AFM Imaging of Polymer Spherulites: A Guide to Structure, Characterization, and Biomedical Applications

This article provides a comprehensive guide to Atomic Force Microscopy (AFM) for imaging and analyzing polymer spherulite structures, targeting researchers and pharmaceutical professionals.

AFM Imaging of Polymer Spherulites: A Guide to Structure, Characterization, and Biomedical Applications

Abstract

This article provides a comprehensive guide to Atomic Force Microscopy (AFM) for imaging and analyzing polymer spherulite structures, targeting researchers and pharmaceutical professionals. It explores the fundamental lamellar organization of spherulites and AFM's role in elucidating crystallization mechanisms. A detailed methodological framework covers sample preparation, imaging modes (Tapping vs. PeakForce), and specific applications in drug-polymer systems. Practical troubleshooting for artifacts, tip selection, and optimizing resolution is addressed. Finally, the article validates AFM data against complementary techniques like POM and XRD and discusses comparative case studies. The conclusion synthesizes key insights for controlling polymer microstructure in advanced drug delivery and biomedical devices.

Unraveling Spherulite Formation: AFM's Role in Visualizing Polymer Crystallization

Polymer spherulites are semicrystalline superstructures that form under specific processing conditions, such as non-equilibrium cooling from the melt. They are characterized by radially symmetric lamellar crystals that grow outward from a central nucleation site. Spherulitic morphology significantly influences bulk polymer properties, including mechanical strength, optical clarity, and diffusion characteristics. For researchers utilizing Atomic Force Microscopy (AFM) to investigate these structures, understanding their formation and optical properties is foundational to interpreting nanoscale topographic and phase images. A core optical characteristic is birefringence, where the anisotropic arrangement of lamellae causes refractive index variations observable under polarized light microscopy (PLM), presenting the classic "Maltese cross" pattern.

The following table summarizes key quantitative characteristics of common polymer spherulites relevant to AFM and PLM analysis.

Table 1: Quantitative Characteristics of Common Polymer Spherulites

| Polymer | Typical Spherulite Diameter (µm) | Radial Growth Rate (µm/min) | Lamellar Thickness (nm) | Birefringence Sign (Radial/Tangential) | Common Crystalline Form |

|---|---|---|---|---|---|

| Polyethylene (PE) | 1 - 1000 | 1 - 1000 | 10 - 50 | Positive / Negative | Orthorhombic |

| Isotactic Polypropylene (iPP) | 50 - 500 | 10 - 100 | 10 - 30 | Positive / Negative | α-Monoclinic |

| Poly(ethylene oxide) (PEO) | 10 - 200 | 5 - 50 | 10 - 20 | Negative / Positive | Monoclinic |

| Poly(ε-caprolactone) (PCL) | 50 - 300 | 5 - 100 | 8 - 15 | Positive / Negative | Orthorhombic |

| Poly(L-lactic acid) (PLLA) | 20 - 200 | 1 - 50 | 5 - 20 | Negative / Positive | α'- or α-Orthorhombic |

Experimental Protocols

Protocol 1: Preparation of Thin-Film Polymer Spherulites for Correlative PLM/AFM Analysis

This protocol details the preparation of thin-film samples suitable for initial PLM screening and subsequent high-resolution AFM imaging.

Materials:

- Polymer pellets or powder (e.g., PEO, PCL, iPP).

- Analytical-grade solvent (e.g., chloroform, toluene, THF) or glass coverslips for melt processing.

- Clean glass microscope slides or small silicon wafers.

- Hot stage with precise temperature controller.

- Polarized Light Microscope.

Procedure:

- Solution Casting (For solvent-soluble polymers): a. Prepare a 0.5-1.0% (w/v) polymer solution in the appropriate solvent. b. Deposit a few drops onto a clean glass slide or silicon wafer. c. Allow the solvent to evaporate slowly at room temperature under a cover to induce spherulitic crystallization.

- Melt Crystallization (Preferred for controlled morphology): a. Place a small polymer pellet or powder on a clean glass slide. b. Heat the sample on a hot stage to at least 30°C above its melting temperature (Tm) and hold for 5 minutes to erase thermal history. c. Rapidly cool the sample to a selected isothermal crystallization temperature (Tc) between Tm and the glass transition temperature (Tg). d. Hold at Tc until crystallization is complete, as monitored by PLM. e. Quench the sample to room temperature.

