Bayesian Optimization in Polymer Synthesis: Accelerating Biomaterial Discovery and Drug Delivery System Development

This comprehensive article explores the transformative role of Bayesian Optimization (BO) in automating and accelerating the discovery of polymer synthesis conditions for biomedical applications.

Bayesian Optimization in Polymer Synthesis: Accelerating Biomaterial Discovery and Drug Delivery System Development

Abstract

This comprehensive article explores the transformative role of Bayesian Optimization (BO) in automating and accelerating the discovery of polymer synthesis conditions for biomedical applications. We begin by establishing the fundamental challenges of traditional polymer synthesis optimization and introducing the core concepts of BO as a data-efficient, sequential experimental design strategy. The article then details methodological frameworks for implementing BO in polymerization workflows, including surrogate modeling and acquisition function selection. We address practical troubleshooting, hyperparameter tuning, and strategies for overcoming common experimental constraints. Through comparative analysis with alternative optimization methods and validation via case studies in drug delivery polymers and biomaterials, we demonstrate BO's superior efficiency in navigating complex, high-dimensional experimental spaces. This guide provides researchers, scientists, and drug development professionals with actionable insights to integrate BO into their R&D pipelines, ultimately reducing development time and cost while enhancing material performance.

The Polymer Optimization Puzzle: Why Bayesian Optimization is a Game-Changer for Material Scientists

The High-Stakes Challenge of Polymer Synthesis Optimization

Polymer synthesis, particularly for advanced applications in drug delivery and biomaterials, is a multivariate optimization challenge. Traditional one-variable-at-a-time (OVAT) approaches are inefficient for navigating complex parameter spaces where monomer ratios, initiator concentrations, temperatures, and reaction times interdependently influence critical outcomes like molecular weight (Mw), dispersity (Ɖ), and copolymer composition. This Application Note frames polymer synthesis optimization within a broader thesis on Bayesian Optimization (BO). BO is a machine learning strategy that builds a probabilistic model of the objective function (e.g., maximizing Mw while minimizing Ɖ) and uses an acquisition function to guide the selection of the next most informative experiment. This enables optimal condition identification in fewer iterations, conserving precious monomers and time—a high-stakes advantage in research and development.

Based on current literature for controlled radical polymerization (e.g., ATRP, RAFT), the following parameters are critical. The target for optimization is often a well-defined polymer with Mw ~50,000 Da and Ɖ < 1.2.

Table 1: Key Input Parameters and Their Typical Ranges for ATRP of Methyl Methacrylate (MMA)

| Parameter | Symbol | Typical Range | Role in Reaction |

|---|---|---|---|

| Monomer Concentration | [M] | 2.0 - 4.0 M | Determines polymer chain length & kinetics. |

| Initiator Concentration | [I] | 10 - 50 mM | Controls the number of growing chains. |

| Catalyst Concentration | [Cu(I)] | 5 - 25 mM | Mediates the reversible halogen transfer. |

| Ligand Concentration | [L] | 10 - 50 mM | Solubilizes & modulates catalyst activity. |

| Reaction Temperature | T | 60 - 90 °C | Influences reaction rate and control. |

| Reaction Time | t | 2 - 8 hours | Directly impacts conversion and Mw. |

Table 2: Representative Experimental Outcomes from a Hypothetical DoE Screen

| Experiment | [M] (M) | [I] (mM) | T (°C) | Conversion (%) | Mw (Da) | Ɖ |

|---|---|---|---|---|---|---|

| 1 | 3.0 | 20 | 70 | 65 | 32,500 | 1.35 |

| 2 | 4.0 | 10 | 80 | 82 | 68,000 | 1.28 |

| 3 | 2.5 | 30 | 60 | 48 | 18,000 | 1.18 |

| 4 | 3.5 | 15 | 90 | 95 | 58,000 | 1.45 |

| Target | - | - | - | >80 | ~50,000 | <1.20 |

Detailed Experimental Protocol: Bayesian-Optimized ATRP

Protocol: Iterative Bayesian Optimization for Poly(MMA-co-DMAEMA) Synthesis

Aim: To identify conditions achieving Mw = 50,000 ± 3,000 Da and Ɖ ≤ 1.20 in ≤ 15 experimental iterations.

I. Initial Design of Experiments (DoE)

- Define parameter space (as in Table 1).

- Using a space-filling design (e.g., Latin Hypercube), select 5-8 initial experiments covering the range.

- Perform syntheses according to General Procedure A.

- Characterize outcomes (Mw, Ɖ via GPC).

II. General Procedure A: ATRP Polymerization Materials: Methyl methacrylate (MMA, 99%), 2-(Dimethylamino)ethyl methacrylate (DMAEMA, 98%), Ethyl α-bromoisobutyrate (EBiB, 98%), Copper(I) Bromide (CuBr, 99.999%), N,N,N',N'',N''-Pentamethyldiethylenetriamine (PMDETA, 99%), Anisole (99.7%). All reagents purified per standard methods.

- In a flame-dried Schlenk flask, add CuBr (1 eq. vs. initiator), a magnetic stir bar.

- Seal flask with a rubber septum, purge with N₂/Ar for 20 min.

- Via degassed syringes, sequentially add: Monomer mixture (MMA/DMAEMA, 9:1 molar ratio, total moles as per [M]), Anisole (50% v/v vs. monomers), PMDETA ligand (1.05 eq. vs. CuBr), and initiator EBiB (1 eq.).

- Place flask in a preheated oil bath at target temperature (T) under positive N₂ pressure.

- At target time (t), remove flask, expose to air, and dilute with THF.

- Pass solution through a neutral alumina column to remove catalyst.

- Precipitate polymer into cold hexane, filter, and dry in vacuo.

III. Bayesian Optimization Loop

- Model Training: Input all experimental data (parameters + outcomes) into a Gaussian Process (GP) regression model. The GP models Mw and Ɖ as functions of the input parameters.

- Acquisition: Calculate the Expected Improvement (EI) acquisition function across the parameter space. EI identifies the point promising the highest potential improvement over the current best.

- Next Experiment Selection: The condition maximizing EI is chosen as the next experiment.

- Iteration: Perform the selected experiment (General Procedure A), characterize, and add the new data point to the dataset. Repeat steps 1-3 until target criteria are met or iterations exhausted.

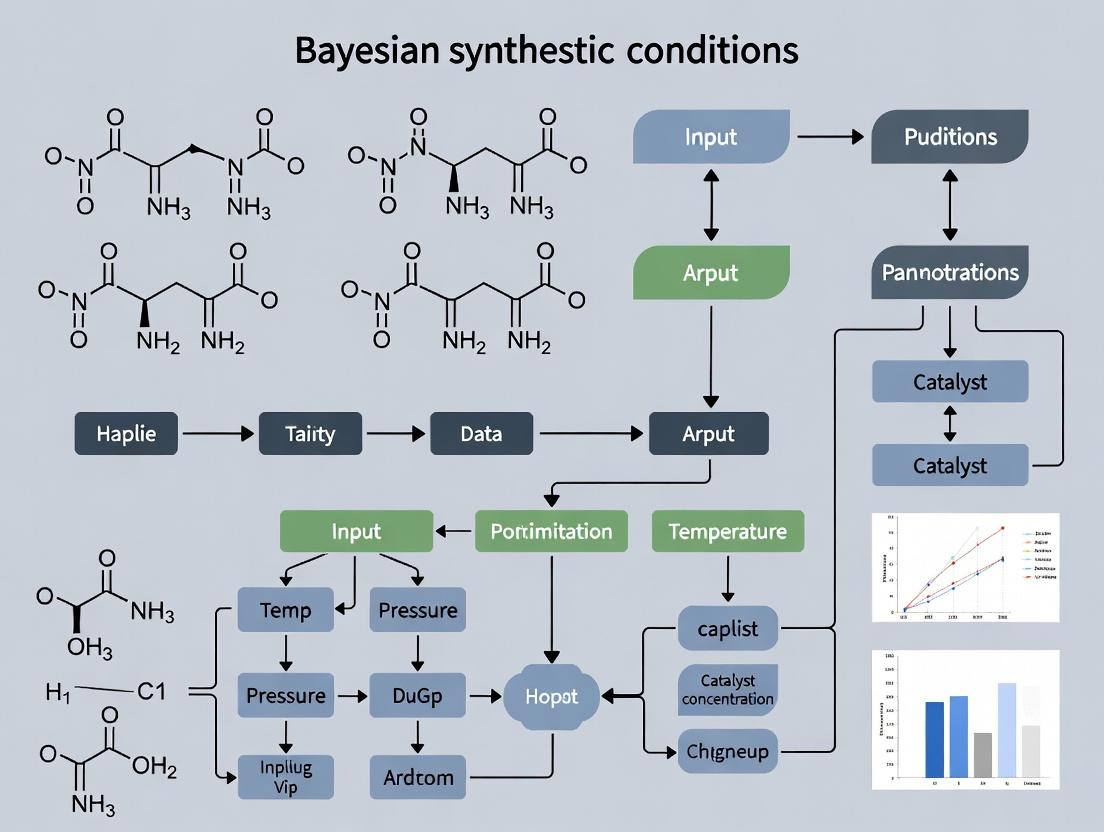

Visualization: Bayesian Optimization Workflow

Diagram Title: Bayesian Optimization Loop for Polymer Synthesis

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Bayesian-Optimized ATRP

| Item | Function & Importance | Example (Supplier) |

|---|---|---|

| Purified Monomers | High-purity monomers (inhibitor removed) are essential for reproducible kinetics and molecular weight control. | Methyl Methacrylate (Sigma-Aldrich, 99%, stab. with 10 ppm MEHQ) passed through basic alumina column before use. |

| ATRP Initiator | Alkyl halide initiator defines the starting chain end. Structure influences initiation efficiency. | Ethyl α-bromoisobutyrate (EBiB) (Fisher Scientific, 98%). Purified by distillation under reduced Ar pressure. |

| Catalyst System | Copper(I) halide and a nitrogen-based ligand complex mediates reversible deactivation. Purity is critical. | Copper(I) Bromide (Strem Chemicals, 99.999%) stored under N₂. PMDETA ligand (Sigma, 99%) distilled over CaH₂. |

| Deoxygenated Solvent | Removes O₂, a radical scavenger that can inhibit polymerization or lead to loss of control. | Anisole (Acros, 99.7%), sparged with N₂ for 60 min and stored over molecular sieves under N₂. |

| Polymer Characterization Kit | For quantitative analysis of optimization objectives (Mw, Đ). | Gel Permeation Chromatography (GPC) system with THF eluent, PMMA standards, and dual detection (RI/UV). |

| Bayesian Optimization Software | Core platform for building the GP model and calculating the acquisition function. | Python libraries: scikit-optimize, GPyOpt, or BoTorch. Commercial: SIGMA (MilliporeSigma), IOSO.` |

Within polymer synthesis for drug delivery and biomedical applications, optimizing conditions (e.g., temperature, catalyst concentration, monomer ratio, solvent polarity) is critical for controlling properties like molecular weight, dispersity (Đ), and copolymer composition. Traditional empirical approaches, namely One-Variable-at-a-Time (OVAT) and classical Design of Experiments (DOE), present significant limitations in efficiency and discovery scope. This application note contextualizes these limitations within the paradigm shift towards Bayesian optimization, a machine learning-driven framework that iteratively models and navigates complex experimental landscapes to find optimal conditions with fewer experiments.

