From Prediction to Production: How AI is Revolutionizing Polymer Nanocomposite Manufacturing

This article explores the transformative role of Artificial Intelligence in polymer nanocomposite manufacturing, with a focus on biomedical applications.

From Prediction to Production: How AI is Revolutionizing Polymer Nanocomposite Manufacturing

Abstract

This article explores the transformative role of Artificial Intelligence in polymer nanocomposite manufacturing, with a focus on biomedical applications. It provides a foundational understanding of AI's core capabilities in this field, details methodological approaches for material design and process optimization, addresses critical troubleshooting and scalability challenges, and evaluates the validation and comparative performance of AI-driven methods against traditional techniques. Aimed at researchers and drug development professionals, the analysis synthesizes current advancements to highlight a paradigm shift towards data-driven, intelligent manufacturing of next-generation drug delivery systems and medical implants.

The AI Catalyst: Understanding the Foundational Role of Machine Learning in Polymer Nanocomposites

Application Notes: AI-Driven Design and Optimization

The integration of Artificial Intelligence (AI) into polymer nanocomposites (PNCs) research is accelerating the discovery and optimization of advanced materials. Key applications include predicting nanocomposite properties, optimizing manufacturing parameters, and designing novel polymer matrices or nanofiller surface chemistries for specific drug delivery or biomedical applications.

Table 1: AI Model Performance in Predicting PNC Properties

| AI Model Type | Target Property | Dataset Size | Avg. Prediction Error (R² Score) | Key Input Features |

|---|---|---|---|---|

| Graph Neural Network (GNN) | Glass Transition Temp (Tg) | 1,250 formulations | 94% (R²=0.94) | Polymer monomer SMILES, nanofiller type/size, wt% loading |

| Random Forest (RF) | Tensile Strength | 890 experiments | 12% MAPE | Processing temp, shear rate, filler aspect ratio, dispersion metric |

| Convolutional Neural Net (CNN) | Dispersion State from TEM | 5,700 images | 96% Accuracy | TEM micrograph patches, spectral features |

| Bayesian Optimization | Drug Release Kinetics | Iterative 50-cycle | 40% improvement vs. baseline | Polymer Mw, crosslink density, nanoparticle porosity, pH |

Research Reagent Solutions Toolkit

| Item | Function in PNC Research for Drug Delivery |

|---|---|

| PLGA (Poly(lactic-co-glycolic acid)) | Biodegradable polymer matrix for controlled drug release; AI models optimize lactide:glycolide ratio. |

| PEGylated Silica Nanoparticles | Surface-functionalized nanofillers; PEG chain length is an AI-optimized variable for stealth and dispersion. |

| Montmorillonite Clay (MMT) | Layered silicate nanofiller; AI predicts intercalation/exfoliation based on cation exchange capacity. |

| RAFT Chain Transfer Agent | Enables controlled polymerization; AI designs polymer architecture (block, graft) for specific nanocomposite morphology. |

| Fluorescently-Labeled Nanocellulose | Allows tracking of filler dispersion in situ via fluorescence microscopy; generates quantitative data for AI training. |

Experimental Protocols

Protocol 2.1: AI-Guided Optimization of Nanocomposite Film for Sustained Release

- Objective: To synthesize and characterize a drug-loaded polymer-clay nanocomposite film with release kinetics predicted by a pre-trained neural network.

- Materials: PLGA (50:50), Doxorubicin HCl, organically modified MMT (Cloisite 30B), dimethylformamide (DMF), phosphate buffered saline (pH 7.4).

- AI Pre-Step: Input desired release profile (e.g., 50% release at 72 hrs) into an inverse design model. The model outputs recommended parameters: PLGA Mw=45kDa, MMT loading=3.2 wt%, film thickness=120 µm.

- Method:

- Solution Preparation: Dissolve 500 mg PLGA in 10 mL DMF. Separately, disperse 16 mg Cloisite 30B in 2 mL DMF via sonication (30 min, 40 kHz).

- Nanocomposite Formation: Combine solutions, add 5 mg doxorubicin. Sonicate for 1 hour (ice bath).

- Film Casting: Pour solution into a glass Petri dish (diameter=8 cm). Dry under vacuum at 40°C for 48 hrs.

- Release Study: Cut film into 1x1 cm squares (n=6). Immerse in 50 mL PBS at 37°C with gentle agitation. Withdraw 1 mL aliquots at predetermined times, replenish with fresh PBS. Analyze doxorubicin concentration via UV-Vis at 480 nm.

- Validation: Compare experimental release profile to AI prediction. Use data to retrain the model.

Protocol 2.2: High-Throughput Screening of Filler Dispersion via ML-Enhanced Image Analysis

- Objective: To quantitatively assess nanofiller dispersion in composite micrographs using a CNN model.

- Materials: Polymer nanocomposite samples, transmission electron microscope (TEM), Python environment with OpenCV & TensorFlow libraries.

- Method:

- Image Acquisition: Capture TEM micrographs at standardized magnifications (e.g., 50kX) from minimum of 5 fields of view per sample.

- Pre-processing: Scale all images to 512x512 pixels. Apply contrast-limited adaptive histogram equalization (CLAHE) to enhance feature visibility.

- Model Inference: Load pre-trained U-Net CNN model for semantic segmentation. Process each image to classify each pixel as "aggregated filler," "dispersed filler," or "polymer matrix."

- Quantitative Analysis: Calculate dispersion metrics: (i) Aggregate Area Fraction, (ii) Dispersion Homogeneity Index (DHI = 1 - (std. dev. of filler density per grid sector)).

- Data Integration: Correlate DHI with mechanical/thermal property data from the same batch to enrich the AI training dataset.

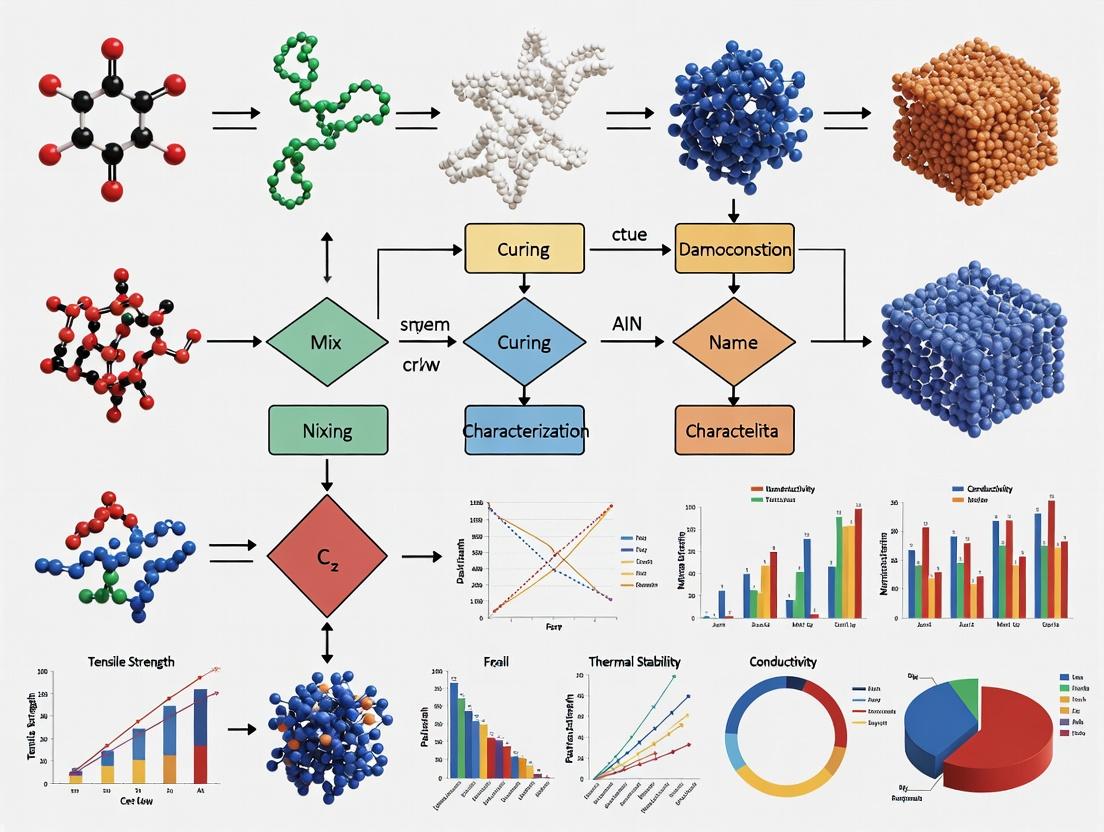

Visualization Diagrams

Diagram Title: AI-Driven PNC Research Closed Loop

Diagram Title: Neural Network for Property Prediction

The integration of artificial intelligence (AI) into polymer nanocomposites manufacturing research represents a paradigm shift necessary to overcome the intrinsic limitations of traditional, empirical methods. Nanoscale manufacturing, particularly for applications in drug delivery and advanced materials, is governed by multivariate, non-linear interactions that are poorly captured by conventional design-of-experiment approaches. This document details specific application notes and protocols that highlight these complexities and demonstrate the emergent AI-enabled methodologies central to our broader thesis: that machine learning (ML) is essential for mapping the high-dimensional parameter space of nanocomposite synthesis, leading to predictable and optimized material properties.

Application Note: Quantifying the Parameter Space Challenge

Traditional one-variable-at-a-time (OVAT) experimentation fails to account for interdependencies in nanocomposite formulation. The table below summarizes key process and formulation variables and their typical ranges for a model system: poly(lactic-co-glycolic acid) (PLGA) nanoparticles encapsulating a hydrophobic active pharmaceutical ingredient (API).

