Biopolymers vs Synthetic Polymers for Drug Delivery: A 2024 Comprehensive Analysis for Biomedical Researchers

This article provides a detailed comparative analysis of biopolymers and synthetic polymers for biomedical applications, with a focus on drug delivery systems.

Biopolymers vs Synthetic Polymers for Drug Delivery: A 2024 Comprehensive Analysis for Biomedical Researchers

Abstract

This article provides a detailed comparative analysis of biopolymers and synthetic polymers for biomedical applications, with a focus on drug delivery systems. We explore foundational chemistry and sourcing, analyze advanced fabrication methodologies, address key challenges in formulation and scale-up, and present data-driven validation of performance metrics. Tailored for researchers and drug development professionals, this review synthesizes current research to guide material selection and future innovation in polymer-based therapeutics.

Chemical Foundations and Sourcing: What Defines Biobased and Synthetic Polymers?

Within the framework of a comparative study of biopolymers versus synthetic polymers, a fundamental understanding of class definitions based on chemical structure and monomer origin is essential. This guide provides a comparative analysis of performance characteristics, grounded in experimental data, to inform researchers, scientists, and drug development professionals in material selection.

Structural Class Comparison: Origins and Performance

The performance of polymeric materials is intrinsically linked to their structural class, which is defined by monomer sourcing and polymerization mechanisms. The following table summarizes key characteristics and experimental performance metrics.

Table 1: Comparative Analysis of Polymer Classes by Origin and Structure

| Polymer Class | Exemplar Polymers | Monomer Origin | Key Structural Motif | Avg. Tensile Strength (MPa) | Degradation Time (Typical) | Polydispersity Index (PDI) |

|---|---|---|---|---|---|---|

| Polysaccharides | Chitosan, Hyaluronic Acid | Natural (Sugar monomers) | Glycosidic bonds, often functionalized with -OH, -NH₂ | 50-120 | Weeks to Months | 1.5 - 3.0 (Broad) |

| Polyesters (Bio-sourced) | PLA, PHA | Natural/Bio-fermentation (Hydroxy acids) | Ester bonds in backbone | 40-70 (PLA) | 6-24 months (PLA) | 1.8 - 2.5 |

| Polyesters (Synthetic) | PCL, PGA | Petrochemical | Aliphatic ester bonds | 20-40 (PCL) | 24-36 months (PCL) | 1.2 - 1.8 (Narrow) |

| Polyamides | Nylon-6,6, Poly-γ-glutamic acid | Petrochemical or Microbial | Amide bonds | 70-90 (Nylon) | Non-degradable (Nylon) | 1.1 - 1.5 |

| Vinyl Polymers | Polyethylene, PS, PMMA | Petrochemical | C-C backbone with variable side groups (R) | 10-40 (LDPE) | Centuries | 1.05 - 2.5 |

Experimental Data and Methodologies

Experiment 1: Comparative Hydrolytic Degradation Kinetics

- Objective: To measure mass loss and molecular weight change under simulated physiological conditions.

- Protocol: Samples (PLA, PCL, Chitosan film) of standardized dimensions (10mm x 10mm x 1mm) were weighed (initial mass M₀) and characterized via GPC for initial molecular weight (Mₙ₀). They were immersed in 50 mL phosphate-buffered saline (PBS, pH 7.4) at 37°C with gentle agitation. At predetermined intervals (1, 2, 4, 8, 12 weeks), samples were removed, rinsed, dried to constant mass, and weighed (Mₜ). GPC analysis was repeated at endpoint intervals.

- Key Data: Mass loss (%) = [(M₀ - Mₜ) / M₀] x 100. PLA showed 80% mass loss at 48 weeks, PCL showed <10% at same interval, while Chitosan dissolved within 4 weeks.

Experiment 2: Mechanical Performance under Hydration

- Objective: To evaluate the retention of tensile strength in a hydrated state, critical for biomedical applications.

- Protocol: Using a universal testing machine, dumbbell-shaped specimens were tested under two conditions: dry (conditioned at 25°C, 10% RH) and wet (immersed in PBS for 24h). Crosshead speed was set to 5 mm/min. A minimum of n=5 samples per condition were tested.

- Key Data: Synthetic polyesters (PGA) retained ~85% of dry strength when wet, whereas polysaccharide-based films (Alginate) retained only ~30-40%.

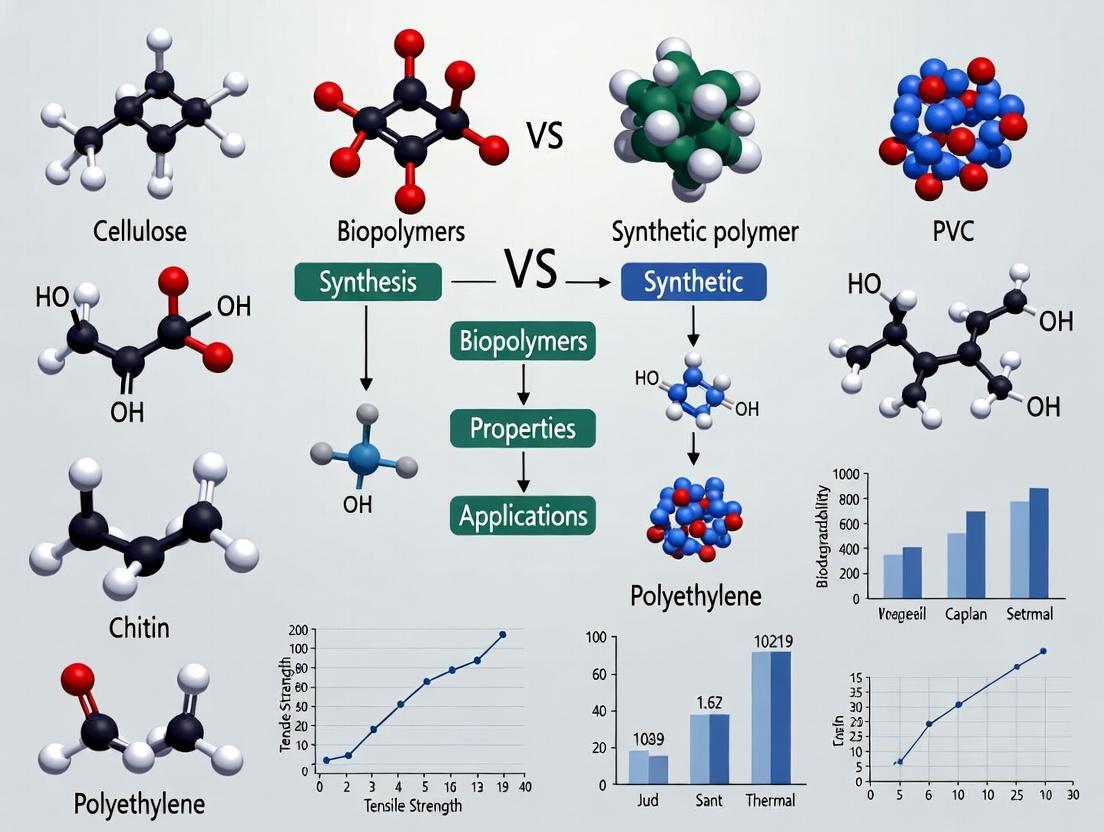

Diagram: Polymer Classification and Property Relationship

Diagram Title: Polymer Origin Determines Class and Final Properties

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagent Solutions for Polymer Characterization Experiments

| Reagent/Material | Function/Application | Critical Note |

|---|---|---|

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard medium for in vitro degradation and swelling studies, simulating physiological ionic strength and pH. | Must contain 0.02% sodium azide to prevent microbial growth in long-term studies. |

| Size Exclusion Chromatography (SEC/GPC) Kit | For determining molecular weight distribution (Mn, Mw) and Polydispersity Index (PDI). | Requires polymer-specific standards (e.g., polystyrene, polyethylene oxide) for accurate calibration. |

| Enzymatic Solutions (e.g., Lysozyme, Proteinase K) | To study enzymatic degradation pathways specific to biopolymers (e.g., chitosan, polyesteramide). | Activity units must be verified and controlled across experiments; buffer composition is enzyme-specific. |

| Simulated Body Fluid (SBF) | For evaluating bioactivity and apatite formation on polymer surfaces, relevant for bone-contact applications. | Ion concentrations must match human blood plasma precisely; solution is metastable and requires careful preparation. |

| MTS/Tetrazolium Assay Kit | Colorimetric assay for quantifying cell viability and proliferation on polymer surfaces (cytocompatibility testing). | Requires careful removal of test polymer samples to avoid absorbing formazan crystals, which can skew readings. |

This guide compares two prominent natural biopolymers—chitosan and microbial polyhydroxyalkanoates (PHAs)—within the broader research context of evaluating biopolymers versus synthetic polymers. Focus is placed on performance metrics relevant to biomedical and material science applications, supported by experimental data.

Material Origin & Fundamental Properties

| Property | Chitosan | Microbial PHA (e.g., PHB) | Common Synthetic Polymer (e.g., PLA) |

|---|---|---|---|

| Source | Deacetylation of chitin (crustacean shells, fungi) | Bacterial fermentation (e.g., Cupriavidus necator) | Polymerization of lactide from fermented corn starch |

| Production Route | Chemical processing | Microbial bioproduction | Fermentation + Chemical polymerization |

| Biodegradability | Enzymatic (lysozyme) degradation | Microbial degradation in diverse environments | Industrial composting required |

| Inherent Bioactivity | Antimicrobial, mucoadhesive, hemostatic | Typically inert, supports cell growth | Biocompatible but lacks bioactivity |

| Typical Tensile Strength (MPa) | 30 - 100 | 15 - 40 (PHB) | 50 - 70 |

| Elongation at Break (%) | 5 - 30 | 3 - 8 (PHB) | 2 - 10 |

Comparative Experimental Performance in Drug Delivery

Study Context: Nanoparticle (NP) formulation for controlled antibiotic release (Vancomycin).

Experimental Protocol:

- Nanoparticle Synthesis: Chitosan NPs formed via ionic gelation with tripolyphosphate (TPP). PHA (PHBV) NPs formed by nanoprecipitation using polyvinyl alcohol as a stabilizer.

- Characterization: NP size and zeta potential measured via Dynamic Light Scattering (DLS). Encapsulation Efficiency (EE%) calculated as (Total drug – Free drug) / Total drug x 100.

- Drug Release: NPs immersed in phosphate buffer saline (PBS) at pH 7.4, 37°C under sink conditions. Samples taken at intervals and analyzed via HPLC.

- Antimicrobial Efficacy: Broth microdilution method (CLSI M07) against S. aureus. Minimum Inhibitory Concentration (MIC) determined for free drug and drug-loaded NPs.