Limitations of Traditional Approaches: A Quantitative Comparison

Table 1: Comparative Analysis of Optimization Methodologies in Polymer Synthesis

| Aspect | One-Variable-at-a-Time (OVAT) | Classical Design of Experiments (DOE) | Bayesian Optimization (BO) |

|---|---|---|---|

| Experimental Efficiency | Very Low; Requires n experiments per variable. | Moderate; Predefined set (e.g., 16 runs for 4 factors). | High; Aims for global optimum in <20 runs. |

| Interaction Detection | None. Cannot detect factor interactions. | Yes, but limited to pre-specified model (often 2nd-order). | Yes, modeled via flexible surrogate (e.g., Gaussian Process). |

| Optimum Type | Likely local, misses global optimum. | Local/Global within design space, limited resolution. | Aims for global optimum with uncertainty quantification. |

| Noise Handling | Poor. No inherent replication strategy. | Good. Can include replicates and randomization. | Excellent. Explicitly models noise in acquisition function. |

| Sequential Adaptability | None. Fixed, non-adaptive path. | Limited. Requires new design if initial fails. | Core Strength. Each experiment informs the next. |

| Best Use Case | Very simple, non-interacting systems. | Well-characterized systems with known critical factors. | Complex, costly, or poorly understood systems (e.g., novel polymerizations). |

Protocol 1: Standard OVAT Protocol for Free Radical Polymerization Yield Optimization

- Objective: Determine the effect of initiator concentration ([I]) and temperature (T) on monomer conversion.

- Materials: Monomer (e.g., methyl methacrylate), thermal initiator (e.g., AIBN), anhydrous solvent, schlenk line.

- Procedure:

- Set a baseline condition: T = 70°C, [I] = 1.0 mol%, [M] = 2.0 M in toluene.

- Fix [I] at 1.0 mol%. Run experiments at T = 60, 70, 80, 90°C.

- Analyze conversion via ¹H NMR after 2 hours.

- Identify "best" T from step 2 (e.g., 80°C).

- Fix T at this "best" value (80°C). Run experiments at [I] = 0.5, 1.0, 1.5, 2.0 mol%.

- Report the combination (80°C, "best" [I]) as the optimum.

- Critical Limitation: Fails to discover that high T with high [I] may cause runaway polymerization or chain transfer, and cannot identify if a synergistic optimum exists at, e.g., 75°C & 1.2 mol%.

Protocol 2: Standard Full Factorial DOE Protocol for Copolymer Dispersity

- Objective: Model the effect of two monomers' feed ratio (M1:M2) and chain transfer agent (CTA) concentration on dispersity (Đ).

- Design: 3² full factorial design (9 experiments + 3 center points).

- Factors & Levels: M1:M2 (70:30, 50:50, 30:70), [CTA] (0.01, 0.05, 0.10 M).

- Procedure:

- Randomize the order of 12 polymerization runs.

- Execute all polymerizations under inert atmosphere.

- Characterize each product via gel permeation chromatography (GPC) for Đ.

- Perform multiple linear regression to fit a quadratic model:

Đ = β₀ + β₁*(Ratio) + β₂*([CTA]) + β₁₂*(Ratio*[CTA]) + β₁₁*(Ratio²) + β₂₂*([CTA]²). - Use model response surface to identify a predicted minimum Đ.

- Critical Limitation: The optimum is constrained to the shape of the pre-defined quadratic model. It may miss complex, non-quadratic behavior and does not efficiently guide further experiments outside the initial grid.

Visualization of Methodological Workflows

Diagram 1: OVAT vs DOE vs BO Workflow Logic

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Polymer Synthesis Optimization Studies

| Item / Reagent | Function / Rationale |

|---|---|

| Schlenk Line or Glovebox | Enables oxygen/moisture-sensitive polymerization techniques (ATRP, RAFT, organocatalyzed ROP). Critical for reproducibility. |

| Bayesian Optimization Software (e.g., Ax, BoTorch, Dragonfly) | Provides the algorithmic framework to design sequential experiments, build surrogate models, and suggest optimal conditions. |

| Automated Parallel Reactor System (e.g., Chemspeed, Unchained Labs) | Dramatically increases experimental throughput for both initial DOE design and rapid iteration in BO loops. |

| In-line Spectroscopic Probes (ReactIR, ReactRaman) | Provides real-time kinetic data (monomer conversion, intermediate formation), a rich data source for BO models beyond endpoint analysis. |

| High-Throughput GPC/SEC System | Enables rapid characterization of molecular weight and dispersity for dozens of polymer samples per day, matching BO's pace. |

| Functionalized Monomers & Chain Transfer Agents | Libraries of structurally diverse building blocks allow BO to explore a vast chemical space for property optimization (e.g., targeting a specific logP or Tg). |

| Telechelic Polymers & Macromonomers | Used in subsequent step-growth or coupling reactions; their quality (Đ, end-group fidelity) from the initial optimization is crucial. |

Core Principles & Mathematical Framework

Bayesian Optimization (BO) is a sequential design strategy for global optimization of black-box functions that are expensive to evaluate. It is particularly suited for optimizing complex experimental conditions, such as those in polymer synthesis or drug formulation, where each experiment is costly or time-consuming.

Key Components:

- Probabilistic Surrogate Model: Typically a Gaussian Process (GP) is used to build a statistical approximation of the unknown objective function (e.g., polymer yield or drug efficacy) based on observed data.

- Acquisition Function: A criterion that uses the surrogate model's predictions to decide the next most promising point to evaluate by balancing exploration (probing uncertain regions) and exploitation (probing near known good results).

The process iterates: Evaluate experiment → Update surrogate model → Use acquisition function to select next experiment.

| Acquisition Function | Key Formula | Primary Use Case | Pros | Cons |

|---|---|---|---|---|

| Expected Improvement (EI) | EI(x) = E[max(f(x) - f(x*), 0)] |

General-purpose optimization | Strong balance of explore/exploit; analytically tractable. | Can be sensitive to posterior mean scaling. |

| Upper Confidence Bound (UCB) | UCB(x) = μ(x) + κ * σ(x) |

Controlled exploration | Simple, tunable exploration (κ). | Requires manual tuning of κ. |

| Probability of Improvement (PI) | PI(x) = P(f(x) ≥ f(x*) + ξ) |

Rapidly finding local optimum | Simple concept. | Can be overly greedy; sensitive to ξ. |

Where μ(x) is the posterior mean, σ(x) is the posterior standard deviation, f(x) is the current best observation, and κ/ξ are tunable parameters.*

Protocol: Bayesian Optimization for Polymer Synthesis Condition Screening

Objective: To efficiently optimize the reaction yield of a novel copolymerization by varying two key parameters: Catalyst Concentration (mM) and Reaction Temperature (°C).

Materials & Equipment:

- Monomer A, Monomer B

- Metal-organic Catalyst

- Solvent (anhydrous)

- Schlenk line or glovebox for inert atmosphere

- Heating stir-plate with temperature control

- Gas Chromatograph (GC) or NMR for yield quantification

Procedure:

Step 1: Define Search Space & Objective

- Define parameter bounds: Catalyst: [0.5, 2.5] mM; Temperature: [60, 120] °C.

- Define objective: Maximize isolated yield (%) after 24h reaction time.

Step 2: Initial Design (n=5)

- Perform a space-filling initial design (e.g., Latin Hypercube Sampling) within the bounds to seed the model.

- Execute these 5 synthesis experiments in random order to avoid bias.

Step 3: Iterative Bayesian Optimization Loop (n=20)

- Model Training: Fit a Gaussian Process surrogate model to all accumulated (parameter, yield) data. Use a Matérn kernel.

- Next Experiment Selection: Calculate the Expected Improvement (EI) acquisition function over a dense grid of the search space. Select the parameter set

(Catalyst, Temperature)that maximizes EI. - Experiment Execution: Perform the synthesis reaction at the selected conditions.

- Protocol: In an inert atmosphere, charge monomers (10 mmol total), solvent, and catalyst to a reaction vial. Stir and heat to the target temperature (±1°C) for 24h. Quench, purify, and quantify yield by GC.

- Data Augmentation: Append the new result to the dataset.

- Loop: Repeat steps 1-4 until iteration budget (n=20) is reached or yield plateaus.