Table 1: Multivariate Parameters in PLGA Nanoparticle Synthesis via Nano-precipitation

| Parameter Category | Specific Variable | Typical Range | Primary Influence on Nanoscale Output |

|---|---|---|---|

| Polymer Properties | PLGA Molar Mass (kDa) | 10 - 100 | Particle size, degradation rate, API release profile. |

| Lactide:Glycolide (L:G) Ratio | 50:50 - 85:15 | Crystallinity, degradation kinetics. | |

| Formulation | Polymer Concentration (mg/mL) | 1 - 20 | Particle size, polydispersity index (PDI). |

| Organic Solvent Type | Acetone, DCM, EA | Solvation rate, particle morphology. | |

| Aqueous:Organic Phase Ratio | 5:1 - 100:1 | Particle size, stability. | |

| Stabilizer (PVA) Concentration (%) | 0.1 - 5 | Particle size, surface charge, colloidal stability. | |

| Process Conditions | Addition Rate (mL/min) | 0.1 - 10 | Mixing efficiency, PDI. |

| Stirring Speed (RPM) | 500 - 5000 | Particle aggregation, final size. | |

| Sonication Energy (J/mL) | 50 - 500 | Size reduction, PDI. | |

| Environmental | Temperature (°C) | 15 - 40 | Solvent diffusion rate, polymer conformation. |

The combinatorial explosion from these variables makes exhaustive exploration via traditional methods impractical. For instance, a coarse grid search over just 5 variables with 3 levels each requires 3⁵ (243) experiments, often without revealing optimal interactions.

Protocol: AI-Guided Design of Experiments (DoE) for Nanoparticle Optimization

This protocol outlines a closed-loop, ML-driven workflow to efficiently navigate the parameter space defined in Table 1.

Objective: To synthesize PLGA nanoparticles with a target hydrodynamic diameter of 150 nm ± 10 nm and a PDI < 0.1.

Materials (Research Reagent Solutions):

Table 2: Essential Research Reagent Solutions

| Item | Function & Specification |

|---|---|

| PLGA Resomers | Biodegradable copolymer backbone. Vary L:G ratio (e.g., RG 502H 50:50, RG 752H 75:25) and molecular weight. |

| Dichloromethane (DCM), HPLC Grade | Organic solvent for polymer and API dissolution. Fast diffusion rate influences nucleation. |

| Polyvinyl Alcohol (PVA), 87-89% hydrolyzed | Stabilizer/emulsifier. Aqueous solution (e.g., 1% w/v) prevents coalescence during nano-precipitation. |

| Model Hydrophobic API (e.g., Coumarin 6) | Fluorescent probe to simulate drug loading and enable tracking. |

| Phosphate Buffered Saline (PBS), pH 7.4 | For purification dialysate/resuspension to simulate physiological conditions. |

| Dynamic Light Scattering (DLS) System | For primary output measurement: hydrodynamic diameter, PDI, and zeta potential. |

Procedure:

Initial Bayesian Experimental Design:

- Define input variables (X) from Table 1 (e.g., PLGA Mw, L:G ratio, polymer concentration, PVA %, addition rate).

- Define target outputs (Y): Hydrodynamic diameter (Z-avg) and PDI.

- Using a Bayesian optimization platform (e.g., Ax, Google Vizier), generate an initial set of 20 suggested experiments that maximize the expected improvement (EI) over a randomly selected starting point.

Parallelized Synthesis:

- Execute the 20 suggested formulations in parallel using an automated liquid handling system.

- Standardized Nano-precipitation Step: Dissolve PLGA and API in DCM. Using a programmable syringe pump, inject this organic phase into the aqueous PVA solution under standardized magnetic stirring (e.g., 800 RPM). Allow stirring for 3 hours to evaporate solvent.

High-Throughput Characterization:

- Purify nanoparticles via one centrifugation step.

- Perform DLS analysis in triplicate for each formulation batch.

- Log precise experimental conditions and results in a structured database.

Model Update & Next-Best-Experiment Prediction:

- The Bayesian model assimilates the new (X, Y) data pairs.

- The algorithm predicts the next-best 10 experiments to simultaneously minimize size and PDI.

- The loop (Steps 2-4) repeats for 5-10 cycles or until the target specifications are reliably achieved.

Validation:

- Synthesize nanoparticles at the predicted optimal formulation in triplicate independent batches.

- Characterize fully (size, PDI, zeta potential, morphology via TEM, loading efficiency).

Visualization of the AI-Driven Workflow

Diagram Title: AI-Optimization Loop for Nanocomposite Synthesis

Application Note: The Characterization Bottleneck

Traditional microscopy (SEM/TEM) provides limited statistical power due to small sample sizes. AI-enhanced analysis bridges this gap.

Protocol: AI-Enhanced TEM Image Analysis for Morphology & Size Distribution

- Sample Preparation & Imaging: Prepare TEM grids from optimized nanoparticle batches. Capture 50+ images at various magnifications using automated TEM stage navigation.

- Data Processing: Use a pre-trained convolutional neural network (CNN) for semantic segmentation (e.g., U-Net architecture).

- Model Training/Fine-Tuning: Manually label 10-15 images (particle vs. background). Use these to fine-tune the CNN for your specific nanoparticle morphology.

- Batch Analysis: The trained CNN processes all images, segmenting individual nanoparticles.

- Quantitative Output: The pipeline extracts diameter, circularity, and aggregation state for >100,000 particles, generating robust statistical distributions unattainable by manual counting.

Diagram Title: AI Pipeline for Nanoparticle TEM Analysis

The protocols outlined herein demonstrate that AI is not merely an additive tool but a foundational component for advanced nanoscale manufacturing research. By replacing inefficient OVAT approaches with adaptive Bayesian DoE and overcoming characterization bottlenecks with computer vision, researchers can effectively manage the complexity that renders traditional methods inadequate. This directly supports the core thesis, enabling the rational design of next-generation polymer nanocomposites with tailored properties for drug delivery and beyond.

The integration of Artificial Intelligence (AI) into polymer nanocomposites (PNC) manufacturing is accelerating the discovery and optimization of materials with tailored properties for drug delivery, medical devices, and diagnostic applications. Core AI technologies—Machine Learning (ML), Deep Learning (DL), and Neural Networks (NNs)—serve as powerful tools for predicting nanocomposite behavior, optimizing synthesis parameters, and deciphering complex structure-property relationships. This application note details these technologies within the specific experimental context of PNC research for pharmaceutical development.

Technology Breakdown & Quantitative Comparison

Table 1: Core AI Technologies Comparison for PNC Research

| Feature | Machine Learning (ML) | Deep Learning (DL) | Neural Networks (NNs) |

|---|---|---|---|

| Core Definition | Algorithms that learn patterns from data to make predictions or decisions without explicit programming. | A subset of ML using multi-layered (deep) neural networks to learn hierarchical data representations. | Computational models (inspired by biological brains) consisting of interconnected nodes (neurons) that are the foundation for both ML and DL. |

| Typical Architecture | Shallow (e.g., Decision Trees, SVMs). | Deep, with many hidden layers (e.g., CNNs, RNNs). | Can be shallow (single hidden layer) or deep. |

| Data Requirement | Can work with smaller, structured datasets (100s-1000s of samples). | Requires large-scale, often unstructured data (1000s-millions of samples). | Varies with depth; deeper networks require more data. |

| Feature Engineering | Mandatory. Researchers must extract relevant features (e.g., nanoparticle size, polymer Mw). | Automatic. The network learns high-level features from raw or minimally processed data. | Can be manual or automatic, depending on architecture and task. |

| Interpretability | Generally higher (model decisions can often be traced). | Often a "black box"; complex to interpret directly. | Varies; simpler networks are more interpretable. |

| Example in PNC Research | Predicting drug release kinetics from composite material properties using Random Forest regression. | Analyzing microscopic images to automatically classify defect types in nanocomposite films. | A feed-forward NN modeling the nonlinear relationship between processing temperature, shear rate, and filler dispersion. |

Table 2: Quantitative Performance of AI Models in Representative PNC Tasks

| Research Task | AI Model Used | Dataset Size | Reported Performance Metric | Key Advantage for Drug Development |

|---|---|---|---|---|

| Predicting Mechanical Strength of Bio-nanocomposites | Gradient Boosting Regressor | 580 formulations | R² = 0.94, MAE = 2.1 MPa | Accelerates scaffold design for tissue engineering. |

| Optimizing Drug Encapsulation Efficiency | Multilayer Perceptron (NN) | 315 experimental runs | Optimization led to 22% efficiency increase. | Reduces experimental waste and time for formulation. |

| Classifying Nanoparticle Dispersion from TEM Images | Convolutional Neural Network (CNN - DL) | 12,500 labeled image tiles | 98.7% classification accuracy. | Enables high-throughput, consistent quality control. |

| Inverse Design of Polymer Carriers for mRNA | Variational Autoencoder (DL) | 45,000 polymer sequences | Successfully generated novel candidates with desired properties. | Drives rational design of next-generation delivery vectors. |

Experimental Protocols & AI Integration

Protocol 1: ML-Guided Optimization of Nanocomposite Synthesis for Controlled Release

Aim: To optimize processing parameters (X) for a drug-loaded PNC to achieve target release profile (Y).

Materials: See "Scientist's Toolkit" (Section 5).

Methodology:

- Design of Experiment (DoE): Generate an initial set of 20-30 synthesis conditions using a space-filling design (e.g., Latin Hypercube) varying parameters: sonication energy (J/ml), polymer-to-nanofiller ratio (w/w), and crosslinking time (min).

- High-Throughput Synthesis & Characterization: Execute experiments, prepare nanocomposite beads, and characterize for:

- Drug Loading (%): UV-Vis spectroscopy of lysed beads.

- Particle Size (nm): Dynamic Light Scattering (DLS).

- Zeta Potential (mV): DLS.

- In-Vitro Release Profile: Conduct pH 7.4 PBS release assay, sample at 10 time points over 72h. Model release curve to extract key metrics (e.g., time for 50% release - T50).

- Dataset Curation: Create a structured table where each row is an experiment, and columns are: Input parameters (3), Characterization results (3), and Release metrics (1-2 targets).

- ML Model Training & Validation:

- Split data: 80% training, 20% hold-out test.

- Train multiple ML models (e.g., Support Vector Regression, Random Forest, Shallow NN) to predict release T50 from the 6 input+characterization features.

