a breakthrough [21] [22]. UPy is self-complementary and forms a dimer through a DDAA array of quadruple hydrogen bonds, achieving an exceptionally high association constant (K ≈ 10⁷ M⁻¹ in chloroform) [20] [22]. When installed at the chain ends of telechelic polymers, UPy units connect chains into long, high molecular weight supramolecular polymers. These materials exhibit viscoelastic behavior and a distinct rubbery plateau in the bulk, mimicking the properties of high-molecular-weight covalent polymers [20] [22].

Table 2: Energetics and Applications of Key Hydrogen Bonding Motifs in Main-Chain Polymers

| H-Bonding Motif | Representative Structure | Association Constant (K) | Key Material Properties |

|---|---|---|---|

| Double H-Bond | Diaminotriazine / Thymine | 10¹ - 10² M⁻¹ | Low degree of polymerization, limited mechanical strength [21] |

| Triple H-Bond | Diaminopyridine / Thymine | ~10³ M⁻¹ | Liquid crystallinity, moderate polymer length [21] [22] |

| Quadruple H-Bond | Ureidopyrimidinone (UPy) Dimer | ~10⁷ M⁻¹ (in CHCl₃) | High molecular weight, viscoelasticity, strong rubbery plateau [20] [22] |

| Nucleobase Pair | Guanine-Cytosine (G-C) | Up to 10⁸ M⁻¹ (in non-competitive solvents) | High directionality and stability, potential for sequence-specific assembly [22] |

The following workflow illustrates the typical process for creating and characterizing a main-chain supramolecular polymer based on telechelic monomers.

Design and Characterization Workflow for Main-Chain Supramolecular Polymers

Experimental Protocol: Synthesis and Characterization of a UPy-based Main-Chain Polymer

Objective: To prepare and characterize a supramolecular polymer from a telechelic poly(ethylene-butylene) functionalized with ureidopyrimidinone (UPy) end groups [22].

Materials:

- Telechelic Polymer: Poly(ethylene-butylene) diamine (Mn ≈ 2000 g/mol).

- UPy Synthon: 2-Amino-4-hydroxy-6-methylpyrimidine and hexamethylene diisocyanate.

- Solvents: Anhydrous toluene, chloroform, methanol.

- Equipment: Round-bottom flask, condenser, magnetic stirrer, NMR spectrometer, rheometer, differential scanning calorimeter (DSC).

Procedure:

- Synthesis of UPy-Functionalized Polymer:

- Dissolve poly(ethylene-butylene) diamine (1 equiv.) in anhydrous toluene.

- Add a slight excess of the UPy-isocyanate synthon (2.2 equiv.) under a nitrogen atmosphere.

- Heat the mixture to 80°C with stirring for 12 hours.

- Allow the reaction to cool and precipitate the product in cold methanol.

- Purify the white solid by filtration and dry under vacuum [22].

Polymerization and Film Preparation:

- Dissolve the purified UPy-functionalized polymer in chloroform at a concentration of 50-100 mg/mL.

- The supramolecular polymerization occurs spontaneously upon dissolution due to the strong dimerization of UPy motifs.

- To prepare a bulk film, cast the solution into a PTFE mold and allow the solvent to evaporate slowly, followed by drying under vacuum for 24 hours.

Characterization:

- Viscosity Measurements: Use a capillary viscometer or rheometer to measure the specific viscosity of the polymer in chloroform at varying concentrations and temperatures. The viscosity will increase significantly with concentration, indicating chain extension [22].

- Dynamic Mechanical Analysis (DMA): Perform DMA on the bulk film to identify the rubbery plateau modulus and flow temperature. The material will exhibit a plateau, confirming the formation of a supramolecular network [22].

- NMR Spectroscopy: Variable-temperature ¹H NMR in d-chloroform can be used to probe the dynamics of the H-bonds. The N-H proton signals of the UPy group will broaden and shift upfield with increasing temperature, indicating the breaking of H-bonds [21].

Side-Chain Supramolecular Polymer Strategies

In side-chain supramolecular polymers, hydrogen-bonding units are appended as pendant groups to a polymer backbone, either covalently or through physical interactions. This architecture creates a dynamic network where the backbone provides a structural framework and the side-chain interactions act as reversible crosslinks, dictating the material's mechanical and responsive properties [24].