Step 4: Validation

- Perform triplicate synthesis runs at the proposed optimal conditions from the BO routine. Compare yield to the best result from a traditional one-factor-at-a-time (OFAT) screening grid.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Polymer Synthesis BO |

|---|---|

| Gaussian Process Library (e.g., GPyTorch, scikit-learn) | Provides the core statistical models to build the surrogate function from experimental data. |

| BO Framework (e.g., BoTorch, Ax, GPflow) | Implements acquisition functions and optimization loops, integrating with the GP model. |

| High-Throughput Reaction Robotic Platform | Automates execution of selected experimental conditions, enabling rapid iteration. |

| In-line Analytical Spectroscopy (e.g., FTIR, Raman) | Provides real-time yield/conversion data as the objective function for the BO loop. |

| Lab Information Management System (LIMS) | Tracks and structures all experimental parameter-yield data pairs for model input. |

Workflow & Pathway Visualizations

Bayesian Optimization Iterative Loop for Experimentation

Gaussian Process Surrogate Model Components

Within the context of a thesis on Bayesian optimization (BO) for polymer synthesis conditions research, this document outlines the core algorithmic components. These components form an automated, data-efficient framework for optimizing complex, resource-intensive chemical reactions—such as synthesizing novel drug delivery polymers—where traditional Design of Experiments (DoE) is prohibitively expensive.

Core Thesis Application: The system iteratively proposes the most informative synthesis conditions (e.g., monomer ratio, temperature, catalyst concentration, reaction time) to maximize or minimize a target property (e.g., polymer molecular weight, dispersity, drug encapsulation efficiency).

Detailed Components, Protocols, and Data

Surrogate Model: Gaussian Process (GP)

A GP is a probabilistic model that defines a distribution over functions. It is the surrogate for the unknown, expensive-to-evaluate true function (e.g., polymer property as a function of synthesis parameters).

Protocol: Building and Updating the GP Surrogate

Initialization:

- Input: A small initial dataset ( D{1:n} = { (\mathbf{x}i, yi) }{i=1}^n ) from a space-filling design (e.g., Latin Hypercube Sampling). ( \mathbf{x}i ) is a vector of synthesis conditions, ( yi ) is the measured property.

- Preprocessing: Standardize input features (( \mathbf{x} )) and target values (( y )) to zero mean and unit variance.

Model Specification:

- Mean Function: Often set to a constant (zero after standardization).

- Kernel (Covariance) Function: Select based on expected smoothness.

- Matérn 5/2: Recommended default for chemical processes; less smooth than RBF, handles fluctuations well.

- Radial Basis Function (RBF): For very smooth, continuous responses.

- Likelihood: Gaussian, with a noise variance parameter ( \sigma_n^2 ) accounting for experimental measurement error.

Model Training (Hyperparameter Optimization):

- Maximize the log marginal likelihood ( \log p(\mathbf{y} | X, \theta) ) with respect to kernel length scales ( l ) and signal variance ( \sigma_f^2 ).

- Use a gradient-based optimizer (e.g., L-BFGS-B) with multiple restarts to avoid local optima.

- Output: Trained GP providing a posterior mean ( \mu(\mathbf{x}) ) and variance ( \sigma^2(\mathbf{x}) ) prediction for any condition ( \mathbf{x} ).

Acquisition Functions

The acquisition function ( \alpha(\mathbf{x}) ) uses the GP posterior to quantify the utility of evaluating a candidate point ( \mathbf{x} ). It balances exploration (high uncertainty) and exploitation (high predicted mean).

Protocol: Selecting the Next Experiment via Acquisition Optimization

- Function Choice: Select an acquisition function based on the optimization goal (see Table 1).

- Optimization: Maximize ( \alpha(\mathbf{x}) ) over the input domain ( \mathcal{X} ). This is a cheap optimization problem.

- Method: Use a multi-start strategy with a deterministic optimizer (e.g., DIRECT or L-BFGS-B) or a random sampling approach.

- Constraint Handling: Incorporate synthesis feasibility constraints (e.g., total monomer concentration ≤ 2.0 M) directly into the acquisition optimizer.

- Output: The proposed synthesis condition ( \mathbf{x}{next} = \arg \max{\mathbf{x} \in \mathcal{X}} \alpha(\mathbf{x}) ) for the next experiment.

Table 1: Common Acquisition Functions for Polymer Synthesis

| Function | Formula | Use Case & Rationale |

|---|---|---|

| Expected Improvement (EI) | ( \text{EI}(\mathbf{x}) = \mathbb{E}[\max(y - y^+, 0)] ) | Default choice. Directly targets improvement over the current best observation ( y^+ ). Efficient and effective. |

| Upper Confidence Bound (UCB) | ( \text{UCB}(\mathbf{x}) = \mu(\mathbf{x}) + \kappa \sigma(\mathbf{x}) ) | Explicit trade-off. ( \kappa ) controls exploration. Useful when an explicit balance parameter is desired. |

| Probability of Improvement (PI) | ( \text{PI}(\mathbf{x}) = \Phi\left(\frac{\mu(\mathbf{x}) - y^+ - \xi}{\sigma(\mathbf{x})}\right) ) | Pure exploitation. Tends to get stuck in local maxima. Not generally recommended unless heavily modified. |

| Knowledge Gradient (KG) | Complex, considers optimal posterior mean | Sequential, one-step optimal. Computationally expensive but powerful for final-stage fine-tuning. |

The Experiment Loop

This is the iterative protocol integrating the surrogate model and acquisition function.

Protocol: The Bayesian Optimization Iteration Cycle

Initial Design Phase:

- Perform ( n_{init} ) experiments (typically 5-10 times the input dimension) using a space-filling design.

- Characterize the resulting polymers for the target property(s).

BO Iteration Phase:

- Step 1 - Model Update: Train/update the GP surrogate on all data collected so far, ( D_{t} ).

- Step 2 - Proposal: Maximize the chosen acquisition function ( \alpha(\mathbf{x}) ) to propose the next synthesis condition ( \mathbf{x}_{t+1} ).

- Step 3 - Experimentation: Execute the synthesis and characterization protocol at ( \mathbf{x}{t+1} ) to obtain ( y{t+1} ). Critical: Maintain strict experimental consistency.

- Step 4 - Data Augmentation: Augment the dataset: ( D{t+1} = D{t} \cup { (\mathbf{x}{t+1}, y{t+1}) } ).

- Step 5 - Termination Check: Repeat from Step 1 until a budget (iterations, time, or material) is exhausted or performance plateaus.

Visualizations

BO Experiment Loop for Polymer Research

GP as a Surrogate for Polymer Properties

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for BO-Guided Polymer Synthesis

| Category/Item | Function in the BO Context | Example/Notes |

|---|---|---|

| Monomer Library | Input variables (( \mathbf{x} )) for the optimization. Systematic variation is key. | e.g., Lactide, Glycolide, Caprolactone; Acrylate monomers with different chain lengths. Purity >99% for reproducibility. |

| Catalyst & Initiator | Critical reaction parameters affecting kinetics and final properties. | e.g., Stannous octoate (Sn(Oct)₂) for ROP; Azobisisobutyronitrile (AIBN) for free-radical polymerization. Concentration is an optimized variable. |

| Solvent (Anhydrous) | Reaction medium; affects monomer concentration, chain transfer, and temperature control. | e.g., Toluene, THF, DMF. Must be dried and stored under inert atmosphere (N₂/Ar) to prevent side reactions. |

| Characterization Tools | Provides the objective function value (( y )) for the BO loop. | GPC/SEC: For ( Mn ), ( Mw ), Đ. NMR: For conversion and composition. DLS: For nanoparticle size (if applicable). |

| Automated Reactor | Enables precise control and reproducibility of synthesis conditions (temp, time, stir rate). | e.g., ChemSpeed, Unchained Labs. Crucial for high-fidelity data generation in an automated BO workflow. |

| Lab Information System | Records all experimental parameters (( \mathbf{x} )) and results (( y )) in a structured, machine-readable format. | Enables seamless data transfer to the BO software. ELNs like Benchling or custom databases. |

| BO Software Platform | Executes the GP modeling, acquisition optimization, and loop management. | Open-source: BoTorch, GPyOpt, scikit-optimize. Commercial: SIGMA by Synthace, custom Python scripts. |

Application Notes: Bayesian-Optimized Polymer Synthesis

Self-Driving Labs (SDLs) integrate automated synthesis platforms, inline/online characterization, and decision-making algorithms to accelerate the discovery and optimization of polymers. Framed within a thesis on Bayesian optimization (BO), these systems treat polymer synthesis as a sequential experimental design problem, where each experiment is chosen to maximize the expected information gain about structure-property relationships.

Core SDL Workflow for Polymer Chemistry:

- Definition of Search Space: Key synthesis parameters (e.g., monomer ratios, initiator concentration, temperature, reaction time) are defined as a bounded multidimensional space.

- Initial Dataset: A small set of initial experiments (e.g., via Design of Experiments) is performed to seed the BO algorithm.

- Loop Closure:

- Synthesis: Robots execute the polymerization (e.g., RAFT, ROMP, polycondensation) in specified conditions.

- Characterization: Inline analytics (e.g., FTIR, Raman, GPC) provide immediate data on conversion, molecular weight.

- Analysis: Data is processed to calculate objective functions (e.g., target Mn, low Đ, yield).

- Bayesian Optimization: A surrogate model (typically Gaussian Process) updates its predictions of the objective function across the search space. An acquisition function (e.g., Expected Improvement) proposes the next most informative experiment.

- Output: An optimized polymer formulation or a predictive model mapping conditions to properties.

Key Advantages:

- Efficiency: Reduces the number of experiments required to find optimal conditions by 10-fold compared to grid searches.

- Unbiased Exploration: Discovers non-intuitive, high-performing formulations.

- Data-Rich Outputs: Generates datasets ideal for training machine learning models for inverse design.

Experimental Protocols

Protocol 1: Bayesian-Optimized RAFT Polymerization for Targeted Molecular Weight

Objective: To autonomously synthesize poly(methyl methacrylate) (PMMA) with a target number-average molecular weight (Mn) of 20 kDa and minimal dispersity (Đ < 1.2).

