ASTM D7028 Standard for DMA Tg Testing: Complete Guide for Pharmaceutical Researchers

This comprehensive guide explains the ASTM D7028 standard for determining the glass transition temperature (Tg) of polymers and polymer matrix composites using Dynamic Mechanical Analysis (DMA).

ASTM D7028 Standard for DMA Tg Testing: Complete Guide for Pharmaceutical Researchers

Abstract

This comprehensive guide explains the ASTM D7028 standard for determining the glass transition temperature (Tg) of polymers and polymer matrix composites using Dynamic Mechanical Analysis (DMA). Targeting pharmaceutical researchers, material scientists, and drug development professionals, it covers the fundamental principles of DMA and Tg, details the standardized D7028 test methodology, provides practical troubleshooting guidance for assay optimization, and validates the technique against alternative methods like DSC. The article serves as an essential resource for ensuring material characterization consistency, supporting robust formulation development, and meeting quality-by-design (QbD) principles in biomedical applications.

What is ASTM D7028? Fundamentals of DMA Tg Testing for Drug Development

The glass transition temperature (Tg) is a fundamental material property dictating the transition of an amorphous solid from a brittle, glassy state to a softer, rubbery state upon heating. Within pharmaceutical and polymer science, the Tg is not merely a thermal point but a critical determinant of stability, processability, and performance. This document frames the discussion of Tg within the context of advanced material characterization, specifically referencing the methodology and principles of the ASTM D7028 standard ("Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA)"). While ASTM D7028 is explicitly for composites, its rigorous DMA methodology for Tg determination is the gold standard extrapolated to amorphous drugs and polymeric excipients. The broader thesis posits that strict adherence to such standardized, instrument-based protocols is essential for reliable, comparable Tg data, which directly informs drug product development, shelf-life prediction, and regulatory filings.

The Critical Role of Tg in Amorphous Drugs and Polymers

For Amorphous Solid Dispersions (ASDs): Most new chemical entities exhibit poor aqueous solubility. Formulating them as ASDs (a drug molecularly dispersed in a polymeric matrix) is a prevalent strategy. The Tg of this binary (or more complex) system is paramount:

- Physical Stability: Below Tg, molecular mobility is low, inhibiting drug crystallization. A higher Tg (often achieved by selecting polymers with high Tg) enhances shelf-life. A common rule of thumb is that storage at least 50°C below Tg maximizes stability.

- Processability: Hot-melt extrusion and spray drying operations must be conducted above the Tg to enable flow and deformation.

- Performance: Dissolution behavior can be influenced by the polymer's Tg and the resulting microstructure of the dispersion.

For Polymeric Excipients: The Tg defines their mechanical and barrier properties.

- Film Coating: The Tg of a coating polymer determines its flexibility and resistance to cracking.

- Modulated Release: Swelling and erosion behaviors of controlled-release polymers are Tg-dependent.

- Blending Compatibility: The proximity of Tg values for different polymers predicts their miscibility.

Key Quantitative Data and Standards

The following table summarizes critical Tg-related data for common pharmaceutical polymers and highlights the central role of the ASTM D7028 method.

Table 1: Glass Transition Temperatures of Common Pharmaceutical Polymers & Method Comparison

| Material/Concept | Typical Tg Range (°C) | Significance in Drug Product | Primary Testing Method (Relevant Standard) |

|---|---|---|---|

| Polyvinylpyrrolidone (PVP) | 150 - 180 | High-Tg carrier inhibits drug crystallization in ASDs. | DMA (ASTM E1640), DSC |

| Hydroxypropyl Methylcellulose (HPMC) | 150 - 180 | Workhorse polymer for ASDs and controlled-release matrices. | DMA, DSC |

| Poly(methacrylate) copolymers (Eudragit) | 40 - 150 | Tg tailored for enteric or sustained release coatings. | DMA, DSC |

| Sucrose | 62 - 70 | Model low-Tg stabilizer in lyophilized products. | DSC |

| Indomethacin (model drug) | ~45 | Demonstrates risk of crystallization if stored near Tg. | DSC |

| ASTM D7028 Method (DMA) | -- | Definitive method for modulus-based Tg (Tan δ peak or E' onset). Measures mechanical relaxation, highly sensitive to molecular motions. | Dynamic Mechanical Analysis |

| DSC Method (Common Alternative) | -- | Measures heat flow change; less sensitive for broad transitions or filled systems. Good for initial screening. | Differential Scanning Calorimetry (ASTM E1356) |

Table 2: Impact of Tg on Amorphous Drug Stability (Representative Data)

| Formulation System | Measured Tg (°C) | Storage Condition (Relative to Tg) | Observed Physical Stability (Time to Crystallization) |

|---|---|---|---|

| Pure Amorphous Drug X | 50 | Tstorage = 25°C (ΔT = -25°C) | > 24 months |

| Pure Amorphous Drug X | 50 | Tstorage = 45°C (ΔT = -5°C) | 3 months |

| Drug X in Polymer A (Tg=80°C) | 65 | Tstorage = 25°C (ΔT = -40°C) | > 36 months |

| Drug X in Polymer B (Tg=180°C) | 95 | Tstorage = 25°C (ΔT = -70°C) | > 36 months (predicted) |

Experimental Protocols

Protocol 1: Tg Determination via DMA (Following Principles of ASTM D7028)

This protocol adapts the core procedural rigor of ASTM D7028 for amorphous film or compacted powder samples.

I. Objective: To determine the glass transition temperature (Tg) of an amorphous drug-polymer film using Dynamic Mechanical Analysis (DMA) via the peak of the tan delta curve.

II. Materials & Preparation:

- Sample: Prepare a homogeneous amorphous solid dispersion film via solvent casting or hot-melt extrusion, compressed into a rectangular bar suitable for the clamp.

- Equipment: DMA with dual/single cantilever or film tension clamps. Temperature calibration kit.

III. Procedure:

- Mounting: Securely clamp the sample of known geometry (length, width, thickness). Ensure uniform contact and record exact sample dimensions.

- Method Setup:

- Deformation Mode: Flexural (cantilever) or tensile.

- Oscillation Parameters: Set a fixed frequency (commonly 1 Hz). Strain amplitude must be within the linear viscoelastic region (determined via strain sweep).

- Temperature Ramp: Program a heating scan from at least 50°C below the expected Tg to 50°C above. A standard rate is 2-3°C/min.

- Atmosphere: Use inert gas purge (N2) at 50 mL/min.

- Execution: Start the temperature program and data acquisition. The instrument measures storage modulus (E'), loss modulus (E''), and tan delta (E''/E').

- Data Analysis:

- Identify the Tg as the peak maximum of the tan delta curve.

- Alternatively, report the onset of the drop in storage modulus (E').

- Report the testing frequency alongside the Tg value.

Protocol 2: Tg Determination via DSC (Screening Method)

I. Objective: To determine the Tg of a material via the step change in heat capacity using Differential Scanning Calorimetry. II. Procedure:

- Seal 5-10 mg of sample in a Tzero pan.

- Run a heat-cool-heat cycle: Equilibrate at 0°C, heat to 180°C at 10°C/min (erase thermal history), cool at 20°C/min, then reheat at 10°C/min.

- Analyze the second heating ramp. Tg is identified as the midpoint of the step transition in the heat flow curve.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Tg Characterization Studies

| Item | Function/Explanation |

|---|---|

| Dynamic Mechanical Analyzer (DMA) | Primary instrument for ASTM D7028-compliant testing. Applies oscillatory stress to measure viscoelastic moduli and their temperature dependence. |

| Differential Scanning Calorimeter (DSC) | Complementary tool for rapid screening of Tg via heat capacity change. Less sensitive for dilute transitions. |

| High-Tg Polymer (e.g., PVP-VA) | Used to elevate the Tg of an amorphous dispersion, enhancing physical stability. |

| Plasticizer (e.g., Triethyl Citrate) | Low-Tg additive used to deliberately lower polymer Tg for processing studies or to model instability. |

| Hermetic DSC Pan & Sealer | Prevents weight loss and sample degradation during thermal analysis, ensuring accurate Tg measurement. |

| Inert Gas Supply (N2) | Provides non-reactive purge atmosphere in DMA/DSC to prevent oxidative degradation during heating. |

| Standard Reference Materials (e.g., Indium, Polystyrene) | Used for temperature and enthalpy calibration of thermal instruments. |