- Initial PLM Characterization: a. Observe the sample under cross-polarized light. b. Identify spherulitic regions exhibiting birefringence and Maltese cross patterns. c. Map and note coordinates of spherulites of interest for AFM analysis.

Protocol 2: AFM Imaging of Radial Lamellar Structures

This protocol describes AFM operation for resolving the nanoscale lamellar structure within a spherulite identified via PLM.

Materials:

- AFM with tapping/intermittent contact mode capability.

- Tapping mode etched silicon probes (e.g., resonance frequency ~300 kHz, spring constant ~40 N/m).

- Sample prepared per Protocol 1.

- Vibration isolation table.

Procedure:

- Sample Transfer & Mounting: a. Carefully transfer the glass slide or silicon wafer from Protocol 1 to the AFM sample stage. b. Secure it firmly using magnetic clips or vacuum hold.

- Probe and System Setup: a. Install a sharp tapping mode probe appropriate for high-resolution polymer imaging. b. Engage the laser and align the photodetector. c. Tune the probe to find its fundamental resonance frequency.

- Locating the Region of Interest: a. Using the AFM's optical microscope (if available) or low-resolution large-scan AFM, navigate to the coordinates of the spherulite identified by PLM.

- High-Resolution Imaging: a. Select a scan size (typically 20x20 µm down to 5x5 µm) to capture the radial pattern from near the nucleus to the spherulite edge. b. Set imaging parameters: Setpoint ratio ~0.8-0.9, drive amplitude to achieve clear phase contrast. c. Initiate scan. Collect both Height (topography) and Phase (material stiffness contrast) images simultaneously. d. The Height channel will show the lamellar topography (e.g., edge-on lamellae appearing as ridges). The Phase channel will enhance contrast between crystalline and amorphous regions.

- Data Analysis: a. Use AFM software to measure lamellar spacing by performing a line profile perpendicular to the radial lamellar orientation. b. Correlate AFM lamellar patterns with the birefringence patterns observed in PLM.