Design and Classification of Side-Chain H-Bonding Units

The properties of side-chain supramolecular polymers are profoundly influenced by the chemical structure and flexibility of the H-bonding units.

- Rigid Multiple H-Bonds: Motifs like UPy and nucleobases (e.g., thymine, adenine) are characterized by structural complementarity and π-conjugation, which confine the H-bonds to a specific plane, imparting strong directionality and high dimerization constants [22]. When incorporated into side chains, they form strong, binary crosslinks. For example, in random polyacrylate copolymers, increasing the loading of UPy side groups elevates the glass transition temperature (Tg) and substantially delays terminal relaxation, creating a supramolecular elastomer [22].

- Flexible Multiple H-Bonds: These motifs, such as aliphatic vicinal diols or derivatives of N-acryloyl glycinamide (NAGA), lack strong π-conjugation and possess conformational freedom [22] [24]. This allows them to form multiple, dynamic H-bonding modes. Polymers based on PNAGA can form dense, cooperative H-bond networks, leading to high-strength hydrogels and thermoresponsive behavior without the strong, binary association of rigid motifs [24].

Table 3: Comparison of Rigid vs. Flexible H-Bonding Motifs in Side-Chain Polymers

| Characteristic | Rigid H-Bond Motifs (e.g., UPy, Nucleobases) | Flexible H-Bond Motifs (e.g., NAGA, Vicinal Diols) |

|---|---|---|

| Structural Features | π-Conjugated, planar, structurally complementary | Aliphatic, conformationally flexible, non-complementary |

| H-Bonding Mode | Defined, directional dimerization | Multiple, dynamic, and transient bonding modes |

| Association Constant | High (10⁶ - 10⁸ M⁻¹) | Weaker and more distributed |

| Primary Material Effects | Strong crosslinks, increased modulus, slowed relaxation | Dense H-bond network, high toughness, energy dissipation |

| Typical Applications | Supramolecular elastomers, self-healing materials [22] | High-strength hydrogels, tough plastics [24] |

Experimental Protocol: Fabricating a High-Strength PNAGA Hydrogel

Objective: To synthesize poly(N-acryloyl glycinamide) (PNAGA) and fabricate a hydrogen-bonded hydrogel with high mechanical strength [24].

Materials:

- Monomer: N-acryloyl glycinamide (NAGA).

- Initiator: Ammonium persulfate (APS).

- Accelerator: N,N,N',N'-Tetramethylethylenediamine (TEMED).

- Solvent: Deionized water.

- Equipment: Schlenk flask, nitrogen inlet, water bath, mechanical tester.

Procedure:

- Synthesis of PNAGA:

- Dissolve NAGA monomer (1-2 g) in deionized water in a Schlenk flask to achieve a concentration of 10-20 w/v%.

- Degas the solution by bubbling nitrogen for 30 minutes.

- Add the initiator APS (1 mol% relative to monomer) and the accelerator TEMED (0.5 mol%).

- Allow the polymerization to proceed at room temperature for 6-12 hours. The formation of a transparent, highly viscous hydrogel indicates successful polymerization [24].

Mechanical Characterization:

- Tensile Test: Mold the hydrogel into dog-bone shaped specimens. Perform uniaxial tensile tests to measure fracture stress, strain, and work of fracture. PNAGA hydrogels can exhibit strengths in the MPa range with high extensibility [24].

- Rheology: Conduct oscillatory shear rheology to determine the storage modulus (G'), loss modulus (G''), and yield stress. The hydrogel will typically show a high storage modulus dominated by the H-bond network.

Investigation of H-Bonding:

- Fourier-Transform Infrared (FTIR) Spectroscopy: Analyze the hydrogel film in transmission mode. The presence of strong H-bonding is indicated by broadened and shifted N-H and C=O stretching vibrations in the amide regions (around 3300 cm⁻¹ and 1650 cm⁻¹, respectively) [24].

- Variable-Temperature NMR: Dissolve the polymer in a deuterated dimethyl sulfoxide (DMSO) / water mixture. As the temperature is increased, the amide proton signals will shift, reflecting the disruption of intermolecular H-bonds [24].

The following diagram summarizes the key design considerations and the resulting material properties for both main-chain and side-chain strategies.