Visualizations

Title: Decision Flow: How Tg Governs Amorphous Material State

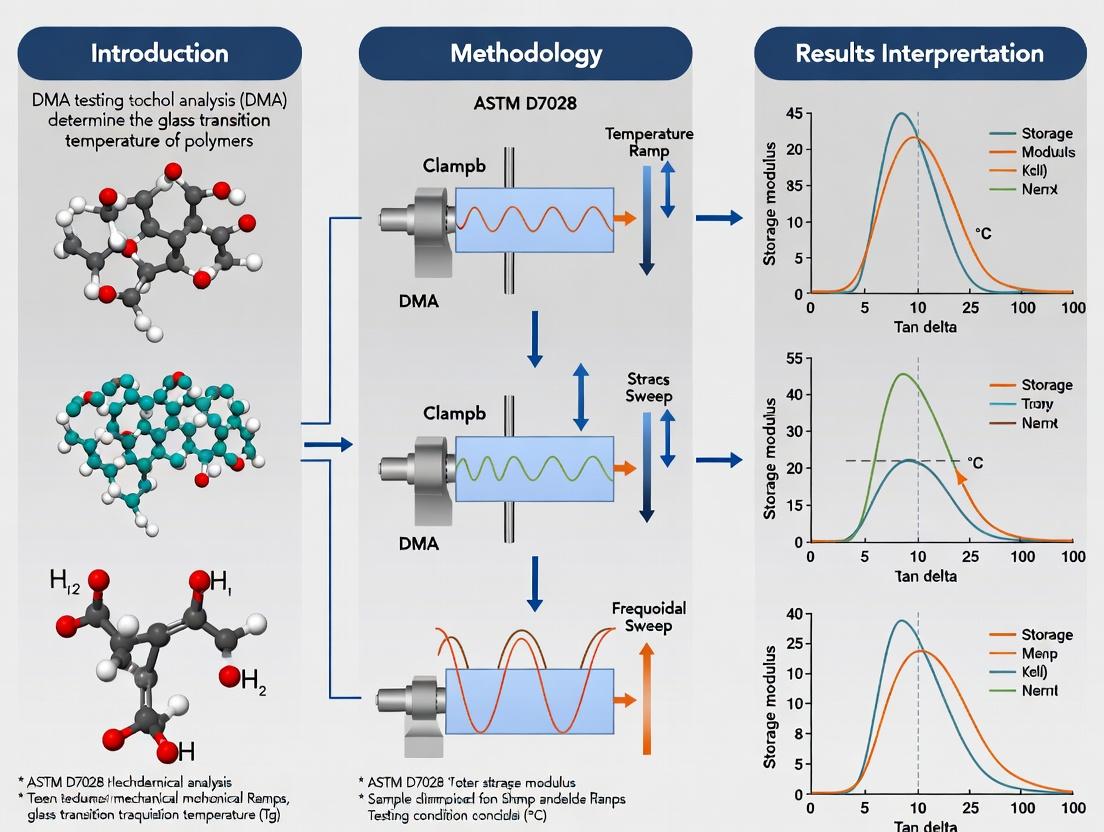

Title: DMA Tg Testing Protocol Workflow (7 Steps)

This application note details the principles and protocols of Dynamic Mechanical Analysis (DMA) for viscoelastic measurement, framed within a thesis researching the optimization and validation of the ASTM D7028 standard for Glass Transition Temperature (Tg) determination. ASTM D7028, "Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis," provides a framework, but practical application requires a deep understanding of viscoelastic theory and instrument operation. This work aims to address gaps in inter-laboratory reproducibility by establishing detailed, standardized experimental protocols for drug delivery system polymers and composite materials.

Principles of Viscoelastic Measurement

Viscoelastic materials exhibit both elastic (solid-like) and viscous (liquid-like) behavior. DMA applies a small sinusoidal deformation (stress or strain) to a sample and measures the resultant response. Key measured and calculated parameters are:

- Storage Modulus (E' or G'): The elastic component, representing energy stored and recovered per cycle.

- Loss Modulus (E'' or G''): The viscous component, representing energy dissipated as heat per cycle.

- Tan Delta (tan δ): The ratio of Loss Modulus to Storage Modulus (E''/E'). It is a measure of damping or internal friction.

- Complex Modulus (E* or G*): The vector sum of storage and loss modulus, representing total resistance to deformation.

The glass transition temperature (Tg) is identified as a peak in tan δ or a rapid drop in storage modulus as temperature is ramped.

Key Quantitative Data: DMA Parameters & ASTM D7028 Specifications

The following tables summarize core viscoelastic parameters and standard test conditions.

Table 1: Summary of Key DMA Viscoelastic Parameters

| Parameter | Symbol | Description | Typical Units | Key Insight Provided |

|---|---|---|---|---|

| Storage Modulus | E' (tension/bending), G' (shear) | Elastic, energy-storing component | Pa, MPa, GPa | Material stiffness; shows step-change decrease at Tg. |

| Loss Modulus | E'' (tension/bending), G'' (shear) | Viscous, energy-dissipating component | Pa, MPa, GPa | Mechanical damping; often shows a peak near Tg. |

| Loss Factor / Tan Delta | tan δ (E''/E') | Ratio of loss to storage modulus | Unitless | Damping efficiency; primary Tg indicator (peak). |

| Complex Modulus | E* or G* (√(E'²+E''²)) | Total stiffness under dynamic load | Pa, MPa, GPa | Overall resistance to deformation. |

| Glass Transition Temp (DMA) | Tg, tan δ max | Temperature at peak of tan δ curve | °C or K | Primary ASTM D7028 reporting parameter. |

| Glass Transition Temp (DMA) | Tg, E' onset | Onset temperature of storage modulus drop | °C or K | Complementary Tg measure. |

Table 2: Typical Experimental Parameters per ASTM D7028 Guidance

| Parameter | Recommended Value/Range (ASTM D7028) | Thesis Research Variable | Purpose/Rationale |

|---|---|---|---|

| Deformation Mode | Dual/Single Cantilever, 3-Point Bending | Primary variable | Clamping must prevent slippage; chosen based on sample stiffness. |

| Frequency | 1.0 Hz (standard) | Controlled variable (0.1, 1, 10 Hz) | To study frequency dependence of Tg (Arrhenius activation energy). |

| Strain Amplitude | 0.01% to 0.1% (within LVR) | Controlled variable | Must be verified via strain sweep to ensure Linear Viscoelastic Region. |

| Heating Rate | 2°C/min to 5°C/min | Primary variable (1, 3, 5°C/min) | Critical for Tg accuracy; slower rates improve resolution but increase testing time. |

| Temperature Range | At least 50°C below to 50°C above Tg | Defined by material | Must fully capture rubbery plateau and glassy region. |

| Sample Dimensions | Rectangular: (L) 10-20mm x (W) <12.7mm x (T) 1-3mm | Fixed per standard | Ensures consistent stress distribution and clamp engagement. |

Detailed Experimental Protocols

Protocol 1: Sample Preparation & Mounting for Composite/Polymer Films (Per Thesis)

Objective: Prepare and mount test specimens for Tg determination via DMA in bending mode. Materials: Test polymer film (e.g., PLGA, PVA), precision razor blade, micrometer, DMA with dual cantilever clamps, torque screwdriver. Procedure:

- Conditioning: Condition material as per its specification (e.g., dry in desiccator, hydrate in controlled RH) for 24 hours prior.

- Cutting: Using a precision template and razor blade, cut rectangular specimens to target dimensions of 15.0mm (L) x 10.0mm (W).

- Measurement: Precisely measure thickness (t) and width (w) at three points along the length using a micrometer. Record average values. Ensure thickness variation is <±5%.

- Mounting: a. Loosen the drive and fixed clamps on the DMA. b. Insert the specimen, ensuring it is seated fully and perpendicular to the clamp faces. c. Using a calibrated torque screwdriver, tighten clamp screws to the manufacturer's specified torque (typically 0.2-0.5 N·m). This is critical for reproducibility. d. Verify the free length (span) between clamps is 10.0mm ± 0.1mm.

- Initialization: Allow the instrument to equilibrate at the starting temperature (e.g., 25°C) for 5 minutes before initiating the temperature program.

Protocol 2: DMA Tg Method via Temperature Ramp (Core Thesis Experiment)

Objective: Determine the Tg of a polymer composite using a temperature ramp, analyzing the effect of heating rate. Materials: DMA instrument with temperature chamber, mounted sample (from Protocol 1), liquid nitrogen or mechanical cooler (for sub-ambient start). Methodology:

- Instrument Setup: Select the appropriate force track or strain amplitude (e.g., 125% of static force needed to maintain 0.01% strain) to prevent slack or overstress.

- Strain Verification: Perform an isothermal strain sweep at a temperature below the expected Tg to confirm the selected strain (e.g., 0.05%) is within the Linear Viscoelastic Region (LVR).

- Method Programming: a. Equilibration: Hold at T_initial (e.g., 25°C or 50°C below expected Tg) for 2 min. b. Temperature Ramp: Apply a heating rate (β) of 1.0, 3.0, and 5.0°C/min in separate experiments to the same sample type. Final temperature must be >50°C above expected Tg. c. Oscillation: Apply a sinusoidal deformation at 1.0 Hz frequency and strain amplitude within LVR throughout the ramp.

- Data Collection: Record storage modulus (E'), loss modulus (E''), and tan δ (tan δ) as a function of temperature and time.

- Tg Determination (Post-Run Analysis): a. Tan δ Peak: Identify the temperature at the maximum of the tan δ curve. Report as Tg (tan δ max). b. E' Onset: On the storage modulus curve, draw tangents to the glassy plateau and the transition region. The intersection point is reported as Tg (E' onset). c. Documentation: Note the heating rate (β) used for each determination. For thesis analysis, plot Tg vs. log(β) to extract activation energy.

Visualization: DMA Workflow & Data Interpretation

DMA Tg Determination Workflow

Viscoelastic Response Deconvolution

The Scientist's Toolkit: DMA Research Essentials

Table 3: Essential Research Reagents & Materials for DMA Tg Testing

| Item | Function/Description | Critical for Thesis Relevance |

|---|---|---|

| Reference Material (Indium, PMMA) | Calibrates temperature and modulus accuracy of the DMA. Must be run periodically to validate instrument performance per ASTM D7028. | Essential for establishing measurement traceability and validating inter-experiment consistency. |

| Calibrated Torque Screwdriver | Ensures consistent and repeatable clamping force on the sample. Prevents slippage (under-torque) or sample damage (over-torque). | Key variable for improving inter-laboratory reproducibility—a core thesis aim. |

| High-Purity Quench Gases (Nitrogen, Helium) | Provides inert, dry atmosphere in the sample chamber. Prevents oxidative degradation and moisture condensation during sub-ambient tests. | Ensures material properties are measured, not environmental artifact. Required by ASTM D7028. |

| Temperature Calibration Kit | Includes materials with known transition temperatures (e.g., indium, gallium) for verifying the instrument's temperature sensor accuracy. | Mandatory for QA/QC. Data from uncalibrated instruments invalidates ASTM D7028 compliance. |

| Linear Viscoelastic Region (LVR) Verification Samples | Standard polymers with known LVR limits. Used to validate strain sweep protocol before unknown sample testing. | Ensures the selected strain amplitude yields true material properties, not strain-affected data. |

| Sample Preparation Kit | Precision cutter (razor blade, die), micrometer (±1µm), flat polishing films, alignment jig. | Ensures sample geometry compliance with ASTM D7028, minimizing dimensional error in modulus calculation. |

ASTM D7028, titled "Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA)," is a standardized methodology for determining the glass transition temperature (Tg) of polymeric materials. While originally developed for composites, its principles are directly applicable and critically relevant to pharmaceutical science, particularly in the characterization of amorphous solid dispersions, polymeric excipients, drug-polymer blends, and coating systems. The purpose of the standard is to provide a consistent, reproducible procedure for measuring Tg using DMA, a technique sensitive to the viscoelastic changes occurring at this critical phase transition.