- Validate on test set using Mean Absolute Percentage Error (MAPE).

- Optimization & Prediction:

- Use the best-performing model with a Bayesian Optimization loop to search the parameter space for conditions predicted to yield a T50 closest to the target (e.g., 24h).

- Synthesize and validate the top 3 predicted formulations.

Diagram Title: ML-Driven Formulation Optimization Workflow

Protocol 2: Deep Learning for Automated Morphology Analysis in PNCs

Aim: To use a Convolutional Neural Network (CNN) for semantic segmentation of transmission electron microscopy (TEM) images to quantify nanofiller dispersion.

Methodology:

- Image Acquisition & Labeling:

- Acquire 300+ high-resolution TEM images of PNC thin sections.

- Use a tool (e.g., LabelBox, VGG Image Annotator) to manually create pixel-wise masks, labeling classes:

Nanoparticle,Polymer Matrix,Aggregate,Void.

- Data Preprocessing & Augmentation:

- Resize all images to a fixed size (e.g., 512x512 pixels).

- Normalize pixel intensities.

- Apply augmentations (rotations, flips, slight contrast changes) to increase dataset size and model robustness.

- Model Selection & Training:

- Implement a U-Net CNN architecture, known for effective biomedical image segmentation.

- Split data: 70% training, 15% validation, 15% test.

- Use a loss function like Dice Loss to handle class imbalance.

- Train for 100+ epochs, monitoring validation accuracy.

- Inference & Quantification:

- Apply trained model to new, unseen TEM images.

- Post-process output masks to calculate critical metrics: Dispersion Index (particle count/area), Aggregate Area Fraction, and Inter-particle Distance Distribution.

Diagram Title: Deep Learning Image Analysis Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for AI-Enhanced PNC Research

| Item / Reagent | Function in PNC Research | Relevance to AI/ML Workflow |

|---|---|---|

| Functionalized Nanofillers (e.g., COOH-MWCNT, amine-modified silica). | Core reinforcement or functional agent; surface chemistry dictates compatibility and drug binding. | Key input variable (feature) in ML models predicting composite properties. |

| Biodegradable Polymers (e.g., PLGA, Chitosan, PCL). | Matrix material controlling degradation and drug release kinetics. | Source of raw data (e.g., molecular weight, viscosity) for predictive modeling. |

| Model Drug Compound (e.g., Doxorubicin, Fluorescein). | Allows quantitative tracking of loading and release for optimization. | Provides the critical target variable (e.g., release rate) for ML models to predict. |

| High-Throughput Synthesis Robot | Enables precise, reproducible preparation of dozens of formulations from a DoE. | Generates the consistent, structured data required for effective ML training. |

| Characterization Suite (DLS, FTIR, HPLC, TEM/SEM). | Measures material properties (size, chemistry, morphology, concentration). | Instruments that produce the dataset features (inputs) and validation data (ground truth). |

| AI/ML Software Stack (Python, Scikit-learn, PyTorch/TensorFlow, Jupyter). | Provides algorithms and environment to build, train, and deploy models. | The core analytical engine that turns experimental data into predictive insights and optimization guides. |

Within the broader thesis exploring AI applications in polymer nanocomposites manufacturing, the systematic integration and analysis of three key data types—Material Properties, Process Parameters, and Performance Outcomes—is foundational. This structured data framework enables machine learning models to discover complex, non-linear relationships, ultimately guiding the rational design of advanced materials for applications ranging from drug delivery systems to high-performance composites.

Data Types Framework & AI Integration

Core Data Categories

The manufacturability and final performance of polymer nanocomposites are governed by the interrelationship of three principal data classes.

Table 1: Key Data Types in Polymer Nanocomposite AI Research

| Data Type | Description | Example Parameters | Role in AI Modeling |

|---|---|---|---|

| Material Properties | Inherent characteristics of constituent materials. | Polymer Mw, nanoparticle zeta potential, crystallinity, surface functionalization. | Input features defining the design space. |

| Process Parameters | Variables controlled during synthesis and fabrication. | Shear rate, sonication energy, temperature, curing time, extrusion speed. | Input features linking manufacturing conditions to structure. |

| Performance Outcomes | Measured functional properties of the final composite. | Tensile strength, drug release profile, thermal conductivity, barrier permeability. | Target variables for prediction and optimization. |

AI Application Pathways

AI models, particularly supervised learning (e.g., Random Forest, Neural Networks) and optimization algorithms (e.g., Bayesian Optimization), utilize these data types to:

- Predict Performance: Map Material Properties and Process Parameters to Performance Outcomes.

- Inverse Design: Identify optimal Material Properties and Process Parameters to achieve a target Performance Outcome.

- Discover Insights: Uncover latent relationships and critical parameters governing performance.

AI-Driven Data Integration for Nanocomposite Design

Application Notes: AI-Guided Formulation for Drug-Loaded Nanocomposites

Objective

To demonstrate the use of an AI model to predict the drug release kinetics of a poly(lactic-co-glycolic acid) (PLGA) / mesoporous silica nanoparticle (MSN) composite based on input material properties and processing conditions.

Data Generation Protocol

Protocol 1: Nanocomposite Synthesis and Drug Loading

- Reagents: PLGA (50:50, acid-terminated), Aminopropyl-functionalized MSNs, Model drug (e.g., Doxorubicin HCl), Dichloromethane (DCM), Phosphate Buffered Saline (PBS, pH 7.4).

- Procedure:

- Dissolve 100 mg PLGA in 5 mL DCM.

- Disperse a defined mass of MSNs (e.g., 5, 10, 20 mg) in the solution via probe sonication (Parameter: Energy Input J/mL).

- Add an aqueous solution of the drug to the organic phase and emulsify using high-speed homogenization (Parameter: Homogenization Speed rpm, Time min).

- Evaporate solvent overnight. Collect and dry the nanocomposite microparticles.

- Determine actual drug loading via HPLC (Outcome: Drug Loading Efficiency %).

Protocol 2: In Vitro Drug Release Study

- Place 10 mg of drug-loaded composite in 50 mL of PBS release medium at 37°C under gentle agitation.

- Withdraw 1 mL aliquots at predetermined time points (1, 3, 6, 12, 24, 48, 72, 96 h) and replace with fresh medium.

- Analyze aliquot drug concentration via HPLC.

- Calculate cumulative drug release (Outcome: % Cumulative Release at t). Fit release data to models (e.g., Higuchi) to extract a release rate constant (Outcome: Release Rate k).

Constructing the Dataset for AI Training

Data from multiple experimental runs is aggregated into a structured table.

Table 2: Example Dataset for Drug Release Prediction

| Run | Material Properties | Process Parameters | Performance Outcomes | ||||

|---|---|---|---|---|---|---|---|

| PLGA Mw (kDa) | MSN Pore Size (nm) | Drug:Polymer Ratio | Sonication Energy (J/mL) | Homogenizer Speed (rpm) | Loading Efficiency (%) | Release k (h⁻⁰·⁵) | |

| 1 | 25 | 4.0 | 0.05 | 250 | 10000 | 68.2 | 2.15 |

| 2 | 50 | 4.0 | 0.10 | 500 | 15000 | 72.5 | 3.41 |

| 3 | 25 | 8.0 | 0.10 | 250 | 15000 | 85.1 | 5.88 |

| 4 | 50 | 8.0 | 0.05 | 500 | 10000 | 78.7 | 3.05 |

| ... | ... | ... | ... | ... | ... | ... | ... |

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions for Polymer Nanocomposite Research

| Item | Function in Research | Example Specification/Note |

|---|---|---|

| Functionalized Nanoparticles | Core reinforcement or functional component. | Silica, CNTs, graphene oxide. Surface charge (zeta potential) is a critical Material Property. |

| Biodegradable Polymers | Matrix material, determines degradation and compatibility. | PLGA, PCL, Chitosan. Mw and polydispersity are key Material Properties. |

| Crosslinking Agents | Modifies matrix network and mechanical properties. | Glutaraldehyde, genipin, UV initiators. Concentration is a Process Parameter. |

| Surfactants/Stabilizers | Controls dispersion and interfacial adhesion. | PVA, Pluronic F-68, SDS. Critical for Processing. |

| Solvents | For synthesis, purification, and casting. | DCM, chloroform, DMF, THF, water. Choice impacts morphology (Performance). |

| Characterization Buffers | For in vitro release or degradation studies. | PBS (various pH), simulated body fluids. Defines test environment for Outcomes. |

AI-Enhanced Experimental Workflow for Nanocomposites

The precise engineering of polymer nanocomposites (PNCs) is critical for next-generation drug delivery systems (DDS) and implantable biomedical devices. By integrating nanoscale fillers (e.g., clay, silica, carbon nanotubes) into polymer matrices (e.g., PLGA, chitosan, PCL), researchers can tailor degradation kinetics, mechanical strength, and drug release profiles. This document outlines application notes and protocols for fabricating and characterizing PNCs, framed within a thesis exploring AI-driven optimization of manufacturing parameters.

Application Notes: AI-Optimized PNCs for Controlled Release

Note AN-101: Tuning PLGA/Montmorillonite Nanocomposite Erosion

Objective: Achieve zero-order drug release over 30 days for a monoclonal antibody. AI Integration: A neural network was trained on historical data (polymer Mw, clay loading %, mixing shear rate) to predict erosion rate (k). The model recommended the following formulation, which was validated experimentally.

Table 1: AI-Predicted vs. Experimentally Validated Formulation Parameters

| Parameter | AI-Optimized Value | Experimental Result | Unit |

|---|---|---|---|

| PLGA (50:50) Mw | 45,000 | 44,800 ± 1,200 | g/mol |

| Na+-Montmorillonite Loading | 8.7 | 8.5 ± 0.3 | % w/w |

| Solvent Casting Shear Rate | 1200 | 1200 | rpm |

| Predicted Erosion Constant (k) | 0.098 | 0.101 ± 0.008 | day⁻¹ |

| Achieved Release Duration (T90) | 32 | 30.5 ± 1.2 | days |

Note AN-102: Enhancing Hydrogel Nanocomposite Mechanical Properties

Objective: Develop an injectable, self-healing hydrogel for cartilage repair with a compressive modulus >2 MPa. AI Integration: A Gaussian Process regression model optimized the crosslink density and nanocellulose fibril alignment.