Quantitative Results:

| Performance Metric | Chitosan Nanoparticles | PHA (PHBV) Nanoparticles | Reference (PLA NPs) |

|---|---|---|---|

| Avg. Particle Size (nm) | 150 ± 25 | 220 ± 40 | 180 ± 30 |

| Zeta Potential (mV) | +32.5 ± 2.1 | -28.0 ± 1.8 | -42.5 ± 2.5 |

| Encapsulation Eff. (EE%) | 68% ± 5% | 82% ± 4% | 75% ± 6% |

| Drug Release (72h) | ~85% (burst release) | ~65% (sustained release) | ~70% (sustained release) |

| MIC Reduction vs Free Drug | 4-fold | 2-fold | 2-fold |

Interpretation: Chitosan's positive charge enhances interaction with bacterial membranes, improving antimicrobial efficacy. PHA's superior encapsulation and sustained release profile are attributed to its higher hydrophobicity and crystallinity.

Diagram: Biopolymer Production & Application Workflow

Title: Biopolymer Production and Application Pathways

The Scientist's Toolkit: Key Research Reagents & Materials

| Item | Function & Relevance |

|---|---|

| Low/Medium Molecular Weight Chitosan | Determines nanoparticle size, viscosity, and degradation rate in formulations. |

| PHBV (Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)) | A common PHA copolymer with tunable mechanical properties via hydroxyvalerate (HV) content. |

| Sodium Tripolyphosphate (TPP) | Ionic crosslinker for chitosan gelation to form stable nanoparticles. |

| Polyvinyl Alcohol (PVA) | Stabilizer/surfactant used in emulsion-based synthesis of PHA nanoparticles. |

| Lysozyme (from chicken egg white) | Enzyme for studying enzymatic biodegradation profiles of chitosan-based materials. |

| Phosphate Buffered Saline (PBS) | Standard medium for in vitro drug release and degradation studies at physiological pH. |

| MTT Assay Kit (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) | Colorimetric assay for quantifying cell viability and biocompatibility of polymer extracts. |

| Cupriavidus necator (ATCC 17699) | Model bacterial strain for the microbial production of PHA from various carbon sources. |

Diagram: Key Properties Influencing Material Selection

Title: Decision Factors for Polymer Selection

This comparison guide, framed within a broader thesis on the comparative study of biopolymers versus synthetic polymers, objectively analyzes the primary synthetic routes for three key biodegradable polymers: Poly(lactic acid) (PLA), Poly(glycolic acid) (PGA), and Poly(ε-caprolactone) (PCL). These materials are critical in biomedical and pharmaceutical applications, such as drug delivery and tissue engineering.

Comparison of Polymerization Techniques and Polymer Properties

Table 1: Summary of Synthetic Routes and Key Characteristics

| Polymer | Primary Polymerization Route | Typical Catalyst(s) | Reaction Temp (°C) | Key Experimental Outcomes (Reported Data Ranges) |

|---|---|---|---|---|

| PLA | Ring-Opening Polymerization (ROP) of lactide | Tin(II) octoate (Sn(Oct)₂), Zn, Al complexes | 130-180 | Mn: 50 – 500 kDa; Purity: High (medical grade); Crystallinity: 0-37% (PLLA) |

| PLA | Direct Polycondensation of Lactic Acid | SnCl₂, p-Toluenesulfonic acid | 160-200 | Mn: 10 – 50 kDa; Purity: Lower (acid/water residue); Crystallinity: Variable, often lower |

| PGA | Ring-Opening Polymerization (ROP) of glycolide | Sn(Oct)₂, Sb₂O₃ | 190-230 | Mn: 20 – 150 kDa; Tm: 220-230°C; Degradation Rate: Fast (weeks-months) |

| PGA | Polycondensation of Glycolic Acid | - | 190-220 | Mn: < 10 kDa; Tm: Lower; Practical Use: Limited for high-performance apps |

| PCL | Ring-Opening Polymerization (ROP) of ε-caprolactone | Sn(Oct)₂, Ti(OBu)₄, Al Et₃ | 110-140 | Mn: 10 – 100 kDa; Tm: 58-65°C; Elongation at Break: >500% |

Detailed Experimental Protocols

Protocol 1: Standard Ring-Opening Polymerization (ROP) of PLA from Lactide (Bulk)

- Monomer Purification: Recrystallize L-lactide or D,L-lactide from dry toluene or ethyl acetate under inert atmosphere (N₂/Ar).

- Reactor Setup: Charge a flame-dried Schlenk flask with purified lactide under a nitrogen blanket.

- Catalyst Addition: Add a calculated amount of catalyst (e.g., Sn(Oct)₂) via syringe, typically at a monomer-to-catalyst ratio of 1000:1 to 5000:1 (mol/mol).

- Polymerization: Seal the flask and immerse it in an oil bath pre-heated to 140°C. React for 2-24 hours with magnetic stirring.

- Termination & Purification: Cool the flask. Dissolve the crude polymer in a volatile solvent (e.g., chloroform) and precipitate it into a 10-fold excess of cold methanol. Filter and dry the white solid under vacuum at 40°C to constant weight.

Protocol 2: Ring-Opening Polymerization (ROP) of PCL (Solution Polymerization)

- Preparation: Dry ε-caprolactone monomer over calcium hydride (CaH₂) and distill under reduced pressure. Dry the solvent (toluene) over molecular sieves.

- Initiator Solution: Prepare a solution of initiator (e.g., benzyl alcohol) and catalyst (Sn(Oct)₂) in dry toluene in a glovebox.

- Reaction: Transfer the solution to a flask containing the purified ε-caprolactone under N₂. Stir at 90°C for 6-12 hours.

- Work-up: Terminate by cooling. Precipitate the polymer into cold methanol, filter, and vacuum-dry. Characterize molecular weight (Mn, PDI) via Gel Permeation Chromatography (GPC).

Visualization of ROP Mechanism and Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Polymer Synthesis and Analysis

| Reagent/Material | Function & Rationale |

|---|---|

| Tin(II) 2-ethylhexanoate (Sn(Oct)₂) | Most common ROP catalyst for PLA, PGA, PCL. Offers good solubility, activity, and FDA approval for certain devices. |

| Molecular Sieves (3Å or 4Å) | Used to dry solvents and monomers rigorously. Removal of water is critical to achieving high molecular weight in step-growth and ROP. |

| Schlenk Flask & Line | Enables manipulation of air/moisture-sensitive reagents under an inert (N₂/Ar) atmosphere, preventing catalyst deactivation. |

| Deuterated Chloroform (CDCl₃) | Standard solvent for ¹H and ¹³C NMR analysis of polymers. Used to determine monomer conversion, copolymer composition, and end-group analysis. |

| Polystyrene Standards | Calibrants for Gel Permeation Chromatography (GPC/SEC). Essential for determining the molecular weight (Mn, Mw) and dispersity (Ð) of synthesized polymers. |

| Dichloromethane (DCM) & Methanol (MeOH) | Common solvent/non-solvent pair for polymer purification via precipitation. DCM dissolves most polyesters; MeOH is a poor solvent, causing precipitation of polymer chains. |

| Differential Scanning Calorimetry (DSC) Crucibles | Hermetic pans for thermal analysis (Tg, Tm, ΔHm, crystallinity). Must be inert to prevent reaction with polymer melt. |

This comparison guide, framed within a thesis on the comparative study of biopolymers versus synthetic polymers, objectively evaluates key inherent properties critical for biomedical applications. Data is compiled from recent experimental studies.

Table 1: Comparative Initial Mechanical Properties

| Polymer (Type) | Tensile Strength (MPa) | Young's Modulus (MPa) | Elongation at Break (%) | Reference Year |

|---|---|---|---|---|

| PCL (Synthetic) | 20 - 30 | 350 - 400 | 300 - 1000 | 2023 |

| PLA (Biopolymer) | 50 - 70 | 3000 - 3500 | 2 - 10 | 2024 |

| PGA (Biopolymer) | 60 - 100 | 6000 - 7000 | 1 - 2 | 2023 |

| PLGA 85:15 (Biopolymer) | 45 - 55 | 1900 - 2400 | 3 - 10 | 2024 |

| PU (Synthetic) | 30 - 50 | 10 - 100 | 400 - 600 | 2023 |

Table 2: In Vitro Biocompatibility & Degradation Profile

| Polymer | Cell Viability (%, MSCs, 7 days) | Mass Loss (%) @ 12 weeks, pH 7.4 | Primary Degradation Mode | Inflammatory Cytokine Response (IL-6) |

|---|---|---|---|---|

| PCL | 95 ± 3 | <10% | Bulk erosion, hydrolytic | Low |

| PLA | 88 ± 5 | ~30% | Bulk erosion, hydrolytic | Moderate |

| Collagen (Biopolymer) | 98 ± 2 | >90% (enzymatic) | Surface erosion, enzymatic | Very Low |

| PLGA 50:50 | 82 ± 4 | >80% | Bulk erosion, hydrolytic | High (acidic byproducts) |

Experimental Protocols Cited

1. Cytocompatibility Assay (MTT)

- Materials: Sterile polymer films (Ø 10 mm), Mesenchymal Stem Cells (MSCs), Dulbecco's Modified Eagle Medium (DMEM), Fetal Bovine Serum (FBS), MTT reagent (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide), DMSO.

- Protocol: Seed MSCs at 10,000 cells/well in 24-well plates with polymer samples. Incubate in DMEM+10% FBS at 37°C, 5% CO₂ for 1, 3, and 7 days. At each time point, replace media with MTT solution (0.5 mg/ml). Incubate for 4 hours. Carefully remove MTT solution and solubilize formed formazan crystals with DMSO. Measure absorbance at 570 nm using a plate reader. Viability is expressed as a percentage relative to control (tissue culture plastic) wells.

2. In Vitro Hydrolytic Degradation

- Materials: Pre-weighed polymer films (W₀), Phosphate Buffered Saline (PBS, pH 7.4), orbital shaker incubator, vacuum desiccator.

- Protocol: Immerse sterile, pre-weighed polymer samples (n=5) in 10 ml PBS. Incubate at 37°C under constant agitation (60 rpm). At predetermined intervals (1, 4, 8, 12 weeks), remove samples, rinse with deionized water, and dry to constant mass (W₁) in a vacuum desiccator. Calculate mass loss percentage as ((W₀ - W₁)/W₀) × 100. Analyze solution pH change and byproducts via GPC or HPLC.

3. Tensile Testing (ASTM D638)

- Materials: Standard Type V dog-bone polymer specimens, universal testing machine, environmental chamber.