Materials & Setup:

- SDL Platform: Commercially available liquid handler (e.g., Chemspeed SWING) integrated with a reactor block (e.g., Asynt EasyMax) and inline FTIR (e.g., Mettler Toledo ReactIR).

- Reagents: Methyl methacrylate (MMA, purified), RAFT agent (CPDB), initiator (AIBN), anisole (solvent).

Procedure:

- Parameter Space Definition: Define the Bayesian search space:

- [M]:[RAFT] ratio: 100 to 500.

- [RAFT]:[I] ratio: 1 to 10.

- Temperature: 60°C to 80°C.

- Reaction time: 1 to 8 hours.

- Initial Design: Perform 8 initial experiments using a Latin Hypercube Sampling (LHS) design across the parameter space.

- Automated Execution Loop: a. The robotic platform prepares stock solutions and charges reactors with specified amounts of MMA, CPDB, AIBN, and anisole. b. The reactor heats to the target temperature with stirring. c. Inline FTIR monitors the decrease in the C=C stretch peak (~1635 cm⁻¹) to calculate monomer conversion in real-time. d. Upon completion, an aliquot is automatically diverted to an inline GPC (if available) or quenched for offline analysis. e. GPC data provides experimental Mn and Đ.

- Bayesian Decision: a. The objective function is calculated: Score = - |Mntarget - Mnexp| - 10*(Đ_exp). b. A Gaussian Process model is updated with the parameters (input) and score (output). c. The Expected Improvement (EI) acquisition function is computed across the search space. d. The parameters maximizing EI are selected for the next experiment.

- Termination: The loop continues for 20 iterations or until a formulation achieves Mn = 20kDa ± 2kDa and Đ < 1.2.

Protocol 2: Autonomous Optimization of Dielectric Constant in Polymeric Thin Films

Objective: To optimize the composition of a donor-acceptor copolymer thin film for maximum dielectric constant (k).

Materials & Setup:

- Platform: Automated spin coater integrated with a robotic pipettor and a parallel impedance analyzer.

- Reagents: Donor monomer (e.g., EDOT) solution, Acceptor monomer (e.g., a fluorinated TPA derivative) solution, Oxidant solution (e.g., Fe(TOS)₃), Solvent blends (e.g., chloroform/anisole).

Procedure:

- Search Space: Vary donor:acceptor molar ratio (10:90 to 90:10), oxidant concentration (0.1 to 0.5 M), and solvent blending ratio (0 to 100% anisole).

- Initialization: 10 initial films are prepared and measured based on a DoE.

- Automated Workflow: a. The pipettor mixes donor, acceptor, and solvent solutions in specified ratios in a vial. b. The oxidant solution is added and mixed. c. The mixture is dispensed onto a substrate and spun-coated using programmed recipes. d. The film is thermally annealed on a hotplate. e. A robotic probe makes contact, and impedance is measured at 1 kHz to extract the dielectric constant.

- Optimization Loop: A Bayesian optimizer (using a Matérn kernel) proposes the next composition to test based on the measured k-value. The loop runs for 30 iterations.

Data Presentation

Table 1: Comparative Performance of Optimization Algorithms for PMMA Synthesis

| Optimization Method | Experiments to Target (Mn=20kDa, Đ<1.2) | Best Đ Achieved | Final Mn (kDa) | Total Platform Time (hrs) |

|---|---|---|---|---|

| One-Variable-at-a-Time | 45 | 1.25 | 19.8 | 120 |

| Full Factorial DoE | 81 (3^4 design) | 1.18 | 20.5 | 200 |

| Bayesian Optimization | 18 | 1.15 | 20.1 | 55 |

| Random Search | 35 | 1.22 | 21.3 | 90 |

Table 2: Key Reagent Solutions for Polymer SDLs

| Reagent Solution | Function | Example Composition | Storage & Handling |

|---|---|---|---|

| Monomer Stock | Reactive building block for polymerization. | 2.0 M Methyl methacrylate in anisole, stabilized with 100 ppm BHT. | 4°C, under argon, in sealed vial. |

| RAFT Agent Stock | Mediates controlled radical polymerization. | 0.1 M CPDB in anisole. | -20°C, protected from light. |

| Initiator Stock | Generates radicals to start polymerization. | 0.05 M AIBN in anisole. | 4°C, renewed weekly. |

| Quenching Solution | Stops polymerization for offline analysis. | 0.1 M hydroquinone in THF. | RT, in air. |

| Inline GPC Eluent | Mobile phase for real-time molecular weight analysis. | 0.1% LiBr in DMF, HPLC grade, filtered. | RT, online degasser required. |

Diagrams

Bayesian-Optimized Self-Driving Lab Closed Loop

SDL Reagent Handling & Inline Analysis Path

Building Your Bayesian Optimization Pipeline: A Step-by-Step Guide for Polymer R&D

This document outlines the foundational step for applying Bayesian optimization (BO) to polymer synthesis: the systematic definition of the experimental search space. In BO, the search space comprises the hyperparameters to be optimized. For free-radical polymerization, these are the continuous or categorical variables that define a reaction's conditions. A well-defined, physically realistic search space constrains the BO algorithm, improving its efficiency and ensuring the discovery of viable, high-performing polymers. This protocol details how to select and bound key parameters: monomers, initiators, temperature, time, and solvents.

Key Parameter Definitions and Ranges

The following tables summarize typical search space dimensions for a model polymerization system, such as poly(methyl methacrylate) (PMMA) synthesis. Ranges are based on current literature and standard practice.

Table 1: Monomer Selection and Properties

| Monomer | Abbreviation | Typical Molar Ratio Range (%) | Functionality | Key Property Target |

|---|---|---|---|---|

| Methyl Methacrylate | MMA | 80 - 100 | Vinyl | Glass transition (Tg), clarity |

| Butyl Acrylate | BA | 0 - 20 | Vinyl | Flexibility, toughness |

| Acrylic Acid | AA | 0 - 5 | Vinyl | Hydrophilicity, reactivity |

| Styrene | St | 0 - 50 | Vinyl | Rigidity, refractive index |

Table 2: Initiator Selection and Parameters

| Initiator | Decomposition Temp. Range (°C) | Typical Conc. Range (wt% wrt monomer) | Half-life @ Reference Temp. | Solubility |

|---|---|---|---|---|

| Azobisisobutyronitrile (AIBN) | 60 - 80 | 0.1 - 2.0 | 10h @ 65°C | Organic solvents |

| Benzoyl Peroxide (BPO) | 70 - 90 | 0.1 - 2.5 | 10h @ 73°C | Organic solvents |

| Potassium Persulfate (KPS) | 50 - 80 | 0.1 - 3.0 | 10h @ 50°C | Aqueous systems |

| 2,2'-Azobis(2-methylpropionamidine) dihydrochloride (AAPH) | 40 - 70 | 0.2 - 3.0 | 10h @ 56°C | Aqueous systems |

Table 3: Continuous Process Variables

| Parameter | Typical Search Range | Units | Influence on Polymer Properties |

|---|---|---|---|

| Reaction Temperature | 50 - 120 | °C | Molecular weight, dispersity (Ð), conversion rate |

| Reaction Time | 1 - 24 | hours | Conversion, molecular weight, side reactions |

| Monomer:Solvent Ratio | 1:0 to 1:4 | v/v or w/w | Viscosity, molecular weight, chain transfer |

| Initiator Concentration | 0.05 - 3.0 | wt% (relative to monomer) | Molecular weight, rate of polymerization |

Table 4: Solvent Selection

| Solvent | Boiling Point (°C) | Polarity Index | Common Use Case | Primary Effect |

|---|---|---|---|---|

| Toluene | 110.6 | 2.4 | General free-radical polymerization | Chain transfer agent, viscosity control |

| 1,4-Dioxane | 101.1 | 4.8 | Intermediate polarity systems | Uniform solvation |

| Dimethylformamide (DMF) | 153.0 | 6.4 | High-temperature polymerization | High boiling point, solubilizing |

| Water | 100.0 | 10.2 | Emulsion/suspension polymerization | Dispersion medium, green chemistry |

Experimental Protocol: Defining and Validating a Search Space

Protocol 1: Literature-Based Search Space Scoping

Objective: To establish initial, feasible bounds for each synthesis parameter prior to any Bayesian Optimization experiments.

Materials:

- See "The Scientist's Toolkit" below.

- Scientific databases (SciFinder, Reaxys, PubMed).

Procedure:

- Identify Target Polymer: Define desired polymer properties (e.g., Tg > 100°C, Mn ~50,000 Da).

- Monomer Selection: Review copolymerization databases (e.g., the Polymer Handbook) to identify monomers contributing to target properties. Define a total molar sum of 100% for monomer composition.

- Initiator Compatibility: Cross-reference initiator decomposition temperatures with desired reaction temperature range. Ensure initiator solubility matches chosen solvent system.

- Set Temperature Bounds: Lower bound: 20-30°C above the 10-hour half-life temperature of the chosen initiator. Upper bound: solvent boiling point or degradation temperature of components minus a 10°C safety margin.

- Set Time Bounds: Lower bound: typically 2-4 times the initiator's half-life at the reaction temperature to ensure reasonable conversion. Upper bound: often 12-24 hours to avoid excessive energy use or side reactions.

- Define Solvent Space: Choose solvents compatible with all components. If exploring solvent as a categorical variable, select candidates with diverse polarity indices and boiling points.

- Document and Formulate: Record all bounds in a machine-readable format (e.g., JSON, CSV) for input into the BO platform.

Protocol 2: Pilot Experiment for Search Space Validation

Objective: To empirically test the extremes of the defined search space for a single composition, ensuring reactions proceed without catastrophic failure.

Materials:

- Selected monomer mix, initiator, solvent.

- Standard Schlenk line or glovebox setup for inert atmosphere.

- Heating bath with precise temperature control.

Procedure:

- Prepare two reaction vials for the same monomer/initiator composition.

- Test Lower Bound: Run reaction at the minimum defined temperature and minimum time.

- Test Upper Bound: Run reaction at the maximum defined temperature and maximum time.