Purpose and Pharmaceutical Relevance

In pharmaceutical development, the Tg is a key parameter influencing:

- Physical Stability: Predicts crystallization tendency and physical aging of amorphous APIs and formulations.

- Processing Conditions: Informs hot-melt extrusion, spray drying, and film coating temperatures.

- Product Performance: Affects dissolution, mechanical properties (brittleness/flexibility), and drug release from polymeric matrices.

- Storage Recommendations: Supports the definition of storage conditions relative to the product's Tg.

DMA provides a more sensitive measure of molecular mobility changes at Tg compared to DSC, making ASTM D7028 a valuable tool for detecting subtle transitions and identifying multiple relaxation events in complex pharmaceutical systems.

Core Methodology and Application Notes

The standard specifies using DMA in controlled flexural (single or dual cantilever) or tensile mode, with a defined heating rate and oscillation frequency, to track the changes in storage modulus (E') and loss modulus (E") or tan delta (E"/E') as a function of temperature. The Tg is identified from the peak of the tan delta curve or the onset of the drop in E'.

Table 1: Key Experimental Parameters per ASTM D7028 and Pharmaceutical Adaptations

| Parameter | ASTM D7028 Typical Specification | Pharmaceutical Application Notes |

|---|---|---|

| Sample Geometry | Rectangular bar (composite). | Adapted for films, compressed discs, or coated substrates. Powder can be analyzed in a powder holder kit. |

| Deformation Mode | Flexural (cantilever) recommended. | Tensile mode often preferred for free-standing films; compression for powders/compacts. |

| Frequency | 1 Hz (standard). | Multi-frequency sweeps (e.g., 0.1, 1, 10 Hz) are valuable to evaluate time-temperature superposition and activation energy. |

| Heating Rate | 2-5°C/min. | 2°C/min is standard to ensure thermal equilibrium. Slower rates may resolve overlapping transitions. |

| Atmosphere | Inert gas (nitrogen) optional. | Dry nitrogen is often essential to prevent moisture plasticization during the run. |

| Tg Identification | Peak of tan delta curve. Primary transition. | Onset of E' drop (for processing), peak of E" (for molecular relaxations), and peak of tan delta are all reported. |

Application Note - Plasticization by Moisture: A critical protocol for hygroscopic pharmaceutical polymers involves preconditioning samples at controlled relative humidities (e.g., 0%, 30%, 60% RH) prior to DMA analysis per D7028. The measured depression of Tg is quantitatively related to water content via the Gordon-Taylor equation, directly informing packaging and storage requirements.

Detailed Experimental Protocols

Protocol 1: Determining Tg of a Free-Standing Amorphous Solid Dispersion Film

Objective: Characterize the Tg of a spray-dried amorphous dispersion of API in a polymer matrix (e.g., PVP-VA). Workflow:

- Sample Preparation: Compress spray-dried powder into a uniform, dense film using a hydraulic press (e.g., 1 ton for 2 min). Cut a rectangular strip (e.g., 20mm L x 10mm W x 0.5mm T).

- Instrument Calibration: Perform temperature and modulus calibration on the DMA using a reference material (e.g., polycarbonate or a metal standard).

- Mounting: Clamp the sample firmly in the tensile grips. Ensure minimal slippage and apply a static force just sufficient to keep the sample taut.

- Method Programming:

- Equilibrate at 25°C.

- Ramp temperature to 150°C at 2°C/min.

- Oscillation frequency: 1 Hz.

- Strain amplitude: 0.01% (within linear viscoelastic region, confirmed by prior strain sweep).

- Purge with dry nitrogen at 150 mL/min.

- Data Collection: Record storage modulus (E'), loss modulus (E"), and tan delta.

- Analysis: Identify Tg from the peak maximum of the tan delta curve. Report the onset temperature from the E' curve as supplementary data.

Protocol 2: Evaluating the Tg of a Tablet Coating

Objective: Assess the film-forming quality and Tg of a polymer coating (e.g., ethylcellulose) applied to a tablet core. Workflow:

- Sample Preparation: Carefully separate the coating from the tablet core. Cut a small, uniform strip of the free film.

- Mounting: Use the film tension clamp if available. For very thin films, a controlled sub-ambient start temperature may be needed to prevent slack.

- Method Programming:

- Equilibrate at -50°C.

- Ramp to 200°C at 3°C/min.

- Frequency: 1 Hz.

- Strain: 0.05%.

- Nitrogen purge.

- Data Collection & Analysis: As in Protocol 1. Compare the coating film Tg to the theoretical value for the pure polymer. A broadened or lowered tan delta peak may indicate incomplete solvent removal, phase mixing with API, or residual stress.

Visualizations

Title: DMA Tg Testing Workflow per ASTM D7028

Title: How DMA Tg Informs Drug Product Stability

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Pharmaceutical DMA Tg Testing

| Item | Function & Rationale |

|---|---|

| DMA Instrument | Core analyzer (e.g., TA Instruments DMA 850, PerkinElmer DMA 8000). Must have precise temperature control, multiple clamping modes, and auto-tension capability. |

| Tensile Film Clamps | For analysis of free-standing films (e.g., coating films, cast films). Minimizes sample slippage and provides uniform stress. |

| Powder Compression Kit | Enables formation of rigid compacts from amorphous powders for reliable testing in flexural or compression modes. |

| Liquid Nitrogen Cooling System | Enables sub-ambient temperature ramps, critical for characterizing materials with low Tg (e.g., some hydrogels, plasticized systems). |

| High-Purity Dry Nitrogen Supply | Prevents oxidative degradation and, crucially, eliminates moisture-induced Tg shifts during the experiment. |

| Calibration Standards | Certified materials (e.g., polycarbonate, aluminum) for verifying temperature and modulus accuracy as required by ASTM D7028. |

| Hydraulic Press & Die | For preparing uniform, dense rectangular specimens from powders, essential for reproducible geometry. |

| Desiccators & Controlled RH Chambers | For preconditioning samples at specific moisture levels to study hygroscopic plasticization effects on Tg. |

Within the broader thesis research on the optimization and application of ASTM D7028, "Standard Test Method for Glass Transition Temperature (Dg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA)," the precise measurement of key viscoelastic properties is paramount. This standard provides the framework, but deep interpretation of data requires a fundamental understanding of Storage Modulus (E'), Loss Modulus (E''), and Tan Delta (tan δ). These properties are critical for characterizing the thermomechanical performance and structural integrity of polymeric materials used in pharmaceutical devices, excipient matrices, and controlled-release systems. This application note details the experimental protocols and data interpretation within the ASTM D7028 framework for researchers in drug development.

Core Property Definitions and Significance

- Storage Modulus (E'): The elastic (solid-like) component. It represents the energy stored and recovered per cycle of deformation, quantifying the material's stiffness. A high E' indicates a rigid material.

- Loss Modulus (E''): The viscous (liquid-like) component. It represents the energy dissipated as heat per cycle of deformation, quantifying the material's damping ability. A peak in E'' is often used to identify the glass transition temperature (Tg).

- Tan Delta (tan δ): The ratio of Loss Modulus to Storage Modulus (E''/E'). It is a dimensionless measure of the material's inherent damping or internal friction. Its peak temperature is another common marker for Tg and indicates the region of maximum energy dissipation.

Table 1: Representative DMA Data for Common Pharmaceutical Polymer States

| Material State | Typical E' at 25°C (MPa) | E'' Peak Temp (°C) | Tan δ Peak Temp (°C) | Primary Transition Identified |

|---|---|---|---|---|

| Glassy State (e.g., PS) | 2500 - 3500 | ~105 | ~110 | Glass Transition (α) |

| Rubbery Plateau (e.g., cured PDMS) | 1 - 10 | ~-120 | ~-115 | Glass Transition |

| Semi-Crystalline (e.g., PEO) | 200 - 1000 | ~-50 (E'') | ~-45 (tan δ) | Glass Transition (Amorphous phase) |

| ~60-80 (E' drop) | N/A | Melting Transition (Crystalline phase) | ||

| Hydrogel (Hydrated) | 0.1 - 1.0 | Broad/Plateau | Broad/Plateau | Network relaxation |

Experimental Protocols Based on ASTM D7028

Protocol 4.1: Sample Preparation and Mounting for Dual Cantilever Bending

- Objective: To prepare a rectangular specimen for Tg determination via the dual cantilever clamp geometry as per ASTM D7028.

- Materials: Polymer film or composite specimen, precision cutter, calipers, DMA equipped with dual cantilever clamps.

- Procedure:

- Cut the test material to dimensions specified by the clamp manufacturer (typical: length 10-18 mm, width 5-10 mm).

- Precisely measure and record the sample thickness at a minimum of three points using a caliper (accuracy ±0.01 mm).

- Mount the sample vertically in the clamp, ensuring it is centered and straight. The clamped length should be uniform and recorded.

- Tighten the clamping screws to the torque specified by the instrument manufacturer to ensure firm, non-slip gripping without crushing the sample.