Design Logic for Supramolecular Polymer Architectures

Advanced Applications and Research Reagent Solutions

The unique attributes of hydrogen-bonded supramolecular polymers have led to their application in diverse, high-tech fields. The following table details key reagents and their functions in constructing these advanced materials.

Table 4: Research Reagent Solutions for Supramolecular Polymer Science

| Reagent / Building Block | Function in Research | Key Application Context |

|---|---|---|

| Ureidopyrimidinone (UPy) | A self-complementary quadruple H-bonding motif for chain extension or crosslinking [22]. | Synthesis of high molecular weight supramolecular polymers and elastomers with self-healing properties [20] [22]. |

| N-Acryloyl Glycinamide (NAGA) | A vinyl monomer whose polymer (PNAGA) forms dense, cooperative H-bond networks via dual amide side groups [24]. | Fabrication of ultra-tough, self-healing hydrogels and high-strength bulk plastics without chemical crosslinkers [24]. |

| Peptide Amphiphiles (PAs) | Molecules combining a peptide sequence (for H-bonding) with a hydrophobic segment [20]. | Construction of bioactive nanofibers for regenerative medicine, e.g., spinal cord repair and cartilage regeneration [20] [25]. |

| Pillar[n]arene Macrocycles | Electron-rich macrocyclic hosts capable of forming host-guest complexes and H-bonded networks [26]. | Development of supramolecular polymer networks for environmental applications, such as selective anion removal from water [26]. |

| Telechelic Polymers (e.g., PDMS, PEO) | Polymer backbones (e.g., poly(dimethylsiloxane), poly(ethylene oxide)) with reactive end groups [21]. | Used as scaffolds to be end-functionalized with H-bonding motifs (e.g., UPy) to create main-chain supramolecular polymers [21] [22]. |

- Biomedical Applications: Supramolecular polymers designed with bioactive signals, such as peptide amphiphiles (PAs), have shown remarkable success in regenerative medicine. For instance, PAs that self-assemble into nanofibers displaying the laminin-derived IKVAV signal have been used to promote the selective differentiation of neural stem cells into neurons, demonstrating potential for treating spinal cord injuries [20] [25]. The dynamic nature of these materials allows them to interact adaptively with biological systems.

- Environmental Remediation: The high designability of H-bonded networks enables targeted environmental applications. A recent study demonstrated a hydrogen-bonded supramolecular polymer network crystal (HBPC) constructed from a functionalized pillar[5]arene (PYP5) [26]. This material leverages clustered hydrogen bonding from its pyridyl-hydrazone arms and ethoxyl groups to efficiently capture perchlorate (ClO₄⁻) anions from water, achieving removal efficiencies up to 99.24% and reducing concentrations below the WHO standard for drinking water [26].

- Energy Storage: Side-chain H-bonding strategies are being explored to create smarter materials for energy. For example, solid polymer electrolytes incorporating thiourea-based H-bonding units have been developed to confer self-healing capabilities, potentially improving the safety and longevity of lithium metal batteries by enabling the repair of mechanical damage that occurs during cycling [27].

The strategic implementation of hydrogen bonds within main-chain and side-chain architectures provides a powerful and versatile toolbox for designing supramolecular polymers with tailored thermodynamic and mechanical properties. Main-chain strategies, leveraging strong and directional motifs like UPy, create polymer-like chains whose reversible nature enables unique processability and recyclability. Side-chain strategies, utilizing a spectrum of motifs from rigid UPy to flexible NAGA derivatives, engineer dynamic crosslinked networks that yield materials with exceptional toughness, self-healing, and stimulus responsiveness. The continued refinement of these design principles, grounded in a deep understanding of H-bonding thermodynamics and kinetics, is pushing the boundaries of polymer science. This progress is paving the way for next-generation functional materials that address critical challenges in sustainability, healthcare, and advanced technology.

The pursuit of polymer materials that combine high strength and exceptional toughness represents a fundamental challenge in materials science, as these properties are often mutually exclusive. Strength refers to a material's resistance to deformation and failure under stress, while toughness characterizes its ability to absorb energy and plastically deform without fracturing. Within the context of polymer thermodynamics research, hydrogen bonding (H-bonding) has emerged as a powerful design tool to transcend this classical trade-off. These reversible, directional non-covalent interactions can be strategically engineered to create dynamic polymer networks that provide simultaneous reinforcement and energy dissipation mechanisms.