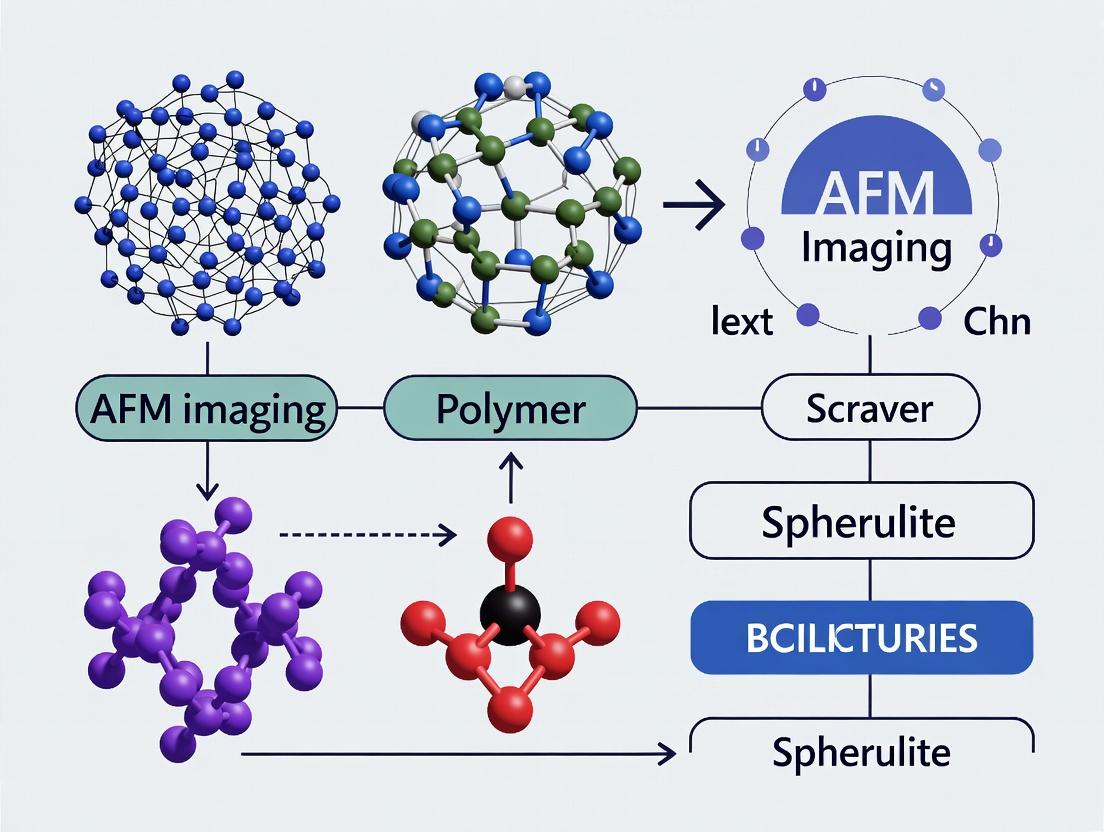

Visualizing Spherulite Analysis Workflow

Title: Polymer Spherulite Analysis Workflow: PLM to AFM

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Essential Materials for Polymer Spherulite Research

| Item | Function/Benefit |

|---|---|

| Atomic Force Microscope (AFM) | Provides nanoscale topographic and phase imaging of lamellar structures within spherulites without requiring conductive coatings. |

| Tapping Mode AFM Probes | Sharp silicon tips for high-resolution imaging of soft polymer surfaces with minimal sample damage. |

| Polarized Light Microscope (PLM) | Enables rapid screening and identification of birefringent spherulites based on Maltese cross patterns. |

| Precision Hot Stage with Controller | Allows for precise thermal history control (melting, isothermal crystallization) to tailor spherulite size and morphology. |

| Optically Flat Substrates (Silicon Wafers) | Provide an atomically smooth, consistent surface for thin-film preparation and optimal AFM imaging. |

| High-Purity Polymer Materials | Ensures consistent crystallization behavior free from impurities that can act as unintended nucleating agents. |

| Analytical-Grade Solvents (e.g., Chloroform) | Used for solution-casting thin, uniform polymer films for analysis. |

| Image Analysis Software (e.g., Gwyddion, ImageJ) | For quantitative measurement of lamellar spacing, spherulite radii, and birefringence patterns from AFM and PLM data. |

This application note details advanced protocols for studying polymer spherulite crystallization, with a focus on utilizing Atomic Force Microscopy (AFM) for high-resolution structural analysis. Within the broader thesis on AFM imaging of polymer spherulite structures, this document provides methodologies to investigate nucleation, sectorization, and banding phenomena critical to material properties in pharmaceutical solid forms and polymer science.

Polymer crystallization is a hierarchical process initiated by nucleation, followed by lamellar growth into spherulitic superstructures. Sectorized and banded spherulites arise from rhythmic twisting or differential growth of lamellae. AFM is indispensable for this research, providing nanoscale topographical and mechanical property mapping without the need for extensive sample preparation, allowing for in situ or ex situ analysis of crystallization dynamics.

Key Research Reagent Solutions & Materials

The following table lists essential materials for experimental protocols in spherulite growth and AFM imaging.

Table 1: Research Reagent Solutions and Essential Materials

| Item | Function/Brief Explanation |

|---|---|

| Polymer Sample (e.g., Polyethylene Oxide, PEO) | Model semicrystalline polymer for spherulite formation studies. Molecular weight and dispersity control nucleation density and morphology. |

| Solvent (e.g., Reagent Grade Chloroform) | High-purity solvent for preparing thin film samples via solvent casting. Must be anhydrous to prevent hydrolysis in sensitive polymers. |

| Silicon Wafers or Mica Disks | Atomically flat, clean substrates for thin film preparation, essential for high-resolution AFM topographical imaging. |

| Hot Stage with Temperature Controller | Precise control of melting and isothermal crystallization temperature (Tc) to regulate nucleation rate and growth. |

| Atomic Force Microscope (Multimode) | Core instrument for imaging. Tapping mode is preferred to minimize sample deformation. Requires sharp, high-frequency probes. |

| AFM Probes (e.g., RTESPA-300) | Silicon tips with a resonant frequency of ~300 kHz for high-resolution tapping mode imaging of soft polymer surfaces. |

| Calibration Grating (e.g., TGZ1) | Standard sample for verifying AFM scanner calibration in X, Y, and Z axes prior to measurement. |

| Image Analysis Software (e.g., Gwyddion) | Open-source software for AFM data analysis, enabling measurement of lamellar spacing, spherulite radius, and surface roughness. |

Experimental Protocols

Protocol 3.1: Preparation of Thin Films for Spherulite Growth

Objective: To prepare isolated, well-developed spherulites for AFM analysis.