- Initiate the furnace enclosure and begin gas purge (typically N₂ at 50-100 mL/min).

Protocol 4.2: Temperature Ramp Method for Tg Determination

- Objective: To measure E', E'', and tan δ as a function of temperature to identify the glass transition region.

- Methodology: Follows ASTM D7028 Section 10.2 (Temperature Scan at Constant Frequency).

- Instrument Parameters:

- Geometry: Dual Cantilever Bending

- Frequency: 1.0 Hz (Fixed as per standard for comparative testing)

- Strain Amplitude: 0.01% (Ensure within linear viscoelastic region, verify via strain sweep)

- Temperature Range: Start at least 50°C below expected Tg, end 50°C above.

- Heating Rate: 2°C/min (Standard recommends 1-5°C/min; 2°C/min balances resolution and time).

- Static Force: Auto-tension or a minimal force to maintain sample contact.

- Data Analysis:

- Plot E', E'', and tan δ versus Temperature.

- Identify the onset of the steep drop in E' as one indicator of Tg onset.

- Record the temperature at the peak maximum of E'' as Tg(E'').

- Record the temperature at the peak maximum of tan δ as Tg(tan δ).

- Note that Tg(tan δ) is typically 5-20°C higher than Tg(E'').

Diagrams for Experimental Workflow and Data Interpretation

Title: DMA Testing Workflow for ASTM D7028 Thesis Research

Title: DMA Thermogram Showing E', E'', and tan δ Peaks

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials and Reagents for DMA Testing of Pharmaceutical Polymers

| Item | Function/Brief Explanation |

|---|---|

| Reference Calibration Materials | Indium (melting point), polycarbonate or polyethylene (Tg/Tm verification). Used to calibrate DMA temperature and modulus scale. |

| Inert Purge Gas (N₂ Cylinder) | Prevents oxidative degradation of samples during high-temperature scans, ensuring data reflects thermal transitions only. |

| Standard Rectangular Film Specimens | Pre-cut, characterized polymer films (e.g., PET, PS) for method validation and inter-laboratory comparison. |

| Precision Thickness Gauge/Calipers | Critical for accurate sample dimension measurement, as modulus calculation is highly sensitive to thickness. |

| Dual Cantilever Clamp Set | The recommended geometry for solid films/composites per ASTM D7028. Must be kept clean and torque-calibrated. |

| Linear Variable Differential Transformer (LVDT) Standard | A physical standard used to verify the displacement measurement accuracy of the DMA instrument. |

| Bio-Compatible Polymer Blanks | Well-characterized polymers like PLGA or PVP for method development specific to drug delivery applications. |

Within the framework of research on the ASTM D7028 standard for Dynamic Mechanical Analysis (DMA) glass transition (Tg) testing, a critical understanding of thermal transitions is essential for solid oral dosage form development. While melting point (Tm) is a first-order transition signifying crystalline order disruption, Tg is a second-order transition reflecting the change in amorphous solid mobility. The relationship and difference between these transitions dictate processing stability, dissolution behavior, and shelf-life.

Key Transition Data: Tg vs. Tm

Table 1: Comparative Properties of Glass Transition (Tg) and Melting Point (Tm)

| Property | Glass Transition (Tg) | Melting Point (Tm) |

|---|---|---|

| Order of Transition | Second-order | First-order |

| Thermodynamic State | Amorphous solid Rubber/Supercooled liquid | Crystalline solid Liquid |

| ASTM Test Method | D7028 (DMA), E1356 (DSC) | E794 (DSC) |

| Key Influencing Factors | Molecular weight, plasticizer content, cooling rate | Molecular symmetry, purity, crystal size |

| Hysteresis | Exhibits cooling/heating rate dependence | Equilibrium, rate-independent |

| ΔH / ΔCp | Change in heat capacity (ΔCp) | Enthalpy of fusion (ΔH) |

Table 2: Tg and Tm Values for Common Pharmaceutical Materials

| Material | Tg (°C) | Tm (°C) | Critical Ratio (Tg/Tm in K) |

|---|---|---|---|

| Sucrose | 62 | 185 | 0.76 |

| Indomethacin (γ-form) | ~45 | 161 | 0.75 |

| Polyvinylpyrrolidone (PVP K30) | ~160 | Decomposes | N/A |

| Sorbitol | -5 | 95 | 0.81 |

| Copolymers of Vinylpyrrolidone-Vinyl Acetate | ~100 | N/A | N/A |

Application Notes

- Physical Stability Prediction: The Tg of the amorphous phase dictates storage conditions. The "Rule of Thumb" states storage should be at least 50°C below Tg to minimize molecular mobility and prevent crystallization, chemical degradation, and changes in dissolution profile.

- Processing Guidance: Hot-melt extrusion and spray drying require operation above Tg but below Tm or decomposition temperature. The Tg/Tm ratio (typically 0.7-0.8 in Kelvin for small molecules) helps estimate the process window.

- Excipient Selection: Plasticizers (e.g., glycerol, triethyl citrate) lower Tg, aiding processing but potentially compromising stability. Antiplasticizers (certain salts) can increase Tg.

- Amorphous Solid Dispersion (ASD) Stability: A single, elevated Tg (relative to components) indicates good miscibility and reduced phase separation risk.

Experimental Protocols

Protocol 1: Determining Tg via DMA per ASTM D7028

Objective: To determine the glass transition temperature of a polymeric film or compacted powder using Dynamic Mechanical Analysis in tension or film/fiber clamp mode.

Key Reagent Solutions & Materials:

- Test Specimen: A free-film cast from solution or a compacted rectangular bar of the material.

- Quartz Reference Beam: For instrument calibration and compliance correction.

- Liquid Nitrogen or Intercooler: For temperature control below ambient.

- Calibrated Weights: For static force application verification.

Procedure:

- Specimen Preparation: Prepare a rectangular specimen (typical dimensions: 15-20mm length x 5-10mm width x 0.1-1mm thickness). Ensure parallel faces and smooth edges.

- Mounting: Insert the specimen into the DMA tension or film clamp. Apply a minimal static force to ensure tautness without creep. Record exact gauge length.

- Method Setup: Program the temperature ramp (standard is 3°C/min). Set a constant oscillatory frequency (commonly 1 Hz). Select a strain amplitude within the linear viscoelastic region (determined by prior strain sweep).

- Equilibration: Equilibrate at a start temperature (typically -50°C or 30°C below expected Tg) under nitrogen purge.

- Data Acquisition: Initiate the temperature ramp. Monitor storage modulus (E'), loss modulus (E''), and tan delta (E''/E').

- Analysis: Identify Tg using the peak of the tan delta curve or the onset/inflection point of the E' drop. Report the method used per ASTM D7028.

Protocol 2: Simultaneous Tg & Tm Analysis via DSC

Objective: To characterize both glass transition and melting point in a single experiment using Differential Scanning Calorimetry.

Key Reagent Solutions & Materials:

- Hermetic Aluminum Crucibles (with lids): For encapsulating samples, ensuring no mass loss.

- Indium Standard: For temperature and enthalpy calibration.

- Nitrogen Gas: For inert purge gas (50 mL/min standard).

Procedure:

- Calibration: Calibrate the DSC cell for temperature and enthalpy using high-purity indium (Tm = 156.6°C, ΔHf ≈ 28.45 J/g).

- Sample Preparation: Precisely weigh 5-10 mg of sample into a hermetic pan. Crimp the lid firmly. Prepare an empty reference pan.

- Method Programming:

- Equilibrate at 25°C.

- Ramp at 10°C/min to a temperature 30°C above the anticipated Tm.

- Hold isothermal for 3-5 minutes to erase thermal history.

- Cool at 10-20°C/min to a temperature 50°C below the anticipated Tg.

- Hold for 5 minutes.

- Re-ramp at 10°C/min to the upper temperature limit (second heat).

- Analysis: Analyze the second heating cycle. Report Tg as the midpoint of the heat capacity step change. Report Tm as the peak of the endothermic melting transition. Report ΔHf from the melting endotherm area.

Visualizations

Thermal Analysis Decision Workflow for Dosage Forms (Max 760px)

Hierarchy of Transition Impact on Dosage Forms (Max 760px)

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Thermal Analysis

| Item | Function/Application |

|---|---|

| Dynamic Mechanical Analyzer (DMA) | Primary instrument for measuring viscoelastic properties and Tg per ASTM D7028 using tension, compression, or shear. |

| Differential Scanning Calorimeter (DSC) | Primary instrument for measuring Tm and Tg via heat flow. Compliments DMA data. |

| Hermetic Aluminum DSC Pans & Lids | Seals volatile or hygroscopic samples during DSC analysis to prevent artifact. |

| High-Purity Calibration Standards (Indium, Zinc) | Calibrates temperature and enthalpy scale of DSC and temperature of DMA furnace. |

| Quartz Reference Beam (for DMA) | Accounts for instrument compliance and calibrates force/displacement. |

| Controlled Humidity Generator/Desiccator | Conditions samples to specific %RH, as moisture drastically lowers Tg. |

| Film Casting Kit (Doctor Blade, Inert Substrate) | Prepares uniform free-films for DMA tension or film clamp testing. |

| Hydraulic Press & Die | Prepares compacted powder specimens for DMA in compression or 3-point bending. |

| Molecular Sieves | Dries purge gases to prevent moisture condensation during sub-ambient DMA runs. |

| Thermal Analysis Software (e.g., TRIOS, Pyris) | Analyzes data to extract Tg (midpoint, onset, tan delta peak), Tm, and ΔHf. |

Role of Tg in Product Stability, Performance, and Regulatory Submission

The glass transition temperature (Tg) is a fundamental physicochemical property of amorphous materials, including polymers and many active pharmaceutical ingredients (APIs). Within the framework of the ASTM D7028 standard for Dynamic Mechanical Analysis (DMA), Tg provides critical insights into the thermomechanical behavior of drug products. This application note details the role of Tg in predicting and ensuring product stability, influencing performance (e.g., dissolution, bioavailability), and supporting regulatory submissions. All protocols and data are contextualized within ongoing research on optimizing and applying the ASTM D7028 DMA method for pharmaceutical systems.