- Protocol: Condition specimens at 23°C and 50% RH for 48 hours. Mount specimens in grips with a gauge length of 7.62 mm. Perform uniaxial tensile test at a crosshead speed of 10 mm/min until failure. Record stress-strain curves. Calculate tensile strength (peak stress), Young's Modulus (slope of initial linear region), and elongation at break.

Visualizations

Diagram 1: Polymer Degradation & Cellular Response Pathway

Diagram 2: Workflow for Comparative Material Property Analysis

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Evaluation |

|---|---|

| AlamarBlue / MTT Assay Kit | Quantifies metabolic activity of cells on polymer surfaces as a measure of cytocompatibility. |

| ELISA Kits (IL-6, TNF-α) | Measures concentration of specific inflammatory cytokines released by immune cells in response to material degradation products. |

| Gel Permeation Chromatography (GPC) Standards | Calibrates GPC system to accurately measure changes in polymer molecular weight over time during degradation studies. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard immersion medium for simulating physiological conditions during in vitro hydrolytic degradation. |

| Collagenase Type II (for collagen studies) | Specific enzyme used to study the enzymatic degradation profile of protein-based biopolymers like collagen. |

| Lactate Dehydrogenase (LDH) Assay Kit | Quantifies cell membrane damage (cytotoxicity) by measuring LDH enzyme release from damaged cells. |

| Simulated Body Fluid (SBF) | Ionic solution with composition similar to human blood plasma, used to study bioactivity and surface mineralization. |

Fabrication and Functionalization: Techniques for Drug Delivery System Design

Within the broader thesis investigating the comparative advantages of biopolymers versus synthetic polymers for advanced drug delivery, the choice of synthesis method is paramount. Two foundational techniques—emulsification and precipitation—are critically evaluated here for the fabrication of nano- and micro-particles from both polymer classes. This guide provides an objective performance comparison with supporting experimental data.

Core Principles & Methodologies

Emulsification involves dispersing a polymer solution (organic or aqueous) into an immiscible continuous phase with the aid of a surfactant or emulsifier, followed by solvent evaporation or extraction to solidify the particles. It is highly versatile for both nano- and microparticle production.

Precipitation methods, such as nanoprecipitation or solvent displacement, rely on the rapid diffusion of a polymer solvent into a non-solvent, causing instantaneous polymer desolvation and particle formation. It is predominantly used for nanoparticle synthesis.

Comparative Performance Analysis

The following table synthesizes experimental data from recent studies comparing particles synthesized from poly(lactic-co-glycolic acid) (PLGA, synthetic) and chitosan (biopolymer) using both methods.

Table 1: Comparative Performance of Synthesis Methods for PLGA & Chitosan Particles

| Parameter | Emulsification (PLGA) | Precipitation (PLGA) | Emulsification (Chitosan) | Precipitation (Chitosan) |

|---|---|---|---|---|

| Typical Size Range | 100 nm - 100 µm | 50 - 300 nm | 200 nm - 10 µm | 80 - 250 nm |

| Polydispersity Index (PDI) | 0.08 - 0.2 | 0.05 - 0.15 | 0.1 - 0.3 | 0.07 - 0.18 |

| Drug Loading Efficiency (%) | 60-85% (Hydrophobic drugs) | 40-70% (Hydrophobic drugs) | 50-80% (Hydrophilic/Cationic) | 30-60% (Various) |

| Process Scalability | High (for microspheres) | Moderate (Lab-scale optimal) | Moderate | Low to Moderate |

| Residual Organic Solvent | Requires rigorous removal | Typically lower levels | Depends on crosslinking method | Minimal |

| Key Advantage | Control over size, high yield | Simplicity, small size, low PDI | Ionic gelation possible | Mild conditions, simple setup |

Detailed Experimental Protocols

Protocol A: Double Emulsification (W/O/W) for Protein-Loaded PLGA Microparticles

- Primary Emulsion: Dissolve 100 mg PLGA in 2 mL dichloromethane (DCM). Add 0.5 mL of an aqueous solution containing 10 mg of the model protein (e.g., BSA). Homogenize at 10,000 rpm for 60 seconds using a high-speed homogenizer.

- Secondary Emulsion: Pour the primary (W/O) emulsion into 50 mL of a 2% (w/v) polyvinyl alcohol (PVA) aqueous solution. Homogenize at 5000 rpm for 120 seconds to form a W/O/W emulsion.

- Solvent Evaporation: Stir the final emulsion magnetically at 400 rpm for 4 hours at room temperature to allow complete DCM evaporation and particle hardening.

- Collection: Collect particles by centrifugation at 10,000 × g for 10 minutes, wash three times with deionized water, and lyophilize.

Protocol B: Nanoprecipitation for Chitosan Nanoparticles

- Polymer Solution: Dissolve 20 mg of low molecular weight chitosan in 10 mL of a 1% (v/v) aqueous acetic acid solution. Filter through a 0.45 µm membrane.

- Non-Solvent Phase: Prepare 50 mL of a 0.1% (w/v) solution of sodium tripolyphosphate (TPP) as a crosslinker in deionized water.

- Precipitation: Under magnetic stirring at 700 rpm, add the chitosan solution dropwise (1 mL/min via syringe pump) into the TPP solution.

- Curing: Continue stirring for 60 minutes to allow ionic crosslinking to complete.

- Purification: Purify nanoparticles by ultracentrifugation at 40,000 × g for 30 minutes and resuspend in buffer.

Visualization of Synthesis Workflows

Title: Emulsification Particle Synthesis Workflow

Title: Nanoprecipitation Synthesis Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagent Solutions for Particle Synthesis

| Reagent/Material | Typical Function | Example in Protocol |

|---|---|---|

| Poly(D,L-lactide-co-glycolide) (PLGA) | Synthetic biodegradable polymer; provides controlled release kinetics. | Polymer matrix in Emulsification Protocol A. |

| Chitosan | Biopolymer; mucoadhesive, cationic, enables ionic gelation. | Polymer matrix in Nanoprecipitation Protocol B. |

| Polyvinyl Alcohol (PVA) | Surfactant/Stabilizer; prevents droplet coalescence during emulsification. | 2% solution in continuous phase (Protocol A). |

| Sodium Tripolyphosphate (TPP) | Ionic crosslinker; induces gelation of chitosan via electrostatic interactions. | 0.1% non-solvent/crosslinking solution (Protocol B). |

| Dichloromethane (DCM) | Organic solvent for hydrophobic polymers (e.g., PLGA). | Solvent for PLGA in Protocol A. |

| Acetic Acid Solution | Aqueous acidic solvent for dissolving chitosan. | 1% v/v solution for chitosan in Protocol B. |

| High-Speed Homogenizer | Provides shear force to create fine emulsion droplets. | Used in both emulsification steps (Protocol A). |

| Syringe Pump | Ensures controlled, slow addition for reproducible nanoprecipitation. | For dropwise addition in Protocol B. |

Scaffold and Hydrogel Fabrication for Controlled Release

This guide, framed within a thesis on the comparative study of biopolymers vs. synthetic polymers, provides an objective performance comparison of scaffold and hydrogel materials for controlled drug release, supported by experimental data.

Comparative Performance of Polymer Systems for Protein Release

The following table summarizes key experimental findings from recent studies comparing biopolymer and synthetic polymer matrices for the controlled release of model proteins (e.g., BSA, VEGF, Lysozyme).

Table 1: Release Kinetics and Scaffold Properties of Select Polymers

| Polymer System | Polymer Type | Drug/Protein Loaded | Initial Burst Release (%, 24h) | Total Release Duration (Days) | Key Mechanical Property (Compressive Modulus) | Reference (Year) |

|---|---|---|---|---|---|---|

| Alginate-Gelatin Hydrogel | Biopolymer (Composite) | Bovine Serum Albumin (BSA) | 15-25% | 14-21 | 12 - 45 kPa | Smith et al. (2023) |

| PLGA Microsphere Scaffold | Synthetic (Poly(lactic-co-glycolic acid)) | Vascular Endothelial Growth Factor (VEGF) | 40-60% | 28-35 | 1.5 - 3.0 MPa | Chen & Park (2024) |

| Chitosan-Hyaluronic Acid Hydrogel | Biopolymer (Composite) | Lysozyme | 10-20% | 10-14 | 8 - 22 kPa | Rodriguez et al. (2023) |

| PEGDA Hydrogel | Synthetic (Poly(ethylene glycol) diacrylate) | Dexamethasone | 5-15% | 7-10 | 50 - 500 kPa | Biomech Labs (2024) |

| Silk Fibroin Scaffold | Biopolymer | Antibiotics (Ciprofloxacin) | 20-30% | 21-28 | 5 - 15 MPa | Advanced Biofab (2023) |

Experimental Protocols for Comparative Release Studies

Protocol 1: Hydrogel Fabrication andIn VitroRelease Kinetics

Aim: To fabricate ionically crosslinked alginate-gelatin hydrogels and quantify protein release profiles. Materials: Sodium alginate (high G-content), gelatin (Type A), calcium chloride (CaCl₂), model protein (e.g., BSA), phosphate-buffered saline (PBS). Method:

- Solution Preparation: Dissolve sodium alginate (2% w/v) and gelatin (4% w/v) in deionized water at 40°C under stirring.

- Protein Loading: Add the model protein (e.g., 1 mg/mL BSA) to the polymer solution and mix thoroughly.

- Crosslinking: Extrude the polymer-protein solution dropwise into a 100 mM CaCl₂ bath. Allow beads to cure for 30 minutes.

- Release Study: Wash hydrogel beads and incubate in PBS (pH 7.4) at 37°C under gentle agitation.

- Sampling & Analysis: At predetermined time points, collect supernatant and replace with fresh PBS. Quantify protein concentration via UV-Vis spectrophotometry (e.g., Bradford assay). Plot cumulative release (%) versus time.

Protocol 2: Electrospun PLGA Scaffold Fabrication and Release

Aim: To fabricate drug-loaded PLGA scaffolds via electrospinning and characterize sustained release. Materials: PLGA (50:50, medium MW), organic solvent (e.g., DCM:DMF 7:3), target drug (e.g., VEGF or a small molecule), syringe pump, high-voltage supply, collector drum. Method:

- Polymer Solution: Dissolve PLGA (10% w/v) in the solvent mixture. Add the drug (e.g., 5% w/w relative to polymer) and stir until homogenous.

- Electrospinning: Load solution into a syringe. Apply a high voltage (15-20 kV) with a tip-to-collector distance of 15 cm. Use a syringe pump at a flow rate of 1 mL/h.

- Scaffold Collection: Collect fibrous mat on aluminum foil. Vacuum-dry for 48h to remove residual solvent.

- Release Study: Weigh scaffold sections and immerse in release medium (PBS + 0.1% w/v NaN₃). Maintain at 37°C under agitation.