- Solution Preparation: Dissolve the polymer (e.g., PEO, Mw ~100k) in chloroform at 0.5-1.0% (w/v). Stir at room temperature for 24 hours to ensure complete dissolution.

- Substrate Cleaning: Sonicate a silicon wafer in acetone for 10 minutes, followed by isopropanol for 10 minutes. Dry under a stream of dry nitrogen.

- Film Casting: Using a micropipette, deposit 50-100 µL of the polymer solution onto the clean substrate. Spread evenly using the pipette tip or a spin coater.

- Solvent Evaporation: Cover the sample with a glass dish to allow slow evaporation over 2 hours at room temperature.

- Thermal Treatment:

- Place the sample on a programmable hot stage.

- Heat to 20°C above the polymer's melting point (Tm) for 5 minutes to erase thermal history.

- Rapidly quench or cool at a controlled rate (e.g., 10°C/min) to the desired isothermal crystallization temperature (Tc).

- Hold at Tc for a predetermined time (t_c) to grow spherulites to the desired size.

Protocol 3.2:In SituandEx SituAFM Imaging of Spherulites

Objective: To capture topographical details of spherulite nucleation, sector boundaries, and banding.

- AFM Setup & Calibration:

- Mount the sample on the AFM sample puck using double-sided tape.

- Install a sharp tapping-mode probe (spring constant ~40 N/m).

- Engage the laser and adjust the photodetector to achieve a sum signal near vendor specification.

- Perform a scanner calibration using a pitch grating (e.g., 10 µm grid).

- Ex Situ Imaging (Post-Crystallization):

- After Protocol 3.1, transfer the sample to the AFM.

- Use a large scan size (e.g., 100x100 µm) to locate spherulites. Identify sector boundaries and banded regions.

- Zoom into regions of interest (e.g., spherulite edge, band) for high-resolution imaging (e.g., 10x10 µm). Set scan rate to 0.5-1.0 Hz.

- Collect height (topography) and phase contrast data simultaneously.

- In Situ Imaging (During Crystallization - Advanced):

- Use an AFM equipped with a temperature-controlled stage.

- Perform thermal treatment as in Protocol 3.1, Step 5, directly on the AFM stage.

- Initiate intermittent scanning at the spherulite growth front to monitor real-time lamellar development and band formation.

Protocol 3.3: Quantitative Analysis of AFM Data

Objective: To extract quantitative parameters from spherulite images.

- Spherulite Growth Rate:

- From a time-series of in situ or multiple ex situ images, measure the radius (R) of a spherulite versus crystallization time (t).

- Plot R vs. t. The slope of the linear region is the radial growth rate (G) in µm/min.

- Lamellar Periodicity (Banding):

- Take a topographic line profile perpendicular to the banding pattern.

- Perform a Fast Fourier Transform (FFT) on the profile using image analysis software.

- The primary peak in the FFT spectrum corresponds to the band spacing (typically 0.1-10 µm).

- Surface Roughness at Sector Boundaries:

- Isolate a topographic image containing a sector boundary.

- Use the software's grain analysis or line profile tool to measure the step height and width of the boundary region.

Data Presentation & Analysis

Table 2: Quantitative Parameters from AFM Analysis of PEO Spherulites (Example Data)

| Parameter | Measurement Method (from Protocol 3.3) | Typical Value Range (PEO) | Significance |

|---|---|---|---|

| Radial Growth Rate (G) | Slope of R vs. t plot | 0.1 - 5.0 µm/min (highly Tc dependent) | Indicates crystallization kinetics; governed by secondary nucleation. |

| Banding Period (λ) | FFT of height profile across bands | 0.5 - 5.0 µm | Relates to lamellar twist periodicity; influenced by crystallization pressure and chain packing. |

| Nucleation Density (ρ) | Count of spherulites per unit area | 10 - 10⁵ spherulites/mm² | Controlled by Tc and impurities; affects final material morphology. |

| Lamellar Thickness (l_c) | Height of edge-on lamellae from section analysis | 5 - 20 nm | Determined by undercooling (ΔT = Tm - Tc); impacts mechanical strength. |

| Sector Boundary Angle | Angle between dominant lamellar orientations in adjacent sectors | 90° - 135° | Reveals symmetry and branching habits of the crystalline lamellae. |