Table 1: Tg Values and Corresponding Product Stability Outcomes for Model Formulations

| Formulation ID | API Tg (°C) by DMA (ASTM D7028) | Polymer Excipient Tg (°C) | Measured Product Tg (°C) | Storage Stability at 25°C/60% RH (Months to 5% Degradation) | Physical Stability (Crystallization Onset) |

|---|---|---|---|---|---|

| F-01 | 45.2 ± 0.5 | 105.3 ± 1.1 | 62.1 ± 0.8 | >36 | No change (24 mo) |

| F-02 | 45.2 ± 0.5 | 125.7 ± 0.9 | 68.5 ± 1.2 | >36 | No change (24 mo) |

| F-03 | 72.8 ± 0.7 | 105.3 ± 1.1 | 89.4 ± 0.9 | 24 | Crystallization at 18 mo |

| F-04 (Plasticized) | 45.2 ± 0.5 | 105.3 ± 1.1 | 42.3 ± 1.5 | 6 | Crystallization at 3 mo |

Table 2: Tg Correlation with In Vitro Performance Metrics

| Formulation ID | Product Tg (°C) | Storage Condition (Accelerated) | Dissolution T80 (min) at t=0 | Dissolution T80 (min) after 3M storage | % API Bioavailability (Rat Model) |

|---|---|---|---|---|---|

| F-01 | 62.1 | 40°C/75% RH | 15.2 | 16.5 | 92.5 ± 5.1 |

| F-02 | 68.5 | 40°C/75% RH | 22.7 | 24.1 | 88.3 ± 4.7 |

| F-04 | 42.3 | 40°C/75% RH | 10.5 | 45.3 (Gelled) | 65.2 ± 8.4 |

Experimental Protocols

Protocol 3.1: Determination of Tg via DMA according to ASTM D7028 (Modified for Pharmaceuticals)

Objective: To determine the glass transition temperature of an amorphous solid dispersion film or compacted disk using DMA in tension or film/fiber clamp mode.

Key Equipment & Reagents: See The Scientist's Toolkit below.

Procedure:

- Sample Preparation: Prepare amorphous solid dispersions via hot-melt extrusion or spray drying. For DMA, either cast into uniform films (~100-200 µm thick) using a controlled solvent evaporation method or compress into coherent disks using a suitable die.

- Conditioning: Condition all samples in a desiccator with P₂O₅ for at least 48 hours to remove residual solvent/water.

- DMA Mounting: Secure the sample in the film/fiber tension clamp. Ensure a snug fit without pre-stress that could damage the sample. Measure the exact sample dimensions (length, width, thickness).

- Method Programming:

- Mode: Oscillation (Tension)

- Frequency: 1 Hz (standard per D7028). Multi-frequency sweeps (0.1, 1, 10 Hz) may be used for activation energy analysis.

- Strain Amplitude: Set to 0.01% (ensure within linear viscoelastic region, confirm via strain sweep).

- Temperature Ramp: 2°C/min from at least 50°C below expected Tg to 50°C above.

- Gas Environment: Dry nitrogen purge at 150 mL/min.

- Data Acquisition: Initiate the temperature ramp. Monitor storage modulus (E'), loss modulus (E''), and tan delta (tan δ).

- Tg Determination: Analyze the resulting thermogram. Per ASTM D7028, identify the Tg as the peak maximum of the tan δ curve OR the onset point of the drop in E'. Both values should be reported. The midpoint of the E' step change is an alternative.

- Reporting: Report Tg value, heating rate, frequency, sample geometry, conditioning history, and the specific method of Tg identification.

Protocol 3.2: Stability Study Correlating Tg with Product Performance

Objective: To correlate measured Tg changes with chemical and physical stability under ICH storage conditions.

Procedure:

- Baseline Characterization: Measure initial Tg (Protocol 3.1), dissolution profile (USP apparatus), and solid-state (via XRD/mDSC).

- Storage: Place samples in controlled stability chambers at conditions: 25°C/60% RH (long-term), 40°C/75% RH (accelerated). Include samples stored below and above their measured Tg.

- Time-point Sampling: Remove samples at predetermined intervals (e.g., 1, 3, 6, 9, 12 months).

- Analysis:

- Chemical Stability: Assay for API and degradants via HPLC.

- Physical Stability: Check for crystallization using powder XRD and polarized light microscopy.

- Tg Monitoring: Measure Tg of stored samples using DMA (Protocol 3.1). Note any shifts.

- Performance: Perform dissolution testing.

- Data Correlation: Plot Tg versus time and correlate with degradation rates and dissolution changes. A formulation is considered stable if its storage temperature remains >20°C below its measured Tg (Rule of Thumb: T - Tg < -20°C).

Diagrams

Title: Tg-Based Stability Decision Pathway

Title: Tg in Regulatory Submission Workflow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials for DMA Tg Analysis

| Item | Function/Justification |

|---|---|

| Dynamic Mechanical Analyzer (DMA) | Core instrument for applying oscillatory stress and measuring viscoelastic modulus as a function of temperature, per ASTM D7028. |

| Film/Fiber Tension Clamp | Standard clamp for thin film or compacted pharmaceutical samples, ensuring proper force application. |

| High-Purity Inert Gas (N₂) | Purge gas to prevent oxidative degradation and eliminate moisture condensation during temperature ramps. |

| Standard Reference Materials (e.g., Polycarbonate, Polystyrene) | Used for temperature and modulus calibration of the DMA instrument, ensuring data accuracy. |

| Desiccant (e.g., Phosphorus Pentoxide, P₂O₅) | For rigorous drying of samples prior to testing to eliminate plasticizing effects of residual moisture. |

| Controlled Humidity Chambers | For preconditioning samples at specific %RH to study moisture sorption impact on Tg. |

| Hot-Melt Extruder or Spray Dryer | Equipment for preparing representative amorphous solid dispersion samples for testing. |

| Calibrated Micrometer | For precise measurement of sample thickness, a critical input for modulus calculation. |

How to Perform ASTM D7028 Testing: Step-by-Step Protocol & Pharmaceutical Applications

The ASTM D7028 standard, "Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA)," provides a critical framework for characterizing thermomechanical properties. A central variable in obtaining accurate, reproducible Tg data is the selection and proper use of the appropriate clamping fixture. This protocol details the selection criteria, application notes, and experimental methodologies for common DMA fixtures—specifically cantilever (single and dual), three-point bending, and tension clamps—within the scope of ASTM D7028-compliant research on advanced polymer composites and drug delivery system matrices.

Fixture Selection Criteria & Quantitative Comparison

The choice of fixture is dictated by sample geometry, stiffness, applied strain mode, and the fundamental material properties under investigation.

Table 1: DMA Fixture Selection Guide for ASTM D7028 Testing

| Fixture Type | Recommended Sample Modulus | Optimal Sample Dimensions (LxWxT) | Strain Mode | Key Advantages | Primary Limitations |

|---|---|---|---|---|---|

| Single Cantilever | 1 MPa - 50 GPa | 10-50mm x 5-15mm x 1-3mm | Shear & Bending | Excellent for stiff composites, high force resolution. | Shear heating, complex clamping stress. |

| Dual Cantilever | 100 MPa - 100 GPa | 30-60mm x 5-15mm x 1-3mm | Pure Bending | Reduced sample slippage, better for high Tg materials. | Requires precise sample parallelism. |

| Three-Point Bending | 10 MPa - 100 GPa | (Span 10-50mm) x 5-15mm x 1-4mm | Pure Bending (Tension/Compression) | Simple loading, minimal clamping artifacts. | Susceptible to indentation, not for soft materials. |

| Tension | < 1 GPa | 10-40mm x 2-10mm x 0.1-2mm | Pure Tension | Ideal for films, fibers, soft hydrogels. | Sample slippage, requires careful alignment. |

Table 2: Impact of Fixture Selection on Measured Tg (Theoretical Δ from Reference)

| Fixture Type | Typical Tg Variation* (±°C) | Primary Source of Error | ASTM D7028 Compliance Notes |

|---|---|---|---|

| Dual Cantilever | 1-2 | Minimal, considered reference for composites. | Primary recommended fixture for most composite beams. |

| Single Cantilever | 2-5 | Shear heating, clamping effects. | Acceptable with corrected calibration and low strain. |

| Three-Point Bending | 3-7 | Contact stress, sample indentation. | Used for specific sample geometries; requires reporting of span-to-thickness ratio. |

| Tension | 5-10 (for films) | Sample slippage, alignment. | For thin films or unsupported matrices; not for rigid composites. |

*Variation is relative to a perfectly implemented dual cantilever clamp on an isotropic, homogeneous specimen.

Experimental Protocols

Protocol 3.1: Fixture Selection & Installation for Composite Tg Testing

Objective: To select and install the correct DMA fixture per ASTM D7028 for accurate Tg determination. Materials: DMA instrument, fixture set, torque screwdriver, calibration standard, composite sample. Procedure:

- Sample Preparation: Machine composite to rectangular beam (typical: 35mm x 12mm x 2mm) per D7028.

- Selection Logic: For a 2mm thick, high-modulus epoxy/carbon fiber composite, select Dual Cantilever.

- Fixture Installation: a. Power off the DMA drive motor. b. Install the fixed and movable clamp arms using a calibrated torque screwdriver (specified by instrument manufacturer). c. Perform a motor zero/gap reset to align the fixtures.

- Gap Setting: Insert a metal calibration standard of known thickness. Set the clamping gap to standard thickness + 0.05 mm.