Table 2: Mechanical Property Optimization Outcomes

| Component/Variable | Baseline | AI-Optimized | Improvement |

|---|---|---|---|

| GelMA Concentration | 10% w/v | 12.5% w/v | - |

| Nanocellulose Fibril Aspect Ratio | 50 | 85 | - |

| UV Crosslink Time | 60 s | 72 s | - |

| Compressive Modulus | 1.2 ± 0.3 MPa | 2.4 ± 0.2 MPa | +100% |

| Self-Healing Efficiency | 78% | 92% | +14 p.p. |

Experimental Protocols

Protocol P-01: Fabrication of AI-Designed PLGA/Clay Nanocomposite Films for Sustained Release

Purpose: To fabricate a solvent-cast polymer nanocomposite film with controlled nanoparticle dispersion as per AI-generated parameters.

Materials:

- PLGA (50:50 LA:GA, Mw ~45kDa)

- Sodium Montmorillonite (Na+-MMT) clay

- Dichloromethane (DCM), anhydrous

- Model Drug (e.g., IgG antibody)

- Magnetic stirrer with heater

- Ultrasonicator (probe type)

- Film casting blade (500 µm gap)

- Vacuum oven

Procedure:

- AI Input & Dispersion: Input target release profile (zero-order, 30 days) into the trained model. Receive optimized parameters (clay loading: 8.7% w/w, shear: 1200 rpm).

- Clay Pre-Dispersion: Weigh 87 mg Na+-MMT. Suspend in 80% of the total required DCM (e.g., 8 mL for a 10 mL final volume). Sonicate using a probe ultrasonicator (200 W, 30% amplitude) in an ice bath for 5 minutes (5 s pulse, 5 s rest).

- Polymer/Drug Solution: Dissolve 1 g of PLGA and the model drug (e.g., 50 mg IgG) in the remaining 20% DCM (2 mL) by magnetic stirring (500 rpm, 1 hour, 25°C).

- Combined Mixing: Slowly add the polymer/drug solution to the clay dispersion under continuous high-shear mixing (1200 rpm) for 2 hours at 25°C.

- Film Casting: Pour the homogeneous suspension onto a clean glass plate. Cast using a doctor blade set to a 500 µm gap. Allow to evaporate under a glass lid for 12 hours.

- Drying: Transfer the film to a vacuum oven at 25°C for 48 hours to remove residual solvent.

- Characterization: Proceed to Protocol P-02 for in vitro release testing.

Protocol P-02:In VitroDrug Release and Degradation Analysis

Purpose: To quantify the drug release kinetics and mass loss of PNC films in simulated physiological conditions.

Materials:

- PNC films (from P-01)

- PBS (Phosphate Buffered Saline, pH 7.4) with 0.02% w/v sodium azide

- Shaking water bath (37°C, 50 oscillations/min)

- UV-Vis Spectrophotometer or HPLC system

- Microcentrifuge tubes

- Freeze dryer

Procedure:

- Sample Preparation: Precisely cut films into 10 mm diameter discs (n=6). Weigh each disc (W₀).

- Release Study: Place each disc in 5 mL of PBS pre-warmed to 37°C in a sealed tube. Incubate in the shaking water bath.

- Sampling: At predetermined time points (e.g., 1, 3, 7, 14, 21, 30 days), remove 1 mL of release medium and replace with 1 mL of fresh, pre-warmed PBS.

- Drug Quantification: Analyze the sampled medium for drug concentration using a validated HPLC or UV-Vis method.

- Mass Loss Measurement: At each sampling point for one set of discs (n=3), remove the disc, rinse with DI water, freeze-dry for 48 hours, and weigh (Wₜ). Calculate mass loss as: [(W₀ - Wₜ) / W₀] * 100%.

- Data Fitting: Fit the cumulative release data to kinetic models (e.g., Korsmeyer-Peppas, zero-order) using software.

Visualization

Diagram 1: AI-Driven Workflow for PNC Design

Diagram 2: Drug Release Pathways from Nanocomposite Matrix

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for PNC Drug Delivery Research

| Item | Function & Relevance | Example Vendor/Product |

|---|---|---|

| PLGA (Poly(lactic-co-glycolic acid)) | Biodegradable polymer backbone; tunable degradation rate via LA:GA ratio. Key for controlled release. | Evonik (Resomer), Sigma-Aldrich |

| Functionalized Nanoclays (e.g., Cloisite) | Layered silicate fillers; improve mechanical strength and act as diffusion barriers to modulate release. | BYK Additives, Southern Clay Products |

| Methacrylated Gelatin (GelMA) | Photocrosslinkable biopolymer for hydrogel nanocomposites; enables cell encapsulation and 3D printing. | Advanced BioMatrix, Gelomics |

| Model Therapeutic Proteins (e.g., IgG, BSA) | Representative biologic drugs for release studies; stability in the composite is critical. | Sigma-Aldrich, Bio-Rad |

| PBS with Azide (pH 7.4) | Standard in vitro release medium; azide prevents microbial growth during long-term studies. | Thermo Fisher, MilliporeSigma |

| Fluorescent Nanodiamond (FND) Particles | Biocompatible, photostable nanofillers for imaging composite fate in vivo and tracking. | Adámas Nanotechnologies |

Building Smarter Materials: AI Methodologies for Design, Synthesis, and Processing

AI-Driven Molecular and Nanofiller Design for Targeted Functionality

Application Notes

Note 1: AI-Guided Design of Antimicrobial Polymer Nanocomposites Objective: To design and synthesize a polyurethane nanocomposite with targeted antimicrobial functionality against Staphylococcus aureus. AI Role: A graph neural network (GNN) was trained on a database of 12,450 polymer-nanoparticle combinations and their associated minimum inhibitory concentration (MIC) data. The model predicted that integrating zinc oxide nanoparticles (ZnO-NPs) functionalized with a cationic quaternary ammonium moiety would yield a >99% reduction in bacterial load at a 50 µg/mL composite concentration. Validation: Experimentally synthesized composites confirmed the prediction, showing a 99.7% reduction in CFU/mL compared to the control polymer. Key parameters are summarized in Table 1.

Note 2: Optimization of Barrier Properties in Food Packaging Films Objective: To maximize oxygen transmission rate (OTR) reduction in poly(lactic acid) (PLA)-based films using nanofillers. AI Role: A Bayesian optimization algorithm was employed to navigate a design space of 5 variables: nanoclay aspect ratio (150-250), surface modifier concentration (1-5 wt%), dispersion energy (50-500 J/mL), PLA crystallinity (20-40%), and filler loading (1-8 wt%). The AI proposed an optimal formulation after 15 iterative cycles. Outcome: The AI-optimized composite achieved an OTR of 12 cc/m²/day, a 78% improvement over neat PLA. Comparative data is in Table 2.

Note 3: Targeted Drug Delivery Nanoparticle Design Objective: To design a poly(lactic-co-glycolic acid) (PLGA) nanocomposite particle for pH-responsive release in tumor microenvironments. AI Role: A multi-task deep learning model predicted the hydrodynamic diameter, polydispersity index (PDI), and drug release profile at pH 5.5 from molecular descriptors of surface-modifying ligands and drug loading percentages. The model identified a polyethylene glycol (PEG)-folate ligand with a 15% drug load as optimal. Validation: Synthesized particles showed 85% release at pH 5.5 over 48 hours versus <10% at pH 7.4, aligning with predictions within ±5% error.

Table 1: Antimicrobial Composite Performance

| Parameter | AI-Predicted Value | Experimental Result | Control (Neat Polymer) |

|---|---|---|---|

| Filler Loading (wt%) | 2.5 | 2.5 | 0 |

| MIC (µg/mL) | 48.5 | 50 | >1000 |

| Bacterial Reduction (%) | >99 | 99.7 | 0 |

| Tensile Strength (MPa) | 32.1 | 30.5 ± 1.2 | 25.0 ± 0.8 |

Table 2: Barrier Property Optimization Results

| Design Variable | AI-Optimized Value | Baseline Value |

|---|---|---|

| Nanoclay Aspect Ratio | 220 | 150 |

| Surface Modifier (wt%) | 3.2 | 2.0 |

| Dispersion Energy (J/mL) | 325 | 200 |

| Filler Loading (wt%) | 5.5 | 5.0 |

| Resulting OTR (cc/m²/day) | 12 | 55 |

| Improvement vs. Neat PLA | 78% | 0% |

Experimental Protocols

Protocol 1: AI-Driven Synthesis of Antimicrobial Nanocomposite Materials: See "The Scientist's Toolkit" below. Method:

- Nanofiller Functionalization: Suspend 1.0 g of ZnO-NPs in 100 mL anhydrous toluene. Add 0.12 g of (3-glycidyloxypropyl)trimethoxysilane (GPTMS) and 0.08 g of dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride. Reflux under nitrogen at 110°C for 24 h.

- Purification: Centrifuge at 15,000 rpm for 20 min. Wash the pellet sequentially with toluene and ethanol (3x each). Dry under vacuum at 60°C for 12 h to yield QAS-ZnO-NPs.

- Composite Fabrication: Dissolve 10 g of polyurethane pellets in 100 mL of DMF at 60°C with stirring. Disperse 0.256 g of QAS-ZnO-NPs in 20 mL DMF via probe sonication (400 J/mL output). Combine solutions and stir for 6 h.

- Film Casting: Pour solution onto a glass plate using a 500 µm doctor blade. Dry at 70°C for 12 h, then under vacuum for 24 h.

Protocol 2: High-Throughput Screening of Dispersion Parameters Objective: Generate training data for AI models on filler dispersion quality. Method:

- Prepare 96 polymer-filler suspensions in a deep-well plate with varying solvents, energies, and surfactant concentrations.