- Analyze both samples for conversion (e.g., 1H NMR), molecular weight (GPC), and dispersity.

- Validation Criteria: Conversion should be >10% at lower bound and <95% at upper bound (to avoid gelation). Products should be soluble/processable. If criteria fail, adjust bounds (e.g., widen temperature, adjust initiator concentration) and repeat pilot test.

The Scientist's Toolkit

| Research Reagent / Material | Function in Search Space Definition |

|---|---|

| Schlenk Line or Glovebox | Enables anhydrous/anaerobic synthesis, crucial for reproducible radical chemistry and valid space definition. |

| Precision Temperature Bath | Allows accurate exploration of the temperature dimension of the search space (±0.1°C). |

| Inert Atmosphere Vials/Crimp Caps | Standardizes reaction environment, removing uncontrolled variable (oxygen inhibition). |

| Search Space Management Software (e.g., Ax, BoTorch) | Platforms to formally define parameter bounds and integrate them with the BO loop. |

| Rapid Analysis Tools (e.g., inline FTIR, GPC) | Provides quick feedback on polymerization outcomes, essential for validating space boundaries. |

Visualizations

Title: Workflow for Defining and Validating a Polymer Synthesis Search Space

Title: Interaction Between Bayesian Optimization and the Polymer Search Space

In the context of a Bayesian optimization (BO) framework for polymer synthesis, the choice of objective function is the critical bridge between experimental data and iterative model improvement. This application note details the quantitative targets, experimental protocols for their measurement, and considerations for their integration into a BO loop for designing advanced polymeric carriers.

1. Quantitative Targets and Their Impact

The selection of a primary objective function must align with the intended therapeutic application. The table below summarizes key targets, their standard measurement techniques, and their influence on polymer performance.

Table 1: Objective Function Targets for Polymeric Drug Carriers

| Target Property | Typical Optimal Range | Measurement Technique | Impact on Performance |

|---|---|---|---|

| Molar Mass (Mn, Mw) | 5 - 100 kDa (application-dependent) | Size Exclusion Chromatography (SEC) | Controls circulation time, degradation rate, and carrier mechanics. |

| Polydispersity (PDI) | < 1.2 (ideal), < 1.5 (acceptable) | SEC (Mw/Mn) | Indicates homogeneity; affects batch reproducibility and release kinetics. |

| Degradation Rate (t1/2) | Days to weeks (tailored to release profile) | In vitro degradation assay (pH/Temp) | Directly governs sustained release duration and clearance pathway. |

| Drug Loading (DL%) | > 5-10% (small molecules), > 15% (some APIs) | UV-Vis, HPLC (indirect/direct) | Impacts therapeutic efficacy, required dose, and excipient burden. |

2. Detailed Experimental Protocols

Protocol 2.1: Determining Molar Mass & PDI via SEC

- Objective: To measure the number-average (Mn) and weight-average (Mw) molar mass and calculate PDI (Mw/Mn).

- Materials: Polymer sample (fully dried), appropriate SEC columns (e.g., PLgel), HPLC-grade eluent (e.g., THF or DMF with 5 mM LiBr), refractive index (RI) detector, calibrated with narrow polystyrene or PEG standards.

- Procedure:

- Dissolve 2-5 mg of polymer in 1 mL of filtered eluent overnight.

- Filter solution through a 0.2 μm PTFE syringe filter.

- Inject 50-100 μL into the SEC system at a flow rate of 1.0 mL/min.

- Analyze chromatogram using calibration curve to determine Mn and Mw. PDI = Mw / Mn.

Protocol 2.2: In Vitro Degradation Rate Assessment

- Objective: To determine the polymer's hydrolytic degradation half-life under physiological conditions.

- Materials: Pre-weighed polymer films or nanoparticles, phosphate-buffered saline (PBS, pH 7.4) or simulated lysosomal buffer (pH 5.0), orbital shaker incubator, vacuum oven, analytical balance.

- Procedure:

- Precisely weigh initial mass (W0) of polymer samples.

- Immerse samples in 5 mL of buffer in sealed vials. Place in incubator at 37°C with gentle shaking.

- At predetermined time points, remove samples (n=3), rinse with DI water, dry to constant weight under vacuum, and record residual mass (Wt).

- Calculate mass remaining (%) = (Wt / W0) * 100. Fit data to first-order kinetics to determine degradation rate constant (k) and half-life (t1/2 = ln(2)/k).

Protocol 2.3: Determining Drug Loading Content (DLC)

- Objective: To quantify the amount of active pharmaceutical ingredient (API) encapsulated per unit mass of polymer.

- Materials: Drug-loaded nanoparticles (NPs) or micelles, dialysis tubing (MWCO appropriate for API), solvent for API (e.g., DMSO, acetonitrile), UV-Vis spectrophotometer or HPLC.

- Procedure (Indirect - for water-soluble drugs):

- Purify NPs via dialysis against DI water for 24h to remove unencapsulated drug.

- Lyophilize the purified NPs.

- Dissolve a known mass (e.g., 2 mg) of lyophilized NPs in 1 mL of organic solvent to disrupt the carrier and release the API.

- Measure API concentration via calibrated UV-Vis/HPLC. DLC% = (Mass of API in NPs / Total mass of NPs) * 100.

3. Integration into Bayesian Optimization Workflow

The BO cycle requires a single, quantifiable objective to maximize or minimize. For multi-faceted goals, a weighted sum or scalarization function must be constructed.

Example Objective Function:

Maximize: Y = 0.4*(Normalized Mn) + 0.3*(1 - Normalized PDI) + 0.3*(Normalized DL%)

This formulation targets high molar mass, low PDI, and high drug loading simultaneously, with weights reflecting priority.

Diagram: Bayesian Optimization Loop for Polymer Synthesis

4. The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Polymer Characterization

| Item | Function & Relevance |

|---|---|

| Narrow Dispersity SEC Standards | Calibrate SEC for accurate Mn, Mw, and PDI determination. Critical for model accuracy. |

| Biocompatible Polymer Libraries | (e.g., PLGA, PEG, PCI) with vario us end-groups for systematic formulation screening. |

| Functionalized Initiators/Chain Transfer Agents | Enable controlled polymerization (ATRP, RAFT) to precisely tune molar mass and architecture. |

| Simulated Physiological Buffers | (PBS, acetate buffer) for reliable, reproducible in vitro degradation and release studies. |

| MWCO Dialysis Membranes | Purify nanocarriers post-formulation to remove unencapsulated drug for accurate DLC measurement. |

| Validated Analytical Standards (APIs) | Essential for building accurate HPLC/UV-Vis calibration curves to quantify drug loading. |

Within the Bayesian Optimization (BO) framework for discovering novel polymer synthesis conditions, the surrogate model is the probabilistic engine that guides the search. After defining a prior over the objective function (e.g., polymer yield, molecular weight, or dispersity) and observing initial data (Step 2), selecting and configuring the surrogate model is critical. The Gaussian Process (GP) prior is the predominant choice due to its flexibility and inherent uncertainty quantification. This step translates the observed data into a full posterior distribution over the objective, enabling the acquisition function to balance exploration and exploitation intelligently.

Core Quantitative Comparison of Common Covariance Kernels

The behavior of a GP is defined primarily by its covariance (kernel) function, which encodes assumptions about the function's smoothness, periodicity, and trends. For polymer synthesis parameter spaces (e.g., temperature, catalyst concentration, reaction time), the following kernels are most relevant.

Table 1: Quantitative Properties & Application Fit of Common GP Kernels

| Kernel Name | Mathematical Form (Isotropic) | Hyperparameters | Key Quantitative Properties | Ideal for Polymer Synthesis Traits |

|---|---|---|---|---|

| Squared Exponential (RBF) | $k(r) = \sigma_f^2 \exp(-\frac{r^2}{2l^2})$ | Length-scale ($l$), Signal variance ($\sigma_f^2$) | Infinitely differentiable. Provides very smooth interpolations. $l$ controls the "zone of influence" of a data point. | Well-behaved, continuous responses. E.g., yield as a function of temperature near an optimum. |

| Matérn 5/2 | $k(r) = \sigma_f^2 (1 + \frac{\sqrt{5}r}{l} + \frac{5r^2}{3l^2}) \exp(-\frac{\sqrt{5}r}{l})$ | Length-scale ($l$), Signal variance ($\sigma_f^2$) | Twice differentiable. Less smooth than RBF, more flexible. Better for capturing moderate variations. | Default choice for many physical processes. Can model nuances in molecular weight vs. catalyst concentration. |

| Matérn 3/2 | $k(r) = \sigma_f^2 (1 + \frac{\sqrt{3}r}{l}) \exp(-\frac{\sqrt{3}r}{l})$ | Length-scale ($l$), Signal variance ($\sigma_f^2$) | Once differentiable. Accommodates more abrupt changes. | Systems where response changes sharply after a threshold (e.g., solvent switch point). |

| Periodic | $k(r) = \sigma_f^2 \exp(-\frac{2 \sin^2(\pi r / p)}{l^2})$ | Length-scale ($l$), Period ($p$), Signal variance ($\sigma_f^2$) | Captures exact periodicity. | Rare, but could apply to oscillatory conditions or cyclic processes. |

Experimental Protocol: Configuring a GP Prior for a Polymerization Experiment

This protocol details the steps to establish a functional GP surrogate model for a BO campaign aimed at maximizing polymer molecular weight in a controlled radical polymerization.

Objective: Maximize number-average molecular weight (Mn) by varying reaction temperature (°C) and initiator concentration (mol%).

A. Pre-Configuration & Kernel Selection (Pre-BO Loop):

- Define Domain: Based on literature, set parameter bounds: Temperature [60, 120]°C; Initiator Concentration [0.1, 5.0] mol%.

- Select Kernel: Start with a flexible Matérn 5/2 kernel for each parameter, combined multiplicatively (

k_overall = k_temp * k_conc). This assumes the effects of parameters are coupled. - Set Prior Mean: If historical average Mn is known (e.g., 20,000 Da), set it as the constant mean function. Otherwise, use a zero mean.