- Calibration: Run a temperature ramp with the standard to verify fixture stiffness and instrument compliance.

Protocol 3.2: Tg Measurement via Dual Cantilever (Per ASTM D7028)

Objective: To determine the glass transition temperature (Tg) of a polymer composite using the dual cantilever fixture. Materials: Cured composite beam, DMA with dual cantilever fixture, liquid N₂ or forced air cooler. Method:

- Mounting: Insert the composite sample squarely into the bottom fixed clamp. Tighten screws to a uniform, specified torque.

- Close Clamp: Engage the movable clamp arm and tighten uniformly. Ensure no visible slippage or misalignment.

- Method Setup: In software, select strain-controlled oscillatory mode.

- Frequency: 1 Hz (as per D7028 default).

- Oscillation Amplitude: 15 μm (strain typically <0.1%).

- Static Force: 110% of dynamic force to maintain tension.

- Temperature Ramp: 3°C/min from 25°C to 250°C.

- Initiate Test: Begin data acquisition. Monitor force tracking to ensure it remains within limits.

- Data Analysis: Plot Storage Modulus (E'), Loss Modulus (E''), and tan δ. Identify Tg via:

- Onset Method (ASTM D7028): Intersection of tangents on the E' drop.

- Peak Method: Temperature at the maximum of the tan δ peak (report method used).

Diagrams

Diagram Title: DMA Fixture Selection Decision Tree

Diagram Title: ASTM D7028 Tg Testing Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for DMA Tg Testing per ASTM D7028

| Item | Function/Benefit | Example/Note |

|---|---|---|

| Calibrated Torque Screwdriver | Ensures reproducible, uniform clamping force across fixtures, critical for data consistency. | 0.5-2.5 Nm range, instrument-specific. |

| Reference Material (Calibration Standard) | Verifies instrument and fixture performance (stiffness, temperature, compliance). | Polymethyl methacrylate (PMMA) or aluminum beam of known modulus. |

| High-Temperature Silicone Grease | Improves thermal contact between sample and clamp for temperature uniformity. | Applied sparingly to clamp faces. |

| Alignment Tool/Jig | Ensures sample is mounted perpendicular and centered within the clamp. | Machined metal block or tool provided by DMA manufacturer. |

| Liquid Nitrogen Cooling System | Enables sub-ambient temperature starts for broad Tg range analysis. | Essential for testing materials with Tg below room temperature. |

| Abrasive Paper (Various Grit) | For finishing sample edges to precise dimensions and smooth surfaces. | Minimizes stress concentrations at clamp contact points. |

Within the broader thesis research on the application of ASTM D7028 for determining the glass transition temperature (Tg) of polymeric materials via Dynamic Mechanical Analysis (DMA), rigorous sample preparation is the foundational determinant of data validity. This standard specifically governs the geometry, dimensions, and conditioning of test specimens for polymer matrix composite materials. Consistent adherence to these protocols is critical for comparative analysis in pharmaceutical development, where excipients and drug-polymer systems must be characterized for stability and performance.

Key Geometrical Specifications and Dimensional Tolerances

ASTM D7028 specifies several specimen geometries suitable for DMA testing in different deformation modes. The choice depends on material form and the intended data output (e.g., modulus, tan δ).

Table 1: Specimen Geometries and Dimensional Tolerances per ASTM D7028

| Geometry (Mode) | Recommended Application | Specimen Dimensions (mm) | Critical Tolerance |

|---|---|---|---|

| Dual/Single Cantilever (Bending) | Stiff composites, solid polymers | Length: 35.0 ± 0.5, Width: 12.0 ± 0.5, Thickness: 3.00 ± 0.10 | Parallelism of clamping surfaces within 0.01 mm. |

| Three-Point Bend (Bending) | Rigid bars, pre-impregnated materials | Span: 50.0 ± 0.5, Width: 10.0 ± 0.2, Thickness: 2.00 ± 0.05 | Support knife edges must be parallel and aligned. |

| Tension (Film/Fiber) | Films, fibers, soft elastomers | Gauge Length: 10-20 ± 0.2, Width: 5.0 ± 0.1, Thickness: < 1.00 ± 0.02 | Uniform cross-section to prevent stress concentration. |

| Compression (Cylindrical) | Viscoelastic solids, gels | Diameter: 10.0 ± 0.2, Height: 5.0 - 25.0 ± 0.1 | End faces must be parallel and perpendicular to axis. |

| Shear (Parallel Plate) | Adhesives, gels, low-modulus materials | Diameter: 5.0 - 15.0 ± 0.1, Thickness: 0.5 - 2.0 ± 0.02 | Uniform thickness across entire specimen. |

Detailed Experimental Protocols

Protocol 1: Machining and Dimensional Verification of a Cantilever Beam Specimen

Objective: To prepare a rectangular specimen for dual-cantilever bending mode from a composite plaque. Materials: Composite plaque, diamond-coated saw, surface grinder, digital caliper (resolution 0.01 mm), micrometer (resolution 0.001 mm), optical flat, and non-abrasive cleaning solvent. Procedure:

- Blank Cutting: Using a diamond-coated saw with a fixture, cut a rough blank approximately 2 mm larger than the final target dimensions (37 mm x 14 mm x 4 mm) to minimize edge damage.

- Surface Grinding: Secure the blank in a fixture and grind the two broad faces (future clamped surfaces) sequentially on a precision surface grinder. Use progressively finer grits to achieve a final surface roughness (Ra) < 1 µm. Cool with inert fluid to prevent thermal stress.

- Final Sizing: Grind the length and width to final dimensions (35.0 mm x 12.0 mm). The thickness is achieved during surface grinding to a target of 3.00 mm.

- Dimensional Verification:

- Measure length and width at five points using digital calipers. Record the mean and standard deviation.

- Measure thickness at nine points (a 3x3 grid) using a micrometer. The variation must not exceed ±0.10 mm.

- Check for parallelism by placing the specimen on an optical flat and using a dial indicator. Deviation across length should be < 0.01 mm.

- Cleaning: Ultricate the specimen in a mild, non-solvent cleaning solution (e.g., 2% detergent in deionized water) for 5 minutes, rinse with deionized water, and dry in a desiccator for 24 hours at room temperature.

Protocol 2: Standard Conditioning for Tg Determination

Objective: To condition prepared specimens to a known state of moisture and thermal history prior to DMA testing, ensuring reproducibility. Materials: Environmental chamber, desiccator, anhydrous calcium sulfate, humidity-saturated salt solutions (e.g., for 0% RH, 50% RH), vacuum oven. Procedure for Moisture Conditioning:

- Drying (Dry State Tg):

- Place specimens in a vacuum oven at 50°C ± 2°C and < 100 Pa pressure for 48 hours.

- Immediately transfer to a desiccator containing anhydrous calcium sulfate (0% RH) at room temperature (23°C ± 2°C) and allow to equilibrate for a further 24 hours. Seal the desiccator.

- Equilibration at Specific Relative Humidity (Wet State Tg):

- Place specimens in an environmental chamber set to 23°C ± 1°C and 50% ± 2% RH.

- Monitor specimen mass daily using an analytical balance (resolution 0.1 mg). Equilibrium is defined as a mass change of less than 0.01% over a 24-hour period. This may take 7-14 days for many polymers.

- Once equilibrated, seal specimens in a barrier bag or container until testing (within 2 hours).

Visualizing the Sample Preparation Workflow

Title: ASTM D7028 Sample Preparation Workflow and Quality Gate

The Scientist's Toolkit: Essential Research Reagent Solutions & Materials

Table 2: Key Materials for Specimen Preparation According to D7028

| Item | Function/Explanation |

|---|---|

| Diamond-Coated Wafering Saw | Provides clean, low-deformation cuts in hard composite and polymer blanks without melting or excessive chipping. |

| Precision Surface Grinder with Fixture | Achieves critical dimensional tolerances and parallel faces. A fixture ensures specimen orientation during grinding. |

| Digital Micrometer (0.001 mm resolution) | For high-accuracy thickness measurements, the most critical dimension for bending stiffness calculation. |

| Optical Flat & Dial Indicator | Used to verify flatness and parallelism of clamping surfaces, preventing misclamping and stress artifacts in DMA. |

| Anhydrous Calcium Sulfate (Drierite) | Desiccant for creating and maintaining a 0% RH environment in storage desiccators for "dry" specimens. |

| Humidity Saturated Salt Solutions (e.g., Mg(NO3)2 for 50% RH) | Provides a constant relative humidity environment in a sealed chamber for moisture equilibration. |

| Non-Solvent Cleaning Solution (e.g., 2% Micro-90 in DI Water) | Removes machining debris and oils without swelling or dissolving the polymer matrix. |

| Analytical Balance (0.1 mg resolution) | For gravimetric monitoring of moisture uptake during conditioning to determine equilibrium. |

| Specimen Storage Container (Sealable, Impermeable) | Prevents moisture exchange between conditioning and DMA testing, which is critical for hygroscopic materials. |

Within the broader research context of optimizing the ASTM D7028 standard for determining the glass transition temperature (Tg) of polymers via Dynamic Mechanical Analysis (DMA), the precise setting of test parameters is critical. This protocol details the application notes for selecting frequency, strain amplitude, heating rate, and temperature range to ensure accurate, reproducible, and physically meaningful Tg measurements relevant to pharmaceutical material science and drug product development.

Quantitative Parameter Guidelines

Based on current literature and ASTM D7028 guidance, the following quantitative ranges are established for amorphous polymer films or molded bars.