Visualization of Concepts and Workflows

Diagram 1: Pathways to Spherulite Morphologies

Diagram 2: AFM Spherulite Research Workflow

Why AFM? Advantages Over Optical Microscopy for Nanoscale Lamellar Resolution

This application note, situated within a broader thesis on Atomic Force Microscopy (AFM) imaging of polymer spherulite structures, details the critical advantages of AFM over optical microscopy for resolving nanoscale lamellae. Polymer spherulites are semi-crystalline aggregates where lamellar crystals (typically 5-50 nm thick) radiate from a central nucleus. The precise characterization of these lamellae is fundamental to understanding structure-property relationships in polymers used in drug delivery systems, medical devices, and pharmaceutical packaging. Optical microscopy, limited by the diffraction of light (~200 nm lateral resolution), cannot resolve individual lamellae. AFM, with its sub-nanometer vertical and nanometer lateral resolution, is therefore indispensable for this nanoscale research.

Comparative Analysis: AFM vs. Optical Microscopy

Table 1: Quantitative Comparison of Key Imaging Parameters

| Parameter | Atomic Force Microscopy (AFM) | Optical Microscopy (Brightfield/Phase Contrast) |

|---|---|---|

| Lateral Resolution | <1 nm (in contact mode) | ~200 nm (diffraction-limited) |

| Vertical Resolution | <0.1 nm | N/A (2D intensity projection) |

| Lamellar Thickness Measurement | Direct, quantitative (3D profile) | Not possible; only spherulite morphology |

| Imaging Environment | Air, liquid, controlled atmosphere | Typically air or liquid (limited control) |

| Sample Preparation | Minimal; often requires flat surface | Often requires staining or sectioning |

| Information Type | Topography, modulus, adhesion, phase | Optical contrast, color (if stained) |

| Damage Potential | Possible tip-induced deformation | Minimal (non-contact, low energy) |

Table 2: Capabilities in Polymer Spherulite Characterization

| Characterization Goal | AFM Capability | Optical Microscopy Capability |

|---|---|---|

| Lamellar Width/Thickness | Direct measurement from cross-section | Not resolvable |

| Crystal Orientation | Clear from topography; chain folding visible | Limited to overall spherulite birefringence |

| Amorphous Region Analysis | Phase imaging distinguishes soft amorphous domains | Not distinguishable without stains |

| In-situ Crystallization | Possible in hot-stage liquid cells | Possible, but only gross morphological changes |

| Surface Modulus Mapping | Nanomechanical mapping (e.g., PeakForce QNM) | Not possible |

Experimental Protocols for AFM of Polymer Spherulites

Protocol 1: Sample Preparation for Lamellar Imaging

Objective: Prepare a thin polymer film to induce spherulitic growth suitable for AFM.

- Solution Casting: Dissolve the polymer (e.g., PLLA, PEO) in a suitable solvent (e.g., chloroform, toluene) at 0.5-1.0% w/v.

- Film Deposition: Drop-cast or spin-coat the solution onto a clean, atomically flat substrate (freshly cleaved mica or silicon wafer).

- Solvent Evaporation: Allow solvent to evaporate slowly under a glass dish to control evaporation rate and prevent dewetting.

- Crystallization: Anneal the film on a hot stage at a temperature between Tg and Tm for a controlled time (minutes to hours), then quench or slow-cool to room temperature to develop spherulites.

Protocol 2: Tapping Mode AFM for High-Resolution Lamellar Imaging

Objective: Acquire high-resolution topography and phase images of lamellar structures with minimal sample damage.

- Probe Selection: Use a high-resolution silicon probe (e.g., RTESPA-300, Bruker) with a nominal tip radius <10 nm and a resonance frequency of ~300 kHz.

- Mounting: Secure the sample to a metal puck using double-sided adhesive tape.

- Loading: Place the puck onto the AFM scanner.

- Engagement: Use the optical viewfinder to position the tip above a spherulite region. Initiate automatic engagement.

- Parameter Tuning:

- Set a moderate scan rate (0.5-1.0 Hz).

- Adjust the drive amplitude to achieve a free air amplitude (A0) of ~1.5 V.

- Set the amplitude setpoint (Asp) to ~0.8 A0 for stable, low-force imaging.

- Optimize feedback gains (proportional and integral) to track topography accurately.