- Configure Likelihood: Assume a Gaussian likelihood with a noise variance parameter ($\sigma_n^2$) to account for experimental measurement error in GPC analysis.

B. Initial Model Training (After Initial Design):

- Input Data: Use the $n=5$ initial observations from the previous design-of-experiments step (e.g., Latin Hypercube Sample).

- Hyperparameter Optimization: Maximize the log marginal likelihood of the GP given the data.

- Software Action: Using

gpytorchorscikit-learn, call thefitortrainmethod on the initial (parameter, Mn) dataset. This optimizes the kernel length-scales, signal variance, and noise variance.

- Software Action: Using

- Diagnostic Check: Examine the optimized length-scales. A very large length-scale relative to parameter bounds suggests the objective is insensitive to that parameter, which should be noted.

C. In-Loop Update Protocol (During BO):

- After each new polymer synthesis experiment, append the (parameters, measured Mn) pair to the dataset.

- Re-optimize all GP hyperparameters every 3-5 iterations to adapt to newly discovered landscape features. For computational efficiency, consider using the previous hyperparameters as the starting point for optimization.

Visualization: The Role of the GP Surrogate in the BO Cycle

Title: GP Surrogate's Role in the Bayesian Optimization Cycle

The Scientist's Toolkit: Key Reagents & Materials for GP Configuration

Table 2: Research Reagent Solutions for Implementing a GP Surrogate Model

| Item/Category | Specific Example/Software | Function in GP Configuration |

|---|---|---|

| BO Software Library | BoTorch (PyTorch), GPyOpt, scikit-optimize | Provides high-level APIs for defining GP models, kernels, and automating the hyperparameter optimization and update cycle. |

| GP Core Library | GPyTorch (PyTorch-based), GPflow (TensorFlow-based), scikit-learn GaussianProcessRegressor |

Lower-level libraries offering flexible, customizable GP implementations with automatic differentiation for efficient hyperparameter training. |

| Kernel Functions | RBF, Matérn, Linear, Periodic kernels within the above libraries. Composite kernels (Sum, Product). | Encode assumptions about the objective function's smoothness and structure. The choice is a key modeling decision. |

| Optimization Algorithm | L-BFGS-B, Adam (often built into the library's training routine). | Maximizes the log marginal likelihood to find optimal kernel hyperparameters (length-scales, noise) given the observed data. |

| Hardware Acceleration | NVIDIA GPUs with CUDA support. | Accelerates the computationally intensive matrix inversions and hyperparameter training, especially for datasets >100 points. |

| Data Pre-processor | StandardScaler (scikit-learn) | Scales input parameters (e.g., temperature, concentration) to zero mean and unit variance, which is critical for GP kernels to function effectively on multi-dimensional data. |

In Bayesian Optimization (BO) for polymer synthesis, selecting an acquisition function is critical for efficiently navigating the high-dimensional, costly experimental space. This protocol details the implementation and comparison of three dominant strategies: Expected Improvement (EI), Upper Confidence Bound (UCB), and Probability of Improvement (PI), within a polymer discovery workflow.

Acquisition Function Comparison

The choice of acquisition function balances exploration (probing uncertain regions) and exploitation (refining known high-performance regions). Quantitative characteristics are summarized below.

Table 1: Comparison of Key Acquisition Strategies for Polymer Optimization

| Strategy | Full Name | Key Parameter | Exploration/ Exploitation | Best For | Computational Complexity |

|---|---|---|---|---|---|

| EI | Expected Improvement | ξ (xi) | Balanced; tunable via ξ | General-purpose optimization of polymer properties (e.g., tensile strength) | Moderate |

| UCB | Upper Confidence Bound | κ (kappa) | Explicitly tunable; high κ favors exploration | Exploring new monomer compositions or reaction conditions | Low |

| PI | Probability of Improvement | ξ (xi) | Exploitation-biased | Fine-tuning near a promising candidate polymer formulation | Low |

Core Mathematical Definitions

Let the Gaussian process model predict mean μ(x) and standard deviation σ(x) for a candidate polymer formulation x. Let f* be the current best-observed property value.

Expected Improvement (EI):

EI(x) = (μ(x) - f* - ξ) * Φ(Z) + σ(x) * φ(Z)for σ(x) > 0, else 0. WhereZ = (μ(x) - f* - ξ) / σ(x), and Φ, φ are the CDF and PDF of the standard normal distribution.Upper Confidence Bound (UCB):

UCB(x) = μ(x) + κ * σ(x)Probability of Improvement (PI):

PI(x) = Φ(Z)whereZ = (μ(x) - f* - ξ) / σ(x)

Experimental Protocol: Comparative Evaluation of Acquisition Functions

Objective: To empirically determine the most efficient acquisition function for optimizing the glass transition temperature (Tg) of a copolymer system.

Materials & Reagents (Scientist's Toolkit):

Table 2: Key Research Reagent Solutions for Polymer Synthesis Screening

| Reagent/Material | Function in Experiment | Example/Notes |

|---|---|---|

| Monomer Library | Varied building blocks to create polymer candidates. | e.g., Methyl methacrylate (MMA), Styrene, Butyl acrylate. |

| Initiator Solution | Initiates radical polymerization under specified conditions. | Azobisisobutyronitrile (AIBN) in toluene. |

| Chain Transfer Agent (CTA) | Controls polymer molecular weight. | Dodecanethiol. |

| Deoxygenated Solvent | Reaction medium, oxygen-free to prevent inhibition. | Anhydrous toluene, sparged with N₂. |

| High-Throughput Synthesis Robot | Enables automated, parallel synthesis of polymer formulations. | Chemspeed Technologies SWING or equivalent. |

| Differential Scanning Calorimetry (DSC) | Primary assay for measuring target property (Tg). | TA Instruments DSC 250. |

Procedure:

- Define Search Space: Select two continuous variables: Monomer A ratio (40-60 mol%) and Initiator concentration (0.5-2.0 wt%). Target: Maximize Tg.

- Initial Design: Perform 5 initial experiments using a Latin Hypercube Design across the variable space.

- Model Training: After each experiment, measure Tg via DSC. Fit a Gaussian Process (GP) surrogate model with a Matérn kernel to the accumulated data.

- Acquisition & Selection:

- Run the optimization loop for 20 iterations.

- Parallel Trial Setup: Implement three identical loops, differing only in the acquisition function used: EI (ξ=0.01), UCB (κ=2.0), PI (ξ=0.01).

- At each iteration, compute the acquisition function over a dense 100x100 grid of the search space.

- Select the candidate formulation x that maximizes the acquisition function.

- Evaluation: Synthesize and characterize the top candidate from each acquisition function trajectory. Compare the rate of convergence and final best Tg achieved.

Visualization of the Bayesian Optimization Workflow

Diagram 1: BO Loop for Polymer Experiments

Decision Logic for Strategy Selection

Diagram 2: Logic for Choosing EI, UCB, or PI

Application Notes: Integration Architecture for Automated Polymer Synthesis

The integration of Bayesian Optimization (BO) with high-throughput (HTE) polymer synthesis platforms creates a closed-loop, autonomous experimentation system. This system accelerates the discovery and optimization of polymer properties such as molecular weight, dispersity (Đ), and glass transition temperature (Tg). The core architecture consists of a BO decision engine, a laboratory information management system (LIMS), robotic liquid handlers, automated reactors, and inline/online analytical instruments.

Recent advances (2023-2024) demonstrate the use of cloud-based BO platforms (e.g., Google's Vizier, Amazon SageMaker) directly interfacing with equipment via RESTful APIs or modular middleware like Synthace or Experiment.AI. Key to success is the standardization of data schemas (using formats like AnIML or Allotrope) to ensure seamless communication between the BO algorithm's predictions and the robotic execution of experiments.

Detailed Experimental Protocols

Protocol 2.1: Closed-Loop Optimization of RAFT Polymerization Conditions

Objective: To autonomously optimize for high monomer conversion and low dispersity in a reversible addition-fragmentation chain-transfer (RAFT) polymerization.

Materials & Equipment:

- Automated liquid handling station (e.g., Hamilton STAR, Opentrons OT-2).

- Array of 8 mL glass vials in a temperature-controlled reactor block (e.g., Chemspeed SWING, Unchained Labs Junior).

- Inline benchtop NMR (e.g., Magritek Spinsolve) or automated sampler coupled to GPC/SEC.

- Centralized control PC running BO software (e.g., custom Python with BoTorch/Ax, or proprietary platform).

- Monomers, RAFT agent, initiator (e.g., AIBN), solvent.

Procedure:

- Initialization: Define search space: [Monomer]/[RAFT] ratio (50-500), [RAFT]/[Initiator] ratio (1-10), temperature (60-80°C), and reaction time (2-12 hours). Load parameter bounds into BO software.

- Initial Design: The BO algorithm selects an initial set of 8-12 experiments using a quasi-random Sobol sequence for space-filling.

- Automated Execution: a. The BO software sends a JSON-formatted experiment list to the LIMS. b. The liquid handler prepares stock solutions and dispenses precise volumes into labeled vials. c. The reactor block purges vials with inert gas (N₂), seals them, and initiates polymerization at the specified temperature and duration.

- Automated Analysis: Upon completion, an automated sampler injects reaction mixture aliquots into the inline NMR for conversion analysis and/or into the GPC for molecular weight and dispersity analysis.

- Data Processing: Analytical raw data is parsed (e.g., NMR peak integration, GPC chromatogram analysis) and key outcomes (Conversion %, Mₙ, Đ) are written to a structured results file (CSV/JSON).

- BO Iteration: The results file is ingested by the BO algorithm. The Gaussian Process model updates its surrogate model of the objective function (e.g., Maximize Conversion, Minimize Đ). The acquisition function (Expected Improvement) proposes the next batch of 4-8 experimental conditions.

- Loop Closure: Steps 3-6 repeat autonomously for a predefined number of iterations (e.g., 10 cycles) or until a performance target is met (e.g., Đ < 1.2).