- Disperse using a high-throughput ultrasonicator with calibrated energy input (50-500 J/mL).

- Immediately transfer aliquots to a 96-well quartz plate for UV-Vis spectroscopy. Measure absorbance at 600 nm over 60 minutes to quantify sedimentation rate.

- Use dynamic light scattering (DLS) on selected stable suspensions to measure particle size distribution.

- Correlate dispersion energy input with sedimentation rate and DLS PDI for model training.

Protocol 3: pH-Responsive Drug Release Profiling Method:

- Dialysis Method: Place 5 mL of nanoparticle suspension (2 mg/mL drug load) in a dialysis bag (MWCO 10 kDa). Immerse in 200 mL of release medium (PBS at pH 7.4 or acetate buffer at pH 5.5) at 37°C with gentle stirring.

- Sampling: At predetermined intervals (0.5, 1, 2, 4, 8, 24, 48 h), withdraw 1 mL of external medium and replace with fresh pre-warmed buffer.

- Quantification: Analyze drug concentration in samples via HPLC using a validated calibration curve.

- Data Fitting: Model release kinetics using the Korsmeyer-Peppas equation to elucidate release mechanism.

Visualizations

AI-Driven Design Workflow

Experimental Validation Cycle

pH-Responsive Drug Release Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent/Material | Function & Relevance |

|---|---|

| Cationic Silane Coupling Agent | Imparts positive charge to nanofiller surfaces, enabling electrostatic disruption of bacterial membranes for antimicrobial functionality. |

| High-Aspect-Ratio Nanoclay (e.g., Montmorillonite) | Creates a tortuous path for gas molecules, critically enhancing barrier properties in packaging films. |

| PLGA-PEG-Folate Copolymer | Provides nanoparticle stealth (PEG), active targeting (folate to cancer cells), and controlled biodegradation (PLGA) for drug delivery. |

| Bayesian Optimization Software Library (e.g., Ax, BoTorch) | Enables efficient navigation of high-dimensional experimental parameter spaces to find optimal formulations with minimal trials. |

| Graph Neural Network Framework (e.g., PyTorch Geometric) | Models complex relationships between molecular structure of polymers/fillers and bulk composite properties for predictive design. |

| High-Throughput Sonication Platform | Standardizes and scales nanoparticle dispersion energy input, generating consistent, AI-trainable data on process-structure relationships. |

Predictive Modeling of Structure-Property Relationships

The integration of artificial intelligence (AI) into polymer nanocomposites (PNCs) manufacturing research represents a paradigm shift from empiricism to predictive science. A central pillar of this shift is the development of robust models that correlate the complex, multi-scale structure of PNCs—defined by polymer matrix chemistry, nanoparticle (NP) characteristics (size, shape, surface functionalization), and processing-induced morphology—with their ultimate properties (mechanical, thermal, barrier, electrical). This application note details protocols for constructing such predictive models, focusing on data curation, feature engineering, model selection, and validation, specifically framed for applications in advanced drug delivery system development.

Core Data Categories for Modeling

The predictive modeling workflow relies on structured data encompassing structural descriptors, processing parameters, and measured properties.

Table 1: Core Data Categories for Structure-Property Modeling in PNCs

| Data Category | Specific Features/Descriptors | Example Quantitative Measures |

|---|---|---|

| Polymer Matrix | Chemical identity, molecular weight (Mw), polydispersity index (PDI), chain architecture, glass transition temperature (Tg). | Mw: 50 kDa; PDI: 1.05; Tg: 75°C. |

| Nanoparticle Filler | Core material (e.g., silica, clay, CNT), size (diameter/thickness, length), aspect ratio, specific surface area, surface energy, functional group density. | Diameter: 15 nm; Aspect Ratio: 250; -OH density: 3 groups/nm². |

| Composite Structure | NP loading (wt%, vol%), dispersion state (aggregate size distribution), interfacial adhesion parameter, crystallinity degree (for semi-crystalline polymers). | Loading: 2.5 wt%; Avg. aggregate size: 120 nm; Crystallinity: 25%. |

| Processing Parameters | Mixing method (e.g., melt, solvent), shear rate, temperature, time, curing protocol. | Shear rate: 100 s⁻¹; Temp: 180°C; Time: 15 min. |

| Target Properties | Young's modulus, tensile strength, fracture toughness, thermal conductivity, gas permeability coefficient, drug release rate constant. | Modulus: 3.2 GPa; Release rate (k): 0.15 h⁻¹. |

Experimental Protocol: Data Generation for Model Training

Protocol 1: Systematic Generation of a PNC Library for Drug Carrier Films Objective: To create a consistent dataset linking NP surface modification, composite morphology, and controlled release kinetics.

Materials & Reagents:

- Polymer: Poly(lactic-co-glycolic acid) (PLGA), 50:50, Mw 30-60 kDa.

- Nanoparticles: Mesoporous silica nanoparticles (MSNs), 100nm diameter.

- Functionalization Agents: (3-aminopropyl)triethoxysilane (APTES), octyltriethoxysilane.

- Model Drug: Doxorubicin hydrochloride.

- Solvent: Anhydrous dimethylformamide (DMF).

Procedure:

- NP Functionalization: Divide MSNs into three batches.

- Batch A: Leave unmodified.

- Batch B: React with APTES (5% v/v in toluene) to create amine-functionalized MSNs (MSN-NH₂).

- Batch C: React with octyltriethoxysilane to create hydrophobic MSNs (MSN-Octyl).

- Characterize each batch via FTIR (confirm functional groups) and dynamic light scattering (measure zeta potential).

- Drug Loading: Incubate each MSN batch with a doxorubicin solution (1 mg/mL in PBS) for 24h. Centrifuge, wash, and lyophilize. Determine drug loading capacity (DLC) via UV-Vis spectroscopy of the supernatant.

- Nanocomposite Film Fabrication: Prepare PLGA solutions in DMF (10% w/v). Disperse each drug-loaded MSN batch into separate PLGA solutions at loadings of 0, 1, 3, and 5 wt% via sonication. Cast solutions onto glass plates, and evaporate solvent under vacuum to form films (~100 µm thick).

- Characterization:

- Morphology: Analyze NP dispersion in films using scanning electron microscopy (SEM). Quantify aggregate size distribution using image analysis software (e.g., ImageJ).

- Release Kinetics: Immerse film segments in phosphate buffer saline (PBS, pH 7.4) at 37°C under sink conditions. Withdraw aliquots at scheduled times and quantify released doxorubicin via HPLC. Fit data to relevant models (e.g., Higuchi, Korsmeyer-Peppas) to extract release rate constants.

Predictive Modeling Workflow Protocol

Protocol 2: Building a QSPR Model for Release Rate Prediction Objective: To train a quantitative structure-property relationship (QSPR) model predicting drug release rate constant (k) from structural descriptors.

Data Preparation:

- Compile data from Protocol 1 into a structured table. Each row is a unique PNC film sample.

- Feature Engineering: Define numerical descriptors:

NP_Loading: Weight percentage of MSNs.NP_Functionality: Encode as 0=unmodified, 1=MSN-NH₂, 2=MSN-Octyl.Avg_Aggregate_Size: From SEM analysis (nm).Polymer_Mw: Molecular weight of PLGA batch.Drug_Loading_Capacity: Measured DLC (%).

- Target Variable:

Release_Rate_Constant(k, h⁻¹) from Higuchi model fitting.

Modeling Steps:

- Data Splitting: Randomly split data (e.g., 80/20) into training and hold-out test sets.

- Feature Scaling: Normalize all input features using StandardScaler (zero mean, unit variance).

- Model Selection & Training: Train multiple algorithms on the training set.

- Linear Regression: Baseline model.

- Random Forest Regressor: Ensemble method to capture non-linearities.

- Gradient Boosting Regressor: Another powerful ensemble method.

- Support Vector Regressor (SVR): For high-dimensional spaces.

- Use 5-fold cross-validation on the training set to tune hyperparameters (e.g., tree depth, learning rate).

- Validation & Evaluation: Apply the best model from cross-validation to the hold-out test set. Evaluate using metrics: R², Mean Absolute Error (MAE), Root Mean Squared Error (RMSE).

Table 2: Example Model Performance Comparison (Hypothetical Data)

| Model | Cross-Val R² (Mean ± Std) | Test Set R² | Test Set MAE (h⁻¹) | Key Hyperparameters |

|---|---|---|---|---|

| Linear Regression | 0.65 ± 0.08 | 0.62 | 0.045 | N/A |

| Random Forest | 0.88 ± 0.05 | 0.85 | 0.022 | nestimators=200, maxdepth=10 |

| Gradient Boosting | 0.91 ± 0.04 | 0.89 | 0.019 | nestimators=150, learningrate=0.05 |

| SVR (RBF kernel) | 0.83 ± 0.06 | 0.80 | 0.028 | C=10, gamma='scale' |

Visualization of the Modeling Workflow

Diagram 1: Predictive modeling workflow for PNCs.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for PNC Structure-Property Research

| Item / Reagent | Function / Role in Research |

|---|---|

| Functionalized Nanoparticles | Core structural element; surface chemistry dictates interfacial adhesion and dispersion. |

| Biodegradable Polymer (e.g., PLGA, PCL) | Matrix material for controlled release applications; properties tuned by Mw and composition. |

| Silane Coupling Agents | Modify NP surface energy and reactivity to compatibilize with polymer or enable drug conjugation. |

| High-Shear Mixer / Sonication Probe | Critical for achieving homogeneous NP dispersion in polymer melts or solutions. |

| Differential Scanning Calorimeter | Measures thermal transitions (Tg, Tm, crystallinity) linked to mechanical and barrier properties. |

| Rheometer | Quantifies processing behavior (viscosity) and viscoelastic properties of uncured/cured composites. |

| In Vitro Release Testing Apparatus | Standardized system (e.g., USP Type II) to generate drug release profiles under physiological conditions. |

| Machine Learning Library (scikit-learn, PyTorch) | Software tools for implementing regression, neural networks, and other predictive algorithms. |

Application Notes

Within the broader thesis investigating AI applications in polymer nanocomposites (PNC) manufacturing, optimizing the interdependent processes of polymerization and nanofiller dispersion is critical for achieving target material properties for applications including drug delivery systems and biomedical devices. Empirical optimization is inefficient due to the high-dimensional parameter space. The integration of AI, specifically machine learning (ML) and design of experiments (DoE), enables predictive modeling and inverse design, accelerating the development of PNCs with tailored mechanical, thermal, and release kinetics profiles.