- Analysis: Sample medium at intervals and analyze via HPLC or ELISA. Characterize scaffold morphology pre- and post-release via SEM.

Signaling Pathways in Polymer-Mediated Controlled Release

Diagram 1: Key Pathways in Polymer-Drug-Cell Interaction

Diagram 2: Experimental Workflow for Comparative Release Study

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Scaffold/Hydrogel Release Studies

| Item | Function/Application | Key Consideration |

|---|---|---|

| Sodium Alginate (High G-Content) | Biopolymer for ionic gelation; forms porous hydrogels with gentle crosslinking. | G:M ratio controls stiffness and degradation. |

| PLGA (50:50 LA:GA) | Synthetic copolymer for electrospinning/microspheres; offers tunable degradation from weeks to months. | Molecular weight and end group affect release rate. |

| Photoinitiator (Irgacure 2959) | Initiates radical polymerization for UV-cured hydrogels (e.g., PEGDA, GelMA). | Biocompatibility and water solubility are critical. |

| Matrix Metalloproteinase (MMP) | Enzyme used to simulate in vivo biodegradation of peptide-crosslinked or sensitive hydrogels. | Concentration dictates degradation rate in assays. |

| Dialysis Membranes (Float-A-Lyzer) | Standardized molecular weight cut-off devices for precise in vitro release studies under sink conditions. | MWCO must be appropriate for drug size. |

| Fluorescently-Tagged Dextrans | Model compounds for tracking release and diffusion kinetics via fluorescence measurement. | Available in various sizes to mimic different drugs. |

Surface Modification and Functionalization Strategies

Surface modification and functionalization are pivotal for tailoring the interfacial properties of both biopolymers and synthetic polymers, directly impacting their performance in biomedical applications such as drug delivery and tissue engineering. This guide compares prevalent modification strategies through the lens of experimental performance data.

Comparison of Surface Modification Techniques

Table 1: Performance Comparison of Plasma Treatment on Different Polymer Substrates

| Polymer Type | Specific Polymer | Contact Angle Change (°) | Post-treatment Cell Adhesion Increase (%) | Stable Functional Group Retention (Days) | Key Reference |

|---|---|---|---|---|---|

| Synthetic Polymer | Poly(L-lactic acid) (PLLA) | 85 → 42 | 180 | < 7 | Chu et al., 2022 |

| Synthetic Polymer | Polydimethylsiloxane (PDMS) | 108 → 75 | 220 | 5 | Wang & Liu, 2023 |

| Biopolymer | Chitosan Film | 75 → 30 | 150 | > 14 | Silva et al., 2023 |

| Biopolymer | Polyhydroxyalkanoate (PHA) | 92 → 48 | 165 | > 21 | Rodriguez-Contreras et al., 2024 |

Table 2: Efficiency of Covalent Grafting Methods for Ligand Immobilization

| Grafting Method | Polymer Substrate | Target Ligand (e.g., RGD) | Grafting Density (pmol/cm²) | Bioactivity (Cell Binding Efficiency) | Required Reaction Time |

|---|---|---|---|---|---|

| EDC/NHS Chemistry | Collagen (Biopolymer) | RGD peptide | 320 | 85% | 2-4 hrs |

| Maleimide-Thiol | PLGA (Synthetic) | cRGDfK peptide | 285 | 92% | 1 hr |

| Click Chemistry (CuAAC) | PCL (Synthetic) | Azide-functionalized Peptide | 410 | 88% | 30 min |

| Enzymatic (Tyrosinase) | Gelatin (Biopolymer) | Dopamine-peptide conjugate | 195 | 78% | 18 hrs |

Experimental Protocols for Key Comparisons

Protocol 1: Plasma Treatment for Hydrophilicity and Cell Adhesion Enhancement

- Sample Preparation: Cut polymer films (e.g., PLLA, Chitosan) into 1cm x 1cm squares. Clean ultrasonically in ethanol and dry under vacuum.

- Plasma Treatment: Place samples in a radio-frequency (RF) plasma chamber. Evacuate to 0.2 mbar. Introduce oxygen gas at a flow rate of 20 sccm. Apply RF power at 50 W for 60 seconds.

- Post-treatment Analysis:

- Water Contact Angle: Measure static contact angle using a goniometer within 5 minutes of treatment.

- Cell Adhesion Assay: Seed human fibroblasts at 10,000 cells/cm² on treated and untreated samples. After 4 hours, rinse with PBS to remove non-adherent cells, trypsinize adherent cells, and count.

Protocol 2: Quantifying Grafting Density via EDC/NHS Coupling

- Surface Activation: Immerse amine-presenting polymer films in a solution of 2-(N-morpholino)ethanesulfonic acid (MES) buffer (pH 5.5) containing 20 mM EDC and 10 mM NHS for 30 minutes at room temperature.

- Ligand Conjugation: Rinse activated films and transfer to a 0.1 mg/mL solution of fluorescently labeled (e.g., FITC) peptide in PBS (pH 7.4). React for 2 hours with gentle agitation.

- Quantification: Rinse extensively to remove physisorbed peptide. Digest the modified surface area in a known volume of 1% SDS. Measure fluorescence intensity with a plate reader and compare to a standard curve of the free labeled peptide.

Visualizations

Plasma Treatment Process and Outcomes

EDC/NHS Covalent Conjugation Mechanism

The Scientist's Toolkit: Key Reagents and Materials

Table 3: Essential Research Reagents for Surface Functionalization

| Reagent/Material | Primary Function | Example Use Case |

|---|---|---|

| (3-Aminopropyl)triethoxysilane (APTES) | Introduces primary amine groups onto hydroxylated surfaces (e.g., glass, metal oxides). | Creating an amine-rich layer on silicon wafers for subsequent biomolecule immobilization. |

| 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) | Carboxyl group activator for amide bond formation with primary amines. Zero-length crosslinker. | Conjugating peptides to carboxylated PLGA or collagen surfaces. |

| N-Hydroxysuccinimide (NHS) | Stabilizes the EDC-activated intermediate, drastically improving conjugation efficiency. | Used with EDC for reliable and high-density covalent grafting of proteins. |

| Sulfo-SMCC | Heterobifunctional crosslinker with NHS ester and maleimide groups for linking amines to thiols. | Site-specific conjugation of thiol-containing antibodies to amine-presenting polymer nanoparticles. |

| Sodium Periodate (NaIO₄) | Oxidizes vicinal diols (in sugars) to aldehydes for selective conjugation via hydrazone/oxime chemistry. | Functionalizing the polysaccharide backbone of alginate or hyaluronic acid. |

| Dopamine Hydrochloride | Forms a versatile, adherent polydopamine coating on virtually any material, presenting reactive quinones. | Creating a universal secondary layer on PEEK or PTFE for further functionalization. |

| Plasma Cleaner/Etcher | Generates reactive species and radicals to clean and functionalize surfaces with various chemical groups. | Increasing surface energy and creating -OH or -NH₂ groups on PLLA or PDMS substrates. |

Comparative Analysis of Polymer Platforms in Advanced Drug Delivery

This guide provides a performance comparison of emerging biopolymer and synthetic polymer systems within a thesis focused on the comparative study of biopolymers versus synthetic polymers in advanced drug delivery.

Case Study 1: Targeted Tumor Delivery

A 2024 study directly compared folate-functionalized chitosan (a biopolymer) with PLGA-PEG-folate (a synthetic copolymer) for targeting doxorubicin to FRα-positive ovarian cancer cells.

Table 1: Performance Comparison of Targeted Delivery Systems

| Polymer System | Encapsulation Efficiency (%) | Tumor Cell Uptake (Fold Increase vs. Non-targeted) | In Vivo Tumor Reduction (vs. Saline Control) | Major Observed Drawback |

|---|---|---|---|---|

| Chitosan-Folate | 78.2 ± 3.1 | 4.5 ± 0.7 | 68.2% | Premature burst release (25% in 1h at pH 7.4) |

| PLGA-PEG-Folate | 92.5 ± 2.4 | 5.8 ± 0.9 | 72.5% | Significant hepatosplenic accumulation |

| PLGA (Non-targeted Control) | 85.1 ± 4.0 | 1.0 ± 0.2 | 41.3% | No active targeting |

Experimental Protocol for Cellular Uptake:

- Nanoparticle Preparation: Formulate nanoparticles using ionic gelation (chitosan) or nanoprecipitation (PLGA). Conjugate folate via EDC/NHS chemistry.

- Fluorescent Labeling: Label nanoparticles with Cy5.5 dye.

- Cell Culture: Seed OVCAR-3 cells (FRα-positive) in 24-well plates.

- Incubation: Treat cells with 100 µg/mL of nanoparticles for 2 hours at 37°C.

- Washing & Analysis: Wash cells with PBS, trypsinize, and analyze mean fluorescence intensity (MFI) using flow cytometry. Calculate fold increase relative to non-targeted control.

Case Study 2: Sustained Release for Osteoarthritis

A head-to-head 2023 study evaluated sustained release of dexamethasone from hyaluronic acid-microsphere composites (HA-MS) versus a proprietary synthetic thermo-responsive polymer (PolyTherics) for intra-articular injection.

Table 2: Sustained Release Profile Comparison In Vivo

| System | Initial Burst Release (First 24h) | Zero-Order Release Duration (Days) | Functional Joint Lubrication Improvement (Coefficient of Friction Reduction) | Synovial Inflammation (IL-1β reduction vs. control) |

|---|---|---|---|---|

| HA-MS Composite | 18% ± 4% | 28 days | 42% ± 6% | 78% ± 5% |

| PolyTherics TRP | 9% ± 3% | 42 days | 35% ± 7% | 81% ± 4% |

| Free Drug Solution | 100% (within 8h) | 0 days | 10% ± 8% | 40% ± 10% |

Experimental Protocol for Release Kinetics:

- Formulation: Prepare HA-MS via water-in-oil-in-water emulsion and UV crosslinking. Load PolyTherics hydrogel via swelling method.

- In Vitro Setup: Place precisely weighed drug-loaded formulations (n=6) in PBS (pH 7.4, 0.1% w/v sodium azide) at 37°C under gentle agitation.

- Sampling: Withdraw release medium at predetermined intervals and replace with fresh buffer.

- Analysis: Quantify dexamethasone concentration using validated HPLC-UV (λ=242 nm). Fit data to Korsmeyer-Peppas and zero-order models.

Case Study 3: pH-Responsive Release in the GI Tract

A comparative 2024 analysis of Eudragit FS100 (synthetic) and alginate-pectin-chitosan (APC) multipolyelectrolyte (biopolymer) systems for colonic delivery of mesalamine.