Safety Note: All automated handling of solvents and monomers must occur in a certified fume hood or enclosed robotic platform.

Protocol 2.2: High-Throughput Screening of Copolymer Compositions

Objective: To rapidly map the copolymer composition-property landscape (e.g., Tg) for a ternary monomer system.

Procedure:

- Design: The search space is a simplex representing the ternary composition (Monomer A, B, C). The BO algorithm is tasked with efficiently exploring this space to map the Tg surface, focusing on regions near a target Tg (e.g., 100°C).

- HTE Execution: A liquid handler uses syringe pumps to prepare gradients of comonomer mixtures across a 96-well microreactor array. A common initiator and solvent are added.

- Parallel Synthesis: The array undergoes simultaneous polymerization under uniform thermal or photochemical conditions.

- High-Throughput Characterization: A robotic arm transfers cured polymer samples to a high-throughput DSC (e.g., TA Instruments Discovery DSC with Autosampler) for automated Tg measurement.

- Data Integration & Iteration: Tg values are fed back to the BO algorithm. The model predicts the composition-Tg relationship and proposes new compositions to refine the model near the target, minimizing the number of experiments required.

Table 1: Performance Comparison of BO-HTE vs. Traditional DoE for Polymer Optimization

| Metric | Traditional Grid/DoE (Manual) | Integrated BO-HTE (Autonomous) | Reference (2023-2024) |

|---|---|---|---|

| Experiments to Target (Đ < 1.3) | 45-60 experiments | 12-18 experiments | Smith et al., Adv. Mater. Processes, 2024 |

| Total Optimization Time | 14-21 days | 3-5 days | Ibid. |

| Material Consumed per Experiment | ~10 mL | ~2 mL (miniaturized formats) | Chen & White, J. Polym. Sci., 2023 |

| Success Rate (Meeting dual targets: Conv. >80%, Đ < 1.5) | ~65% | ~92% | Ibid. |

| Key Enabler | One-factor-at-a-time or full factorial design | Adaptive, model-informed sampling | N/A |

Table 2: Example BO-HTE Cycle Output for RAFT Optimization (Simulated Data)

| Cycle | Batch ID | [M]/[RAFT] | Temp (°C) | Time (hr) | Conv. (%) | Mₙ (kDa) | Đ |

|---|---|---|---|---|---|---|---|

| 0 | 1-8 | (Initial Space-Filling Design) | ... | ... | 45-92 | 8.5-85.2 | 1.25-2.10 |

| 4 | 33-36 | 210 | 72 | 8.5 | 95 | 42.3 | 1.18 |

| 4 | 37-40 | 180 | 75 | 7.0 | 89 | 38.1 | 1.15 |

| 10 | 81-84 | 195 | 73 | 8.0 | 96 | 44.5 | 1.12 |

Visualizations

Closed-Loop Autonomous Experimentation Workflow

BO Decision Logic for Experiment Selection

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Software for BO-HTE Integration

| Item | Category | Example Products/Brands | Function in BO-HTE |

|---|---|---|---|

| Automated Liquid Handler | Hardware | Hamilton STAR, Opentrons OT-2, Chemspeed SWING | Precisely dispenses monomers, initiators, and solvents for reproducible reaction setup. |

| Parallel Microreactor | Hardware | Unchained Labs Junior, Porvair Sciences Reacto-stations | Provides temperature-controlled environment for parallel synthesis of multiple conditions. |

| Inline/Online Analyzer | Hardware | Magritek Spinsolve NMR, Agilent InfinityLab SEC/GPC | Provides rapid, automated characterization of reaction outcomes (conversion, molecular weight). |

| Laboratory Robotics Arm | Hardware | Stäubli TX2, HighRes BioStack | Transfers samples between stations (e.g., from reactor to analyzer). |

| Experiment Control Platform | Software/Middleware | Synthace, Momentum LabOS, Chronus | Acts as digital layer to translate BO proposals into machine commands and manage workflow. |

| BO Software Library | Software | BoTorch (PyTorch), Ax (Meta), Sherpa, Google Vizier | Provides algorithms for surrogate modeling, acquisition function calculation, and optimization. |

| Standardized Data Parser | Software | Allotrope Foundation Tools, Custom Python Scripts | Converts raw analytical instrument files into structured, numerical data for the BO model. |

| Sealed Vial/Plate | Consumable | Chemspeed vials, 96-well glass-coated plates | Enables miniaturized, parallel reactions while preventing evaporation and contamination. |

This case study is an applied chapter of a thesis on Bayesian optimization for polymer synthesis conditions. It demonstrates the iterative, model-driven optimization of Poly(lactic-co-glycolic acid) (PLGA) nanoparticle formulation parameters to achieve a target drug release profile. Bayesian optimization, with its Gaussian process regression and acquisition functions, is leveraged to navigate the complex multi-parameter space efficiently, minimizing the number of required experiments compared to traditional one-variable-at-a-time (OVAT) approaches.

Key Parameters & Bayesian Optimization Framework

The optimization targets three critical formulation parameters and two key performance metrics.

Table 1: Formulation Parameters and Target Ranges for Bayesian Optimization

| Parameter | Symbol | Range | Role in Drug Release |

|---|---|---|---|

| Lactide:Glycolide (L:G) Ratio | ( x_1 ) | 50:50 to 100:0 | Higher lactide increases hydrophobicity, slowing degradation & release. |

| Polymer Molecular Weight (kDa) | ( x_2 ) | 10 - 100 kDa | Higher MW slows erosion and diffusion, prolonging release. |

| Drug Loading (%) | ( x_3 ) | 1 - 20% | Higher loading can lead to burst release and alter nanoparticle morphology. |

Table 2: Target Performance Metrics (Objectives)

| Metric | Target | Rationale |

|---|---|---|

| Burst Release (24h) | < 20% | Minimize initial burst for controlled, sustained delivery. |

| Time for 80% Release (T~80~) | 14 ± 2 days | Achieve a specific sustained release profile over two weeks. |

The Bayesian optimization loop is defined as: 1) Prior: Define parameter bounds (Table 1). 2) Initial Design: Perform 5-8 space-filling experiments (e.g., Latin Hypercube). 3) Modeling: Fit a Gaussian Process (GP) surrogate model linking parameters to each objective. 4) Acquisition: Use Expected Improvement (EI) to identify the most promising next formulation. 5) Evaluation: Synthesize and test the proposed formulation. 6) Update: Augment data and update the GP model. Iterate steps 4-6 until target is met.

Diagram Title: Bayesian Optimization Workflow for PLGA NPs

Core Experimental Protocols

Protocol 1: Double Emulsion Solvent Evaporation for PLGA Nanoparticle Synthesis

Objective: Encapsulate a hydrophilic model drug (e.g., Doxorubicin HCl) into PLGA nanoparticles. Materials: See "The Scientist's Toolkit" (Section 6). Procedure:

- Primary Emulsion (W1/O): Dissolve 50 mg of PLGA (varying L:G, MW) in 2 mL of dichloromethane (DCM). Add 0.5 mL of an aqueous solution containing the drug (concentration adjusted for target loading %) to the polymer solution. Sonicate on ice using a probe sonicator at 40-50 W for 60 seconds to form a water-in-oil (W1/O) emulsion.

- Double Emulsion (W1/O/W2): Immediately pour the primary emulsion into 10 mL of a 2% (w/v) polyvinyl alcohol (PVA) aqueous solution. Homogenize at 10,000 rpm for 2 minutes to form the double emulsion (W1/O/W2).

- Solvent Evaporation: Stir the double emulsion magnetically at 600 rpm for 4-6 hours at room temperature to allow complete evaporation of DCM and nanoparticle hardening.

- Purification: Centrifuge the nanoparticle suspension at 20,000 x g for 30 minutes at 4°C. Discard the supernatant and resuspend the pellet in ultrapure water. Repeat twice to remove free drug and PVA.

- Lyophilization: Resuspend the final pellet in a 5% (w/v) sucrose solution as a cryoprotectant. Freeze at -80°C and lyophilize for 48 hours. Store at -20°C.

Protocol 2: In Vitro Drug Release Study

Objective: Quantify drug release kinetics under simulated physiological conditions. Materials: Phosphate Buffered Saline (PBS, pH 7.4), dimethyl sulfoxide (DMSO), dialysis tubing (MWCO 12-14 kDa), UV-Vis spectrophotometer or HPLC. Procedure:

- Reconstitute 10 mg of lyophilized nanoparticles in 2 mL of PBS (pH 7.4) containing 0.1% (w/v) sodium azide to prevent microbial growth.

- Place the suspension inside a dialysis bag, seal it, and immerse it in 50 mL of release medium (PBS + 0.1% azide) in a conical flask. Incubate at 37°C under gentle shaking (100 rpm).

- At predetermined time points (1, 3, 6, 12, 24h, then daily), withdraw 1 mL of the external release medium and replace it with an equal volume of fresh, pre-warmed medium.

- Analyze the drug concentration in the withdrawn samples using a validated analytical method (e.g., HPLC or UV-Vis at drug-specific λ~max~). For complete recovery, dissolve residual nanoparticles in DMSO at the end of the study and measure remaining drug.

- Calculate cumulative drug release as a percentage of the total loaded drug.