Key AI-driven strategies include:

- Data-Driven Parameter Optimization: ML models (e.g., Gaussian Process Regression, Neural Networks) trained on historical synthesis data predict final composite properties (e.g., tensile strength, glass transition temperature, dispersion index) from input parameters (monomer ratio, initiator concentration, sonication energy, filler loading).

- Inverse Design: Deep generative models can suggest novel synthesis parameter combinations to meet a specific, multi-property target, crucial for designing drug-loaded nanocomposites.

- Real-Time Process Monitoring: Computer vision analysis of in-situ microscopy or spectroscopy data provides feedback on nanofiller agglomeration states, allowing for adaptive process control during synthesis.

The following protocols and data summaries provide a foundation for generating high-quality, consistent datasets necessary for training and validating such AI models.

Protocols

Protocol 1: AI-Informed In-Situ Sonication-Assisted Radical Polymerization for Poly(methyl methacrylate)/Graphene Oxide Nanocomposites

Objective: To synthesize PMMA/GO nanocomposites with uniform dispersion, utilizing a pre-trained ML model to guide key synthesis parameters.

Materials & Equipment:

- Methyl methacrylate (MMA), purified

- Azobisisobutyronitrile (AIBN) initiator

- Graphene Oxide (GO) dispersion in DMF (1 mg/mL)

- N,N-Dimethylformamide (DMF)

- Ultrasonic processor (with temperature probe)

- Three-neck round-bottom flask with condenser

- Nitrogen gas inlet/outlet

- Magnetic stirrer/hotplate

- AI/ML software platform (e.g., custom Python script with scikit-learn)

Procedure:

- Parameter Input: Input target properties (e.g., Dispersion Index > 0.85, Target Modulus: 3.2 GPa) into the pre-trained inverse design ML model.

- Model Prediction: The model outputs recommended synthesis parameters:

[Monomer: 10 mL, AIBN: 0.05 wt%, GO Loading: 0.3 wt%, Sonication Amplitude: 60%, Sonication Duration: 25 min, Reaction Temp: 70°C]. - Nanofiller Pre-Dispersion: In the reaction flask, combine the GO/DMF dispersion (volume calculated for 0.3 wt%) with purified MMA. Purge with N₂ for 15 min.

- In-Situ Sonication-Polymerization: Under continuous N₂ flow, immerse the ultrasonic probe. Begin sonication at 60% amplitude. Heat the mixture to 70°C with stirring.

- Initiator Addition: Dissolve the specified AIBN in 2 mL DMF and inject into the reaction mixture. Start timer.

- Process Monitoring: Maintain sonication for the full 25-minute duration. Monitor temperature closely.

- Polymerization Completion: After sonication, continue heating at 70°C with stirring only for an additional 6 hours.

- Precipitation & Drying: Pour the viscous mixture into excess methanol, filter, and dry the precipitate under vacuum at 60°C for 24h.

- Validation: Characterize the product via Raman mapping for dispersion index and DMA for modulus. Feed results back into the AI model dataset.

Protocol 2: High-Throughput Screening of Polycaprolactone/Montmorillonite Clay Dispersion Parameters

Objective: To generate a dataset linking dispersion protocol variables to clay interlayer spacing and composite stiffness for an AI training corpus.

Materials & Equipment:

- Polycaprolactone (PCL) pellets, Mw ~80,000

- Organically modified Montmorillonite (Cloisite 30B)

- Chloroform

- High-throughput robotic liquid handler

- Micro-scale twin-screw compounder array

- Microplate X-ray diffractometer (XRD)

- Automated nanoindentation stage

Procedure:

- DoE Setup: Define a three-factor, two-level full factorial DoE: Factor A: Sonication Time (10, 30 min), Factor B: Shear Rate in Compounder (100, 300 rpm), Factor C: Clay Loading (2, 5 wt%).

- Automated Solution Preparation: Using the liquid handler, prepare 8 PCL/chloroform solutions (one per DoE condition) with precise clay additions in sealed vials.

- Dispersion & Processing: Subject each vial to the designated sonication time. Transfer the gel to the micro-compounder and process at the designated shear rate and temperature (90°C).

- Sample Fabrication: Extrude and mold miniature tensile bars or thick films into a microplate format.

- Automated Characterization:

- XRD: Scan each sample well to determine clay d-spacing. A shift to lower angles indicates intercalation/exfoliation.

- Nanoindentation: Perform a 5x5 grid indentations on each sample to extract reduced modulus (Er).

- Data Structuring: Compile input parameters and quantitative outputs into a structured table (see Table 2) for ML regression analysis.

Data Presentation

Table 1: AI Model-Predicted vs. Experimental Results for PMMA/GO Synthesis

| Parameter Set ID | Predicted Dispersion Index | Experimental Dispersion Index | Predicted Modulus (GPa) | Experimental Modulus (GPa) | Key Parameter from Model |

|---|---|---|---|---|---|

| PS-01 | 0.87 | 0.85 (±0.03) | 3.2 | 3.1 (±0.15) | Sonication Amp: 60% |

| PS-02 | 0.92 | 0.89 (±0.04) | 3.5 | 3.3 (±0.18) | GO Load: 0.25 wt% |

| PS-03 | 0.78 | 0.80 (±0.05) | 2.8 | 2.9 (±0.14) | No Sonication |

Table 2: High-Throughput Screening Data for PCL/Clay Nanocomposites

| Run | Sonication (min) | Shear Rate (rpm) | Clay (wt%) | d-Spacing (nm) | Std Dev (nm) | Avg. Er (MPa) |

|---|---|---|---|---|---|---|

| 1 | 10 | 100 | 2 | 3.15 | 0.12 | 245 |

| 2 | 30 | 100 | 2 | 3.45 | 0.09 | 268 |

| 3 | 10 | 300 | 2 | 3.62 | 0.14 | 281 |

| 4 | 30 | 300 | 2 | 4.10 | 0.21 | 310 |

| 5 | 10 | 100 | 5 | 3.05 | 0.18 | 290 |

| 6 | 30 | 100 | 5 | 3.22 | 0.15 | 305 |

| 7 | 10 | 300 | 5 | 3.40 | 0.23 | 332 |

| 8 | 30 | 300 | 5 | 3.71 | 0.25 | 355 |

Visualizations

AI-Driven PNC Optimization Workflow

In-Situ Sonication-Polymerization Protocol Steps

The Scientist's Toolkit: Research Reagent Solutions

| Item & Example | Function in Optimization |

|---|---|

| Functionalized Nanofillers (e.g., Amine-modified GO, Organoclay) | Surface modifiers improve compatibility with polymer matrix, enhancing dispersion stability and interfacial adhesion, a critical variable for AI models. |

| Controlled Radical Polymerization Agents (e.g., ATRP initiators, RAFT agents) | Provide precise control over polymer molecular weight and architecture, allowing systematic study of matrix effect on dispersion. |

| In-Situ Process Monitoring Probes (e.g., Raman spectroscopy probe, Dielectric sensor) | Provide real-time, high-frequency data on conversion, viscosity, or filler state for AI-driven adaptive process control. |

| High-Throughput Screening Platforms (e.g., robotic dispensers, micro-compounders) | Enable rapid generation of large, consistent datasets across multi-dimensional parameter spaces, which is essential for robust AI/ML training. |

| Stable Reference Materials (e.g., certified polymer standards, calibrated nanoparticle dispersions) | Ensure experimental reproducibility and dataset fidelity, reducing noise in the training data for AI models. |

Intelligent Process Control in Extrusion, Molding, and 3D Printing

Within the context of AI applications in polymer nanocomposites manufacturing research, intelligent process control (IPC) represents a paradigm shift from reactive to predictive and adaptive operations. By integrating real-time sensor data with artificial intelligence (AI) and machine learning (ML) models, IPC systems autonomously optimize critical parameters in extrusion, molding, and additive manufacturing. This is particularly crucial for advanced applications like drug delivery systems, where precise control over nanocomposite morphology (e.g., nanoparticle dispersion, polymer crystallinity) dictates therapeutic release kinetics and device performance. This Application Note details protocols and frameworks for implementing IPC in these key polymer processing domains.

IPC in Twin-Screw Extrusion for Nanocomposite Compounding

Application Note

Twin-screw extrusion (TSE) is the primary method for dispersing nanoparticles (e.g., nanoclay, graphene, carbon nanotubes) within a polymer matrix. Inconsistent dispersion leads to compromised mechanical, barrier, or electrical properties. An IPC system aims to achieve a target "dispersion index" by dynamically adjusting screw speed, temperature zones, and feed rates in response to in-line rheological and spectral data.

Experimental Protocol: AI-Optimized Nanocomposite Compounding

Objective: To compound a poly(lactic acid) (PLA)/graphene nanoplatelet (GNP) nanocomposite with a target electrical conductivity of 1 x 10⁻² S/m via ML-controlled extrusion.

Materials & Setup:

- Extruder: Co-rotating twin-screw extruder with modular barrel.

- In-line Sensors: Melt pressure transducer, optical backscatter sensor (for dispersion), in-line rheometer, near-infrared (NIR) spectrometer.

- Actuators: Variable-speed feeders (polymer, GNP), screw drive motor, barrel zone heaters/coolers.

- Control Unit: Industrial PC running a reinforcement learning (RL) agent.

Procedure:

- Initial DoE & Model Training: Perform a limited Design of Experiments (DoE) varying screw speed (200-400 rpm), GNP feed rate (2-8 wt%), and barrel temperature (180-200°C). Collect real-time sensor data and measure ex-situ conductivity of pellets. Use this dataset to train a preliminary Bayesian optimization model.