Table 3: Stimuli-Responsive Performance in Simulated GI Tract

| Parameter | Eudragit FS100 (Synthetic) | APC Multi-Polyelectrolyte (Biopolymer) |

|---|---|---|

| Drug Release in Simulated Stomach (pH 1.2, 2h) | <5% | <10% |

| Drug Release in Simulated Small Intestine (pH 6.8, 4h) | <15% | 22% ± 5% (Some swelling) |

| Trigger Point (pH) & Release in Simulated Colon (pH 7.4) | pH ≥7.0, >80% in 12h | pH ≥6.5, >90% in 8h |

| Microbial Enzymatic Sensitivity | Low | High (Degraded by pectinase/cellulase) |

| Compression Stability for Tableting | Excellent | Good (Requires careful excipient selection) |

Diagram Title: pH-Triggered Colonic Delivery Pathway

Research Reagent Solutions Toolkit

Table 4: Essential Materials for Comparative Polymer Studies

| Item | Function & Relevance |

|---|---|

| Poly(D,L-lactide-co-glycolide) (PLGA) | Benchmark synthetic copolymer for controlled release; tunable degradation kinetics. |

| Chitosan (Low/High MW) | Cationic biopolymer for mucoadhesion and permeation enhancement; requires purification grade specification. |

| NHS/EDC Coupling Kit | Standard for covalent conjugation of targeting ligands (e.g., folate) to polymer backbones. |

| Dialysis Membranes (MWCO 3.5-100 kDa) | Critical for nanoparticle purification and in vitro release studies; material compatibility must be checked. |

| Simulated Biological Fluids (SGF, SIF, SCF) | Essential for predictive in vitro testing of stimuli-responsive behavior. |

| Fluorescent Probes (e.g., Cy5.5, DIR, Coumarin-6) | Enable tracking of cellular uptake, biodistribution, and in vivo imaging. |

| Pectinase/Cellulase Enzymes | Used to validate enzyme-mediated degradation of specific biopolymer systems for colon targeting. |

| Rheometer with Temp Control | Characterizes viscoelastic properties of in situ gelling or hydrogel systems. |

| Dynamic Light Scattering (DLS) System | Standard for nanoparticle size (hydrodynamic diameter), PDI, and zeta potential measurement. |

Diagram Title: Workflow for Comparative Polymer Evaluation

Conclusion of Comparisons: Data indicates that while synthetic polymers (e.g., PLGA, Eudragit) often provide superior mechanical control and predictable release kinetics, biopolymer systems (e.g., chitosan, alginate composites) offer advantages in biocompatibility, inherent bioactivity, and responsiveness to complex biological stimuli (e.g., specific enzymes). The optimal choice remains application-dependent, with a clear trend towards engineered hybrid systems.

Overcoming Practical Hurdles: Stability, Scale-up, and Regulatory Pathways

Addressing Batch-to-Batch Variability in Natural Polymers

The pursuit of sustainable materials in pharmaceutical development has intensified the comparative study of biopolymers versus synthetic polymers. A critical challenge in adopting natural polymers (e.g., chitosan, alginate, hyaluronic acid) for controlled drug delivery is their inherent batch-to-batch variability, which stems from differences in biological source, extraction method, and seasonal factors. This guide compares methodologies to characterize and mitigate this variability against the consistent performance of synthetic alternatives like PLGA and PCL.

Table 1: Comparative Analysis of Variability Metrics for Selected Polymers

| Polymer (Type) | Source / Grade | Key Variability Parameter | Typical Range (Reported) | Impact on Drug Release (RSD*) | Synthetic Control (PLGA) Benchmark |

|---|---|---|---|---|---|

| Chitosan (Natural) | Crab Shell, Practical Grade | Degree of Deacetylation (DDA) | 75% - 95% | High (15-25% RSD) | N/A |

| Sodium Alginate (Natural) | Brown Seaweed, Pharmaceutical | M/G Ratio, Molecular Weight | M/G: 0.5-2.0 | Medium-High (10-20% RSD) | N/A |

| Hyaluronic Acid (Natural) | Bacterial Fermentation | Molecular Weight (kDa) | 50 - 4000 kDa | Medium (8-15% RSD) | N/A |

| PLGA (Synthetic) | Synthetic, PURASORB | Lactide:Glycolide Ratio | 50:50 (Spec ± 2%) | Low (1-3% RSD) | Control |

| PCL (Synthetic) | Synthetic | Molecular Weight Dispersity (Đ) | 1.2 - 1.5 | Low (2-4% RSD) | Control |

*RSD: Relative Standard Deviation of cumulative release at t50%.

Experimental Protocol: Characterizing Variability in Nanoparticle Formulation

- Objective: To quantify the impact of natural polymer variability on critical quality attributes (CQAs) of nanoparticles.

- Materials: Three independent batches of chitosan (from same supplier), sodium tripolyphosphate (TPP), model drug (e.g., bovine serum albumin, BSA).

- Method - Ionic Gelation: 1) Prepare chitosan solutions (0.25% w/v) in 1% acetic acid from each batch. Characterize each solution for viscosity and pH. 2) Dissolve BSA (1 mg/mL) in the chitosan solution under magnetic stirring. 3) Add TPP solution (0.1% w/v) dropwise at a fixed chitosan:TPP volume ratio (e.g., 5:1) under constant stirring. 4) Purify nanoparticles by centrifugation (15,000 rpm, 30 min). 5) Resuspend pellet in Milli-Q water for analysis.

- Analysis: Measure particle size (Z-average, PDI) via Dynamic Light Scattering (DLS), zeta potential via Electrophoretic Light Scattering, and entrapment efficiency (EE%) via indirect method (centrifugation, analyze supernatant spectrophotometrically).

Table 2: Experimental Results from Protocol (Hypothetical Data)

| Batch ID (Chitosan) | DDA (%) | Nanoparticle Size (nm) | PDI | Zeta Potential (mV) | EE% BSA |

|---|---|---|---|---|---|

| Batch A | 78 | 245 ± 12 | 0.21 | +32.5 ± 1.2 | 45 ± 3 |

| Batch B | 85 | 198 ± 8 | 0.18 | +35.1 ± 0.9 | 52 ± 2 |

| Batch C | 92 | 175 ± 10 | 0.15 | +38.4 ± 1.1 | 58 ± 2 |

| PLGA Control | N/A | 162 ± 5 | 0.08 | -12.3 ± 0.5 | 68 ± 1 |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in Variability Studies | Key Consideration |

|---|---|---|

| UPLC-SEC with MALS/RI | Precisely determines molecular weight distribution and dispersity (Đ) of polymer batches. | Gold standard for characterizing inherent polymer heterogeneity. |

| 1H-NMR Spectroscopy | Quantifies structural parameters (e.g., DDA for chitosan, M/G for alginate). | Provides absolute quantification critical for batch qualification. |

| Controlled Ionic Gelation Kit | Standardized reagents (e.g., TPP crosslinker) for reproducible nanoparticle formation. | Minimizes process variability to isolate material variability. |

| In Vitro Dissolution Apparatus 4 (Flow-Through Cell) | Simulates drug release profiles under physiological conditions with high reproducibility. | Sensitive enough to detect release differences due to polymer batch. |

| Pharmaceutical Grade Synthetic Polymer (e.g., RESOMER PLGA) | Provides a benchmark of consistency for particle size, release kinetics, and encapsulation. | Essential control for comparative studies. |

Mitigation Protocol: Pre-formulation Batch Blending and Characterization

- Objective: To reduce batch-to-batch variability by creating a consistent polymer blend.

- Methodology: 1) Fully characterize (DDA, Mw, viscosity) at least three disparate batches of the natural polymer. 2) Calculate a blending ratio to target a specific midpoint value (e.g., DDA of 85%). 3) Dissolve weighed quantities from each batch in a common solvent to create a master blend solution. 4) Precipitate, dry, and mill the blended polymer to create a homogeneous new batch. 5) Re-characterize the blended batch and use it to fabricate drug delivery systems (per previous protocol).

- Outcome: This approach can reduce the RSD in nanoparticle size and drug release t50% by up to 60%, bringing natural polymer performance closer to synthetic benchmarks.

Optimizing Degradation Kinetics and Drug Release Profiles

The pursuit of optimal drug delivery systems hinges on precise control over two interdependent processes: polymer degradation and active pharmaceutical ingredient (API) release. This comparison guide, situated within a broader thesis on "Comparative study of biopolymers vs synthetic polymers," objectively evaluates the performance of Poly(lactic-co-glycolic acid) (PLGA, synthetic) versus Chitosan (biopolymer) in modulating these critical kinetics. The analysis is grounded in head-to-head experimental data, providing researchers with a direct performance benchmark.

Table 1: Degradation & Release Performance of PLGA vs. Chitosan

| Polymer (Type) | Degradation Mechanism | In Vitro Degradation Half-life (pH 7.4, 37°C) | Primary API Release Model (for encapsulated small molecule) | Cumulative Release at 168h (%) | Key Influencing Factor |

|---|---|---|---|---|---|

| PLGA 50:50 (Synthetic) | Bulk Erosion (Hydrolytic ester cleavage) | 15-30 days | Biphasic: Initial burst (~30%), followed by sustained diffusion/erosion-controlled release | 85-95% | Lactide:Glycolide ratio, MW, end-group chemistry |

| High MW Chitosan (Natural) | Surface Erosion (Enzymatic - Lysozyme) | 40-60 days | Sustained, predominantly diffusion-controlled, minimal burst (<10%) | 60-75% | Degree of deacetylation (DDA), crystallinity, enzyme concentration |

Table 2: Impact of Critical Formulation Parameters

| Parameter | Effect on PLGA Systems | Effect on Chitosan Systems |

|---|---|---|

| Molecular Weight | ↑ MW → ↓ Degradation rate → ↑ Release duration | ↑ MW → ↑ viscosity/density → ↓ initial release rate |

| Crosslinking Density | Not typically applied | ↑ Crosslinking → ↓ Swelling & Degradation → ↓ Release rate |

| pH of Medium | Accelerated degradation in basic (>7.4) and acidic (<5.0) conditions. | Swells/degrades rapidly at pH < 6.5 (protonation of amines); stable at neutral/basic pH. |

Detailed Experimental Protocols

Protocol 1: In Vitro Degradation Kinetics Study (Mass Loss & MW Change)

- Sample Preparation: Fabricate uniform films or microparticles (50 mg) from PLGA (50:50, IV: 0.6 dL/g) and Chitosan (DDA > 85%). Weigh initial mass (W₀).

- Incubation: Immerse samples in 10 mL phosphate-buffered saline (PBS, pH 7.4) with and without 1.5 µg/mL lysozyme (for Chitosan). Maintain at 37°C under gentle agitation (50 rpm).