- Scanning: Capture images at a resolution of at least 512x512 pixels over areas ranging from 20x20 µm (overview) to 2x2 µm (lamellar detail).

- Data Analysis: Use software (e.g., Gwyddion, NanoScope Analysis) to perform cross-sectional analysis to measure lamellar periodicity and height.

Protocol 3: Nanomechanical Mapping of Spherulites (PeakForce QNM)

Objective: Map the distribution of elastic modulus across crystalline lamellae and amorphous regions.

- Probe Selection & Calibration: Use a probe calibrated for quantitative nanomechanics (e.g., RTESPA-150, Bruker). Pre-calibrate the spring constant, deflection sensitivity, and most critically, the exact tip radius using a certified reference sample.

- Setup: Load the sample as in Protocol 2.

- Parameter Configuration:

- Enable PeakForce Tapping mode.

- Set the PeakForce frequency to 1-2 kHz.

- Adjust the PeakForce amplitude to 50-150 nm.

- Set the PeakForce setpoint as low as possible while maintaining contact.

- Mapping: Capture simultaneous topography, DMT Modulus, and adhesion maps.

- Analysis: Correlate high-modulus features with crystalline lamellae and low-modulus regions with amorphous interlamellar zones.

Visualization of Key Concepts

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AFM Spherulite Research

| Item | Function & Rationale |

|---|---|

| Freshly Cleaved Mica Substrates | Provides an atomically flat, inert, and hydrophilic surface for polymer film deposition, crucial for high-resolution imaging of lamellae. |

| Silicon Wafers (P-type, Boron-doped) | Alternative flat substrate; can be cleaned with piranha solution for ultra-clean, hydrophobic surfaces. |

| High-Resolution AFM Probes (e.g., RTESPA) | Silicon tips with sharp radii (<10 nm) and high resonance frequencies are essential for resolving nanoscale lamellar details. |

| Calibration Grating (e.g., TGQ1) | Grid of sharp spikes used to verify the tip's sharpness and the scanner's lateral calibration before and after experiments. |

| Nanomechanics Reference Sample (e.g., PDMS) | Sample with known modulus for calibrating PeakForce QNM probes, ensuring quantitative nanomechanical data. |

| Anhydrous Organic Solvents (e.g., Chloroform) | High-purity solvents for preparing polymer solutions without introducing impurities that can act as nucleation sites. |

| Precision Hot Stage | Allows for controlled isothermal crystallization of polymer films, enabling study of lamellar growth kinetics. |

| Vibration Isolation System | An active or passive isolation platform is mandatory to achieve sub-nanometer vertical resolution by dampening environmental noise. |

Application Notes

Atomic Force Microscopy (AFM) is a cornerstone technique for characterizing semi-crystalline polymer spherulites, providing multidimensional data beyond surface morphology. In the context of polymer spherulite research, integrating topography, phase imaging, and nanomechanical mapping is critical for correlating structural features with material properties, which is essential for applications in controlled drug delivery systems and biodegradable medical implants.

Topography Imaging reveals the characteristic lamellar organization of spherulites, allowing measurement of fibril width (typically 10-30 nm) and spherulite radius (often 1-100 μm). Surface roughness parameters (Ra, Rq) are key indicators of crystallization conditions and polymer blend homogeneity.

Phase Imaging in tapping mode detects viscoelastic heterogeneity within spherulites. The contrast between crystalline lamellae and amorphous regions provides a qualitative map of material distribution. Recent studies show phase lag differences of 5-30° correlate with local stiffness and energy dissipation, identifying interlamellar amorphous zones critical for drug incorporation.

Nanomechanical Property Mapping via PeakForce QNM or force-volume mapping quantifies the elastic modulus (E) and adhesion forces. For common biomedical polymers like PLLA or PCL, crystalline lamellae exhibit moduli of 2-8 GPa, while amorphous regions are softer (0.1-2 GPa). This mechanical contrast directly influences drug release kinetics from spherulitic matrices.