Table 1: Recommended DMA Test Parameters for Tg Determination per ASTM D7028

| Parameter | Recommended Range | Typical Value for Pharmaceutical Polymers | Rationale & Impact |

|---|---|---|---|

| Frequency | 0.1 Hz to 10 Hz | 1 Hz | Standard reference point; higher frequencies shift Tg to higher temperatures (~3-10°C per decade). |

| Strain Amplitude | 0.01% to 0.1% (Tension) | 0.05% | Ensures linear viscoelastic response; must be verified via strain sweep prior to temperature ramp. |

| Heating Rate | 1°C/min to 3°C/min | 2°C/min | Balances thermal lag, signal quality, and test duration. Higher rates overestimate Tg. |

| Temperature Range | Start: Tg,est - 50°C | e.g., 0°C to 150°C | Must fully capture the rubbery plateau, transition, and glassy plateau. |

| End: Tg,est + 50°C | |||

| Sample Geometry | Film: ~18 x 5 x 0.1 mm | As per ASTM clamp | Dimensions critical for calculating accurate modulus values. |

Detailed Experimental Protocols

Protocol 1: Strain Sweep for Linear Viscoelastic Region (LVER) Determination

Objective: To identify the maximum permissible strain amplitude for subsequent temperature ramp tests without inducing nonlinear behavior.

- Sample Preparation: Cut polymer film to dimensions of 18 mm (length) x 5 mm (width). Thickness measured precisely at five points.

- Mounting: Install sample in DMA tension film clamps. Ensure slight, uniform tautness (≤ 0.001 N pre-load force).

- Isothermal Conditioning: Set furnace to estimated Tg - 30°C. Equilibrate for 5 minutes.

- Sweep Setup: Set frequency to 1 Hz. Program a strain amplitude sweep from 0.001% to 0.5%.

- Execution: Run sweep. Monitor storage modulus (E').

- Analysis: Plot E' vs. Strain %. Identify the strain value where E' deviates by >2% from its plateau. Define the LVER limit as 80% of this critical strain.

Protocol 2: Multi-Frequency Temperature Ramp for Tgand Activation Energy

Objective: To determine the Tg and estimate the activation energy of the glass transition (Ea) using time-temperature superposition principles.

- Parameter Setting: Based on Protocol 1, set strain to a value within the LVER (e.g., 0.05%).

- Frequency Selection: Program a multi-frequency temperature ramp using frequencies of 0.5, 1, 2, 5, and 10 Hz.

- Temperature Program: Set range from Tg,est - 50°C to Tg,est + 50°C at a heating rate of 2°C/min.

- Data Collection: Record storage modulus (E'), loss modulus (E"), and tan delta (E"/E') as a function of temperature for each frequency.

- Tg Determination: Identify the peak of the tan delta curve for the 1 Hz data. Report as Tg (tan δ max).

- Activation Energy: Apply the Arrhenius equation to the shift of tan δ peak temperature with frequency: ln(f) = -Ea/RTpeak + constant. Plot ln(frequency) vs. 1/Tpeak (K). The slope is -Ea/R.

Diagrams

Title: DMA Tg Test Parameter Optimization Workflow

Title: Data Interpretation and Parameter Effects on DMA Tg

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions & Materials for DMA Tg Testing

| Item | Function / Relevance |

|---|---|

| DMA Instrument | Equipped with tension film clamps and a precise temperature-controlled furnace. Essential for applying oscillatory force and measuring viscoelastic response. |

| Polymer Film Samples | Amorphous pharmaceutical polymers (e.g., PVP, HPMC, acrylics). Must be prepared with uniform thickness (0.05-0.2 mm) and free of bubbles/defects. |

| Liquid Nitrogen or Intracooler | For temperature control below ambient, enabling sub-ambient Tg measurements and thermal equilibrium. |

| Precision Thickness Gauge | Micrometer or digital gauge. Critical for accurate measurement of sample cross-sectional area to calculate absolute modulus values. |

| Sample Cutting Die | A precision razor die (e.g., 18 x 5 mm rectangle). Ensures uniform, reproducible sample geometry as required by ASTM D7028. |

| Calibration Standards | Certified materials (e.g., known modulus polymers, indium for temperature). Used for routine validation of DMA force, displacement, and temperature sensors. |

| Data Analysis Software | Capable of multi-frequency peak analysis and Arrhenius fitting. Necessary for extracting Tg and activation energy from complex datasets. |

Step-by-Step Execution of a Standard D7028 Tg Measurement

The measurement of the glass transition temperature (Tg) using Dynamic Mechanical Analysis (DMA) is a critical methodology in the characterization of polymeric materials, composites, and formulated products, including those in drug delivery systems. ASTM International Standard D7028, "Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis," provides a rigorous framework for this determination. Within a broader thesis on this standard, this protocol details the precise, step-by-step execution of a standard Tg measurement, emphasizing procedural fidelity, data interpretation, and error minimization essential for research reproducibility and material science advancement.

Principle of Operation

DMA measures the viscoelastic properties of a material as it is subjected to a periodic oscillatory stress (or strain) under a controlled temperature program. The key parameters are storage modulus (E' – elastic response), loss modulus (E'' – viscous response), and tan delta (E''/E' – damping). The Tg, signifying the transition from a glassy to a rubbery state, is identified by a marked drop in E' and a peak in E'' and tan delta.

Detailed Experimental Protocol

Pre-Experimental Preparation & Calibration

- Instrument Calibration: Perform routine DMA calibrations for force, displacement, and temperature according to the manufacturer's specifications. Document calibration dates.

- Fixture Selection & Installation: Select appropriate fixtures based on sample geometry and stiffness. Common fixtures for D7028 include dual/single cantilever for solid polymers/composites or a tension clamp for films/fibers. Clean fixtures thoroughly with solvent (e.g., acetone) and install securely.

- Sample Preparation (Critical Step):

- Material: Obtain or fabricate sample to dimensions specified in D7028: typical rectangular bars are 35-65 mm long, 10-15 mm wide, and 1-4 mm thick.

- Dimensional Measurement: Precisely measure sample length (L), width (b), and thickness (h) at multiple points using a calibrated micrometer. Record the average values.

- Mounting Verification: Ensure the sample is mounted squarely and securely in the fixtures with the correct clamping force/gap to prevent slippage or undue stress concentration.

Step-by-Step Instrumental Execution

Method Creation in Software: Create a new method file. Define the experimental sequence:

- Pre-load/Static Force: Apply a small static force to maintain contact (e.g., 0.01 N for tension, 0.1 N for cantilever). Avoid sample compression/buckling.

- Dynamic Oscillation Parameters: Set the oscillatory force (or amplitude) to achieve a strain typically within the linear viscoelastic region (often 0.01-0.1%). Set the frequency to 1 Hz, as specified by D7028 for standard Tg determination.

- Temperature Program:

- Equilibration: Hold at a start temperature well below the expected Tg (e.g., Tg - 50°C) for 5 minutes.

- Ramp: Program a heating ramp at 2°C/min, as recommended by D7028 for most materials, to a temperature well above the expected Tg.

- Gas Environment: Specify nitrogen purge flow (e.g., 50-100 mL/min) to minimize oxidative degradation.

Sample Loading & Geometry Entry:

- Mount the prepared sample in the fixtures.

- Input the exact sample dimensions (L, b, h) and the fixture type into the software. For a cantilever clamp, the effective length (L) is the free length between clamps.

Method Execution:

- Initiate the method. The instrument will apply the pre-load, begin the temperature equilibration, and then start the temperature ramp with superimposed oscillation.

- Visually monitor the initial readings to ensure stability (no slippage, reasonable modulus values).

Data Collection Completion: Allow the run to complete through the full temperature ramp. The software will record E', E'', tan delta, temperature, and time at defined intervals (e.g., 1 sec or 0.5°C).

Post-Run Analysis & Tg Determination

- Data Examination: Plot E', E'', and tan delta versus temperature.

- Tg Identification per D7028: The standard defines Tg as the temperature at the peak of the tan delta curve unless otherwise specified. Secondary indicators are the onset of the drop in E' and the peak of E''.

- Peak Analysis: Use the software's peak analysis tool to identify the tan delta peak temperature. Ensure the correct peak is selected if multiple transitions are present.

- Reporting: Report Tg to the nearest 0.1°C. Include the heating rate (2°C/min), frequency (1 Hz), sample geometry, and fixture type.

Data Presentation & Representative Results

Table 1: Representative DMA Tg Data for Common Polymers (1 Hz, 2°C/min)

| Polymer Material | Sample Geometry | Tg from tan delta peak (°C) | Tg from E'' peak (°C) | Onset of E' Drop (°C) |

|---|---|---|---|---|

| Polycarbonate | 3pt Bending | 152.1 ± 0.5 | 148.3 ± 0.7 | 145.5 ± 0.5 |

| Epoxy Resin | Dual Cantilever | 122.5 ± 1.2 | 118.8 ± 1.0 | 115.0 ± 1.5 |

| PMMA | Single Cantilever | 108.3 ± 0.8 | 105.1 ± 0.9 | 102.4 ± 0.7 |

| Polystyrene | Dual Cantilever | 101.7 ± 0.4 | 98.5 ± 0.5 | 95.2 ± 0.6 |

Table 2: Critical Method Parameters & Specifications per ASTM D7028

| Parameter | ASTM D7028 Specification / Typical Value | Purpose / Rationale |

|---|---|---|

| Frequency | 1 Hz (Standard) | Standardizes kinetic measurement; allows comparison. |

| Heating Rate | 2°C/min (Recommended) | Balances thermal equilibrium and experiment duration. |

| Strain/Stress | Within Linear Viscoelastic Region | Ensures measured properties are intrinsic, not deformation-dependent. |

| Sample Atmosphere | Inert gas purge (N₂) recommended | Prevents thermal-oxidative degradation during scan. |

| Tg Definition | Peak of tan delta curve (Primary) | Provides a sensitive, reproducible metric for the transition. |