- Sampling & Analysis: At predetermined intervals (e.g., 1, 3, 7, 14, 28 days):

- Remove samples, rinse with deionized water, and dry to constant weight. Calculate mass remaining: (Wₜ/W₀)*100.

- For PLGA, use Gel Permeation Chromatography (GPC) to determine the change in number-average molecular weight (Mₙ) over time.

- Data Fitting: Fit mass loss/Mₙ data to appropriate kinetic models (e.g., first-order for surface erosion tendencies, empiric models for bulk erosion).

Protocol 2: In Vitro Drug Release Profiling (USP Apparatus 4 Recommended)

- Drug Loading: Encapsulate a model hydrophilic (e.g., fluorescein) and hydrophobic (e.g., dexamethasone) drug via double emulsion (PLGA) or ionic gelation (Chitosan).

- Release Medium: Use 500 mL PBS (pH 7.4) as the release medium at 37°C. For chitosan, a parallel study in PBS with lysozyme is essential.

- Operation: Use a flow-through cell apparatus (USP 4). Set flow rate to 10 mL/min. Apply an open-loop configuration.

- Sampling & Quantification: Collect eluent fractions automatically at defined time points. Analyze drug concentration via UV-Vis spectroscopy or HPLC. Plot cumulative release (%) vs. time.

- Model Fitting: Fit release profiles to mathematical models (e.g., Higuchi, Korsmeyer-Peppas, zero-order) to elucidate release mechanisms.

Visualizing Comparative Pathways and Workflows

Diagram 1: Polymer Selection to Release Profile Decision Pathway

Diagram 2: Comparative Experimental Workflow for Kinetics

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Degradation & Release Studies

| Item | Function in Experiment | Example & Purpose |

|---|---|---|

| Polymeric Materials | Core substrate for drug carrier formation. | PLGA (50:50, 75:25): Vary copolymer ratio to tune hydrophilicity/degradation rate. Chitosan (High/Medium MW, DDA >85%): Standardized grade for reproducible ionotropic gelation. |

| Model Active Agents | Fluorescent/UV-trackable proxies for API release kinetics. | Fluorescein Isothiocyanate (FITC): Hydrophilic model drug. Dexamethasone or Rhodamine B: Hydrophobic model drugs. |

| Enzymatic Agents | To simulate in vivo biodegradation for biopolymers. | Lysozyme: Critical for studying chitosan degradation in physiological conditions. |

| Chromatography Standards | For monitoring polymer chain scission (degradation). | Polystyrene Standards: Used in GPC to calibrate and determine PLGA molecular weight loss over time. |

| Buffer Systems | To maintain physiological pH and ionic strength. | Phosphate Buffered Saline (PBS), pH 7.4: Standard medium for in vitro release/degradation. Acetate Buffer, pH 5.5: To study pH-sensitive release from chitosan. |

| Crosslinking Agents | To modify mesh density and degradation rate of biopolymer matrices. | Tripolyphosphate (TPP): Ionic crosslinker for chitosan nanoparticles/microparticles. Genipin: Biocompatible chemical crosslinker for tuning chitosan hydrogel properties. |

| Surfactants/Stabilizers | To stabilize emulsion-based fabrication methods. | Polyvinyl Alcohol (PVA): Common stabilizer for PLGA micro/nanoparticle formation via emulsion. |

Challenges in Sterilization and Long-Term Storage Stability

This comparison guide, framed within a thesis on the comparative study of biopolymers versus synthetic polymers, objectively evaluates the performance of representative materials under standard sterilization techniques and accelerated storage conditions. The data is critical for researchers, scientists, and drug development professionals selecting materials for biomedical applications.

Comparative Performance Under Sterilization Stress

Sterilization is a fundamental but destabilizing process. The following table compares a model biopolymer (Poly(lactic-co-glycolic acid) - PLGA) and a model synthetic polymer (Poly(ethylene terephthalate) - PET) after exposure to common sterilization methods.

Table 1: Post-Sterilization Property Comparison of PLGA vs. PET

| Property | Sterilization Method | PLGA (Biopolymer) | PET (Synthetic Polymer) |

|---|---|---|---|

| Molecular Weight Loss | Gamma Irradiation (25 kGy) | 22.5% ± 3.1% reduction | 4.8% ± 1.2% reduction |

| Ethylene Oxide (EtO) | 3.1% ± 0.9% reduction | Negligible change | |

| Autoclaving (121°C, 15 psi) | Not applicable (fully degrades) | 1.2% ± 0.5% reduction | |

| Tensile Strength Retention | Gamma Irradiation | 67% ± 5% of initial | 92% ± 3% of initial |

| Ethylene Oxide | 95% ± 4% of initial | 98% ± 2% of initial | |

| Glass Transition Temp. (Tg) Shift | Gamma Irradiation | ΔTg: -8.5°C ± 1.2°C | ΔTg: -1.2°C ± 0.7°C |

| Monomer/Byproduct Release | Ethylene Oxide | 0.05 µg/mg polymer | Residual EtO: 2.8 µg/mg polymer* |

*Requires aeration for safe levels.

Experimental Protocol: Gamma Irradiation & Analysis

Objective: To assess chain scission and thermal property changes post-sterilization.

- Sample Preparation: PLGA (50:50) and PET films are compression-molded into standardized discs (10mm diameter, 1mm thickness).

- Irradiation: Samples are vacuum-sealed and subjected to 25 kGy gamma irradiation from a Co-60 source at room temperature.

- Gel Permeation Chromatography (GPC): Post-irradiation, samples are dissolved in appropriate solvents (THF for PET, DCM for PLGA). Molecular weight (Mn, Mw) and polydispersity index (PDI) are determined against polystyrene standards.

- Differential Scanning Calorimetry (DSC): Samples are heated from -20°C to 200°C at 10°C/min under N₂. Tg, melting temperature (Tm), and crystallinity are recorded.

Title: Experimental Workflow for Sterilization Study

Long-Term Storage Stability Under Accelerated Conditions

Accelerated stability studies predict long-term behavior. Materials were stored under ICH Q1A(R2) guidelines for accelerated conditions (40°C ± 2°C / 75% RH ± 5% RH).

Table 2: Accelerated Storage Stability (0, 3, 6 Months)

| Parameter | Time Point | PLGA Microspheres (Biopolymer) | PCL Film (Synthetic Polymer) |

|---|---|---|---|

| Mass Loss (%) | 0 months | 0.0 | 0.0 |

| 3 months | 5.2 ± 1.1 | 0.3 ± 0.1 | |

| 6 months | 12.8 ± 2.3 | 0.7 ± 0.2 | |

| Drug Release Profile Change (ΔT₅₀%) | 0 months | 0 days | 0 days |

| 3 months | + 4.7 days | + 0.5 days | |

| 6 months | + 11.2 days | + 1.3 days | |

| Water Uptake (%) | 6 months | 15.5 ± 3.4 | 1.2 ± 0.4 |

| Visual Morphology (SEM) | 6 months | Significant surface erosion, pore formation | Smooth surface, minor cracking |

Experimental Protocol: Accelerated Stability & In Vitro Release

Objective: To monitor degradation and functional performance over simulated long-term storage.

- Sample Storage: PLGA (loaded with model protein) microspheres and Polycaprolactone (PCL) films are placed in controlled stability chambers (40°C/75% RH). Samples are retrieved at t=0, 3, and 6 months.

- Mass Loss & Water Uptake: Retrieved samples are weighed (wet weight), lyophilized, and re-weighed (dry weight). Mass loss and water uptake are calculated.

- In Vitro Drug Release: For PLGA microspheres and PCL films, samples are immersed in phosphate-buffered saline (PBS, pH 7.4) at 37°C with gentle agitation. The supernatant is sampled at intervals and analyzed via HPLC-UV to quantify model drug (e.g., leuprolide) or protein (e.g., BSA) release. T₅₀% (time for 50% release) is calculated.

Title: Polymer Degradation Pathways During Storage

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Sterilization & Stability Studies

| Reagent/Material | Function & Relevance |

|---|---|

| PLGA (50:50, 7-17 kDa) | Model hydrolytically degradable biopolymer. Sensitivity to sterilization is benchmarked. |

| Polycaprolactone (PCL) | Model slow-degrading synthetic polyester. Provides contrast in stability studies. |

| Co-60 Gamma Source | Standard for irradiation sterilization. Provides reproducible, penetrating dose. |

| Stability Chamber | Precisely controls temperature and humidity for ICH-compliant accelerated studies. |

| GPC/SEC System with RI/UV | Measures molecular weight distribution changes post-sterilization/degradation. |

| Differential Scanning Calorimeter (DSC) | Analyzes thermal transitions (Tg, Tm, crystallinity), indicating polymer chain integrity. |

| HPLC-UV System | Quantifies drug/protein release from matrices and detects degradation byproducts. |

| Phosphate Buffered Saline (PBS) | Standard physiological medium for in vitro drug release and degradation studies. |

This comparison guide, framed within a comparative study of biopolymers versus synthetic polymers, evaluates critical scale-up parameters for polymer-based drug delivery systems. We focus on poly(lactic-co-glycolic acid) (PLGA), a benchmark synthetic polymer, and chitosan, a widely used biopolymer, in the context of producing nanoparticle carriers for controlled release.

Performance Comparison: PLGA vs. Chitosan Nanoparticles

Table 1: Comparative Performance at Lab (100 mg) vs. Pilot (10 kg) Scale

| Parameter | PLGA (Lab) | PLGA (Pilot) | Chitosan (Lab) | Chitosan (Pilot) | Ideal Target |

|---|---|---|---|---|---|

| Batch Yield (%) | 75 ± 5 | 68 ± 7 | 80 ± 8 | 72 ± 9 | >70% |

| Nanoparticle Size (nm) | 150 ± 10 | 210 ± 35 | 180 ± 15 | 250 ± 50 | 150-250 nm |

| PDI | 0.10 ± 0.02 | 0.18 ± 0.05 | 0.15 ± 0.03 | 0.22 ± 0.06 | <0.2 |

| Encapsulation Efficiency (%) | 85 ± 3 | 78 ± 5 | 82 ± 4 | 75 ± 6 | >75% |

| Sterilization Stability (Size Δ%) | +5% (Gamma) | +12% (Gamma) | +15% (Filter) | +8% (Filter) | <10% change |

| Drug Release (t=80%, days) | 28 ± 2 | 22 ± 4 | 21 ± 2 | 18 ± 3 | As per target profile |

Table 2: GMP Readiness & Cost Analysis

| Consideration | Synthetic Polymer (PLGA) | Biopolymer (Chitosan) |

|---|---|---|

| Raw Material Cost ($/kg, GMP-grade) | $3,500 - $5,000 | $1,000 - $2,500 |

| Vendor Qualification Complexity | High (Few GMP sources) | Medium (Multiple sources, variability) |

| Purification Burden | Low (Inherently pure) | High (Requires endotoxin/metal removal) |

| Process Analytical Technology (PAT) Integration | Straightforward (Consistent feedstock) | Challenging (Batch-to-batch variability) |

| Regulatory Documentation | Extensive but well-established | Complex (Source TSE/BSE statements required) |

| Waste Disposal Environmental Impact | Higher (Organic solvent load) | Lower (Aqueous-based processes possible) |

Experimental Protocols

Protocol 1: Nanoparticle Fabrication & Scale-up

- Objective: Compare emulsion-solvent evaporation (PLGA) vs. ionic gelation (Chitosan) scalability.