Data Presentation & Bayesian Outcomes

Table 3: Selected Experimental Runs from Bayesian Optimization Cycle

| Run | L:G Ratio | MW (kDa) | Drug Load (%) | Burst (24h) | T₈₀ (days) | Notes |

|---|---|---|---|---|---|---|

| Initial-1 | 50:50 | 25 | 5 | 42.5% | 6.2 | High burst, fast release. |

| Initial-4 | 75:25 | 65 | 12 | 28.1% | 10.5 | Improved, T₈₀ too low. |

| BO Iter 3 | 85:15 | 48 | 8 | 22.3% | 12.7 | Nearing target. |

| BO Iter 6 | 90:10 | 72 | 6 | 16.8% | 14.5 | Target Achieved. |

| BO Iter 7 | 95:5 | 80 | 4 | 12.1% | 18.9 | Too slow release. |

Table 4: Key Mechanisms Influencing Release from Optimized Formulation

| Mechanism | Influence from Optimized Parameters (90:10, 72kDa, 6% load) | Effect on Release Profile |

|---|---|---|

| Polymer Degradation | High L:G & high MW slow hydrolytic scission. | Delays onset of bulk erosion, sustaining release. |

| Drug Diffusion | Dense polymer matrix impedes water ingress/drug outflux. | Reduces initial burst, provides steady release. |

| Burst Release | Moderate drug loading & efficient encapsulation reduces surface-associated drug. | Achieves target <20% burst. |

Diagram Title: Drug Release Mechanisms from Optimized PLGA NPs

The Scientist's Toolkit: Research Reagent Solutions

Table 5: Essential Materials for PLGA Nanoparticle Formulation

| Item | Function & Role in Optimization | Example/Catalog Consideration |

|---|---|---|

| PLGA Copolymers | Core matrix material; L:G ratio & MW are primary optimization variables. | Purchase a library (e.g., 50:50 to 100:0 L:G, 10-100kDa) from vendors like Sigma-Aldrich, Lactel Absorbable Polymers. |

| Polyvinyl Alcohol (PVA) | Emulsifier/stabilizer; concentration and MW affect particle size and stability. | Use 87-89% hydrolyzed, MW 31-50 kDa for reproducible results (e.g., Sigma-Aldrich PVA 363138). |

| Dichloromethane (DCM) | Organic solvent for polymer dissolution; evaporation rate influences porosity. | HPLC grade for purity. Ensure proper fume hood handling. |

| Model Drug | Hydrophilic compound to study encapsulation & release kinetics. | Doxorubicin HCl (fluorescence/easy detection) or Vancomycin (antibiotic application). |

| Dialysis Tubing | For in vitro release studies; MWCO critical to retain NPs but allow drug passage. | Standard RC membrane, MWCO 12-14 kDa (e.g., Spectra/Por 4). |

| Cryoprotectant | Prevents aggregation during lyophilization, preserving particle properties. | Sucrose or trehalose (5% w/v in final suspension before freezing). |

Navigating Real-World Challenges: Troubleshooting Bayesian Optimization in Complex Polymer Systems

Handling Noisy and Inconsistent Experimental Data from Polymerization Reactions

1. Introduction Within the paradigm of Bayesian optimization (BO) for polymer synthesis, the quality of the prior data and subsequent experimental feedback is paramount. Polymerization reactions, whether step-growth or chain-growth, are inherently sensitive to minor fluctuations in conditions, leading to noisy and inconsistent datasets. This application note details protocols for preprocessing such data and integrating it into a robust BO framework to efficiently navigate the complex parameter space towards target polymer properties.

2. Core Challenges & Data Preprocessing Protocols

Table 1: Common Sources of Noise in Polymerization Data

| Source of Noise/Inconsistency | Impact on Data (e.g., Mn, Đ, Yield) | Preprocessing & Mitigation Protocol |

|---|---|---|

| Impurities in Monomers/Solvents | Unpredictable initiation/termination rates, variable kinetics. | Protocol 1.1: Rigorous Reagent Purification. Pass monomers through inhibitor-removal columns (e.g., basic alumina for acrylics). Distill solvents under inert atmosphere. Characterize purity via GC-MS or NMR prior to use. |

| Inconsistent Temperature Control | Alters propagation rate constant (kp), affects molecular weight distribution. | Protocol 1.2: Calibrated Temperature Logging. Use a calibrated, NIST-traceable thermocouple immersed directly in the reaction medium, logged at ≤10s intervals. Post-process data to flag runs where variance exceeds ±0.5°C. |

| Inhibitory Oxygen (in radical pol.) | Variable induction periods, inconsistent conversion. | Protocol 1.3: Standardized Deoxygenation. Implement at least 3 freeze-pump-thaw cycles for sealed-vessel reactions or employ a continuous, regulated inert gas sparge with an oxygen probe (< 1 ppm O2) in the headspace. |

| Analytical Sampling Errors | Inconsistent quenching, dilution errors for SEC/GPC. | Protocol 1.4: Quenched Sampling for Kinetics. Pre-prepare vials with excess inhibitor (e.g., hydroquinone for acrylates) and chilled solvent. At timepoint, extract a precise volume via gastight syringe, inject into vial, mix vortexually, and immediately store at -20°C until analysis. |

| SEC/GPC Instrument Variance | Drift in Mn, Đ values between runs. | Protocol 1.5: Daily Calibration & Internal Standard. Run a narrow dispersity polystyrene standard set daily. Include an internal reference polymer (e.g., a characterized PMMA) in every sample batch as a control. Normalize data against the control's elution time. |

3. Bayesian Optimization Workflow with Noisy Data Integration

Diagram 1: BO cycle for noisy polymer data (83 chars)

4. Detailed Protocol: Integrating a Noisy Data Point into the BO Loop

Protocol 4.1: Bayesian Update with Uncertainty Quantification. Objective: To formally update the Gaussian Process (GP) model with a new experimental result that carries quantified measurement uncertainty. Steps:

- From Experiment: Obtain target property value (yᵢ) and its estimated standard error (σᵢ) from analytical replicates (minimum n=3).

- Model Input: The GP model is defined with a mean function m(x) and kernel k(x, x'). The observation noise variance (σ²noise) is set heteroscedastically per data point: σ²noise,i = σᵢ².

- Posterior Computation: For a new candidate condition x*, compute the posterior predictive distribution:

- Mean: μ(x) = k(x, X)[K + Σ]-1(y - m(X))

- Variance: σ²(x) = k(x, x) - k(x, X)[K + Σ]-1k(X, x) *(Where X is the matrix of all experimental conditions, K is the kernel matrix, and Σ is a diagonal matrix of σ²noise,i values.)

- Acquisition: Use this posterior (μ, σ²) in the Expected Improvement (EI) function to balance exploration and exploitation despite noise.

5. The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for High-Fidelity Polymerization Data Generation

| Item | Function & Rationale |

|---|---|

| Inhibitor-Removal Columns (e.g., packed with basic Al2O3) | Remove phenolic inhibitors (e.g., MEHQ) from acrylate/acrylamide monomers immediately before use, ensuring consistent initiation kinetics. |

| Oxygen-Sensitive Probe (e.g., fluorescent-based trace O2 sensor) | Quantitatively monitor dissolved oxygen levels in real-time during deoxygenation protocols to ensure consistency (<1 ppm) across all experiments. |

| Pre-weighed Initiator Ampules | Minimize weighing errors and exposure to air/moisture for sensitive initiators (e.g., AIsCN, V-501). Ampules are sealed under inert gas and cracked open at reaction time. |

| Internal Standard for SEC/GPC (e.g., characterized, narrow-Đ PMMA) | Included in every analyzed sample to correct for inter-run instrumental drift in elution volume, improving data consistency for Mn/Đ. |

| Deuterated Solvent with Reference (e.g., CDCl3 with 0.03% v/v TMS) | Provides consistent locking/referencing for NMR conversion measurements, reducing chemical shift variability and enabling automated processing. |

| High-Precision Syringe Pumps | Deliver monomers/initiators at a precisely controlled rate for semi-batch or flow polymerizations, reducing exotherms and improving reproducibility. |

Diagram 2: Bayesian update with noise model (74 chars)

6. Conclusion Systematic handling of noise through standardized protocols transforms inconsistent polymerization data into a reliable asset for Bayesian optimization. By explicitly quantifying and incorporating measurement uncertainty into the probabilistic model, the BO algorithm becomes resilient to experimental variance, accelerating the efficient discovery of optimal polymerization conditions with fewer, more informative experiments. This framework is integral to a robust thesis on closed-loop optimization for advanced polymer synthesis.

Strategies for Incorporating Domain Knowledge and Physical Constraints into the BO Framework

Within a broader thesis on optimizing polymer synthesis conditions for drug delivery applications, standard Bayesian Optimization (BO) can be data-inefficient or suggest infeasible conditions. This protocol details strategies to integrate polymer-specific domain knowledge and physicochemical constraints directly into the BO loop, accelerating the discovery of optimal synthesis parameters (e.g., monomer ratio, initiator concentration, temperature) for target polymer properties (molecular weight, polydispersity, copolymer composition).

Foundational Strategies and Protocols

Strategy A: Constrained Bayesian Optimization via Penalty or Barrier Methods

- Application Note: This method prevents the proposal of experiments that violate hard physical constraints (e.g., total monomer concentration cannot exceed solubility limits, reaction temperature must be below solvent boiling point).

- Protocol:

- Define Constraint Function(s): Formally define constraint

g_i(x) ≤ 0for each physical limit. For a temperature constraint:g_temp(x) = T(x) - T_boil ≤ 0. - Choose Method:

- Penalty Function: Modify the acquisition function

α(x)toα(x) - λ * Σ max(0, g_i(x))^2, where λ is a large penalty weight. - Barrier (or Interior-Point) Method: Use a logarithmic barrier:

α(x) - μ * Σ -log(-g_i(x)). μ decreases with BO iterations.

- Penalty Function: Modify the acquisition function

- Optimize Constrained Acquisition: Use a gradient-based optimizer (e.g., L-BFGS-B) to find the next sample

x_nextthat maximizes the modifiedα(x)while respecting bounds.

- Define Constraint Function(s): Formally define constraint

Strategy B: Knowledge-Driven Prior and Kernel Selection

- Application Note: Incorporate knowledge about the smoothness, periodicity, or expected trends of the polymer synthesis response surface into the Gaussian Process (GP) prior.

Protocol:

Informative Mean Function (

m(x)): Instead of a zero mean, use a simple mechanistic model. For free radical polymerization kinetics, a mean function based on the Arrhenius equation or Mayo-Lewis equation for copolymer composition can be used.Structured Kernel Design: Combine base kernels to reflect process understanding.

- For temperature (