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for ASTM D7028 Tg Measurement

| Item | Function & Importance |

|---|---|

| DMA Instrument | Core analyzer (e.g., TA Instruments Q800, Netzsch DMA 242, PerkinElmer DMA 8000) to apply stress/strain and measure modulus. |

| Calibrated Fixtures | Dual/Single Cantilever, 3-Point Bending, Tension clamps. Must match sample geometry and modulus range. |

| Liquid Nitrogen or Intercooler System | Provides cooling for sub-ambient temperature starts or controlled low-temperature ramps. |

| High-Purity Nitrogen Gas Cylinder & Regulator | Provides inert purge gas to the sample chamber, essential for preventing oxidation at high temperatures. |

| Precision Micrometer (±0.001 mm) | For accurate measurement of sample dimensions (thickness, width), critical for correct modulus calculation. |

| Sample Fabrication Tools | Precision saw, cutter, and polishing materials to prepare specimens to the exact dimensions required by D7028. |

| Calibration Standards | Certified reference materials (e.g., polycarbonate, aluminum) for verifying instrument accuracy in displacement, force, and temperature. |

| Software for Data Analysis | Vendor-specific or third-party software capable of performing peak analysis on modulus and tan delta curves. |

Visualization of Experimental Workflow

Title: DMA Tg Measurement Workflow per ASTM D7028

Title: From Parameters to Tg: The DMA Signal Chain

Data Acquisition and Signal Interpretation During the Thermal Ramp

Abstract This application note details the protocols and data interpretation strategies for dynamic mechanical analysis (DMA) during a thermal ramp, specifically within the framework of ASTM D7028 for determining the glass transition temperature (Tg) of polymeric materials, including amorphous drug formulations. Accurate Tg determination is critical in pharmaceutical development for predicting product stability, shelf life, and processing conditions.

1. Introduction Within ASTM D7028, the thermal ramp is the fundamental experiment for identifying viscoelastic transitions. The standard specifies methods but leaves optimization of data acquisition and interpretation to the researcher. This document provides enhanced protocols for generating high-fidelity data, crucial for a thesis investigating method variables on Tg precision.

2. Key Parameters & Data Acquisition Protocol

Table 1: Standard & Optimized Thermal Ramp Parameters for DMA Tg Testing

| Parameter | ASTM D7028 Guideline | Optimized Protocol for Amorphous Solids | Function/Rationale |

|---|---|---|---|

| Deformation Mode | Single/dual cantilever, 3-point bending, shear | 3-point bending (for solids) | Minimizes clamping artifacts, suitable for rigid films. |

| Frequency | 1 Hz (typical) | 1 Hz (multi-frequency optional) | Standard reference point. Multi-freq aids in activation energy calculation. |

| Heating Rate | 1 to 5°C/min | 2°C/min (compromise) | Balances thermal lag (slow rate) with experiment time and signal clarity. |

| Strain/Amplitude | To remain in linear viscoelastic region | Auto-strain or 0.01% pre-test | Prevents sample damage, ensures modulus values are intrinsic. |

| Temperature Range | At least 50°C below to 50°C above Tg | Tg(nominal) -30°C to +50°C | Captures baseline, transition, and rubbery plateau. |

| Data Sampling Rate | Not specified | ≥ 2 points/°C | Ensures sufficient density for accurate derivative analysis. |

2.1 Detailed Experimental Workflow Protocol

- Step 1: Sample Preparation. Machine drug-polymer film to rectangular bars (typical: ~17.5 x 12.5 x 3 mm). Measure exact dimensions with digital calipers.

- Step 2: Instrument Calibration. Perform factory-specified temperature, displacement, and force calibrations. Use a reference material (e.g., polycarbonate) for validation.

- Step 3: Mounting. Insert sample into fixture, ensuring even contact and no slippage. Tighten to manufacturer's specified torque.

- Step 4: Pre-Test Equilibrium. Allow isothermal hold at starting temperature (Tg - 30°C) for 5 minutes to equilibrate.

- Step 5: Thermal Ramp Execution. Initiate temperature ramp at 2°C/min while applying oscillatory strain. Data acquisition systems record Storage Modulus (E'), Loss Modulus (E''), Loss Tangent (tan δ), and Temperature at ≥2 Hz.

- Step 6: Data Export. Export raw data (time, temperature, E', E'', tan δ) for subsequent analysis.

3. Signal Interpretation & Tg Determination

Table 2: Quantitative Indicators of Tg from DMA Thermal Ramp Data

| Signal | Typical Pre-Tg Value | Transition Signature | Common Tg Assignment | Notes for Interpretation |

|---|---|---|---|---|

| Storage Modulus (E') | High (~1-10 GPa) | Sharp drop (order of magnitude) | Onset of drop (conservative) | Indicates softening. Onset is often used for "mechanical Tg". |

| Loss Modulus (E'') | Low | Distinct peak | Peak maximum (E'' max) | Represents maximum energy dissipation. Most sensitive to molecular motions. |

| Loss Tangent (tan δ) | Very low (<0.01) | Sharp peak | Peak maximum (tan δ max) | Dimensionless, normalized. Peak is often at a higher T than E'' peak. |

Diagram Title: DMA Tg Determination Analysis Workflow

4. The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for DMA Sample Preparation

| Item | Function/Explanation | Example/Note |

|---|---|---|

| Amorphous Drug Substance | The active pharmaceutical ingredient (API) whose physical stability is under investigation. | e.g., Itraconazole, Indomethacin. Must be confirmed amorphous by XRD. |

| Polymeric Stabilizer | Matrix former that inhibits crystallization and dictates the blend's Tg. | e.g., PVP-VA (vinylpyrrolidone-vinyl acetate copolymer), HPMC (hydroxypropyl methylcellulose). |

| Volatile Solvent | Dissolves API and polymer for homogeneous film casting. | e.g., Dichloromethane (DCM), Methanol, Acetone. Choice depends on solubility. |

| Liquid Nitrogen | Used for quenching solvent-cast films to create an amorphous solid. | Rapid cooling minimizes phase separation and crystallization. |

| Desiccant | For drying and storing films under inert, dry conditions. | e.g., Silica gel, molecular sieves. Prevents moisture-induced plasticization. |

| Reference Material | For DMA instrument performance verification. | e.g., Polycarbonate (Tg ~147°C), Polymethyl methacrylate (PVA). |

| Calibration Standards | Certified weights and displacement gauges. | Ensures accuracy of force and deformation measurements. |

5. Advanced Considerations for a Thesis Context A thesis on ASTM D7028 should investigate the impact of method variables. Experiments should include:

- Effect of Heating Rate: Execute ramps at 1, 2, and 5°C/min on identical samples. Plot Tg vs. heating rate to assess kinetic effects.

- Frequency Dependence: Perform multi-frequency sweeps (0.5, 1, 2, 5 Hz). Use the Arrhenius equation to calculate activation energy for the relaxation.

- Fixture Comparison: Test identical samples in 3-point bending vs. dual cantilever to quantify fixture-derived variance.

Diagram Title: Thesis Research Framework on DMA Variables

Conclusion Precise data acquisition during the thermal ramp, followed by systematic signal interpretation using multiple indicators, is foundational for reliable Tg determination per ASTM D7028. The protocols and toolkit outlined herein provide a framework for rigorous research, enabling scientists to generate high-quality data essential for robust pharmaceutical formulation development.

Characterizing the glass transition temperature (Tg) is paramount in pharmaceutical development, particularly for amorphous solid dispersions (ASDs), excipients, and functional polymer coatings. This work is framed within a broader research thesis investigating the application and optimization of the ASTM D7028 standard, "Standard Test Method for Glass Transition Temperature (Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA)." While originally for composites, this standard's rigorous methodology for Tg determination via the peak of the loss modulus (E'' or tan δ) is critically evaluated for its adaptability to complex, multi-component pharmaceutical systems where structural integrity and performance are Tg-dependent.

Application Notes

Role ofTgin Pharmaceutical Systems

The physical stability and dissolution performance of ASDs are governed by their Tg. A higher Tg relative to storage temperature reduces molecular mobility, inhibiting crystallization of the active pharmaceutical ingredient (API). For polymer coatings (e.g., enteric or sustained-release), Tg dictates film formation, mechanical properties, and drug release profiles. ASTM D7028 provides a standardized framework to measure these critical transitions under simulated processing and storage conditions.

Comparative Data from Recent Studies

Table 1: DMA-Derived Tg for Common Pharmaceutical Polymers (ASTM D7028 Method)

| Polymer/Excipient | Formulation Context | Tg from E'' peak (°C) (Mean ± SD) | Key Finding | Reference (Type) |

|---|---|---|---|---|

| PVP-VA64 | Pure Polymer | 106.2 ± 1.5 | Benchmark for spray-dried dispersions | Supplier Data |

| HPMCAS-LF | Pure Polymer | 118.5 ± 2.1 | Tg varies with grade (LF/MF/HF) | (2023) Int J Pharm |

| Eudragit L100-55 | Free Film | 125.7 ± 1.8 | Critical for enteric coating performance | (2024) AAPS PharmSciTech |

| Soluplus | Pure Polymer | 72.3 ± 0.9 | Low Tg enables cold extrusion | (2023) J Drug Deliv Sci Tech |

Table 2: Tg Depression in Model Amorphous Solid Dispersions

| API (10% w/w) | Polymer Matrix | Tg of ASD via DMA (°C) | ΔTg from Pure Polymer | Predicted (Gordon-Taylor) |

|---|---|---|---|---|

| Itraconazole | PVP-VA64 | 94.5 ± 1.2 | -11.7 °C | -12.1 °C |

| Itraconazole | HPMCAS-LF | 107.8 ± 1.8 | -10.7 °C | -11.4 °C |

| Celecoxib | Soluplus | 65.1 ± 2.0 | -7.2 °C | -6.8 °C |