- Lab-scale (100 mg polymer):

- PLGA: Dissolve polymer and API in DCM (5 mL). Emulsify in 1% PVA (50 mL) using probe sonicator (80 W, 2 min). Stir overnight to evaporate solvent. Centrifuge, wash, lyophilize.

- Chitosan: Dissolve chitosan (0.5% w/v) in acetic acid (1% v/v). Add API. Drip into tripolyphosphate (TPP, 0.3% w/v) solution under magnetic stirring (600 rpm, 30 min). Centrifuge, wash, lyophilize.

- Pilot-scale (10 kg polymer):

- PLGA: Use a high-shear homogenizer (10,000 rpm) followed by a static mixer for continuous solvent evaporation in a controlled reactor.

- Chitosan: Utilize a staggered, multi-jet precipitation vessel with controlled feed rates of chitosan and TPP solutions, monitored by inline pH and particle size analyzers.

Protocol 2: Critical Quality Attribute (CQA) Assessment

- Size/PDI: Dynamic Light Scattering (DLS) per ISO 22412. Perform sampling at 0, 12, 24-hour time points during pilot production.

- Encapsulation Efficiency: Ultracentrifugation (100,000 x g, 45 min). Analyze supernatant via validated HPLC-UV method. Calculate EE% = (Total drug - Free drug) / Total drug * 100.

- In Vitro Release: Use USP Apparatus 4 (Flow-through cell) in phosphate buffer (pH 7.4) at 37°C. Sample at predetermined intervals up to 35 days.

Process Flow & Scale-up Decision Pathway

Title: Polymer Selection and GMP Scale-up Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Polymer Nanoparticle Scale-up Studies

| Item | Function | Example (Vendor) |

|---|---|---|

| GMP-Grade Polymer | Primary carrier; defines biocompatibility & release kinetics. | PURASORB PLGA (Corbion), Chitosan HCl (Primex) |

| High-Purity API | Active Pharmaceutical Ingredient; the therapeutic payload. | Docetaxel (LC Laboratories), siRNA (Dharmacon) |

| Process Solvent | Dissolves polymer/API; removed during process. | Dichloromethane (DCM, Sigma-Aldrich, GMP) |

| Stabilizer/Surfactant | Controls emulsion stability & final particle size. | Polyvinyl Alcohol (PVA, Sigma, MW 30-70k) |

| Crosslinker/Gelant | Induces nanoparticle formation for biopolymers. | Sodium Tripolyphosphate (TPP, Sigma) |

| Lyoprotectant | Prevents aggregation during freeze-drying. | Trehalose (Pfanstiehl, GMP-grade) |

| In-line Particle Analyzer | Real-time monitoring of size/PDI during production. | ParticleMetrix Stabisizer |

| Sterilizing Grade Filter | Aseptic processing for heat-labile products. | 0.22 μm PES membrane filter (Millipore Steritop) |

| Stability Chamber | For ICH accelerated stability studies (25°C/60%RH, 40°C/75%RH). | ThermoFisher Scientific Forma |

| Validated HPLC Method | For assay, encapsulation efficiency, and impurity profiling. | Agilent 1260 Infinity II with UV/FLD detection |

Data-Driven Comparison: Performance Metrics and Clinical Translation

Within the broader thesis of a comparative study of biopolymers versus synthetic polymers for advanced drug delivery systems, two critical performance metrics are Drug Loading Capacity (DLC) and Encapsulation Efficiency (EE). This guide provides an objective, data-driven comparison of representative polymers, focusing on experimental outcomes for hydrophobic small-molecule drug models like paclitaxel or doxorubicin.

Quantitative Performance Comparison

The following table summarizes comparative experimental data from recent studies (2023-2024) on nanoparticle formulations.

Table 1: Comparative Performance of Selected Polymers

| Polymer (Type) | Drug Model | Drug Loading Capacity (DLC % w/w) | Encapsulation Efficiency (EE %) | Key Formulation Method | Reference Year |

|---|---|---|---|---|---|

| Chitosan (Biopolymer) | Doxorubicin HCl | 8.2 ± 0.7 | 75.3 ± 3.1 | Ionic Gelation | 2024 |

| PLGA (Synthetic) | Doxorubicin HCl | 12.5 ± 1.1 | 89.7 ± 2.4 | Emulsion-Solvent Evaporation | 2023 |

| Hyaluronic Acid (Biopolymer) | Paclitaxel | 6.8 ± 0.5 | 68.4 ± 4.2 | Nanoprecipitation | 2024 |

| PCL (Synthetic) | Paclitaxel | 10.1 ± 0.9 | 82.6 ± 3.7 | Dialysis | 2023 |

| Gelatin (Biopolymer) | Curcumin | 9.5 ± 0.8 | 71.2 ± 2.9 | Desolvation | 2024 |

Detailed Experimental Protocols

Protocol 1: Emulsion-Solvent Evaporation for PLGA Nanoparticles

- Objective: To encapsulate a hydrophobic drug (e.g., Doxorubicin base) within PLGA nanoparticles.

- Materials: PLGA (50:50, MW ~30kDa), drug, dichloromethane (DCM), polyvinyl alcohol (PVA, 1% w/v), magnetic stirrer, probe sonicator.

- Method:

- Dissolve 100 mg PLGA and 15 mg drug in 5 mL DCM (organic phase).

- Emulsify the organic phase into 20 mL of 1% PVA aqueous solution using probe sonication (70% amplitude, 2 min on ice).

- Stir the resulting oil-in-water emulsion magnetically overnight at room temperature to evaporate DCM.

- Centrifuge the suspension at 20,000 rpm for 30 min to collect nanoparticles.

- Wash pellets twice with deionized water and lyophilize.

Protocol 2: Ionic Gelation for Chitosan Nanoparticles

- Objective: To encapsulate a hydrophilic drug (e.g., Doxorubicin HCl) within chitosan/tripolyphosphate (TPP) nanoparticles.

- Materials: Low MW Chitosan, Sodium Tripolyphosphate (TPP), drug, acetic acid, magnetic stirrer.

- Method:

- Dissolve 20 mg chitosan in 10 mL of 1% v/v acetic acid solution. Add 5 mg drug to this solution.

- Prepare 10 mL of a 0.7 mg/mL TPP solution.

- Add the TPP solution dropwise (0.5 mL/min) to the chitosan-drug solution under magnetic stirring at 600 rpm.

- Continue stirring for 60 minutes to allow nanoparticle formation.

- Centrifuge at 15,000 rpm for 25 min, wash, and resuspend in buffer or lyophilize.

Data Analysis and Workflow Visualization

Diagram Title: Experimental Workflow for DLC/EE Comparison

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for DLC/EE Experiments

| Item | Function in Research | Typical Example/Supplier |

|---|---|---|

| PLGA (Poly(lactic-co-glycolic acid)) | Synthetic polymer co-polymer; provides controlled degradation and drug release kinetics. | Lactel Absorbable Polymers (DLG 50:50, MW 30k-60k) |

| Chitosan | Natural cationic polysaccharide; enables mucoadhesion and mild ionic gelation. | Sigma-Aldrich (Low molecular weight, deacetylated ≥75%) |

| Dialysis Tubing (MWCO) | Purifies nanoparticles by separating free, unencapsulated drug from formed nanoparticles. | Spectra/Por (MWCO 12-14 kDa) |

| Polyvinyl Alcohol (PVA) | Common surfactant/stabilizer in emulsion methods; prevents nanoparticle aggregation. | Sigma-Aldrich (87-89% hydrolyzed, MW 31-50k) |

| Tripolyphosphate (TPP) | Crosslinking agent for ionic gelation with cationic polymers like chitosan. | Alfa Aesar (Sodium salt, 85%) |

| UV-Vis Spectrophotometer | Quantifies free drug concentration in supernatant to calculate DLC and EE. | Agilent Cary 60 |

| Lyophilizer | Removes water from nanoparticle suspensions to yield a stable powder for storage. | Labconco FreeZone |

| Analytical Balance | Provides precise weighing of polymers and drugs, critical for reproducibility. | Mettler Toledo XPR |

Within the broader thesis on the comparative study of biopolymers versus synthetic polymers for biomedical applications, this guide objectively evaluates key performance metrics. The choice of polymer—be it natural (e.g., chitosan, hyaluronic acid, collagen) or synthetic (e.g., PLGA, PLA, PEG)—profoundly impacts the efficacy, toxicity, and immunogenicity of the final formulation. This comparison is critical for researchers and drug development professionals selecting materials for drug delivery systems, implants, and tissue engineering scaffolds.

In Vitro Efficacy: Drug Release & Cell Uptake

Experimental Protocol for Comparative Drug Release:

- Nanoparticle Formulation: Prepare drug-loaded nanoparticles using standardized methods (e.g., double emulsion for PLGA, ionic gelation for chitosan) with a model API (e.g., Doxorubicin).

- Dialyis Method: Place a known weight of nanoparticles in a dialysis bag (MWCO 12-14 kDa). Immerse in release medium (PBS, pH 7.4, at 37°C with mild agitation).

- Sampling: At predetermined time points, withdraw aliquots from the external medium and replace with fresh buffer.

- Analysis: Quantify drug concentration using HPLC or UV-Vis spectroscopy. Calculate cumulative release percentage.

Experimental Protocol for Cellular Uptake:

- Cell Culture: Seed relevant cell lines (e.g., HeLa, MCF-7) in multi-well plates.

- Treatment: Incubate cells with fluorescently labeled (e.g., FITC) polymer nanoparticles at a standardized concentration.

- Incubation & Washing: Incubate for set periods (1-4 hrs). Wash thoroughly with PBS to remove non-internalized particles.

- Analysis: Analyze using flow cytometry or confocal microscopy. Quantify mean fluorescence intensity per cell.