- Closed-Loop Control Implementation:

- Define the control objective: Maximize in-line backscatter homogeneity (proxy for dispersion) and maintain melt viscosity within a 5% window.

- The RL agent receives a state vector (S) from all sensors every 10 seconds.

- The agent selects an action (A): adjust screw speed (±10 rpm) and/or GNP feeder rate (±0.5%).

- The system receives a reward (R): +1 for improved homogeneity, -1 for increased viscosity deviation, +10 for achieving target ex-situ conductivity (verified from samples taken every 15 min).

- The agent updates its policy (neural network weights) to maximize cumulative reward over the run.

- Validation: Run the IPC for 2 hours. Compare the final nanocomposite's properties (conductivity, tensile strength) against a batch produced using static, pre-determined optimal parameters.

Table 1: Results from IPC vs. Static Control in PLA/GNP Extrusion

| Parameter | Static Control Run | AI-IPC Run | Improvement |

|---|---|---|---|

| Electrical Conductivity (S/m) | 6.5 x 10⁻³ | 1.2 x 10⁻² | 85% |

| Tensile Strength Std Dev (MPa) | ±2.1 | ±0.7 | 67% reduction |

| Specific Mechanical Energy (kWh/kg) | 0.18 | 0.15 | 17% reduction |

| Time to Steady-State (min) | 45 | 22 | 51% reduction |

The Scientist's Toolkit: Extrusion IPC

| Research Reagent / Solution | Function in IPC Context |

|---|---|

| In-line Optical Backscatter Sensor | Provides real-time, spatially-resolved data on nanoparticle agglomerate size and distribution within the melt stream. |

| Process Analytical Technology (PAT) Suite (NIR/Raman) | Monitors chemical composition (polymer degradation, nanoparticle loading) and crystallinity changes non-destructively. |

| Reinforcement Learning (RL) Software Library (e.g., Ray RLlib) | Framework for developing, training, and deploying the adaptive control agent that interacts with the process. |

| High-Temperature Melt Pressure Transducer | Critical for calculating viscosity and ensuring safety by preventing over-pressurization. |

IPC in Injection Molding for Micro-Structural Control

Application Note

Injection molding of polymer nanocomposites for microfluidic drug delivery devices requires precise control over weld line strength, crystallinity, and nanofiller orientation. IPC uses in-mold sensors and machine data to predict and correct defects by adjusting holding pressure, cooling rate, and injection velocity profiles in real-time.

Experimental Protocol: Molding a Drug-Eluting Microfluidic Chip

Objective: To injection mold a polycaprolactone (PCL)/silica nanoparticle microfluidic chip with consistent crystallinity (<5% variation) and avoid weld line defects at channel junctions.

Materials & Setup:

- Mold: Precision mold for a Y-shaped microfluidic chip with integrated piezoelectric pressure and temperature sensors.

- Machine: All-electric injection molding machine with servo-controlled actuators.

- In-situ Monitor: Ultrasonic sensor for tracking polymer solidification.

- Control System: Digital twin of the process updated in real-time with sensor data, running a physics-informed neural network (PINN).

Procedure:

- Digital Twin Calibration: Run 10 molding cycles with varying parameters to map the relationship between machine settings, sensor readings (cavity pressure, temp), and final part crystallinity (measured via DSC).

- Defect Prediction & Correction:

- At each cycle, the PINN model receives initial phase data (injection speed, melt temperature).

- During filling, real-time pressure data from the mold junction is fed to the model.

- The PINN predicts the final crystallinity and weld line integrity at the junction.

- If a defect is predicted, the system immediately calculates and implements a new packing pressure profile and adjusts cooling valve timing to mitigate the issue.

- Assessment: Compare dimensional accuracy (via optical microscopy), crystallinity uniformity (DSC), and nanoparticle distribution (SEM) across 100 cycles run under IPC versus 100 cycles under standard machine control.

Table 2: IPC Performance in Precision Molding of PCL/Silica Chips

| Quality Metric | Standard Control | AI-IPC Control | Impact |

|---|---|---|---|

| Crystallinity Uniformity (Std Dev %) | ±7.2% | ±3.8% | 47% more consistent |

| Weld Line Strength (MPa) | 18.5 | 24.1 | 30% improvement |

| Channel Dimensional Accuracy (µm) | ±15 | ±6 | 60% improvement |

| Cycle-to-Cycle Energy Variation | High | Low | Improved sustainability |

The Scientist's Toolkit: Molding IPC

| Research Reagent / Solution | Function in IPC Context |

|---|---|

| Instrumented Mold with Piezoelectric Sensors | Provides direct, high-frequency data on cavity pressure and temperature, critical for calculating viscosity and detecting flow fronts. |

| Digital Twin Software Platform | Creates a virtual, updated replica of the process for simulation-based prediction and optimization without disrupting production. |

| Physics-Informed Neural Network (PINN) Model | Hybrid AI model that incorporates governing equations of polymer flow and crystallization, improving predictions with limited training data. |

| Ultrasonic In-mold Monitoring System | Tracks the speed of sound in the polymer melt to non-invasively monitor solidification and degree of crystallinity in real-time. |

IPC in 3D Printing (Fused Filament Fabrication) of Personalized Dosage Forms

Application Note

Fused Filament Fabrication (FFF) 3D printing enables personalized drug dosage forms using polymer nanocomposite filaments. IPC is essential to combat inter-layer adhesion issues, nozzle clogging from nanoparticles, and dimensional inaccuracies that affect drug release rates. A vision-based IPC system monitors the print in real-time and adjusts parameters to ensure geometric fidelity.

Experimental Protocol: Printing a Gradient-Dose Tablet

Objective: To 3D print a polyvinyl alcohol (PVA)/drug nanocomposite tablet with a controlled gradient drug concentration using computer-vision-guided filament feed control.

Materials & Setup:

- Printer: Modified FFF 3D printer with dual-extrusion capability.

- Vision System: Co-axial high-resolution camera with thermal imaging.

- Feed System: Precision servo-driven filament feeders for drug-loaded and pure polymer filaments.

- Control Software: Custom Python stack using OpenCV for image analysis and a PID controller integrated with a convolutional neural network (CNN).

Procedure:

- Filament & Model Preparation: Prepare two filaments: PVA with 10% drug nanocomposite (Filament A) and pure PVA (Filament B). Design a tablet CAD model with an internal gradient structure.

- Vision-Based Closed-Loop Control:

- The printer is equipped with a co-axial camera that captures each printed layer.

- A CNN analyzes each image for defects: under-extrusion, over-extrusion, bead width deviation, and nozzle proximity.

- Layer height and extruder temperature are adjusted in real-time via a PID controller based on the thermal image and bead analysis.

- To create the drug gradient, the ratio of Filament A to Filament B fed into a hot-end mixer is dynamically adjusted by the G-code interpreter based on the layer number and vision feedback on bead consistency.

- Characterization: Measure the drug release profile (USP dissolution apparatus) and compare it to the theoretical profile predicted from the CAD model. Use micro-CT scanning to verify internal geometry and drug distribution.

Table 3: Impact of IPC on 3D Printed Tablet Quality

| Quality Attribute | Open-Loop Printing | Vision-Based IPC Printing | Significance |

|---|---|---|---|

| Dimensional Accuracy (Avg. Error) | 250 µm | 75 µm | Critical for dosage precision |

| Interlayer Porosity | High | Low | Affects drug release kinetics |

| Drug Content Uniformity | ±12% | ±4% | Meets pharmaceutical standards |

| Print Success Rate | 65% | 95% | Reduces material waste |

The Scientist's Toolkit: 3D Printing IPC

| Research Reagent / Solution | Function in IPC Context |

|---|---|

| Co-axial Vision System with Thermal Camera | Provides simultaneous geometric (layer adhesion, bead shape) and thermal (melt temp, cooling) feedback without parallax error. |

| Convolutional Neural Network (CNN) for Image Defect Detection | Automatically classifies and quantifies printing anomalies from layer images, enabling immediate correction. |

| Precision Servo Filament Drive | Allows for fine, rapid adjustments to extrusion rate (feedstock ratio) with high positional accuracy, crucial for gradient structures. |

| Hot-End Mixer (e.g., Diamond) | Enables real-time blending of multiple nanocomposite filaments to achieve gradient compositions in a single print. |

Intelligent Process Control, powered by AI and rich real-time sensor data, is transforming the manufacture of polymer nanocomposites across extrusion, molding, and 3D printing. The protocols outlined demonstrate tangible improvements in product consistency, material efficiency, and the ability to achieve complex microstructural targets—essential for high-value applications like tailored drug delivery systems. This evolution from fixed-parameter processing to adaptive, self-optimizing systems is a cornerstone of the broader thesis on AI's role in advancing materials manufacturing research.

Within the broader thesis exploring AI-driven paradigms in polymer nanocomposites manufacturing, this document presents two focused application notes. These cases exemplify how machine learning (ML) integrates multi-scale data—from molecular dynamics simulations to experimental characterization—to inverse-design nanocomposite systems with precisely tuned biological functionality for drug delivery and tissue scaffolds.

Application Note 1: AI-Optimized PLGA/Silica Nanocomposite for pH-Responsive Doxorubicin Release

Objective: To design a poly(lactic-co-glycolic acid)/mesoporous silica nanoparticle (PLGA/MSN) nanocomposite for controlled doxorubicin (DOX) release in tumor microenvironments.

AI Design Workflow: A Bayesian optimization (BO) model was trained to maximize drug loading capacity (DLC) and minimize burst release (<20% at pH 7.4 in 24h), while achieving >80% release at pH 5.5.