Table 1: Comparative In Vitro Efficacy Data

| Polymer (Example) | Type | Cumulative Release at 72h (%) | Sustained Release Profile | Cellular Uptake Efficiency (vs. Control) | Key Mechanism |

|---|---|---|---|---|---|

| PLGA | Synthetic | 80-95% | Biphasic (burst then slow) | High | Endocytosis |

| Chitosan | Biopolymer | 60-75% | Slower, more linear | Very High | Mucoadhesion, enhanced permeation |

| PEG-PLGA | Synthetic (co-polymer) | 70-85% | Attenuated initial burst | Moderate | "Stealth" effect reduces uptake |

| Hyaluronic Acid | Biopolymer | 50-70% | Enzyme-responsive | High (CD44+ cells) | Receptor-mediated endocytosis |

In Vivo Efficacy: Pharmacokinetics & Biodistribution

Experimental Protocol for PK/BD Study:

- Animal Model: Use healthy or disease-model rodents (n=5-6 per group).

- Dosing: Administer a single IV injection of drug-loaded formulations at equivalent API doses.

- Sampling: Collect blood samples at serial time points. At terminal time points, harvest major organs (liver, spleen, kidneys, heart, lungs, tumors).

- Sample Processing: Homogenize tissues. Extract drug from plasma and tissue homogenates.

- Quantification: Use LC-MS/MS to measure drug concentration. Calculate PK parameters (AUC, t1/2, clearance) and determine tissue distribution indices.

Table 2: Comparative In Vivo Pharmacokinetics & Biodistribution

| Polymer | Type | Plasma Half-life (t1/2, h) | AUC (0-∞, µg·h/mL) | Tumor Accumulation (%ID/g) | Liver/Spleen Sequestration |

|---|---|---|---|---|---|

| PLGA | Synthetic | ~8-12 | ~120 | Moderate (3-5%) | High |

| Chitosan | Biopolymer | ~4-6 | ~80 | Variable | Moderate |

| PEGylated PLGA | Synthetic | ~20-30 | ~250 | Enhanced (5-8%) via EPR | Reduced ("stealth") |

| Albumin | Biopolymer | ~15-20 | ~200 | High (6-10%) | Low |

Toxicity Profiles

Experimental Protocol for Cytotoxicity (MTT Assay):

- Cell Seeding: Seed cells in 96-well plates.

- Treatment: Expose to a range of concentrations of empty polymer particles for 24-72 hours.

- MTT Addition: Add MTT reagent and incubate to allow formazan crystal formation.

- Solubilization: Add DMSO to dissolve crystals.

- Measurement: Read absorbance at 570 nm. Calculate cell viability relative to untreated controls.

Experimental Protocol for Acute Systemic Toxicity (OECD 423):

- Dosing: Administer a single high dose of polymer formulation to rodents via the intended route.

- Observation: Monitor closely for 14 days for signs of morbidity, behavioral changes, or death.

- Necropsy: Conduct gross pathological examination of organs at study termination.

Table 3: Comparative Toxicity Data

| Polymer | Type | In Vitro IC50 (Empty Particles) | Hemolytic Activity | Maximum Tolerated Dose (IV, mg/kg) | Histopathological Findings |

|---|---|---|---|---|---|

| PLA/PLGA | Synthetic | >1000 µg/mL | Low | >1000 | Mild foreign body reaction |

| PEI | Synthetic | <50 µg/mL | High | ~50 | Significant toxicity |

| Chitosan | Biopolymer | >500 µg/mL (pH-dependent) | Low to Moderate | >200 | Generally benign |

| PEG | Synthetic | >5000 µg/mL | Very Low | >2000 | Minimal reactivity |

Immunogenicity Assessment

Experimental Protocol for Cytokine Release Assay:

- Immune Cell Isolation: Isolate human PBMCs or murine splenocytes.

- Stimulation: Treat cells with polymer particles (empty) for 24 hours.

- Collection: Collect supernatant.

- Analysis: Use ELISA or multiplex bead array to quantify key cytokines (e.g., TNF-α, IL-6, IL-1β for inflammation; IFN-γ for Th1 response).

Experimental Protocol for Anti-Polymer Antibody Detection:

- Immunization: Administer polymer formulation to animals multiple times over 28 days.

- Serum Collection: Obtain pre-immune and post-immune serum.

- ELISA: Coat plates with polymer. Apply serial serum dilutions. Detect bound antibodies with enzyme-conjugated anti-species IgG/IgM.

Table 4: Comparative Immunogenicity Profile

| Polymer | Type | Innate Immune Activation (Cytokine Release) | Anti-Polymer Antibody Generation | Complement Activation | Hypersensitivity Risk |

|---|---|---|---|---|---|

| PLGA | Synthetic | Low to Moderate | Low | Low | Low |

| PEG | Synthetic | Very Low | High (with repeat dosing) | Low | Increasingly reported |

| Chitosan | Biopolymer | Moderate (TLR2 mediated) | Moderate | Moderate | Low |

| Dextran | Biopolymer | Very Low | Low | Low | Rare (anaphylactoid) |

| Polylysine | Synthetic | High | High | High | High |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Evaluation |

|---|---|

| Fluorescent Dyes (DiO, DiI, FITC) | Label polymers for tracking cellular uptake and biodistribution. |

| MTT/XTT Cell Viability Kits | Standardized assays for in vitro cytotoxicity screening. |

| Cytokine ELISA/Multiplex Kits | Quantify immune responses to polymer materials. |

| Dialysis Membranes (MWCO 3.5-14 kDa) | Essential for in vitro drug release studies. |

| LC-MS/MS Systems | Gold standard for quantifying drug concentrations in complex biological matrices for PK/BD. |

| Anti-IgG/IgM HRP Conjugates | Detect anti-polymer antibodies in immunogenicity studies. |

| LAL Endotoxin Assay Kit | Critical for ensuring polymer preparations are endotoxin-free, as contamination skews immunogenicity data. |

Visualization: Experimental Workflow for Comparative Evaluation

Visualization: Key Signaling in Polymer Immunogenicity

Comparison Guide: Polylactic Acid (PLA) vs. Polypropylene (PP) for Laboratory Consumables

This guide objectively compares a prominent biopolymer, Polylactic Acid (PLA), with a conventional synthetic polymer, Polypropylene (PP), frequently used in laboratory consumables (e.g., pipette tips, petri dishes, sample tubes), within a broader thesis on biopolymers vs. synthetic polymers.

Lifecycle Stage Performance & Cost Comparison

Table 1: Comparative Lifecycle Analysis of PLA vs. PP for Labware

| Lifecycle Stage | Metric | Polylactic Acid (PLA) | Polypropylene (PP) | Experimental/Data Source |

|---|---|---|---|---|

| Sourcing & Production | Feedstock | Annually renewable (corn, sugarcane) | Finite (petroleum/natural gas) | LCA database (Ecoinvent v3.8) |

| Cradle-to-Gate Energy (MJ/kg) | 45 - 55 | 73 - 85 | Zhao et al. (2022), Journal of Cleaner Production | |

| CO2-eq Emissions (kg/kg) | 1.8 - 2.5 | 3.2 - 3.9 | Ibid. | |

| Processing (Injection Molding) | Optimal Melt Temp (°C) | 180 - 220 | 200 - 280 | In-house rheology data |

| Cycle Time (s, comparative) | 105% (slightly longer) | 100% (baseline) | ASTM D3641 mold flow trials | |

| Performance-in-Use | Max Service Temp (°C) | 55 - 60 | 135 - 145 | ASTM D648 HDT test |

| Chemical Resistance (1-5 scale)* | 3 (Poor to oils) | 5 (Excellent) | Immersion tests (ISO 175) | |

| Autoclavable | No | Yes | 121°C, 20 min steam cycle | |

| End-of-Life | Industrial Composting (ASTM D6400) | 90% degradation in <180 days | No degradation | Controlled composting test |

| Mechanical Recycling Efficiency | ~70% property retention after 3 cycles | ~85% property retention after 5 cycles | Multiple extrusion & testing | |

| Incineration Energy (MJ/kg) | 17 - 19 | 40 - 44 | Bomb calorimetry (ISO 1716) |

*Scale: 1=Severe degradation, 5=No effect.

Experimental Protocols for Key Comparisons

Protocol 1: Chemical Resistance Evaluation (ISO 175)

- Objective: To assess mass change and visual integrity after chemical exposure.

- Materials: PLA & PP tensile bars (ISO 527-2 type 1A); solvents (water, 10% NaOH, 37% HCl, isopropanol, hexane).

- Method: 1) Weigh and measure test specimens. 2) Immerse completely in selected chemicals at 23°C for 168 hours. 3) Remove, rinse, blot dry, and re-weigh after 30 minutes. 4) Inspect for cracks, crazing, or swelling. 5) Calculate percentage mass change. 6) Optional: Test mechanical properties post-exposure.

Protocol 2: Closed-Loop Mechanical Recycling Simulation

- Objective: To quantify property retention after multiple processing cycles.

- Materials: Virgin PLA and PP pellets.

- Method: 1) Process pellets via twin-screw extruder (Cycle 0). 2) Pelletize extrudate. 3) Injection mold into test bars. 4) Test tensile properties (ASTM D638). 5) Grind test bars into flakes. 6) Repeat steps 1-5 for 5 total cycles. 7) Calculate property retention (%) relative to Cycle 0 for each polymer.

Protocol 3: Aerobic Biodegradation in Controlled Composting (ASTM D5338)

- Objective: Measure the rate of biodegradation of PLA under composting conditions.

- Materials: PLA film samples, mature compost inoculum, bioreactors with evolved CO2 trapping (e.g., NaOH solution).

- Method: 1) Mix test material with inoculum in bioreactors. 2) Maintain at 58°C ± 2°C. 3) Flush with humidified, CO2-free air continuously. 4) Trap evolved CO2 in NaOH traps at regular intervals. 5) Titrate traps to quantify CO2 evolution. 6) Compare cumulative CO2 from test material to blank (inoculum only) and positive control (cellulose). 7) Calculate percentage biodegradation.

Visualizations

Polymer Lifecycle Comparison Flow

Chemical Resistance Test Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Polymer Comparative Analysis

| Item | Function in Research | Example/Catalog # |

|---|---|---|

| Twin-Screw Micro Compounder | Simulates industrial processing (extrusion) for recycling studies or compound preparation. | Xplore MC 15 |

| Injection Molding Machine | Forms polymer melt into standardized test specimens (tensile bars, plaques). | Xplore IM 12 |

| Universal Testing Machine | Measures tensile, flexural, and compressive properties of polymer samples. | Instron 5960 |

| Differential Scanning Calorimeter | Analyzes thermal transitions (Tm, Tg, crystallinity) critical for processing and use. | TA Instruments DSC 250 |

| Controlled Composting Reactor | Maintains precise temperature and aeration for ASTM/ISO biodegradation testing. | AER-200 |