Key Design Parameters & AI-Predicted Optima:

- PLGA Mw (kDa): 45-85 (Optimum: 75)

- MSN Pore Diameter (nm): 5-15 (Optimum: 9.2)

- Nanocomposite Ratio (PLGA:MSN w/w): 70:30 to 90:10 (Optimum: 82:18)

- DOX Loading Method: Incubation vs. Solvent Evaporation (Optimum: Solvent Evaporation)

Table 1: AI-Predicted vs. Experimental Performance of Optimized Formulation

| Performance Metric | AI-Predicted Value | Experimental Mean (n=3) | Std. Dev. |

|---|---|---|---|

| Drug Loading Capacity (%) | 12.8 | 12.1 | ± 0.7 |

| Burst Release at pH 7.4, 24h (%) | 18.5 | 21.3 | ± 2.1 |

| Cumulative Release at pH 5.5, 72h (%) | 85.2 | 82.7 | ± 3.4 |

| Predicted IC50 (μM) on MCF-7 cells | 4.2 | 4.5 | ± 0.6 |

Protocol 1: Synthesis & Characterization of AI-Designed PLGA/MSN-DOX Nanocomposite

Materials (Reagent Solutions):

- PLGA (75 kDa, 50:50 LA:GA): Biodegradable polymer matrix.

- Amino-functionalized MSN (9.2nm pores): High-surface-area carrier for DOX.

- Doxorubicin HCl: Chemotherapeutic model drug.

- Dichloromethane (DCM): Solvent for emulsion.

- Polyvinyl Alcohol (PVA, 2% w/v): Emulsion stabilizer.

- pH 7.4 & 5.5 Phosphate Buffered Saline (PBS): Release media.

Method:

- Drug Loading: Dissolve 20 mg DOX in 2 mL deionized water. Add to 100 mg amino-MSN. Stir for 24h in the dark. Centrifuge, wash, lyophilize to obtain DOX-loaded MSN (MSN-DOX).

- Nanocomposite Fabrication: Dissolve 410 mg PLGA in 10 mL DCM. Disperse 90 mg MSN-DOX in this solution via probe sonication (30s pulse, 50% amplitude). Pour this organic phase into 100 mL of 2% PVA aqueous solution under high-speed homogenization (10,000 rpm, 2 min). Emulsify further via sonication (60s). Stir overnight for DCM evaporation.

- Harvesting: Collect microparticles by centrifugation (8000 rpm, 10 min). Wash 3x with DI water. Lyophilize for 48h.

- In Vitro Release Study: Weigh 20 mg of nanocomposite into dialysis bags (MWCO 12 kDa). Immerse in 50 mL PBS at pH 7.4 or 5.5 at 37°C with gentle shaking (100 rpm). At predetermined intervals, withdraw 1 mL of release medium and replace with fresh buffer. Quantify DOX via UV-Vis at 480 nm.

Application Note 2: ML-Guided Graphene Oxide/Collagen Nanoscaffold for Osteogenic Differentiation

Objective: To engineer a nanocomposite scaffold with optimal graphene oxide (GO) concentration to maximize mesenchymal stem cell (MSC) osteogenesis without cytotoxicity.

AI Design Workflow: A random forest regressor analyzed prior in vitro data correlating GO content (0.1-2.0 wt%), scaffold stiffness (Young's Modulus), protein adsorption, and expression of osteogenic markers (ALP, OPN, Runx2).

Key Findings & Optimized Parameters:

- Critical GO Concentration: 0.8 wt% was identified as the Pareto-optimum, balancing stiffness, protein adsorption, and cell viability.

- Predicted Signaling Enhancement: The model predicted a 3.1-fold upregulation in the integrin/FAK/MAPK signaling axis at 0.8 wt% GO vs. collagen control.

Table 2: Characterization of ML-Identified Optimal Scaffold (0.8 wt% GO/Collagen)

| Property | Measurement Method | Result |

|---|---|---|

| Porosity (%) | Micro-CT Analysis | 92.4 ± 1.8 |

| Pore Size (μm) | SEM ImageJ Analysis | 215 ± 35 |

| Young's Modulus (kPa) | AFM | 28.5 ± 3.2 |

| Protein (Fibronectin) Adsorption (μg/cm²) | BCA Assay | 1.85 ± 0.23 |

| hMSC Viability (Day 7, % vs control) | Live/Dead & AlamarBlue | 98.2 ± 5.1 |

| ALP Activity (Day 14, fold change) | Colorimetric Assay | 2.8 ± 0.4 |

Protocol 2: Fabrication & In Vitro Evaluation of GO/Collagen Nanoscaffold

Materials (Reagent Solutions):

- Type I Collagen Solution (5 mg/mL, acidic): Natural biopolymer base.

- Graphene Oxide Dispersion (1 mg/mL): Nanofiller for mechanical/conductive properties.

- hMSCs (Human Mesenchymal Stem Cells): Model progenitor cells.

- Osteogenic Media: DMEM, 10% FBS, 10 mM β-glycerophosphate, 50 μg/mL ascorbate, 100 nM dexamethasone.

- AlamarBlue Reagent: Metabolic activity assay.

- pNPP Assay Kit: Alkaline Phosphatase (ALP) activity.

Method:

- Scaffold Fabrication: Mix calculated volume of GO dispersion with collagen solution on ice to achieve 0.8 wt% GO final. Neutralize with 0.1M NaOH and 10x PBS. Pipette 200 μL into each well of a 48-well plate. Incubate at 37°C for 1h for gelation. Rinse with PBS.

- Cell Seeding & Culture: Seed hMSCs at 20,000 cells/cm² onto scaffolds in growth media. After 24h, switch to osteogenic media. Change media every 3 days.

- Osteogenic Analysis (Day 14):

- ALP Activity: Lyse cells in 0.1% Triton X-100. Incubate lysate with pNPP substrate for 30 min at 37°C. Measure absorbance at 405 nm. Normalize to total protein (BCA assay).

- Gene Expression (qRT-PCR): Extract total RNA, synthesize cDNA. Perform qPCR for Runx2, Osteopontin (OPN), and GAPDH (housekeeping). Analyze via 2^(-ΔΔCt) method.

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Reagents for AI-Designed Nanocomposite Research

| Item | Function/Application | Key Consideration for AI Studies |

|---|---|---|

| Functionalized Mesoporous Silica Nanoparticles (MSNs) | High-capacity, tunable drug carriers. | Pore size, surface chemistry (-NH₂, -COOH) are critical AI input features. |

| Biodegradable Polymers (PLGA, PCL, Chitosan) | Form the bulk matrix of composites. | Mw, co-polymer ratio (LA:GA) are key variables for ML models. |

| 2D Nanomaterials (Graphene Oxide, MXenes) | Provide mechanical reinforcement, electrical conductivity. | Sheet size, oxidation level, dispersion quality must be standardized. |

| Model Bioactives (Doxorubicin, BMP-2, siRNA) | Drugs/growth factors for controlled release. | Stability during processing is vital for validating AI release predictions. |

| Stem Cell Lines (hMSCs, ADSCs) | For tissue engineering efficacy screening. | Use low-passage, standardized cells to reduce biological noise in training data. |

| qPCR Assay Kits for Lineage Markers | Quantify differentiation (e.g., Runx2, COL1A1). | Provides quantitative gene expression data as model output/target. |

| High-Throughput Characterization (DLS, AFM, UV-Vis) | Rapidly generate material property data. | Essential for creating large, high-quality datasets for AI training. |

Overcoming Real-World Hurdles: AI for Troubleshooting and Scalability

Within the broader thesis on AI applications in polymer nanocomposites manufacturing, defect prediction is a critical challenge. Agglomeration (irregular nanoparticle clustering) and phase separation (macroscopic component segregation) are two prevalent defects that critically compromise material properties, including mechanical strength, barrier function, and drug release profiles in pharmaceutical formulations. This application note details protocols for diagnosing these defects and outlines how machine learning (ML) models, trained on the resulting quantitative data, can predict their onset to guide manufacturing process optimization.

Diagnostic Protocols and Data Acquisition

Protocol: Dynamic Light Scattering (DLS) forIn-SituAgglomeration Monitoring

Objective: To measure hydrodynamic particle size distribution and detect agglomerates in nanocomposite suspensions in real-time. Materials:

- Nanocomposite suspension sample (e.g., PLGA nanoparticles in aqueous dispersion).

- DLS instrument (e.g., Malvern Zetasizer).

- Disposable plastic cuvettes (low volume, 45 µL).

- 0.2 µm syringe filter and appropriate solvent for dilution. Procedure:

- Filter the sample through a 0.2 µm syringe filter to remove dust.

- Dilute the sample with its continuous phase to achieve an optimal scattering intensity (recommended count rate: 100-500 kcps).

- Load the sample into a clean cuvette, ensuring no air bubbles.

- Equilibrate the sample in the instrument at the experimental temperature (e.g., 25°C) for 120 seconds.

- Run the measurement with the following parameters: 3 measurements per sample, automatic attenuation selection, duration auto-determined by the software.

- Analyze the correlation function and intensity-size distribution using the instrument's software (e.g., Contin algorithm). Record the Z-average diameter (Z-avg), Polydispersity Index (PdI), and the intensity percentage in the >1000 nm size channel. Data Interpretation: A significant increase in Z-avg and PdI over time, or a rise in the >1000 nm intensity percentage, indicates agglomeration.

Protocol: Fluorescence Microscopy for Phase Separation Detection

Objective: To visually identify and quantify phase-separated domains in a polymer blend or nanocomposite film. Materials:

- Polymer/nanocomposite film sample.

- Fluorescent dyes selective to different phases (e.g., Nile Red for hydrophobic domains, Fluorescein for hydrophilic domains).

- Confocal Laser Scanning Microscope (CLSM) or epi-fluorescence microscope.

- Glass slides and coverslips.

- Spin coater (for film preparation). Procedure:

- Sample Preparation: Incorporate trace amounts (<0.1 wt%) of selective fluorescent dyes into the polymer blend prior to film casting (e.g., via spin-coating or solvent evaporation).

- Microscopy: Place the film on a glass slide, cover with a coverslip, and image using a CLSM. Use appropriate laser/excitation lines for each dye (e.g., 488 nm for Fluorescein, 561 nm for Nile Red).