Key Quantitative Data Summary

Table 1: Representative AFM Data from Poly(L-lactic acid) (PLLA) Spherulites

| AFM Mode | Measured Parameter | Crystalline Region | Amorphous Region | Significance for Drug Development |

|---|---|---|---|---|

| Topography | Height (Lamella) | 5-15 nm | N/A | Determines surface area for API attachment. |

| Topography | Roughness (Ra) | 2-5 nm (over 1 μm²) | 5-15 nm (over 1 μm²) | Impacts biocompatibility and protein adsorption. |

| Phase Imaging | Phase Lag Shift | +10° to +30° | -5° to +10° | Identifies optimal API dispersion zones. |

| Nanomechanical (QNM) | Reduced Modulus (Er) | 4-8 GPa | 0.5-1.5 GPa | Predicts degradation rate and release mechanics. |

| Nanomechanical (QNM) | Adhesion Force | 1-5 nN | 10-50 nN | Indicates potential for burst release. |

Table 2: Protocol-Specific Parameters for PCL Spherulite Imaging

| Parameter | Topography | Phase Imaging | Force Mapping | Rationale |

|---|---|---|---|---|

| Scan Rate | 0.5-1.0 Hz | 0.5-1.0 Hz | 0.1-0.3 Hz | Balances resolution, fidelity, and tip preservation. |

| Set Point | 0.7-0.9 V (A/A₀ ~0.8) | 0.7-0.9 V | 50-300 pN (PeakForce) | Maintains stable tapping; avoids sample deformation. |

| Probe | RTESPA-300 (k~40 N/m) | RTESPA-300 | ScanAsyst-Air (k~0.4 N/m) | Stiffness suited for modality; soft lever for quantitative mapping. |

| Resolution | 512 x 512 pixels | 512 x 512 pixels | 128 x 128 to 256 x 256 pixels | Optimizes time vs. property map detail. |

| Post-Processing | Plane fit, flatten | None applied | DMT model fitting, pixel-by-pixel | Extracts accurate modulus from force curves. |

Experimental Protocols

Protocol 1: Topography and Phase Imaging of Polymer Spherulites

Objective: To simultaneously acquire high-resolution height and phase contrast images of spherulitic structures.

- Sample Preparation: Solution-cast a 0.5-1.0 wt% polymer (e.g., PLLA) in chloroform onto a clean silica wafer. Anneal at a controlled temperature (e.g., 130°C for PLLA) for 2 hours to induce spherulite growth, then quench to room temperature.

- AFM Setup: Mount the sample on a magnetic puck. Install a silicon cantilever (e.g., Bruker RTESPA-300, f₀ ~300 kHz, k ~40 N/m). Engage in Tapping Mode under ambient conditions (20-25°C, 30-50% RH).

- Tuning & Engagement: Tune the cantilever resonance frequency. Set the drive amplitude to achieve a free amplitude (A₀) of ~50 nm. Set the amplitude set point to 80% of A₀.

- Imaging: Scan a 5 μm x 5 μm area at a scan rate of 0.8 Hz with 512 samples/line. Simultaneously record height and phase channels.

- Analysis: Use software (e.g., Gwyddion, NanoScope Analysis) to apply a first-order flatten to height data. Analyze phase images without filtering to preserve material contrast.

Protocol 2: PeakForce QNM Nanomechanical Mapping

Objective: To quantitatively map elastic modulus and adhesion across spherulite structures.

- Sample & Probe Preparation: Use the same spherulite sample. Install a soft, calibrated cantilever designed for PeakForce QNM (e.g., Bruker ScanAsyst-Air, k ~0.4 N/m, f₀ ~70 kHz).

- Calibration: Perform thermal tune to determine the spring constant. Calibrate the optical lever sensitivity on a rigid, clean surface (e.g., silica wafer).

- Parameter Optimization: Set the PeakForce amplitude to 50-100 nm and frequency to 1-2 kHz. Adjust the PeakForce set point (typically 50-300 pN) to maintain gentle, non-destructive contact. Set the scan rate to 0.2 Hz for a 5 μm x 5 μm area.

- Data Acquisition: Acquire maps of height, DMT modulus, adhesion, and deformation simultaneously at 128 x 128 or 256 x 256 pixels resolution.

- Data Processing: Use the NanoScope Analysis software to apply the Derjaguin-Muller-Toporov (DMT) model to each force curve in the map. Filter modulus maps by adhesion or deformation to remove artifacts from voids or debris.

Visualization of AFM Workflow for Spherulite Analysis

Title: AFM Workflow for Polymer Spherulite Characterization

Title: Relating AFM Data to Spherulite Function

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AFM of Polymer Spherulites

| Item / Reagent | Function / Role | Example Product / Specification |

|---|---|---|

| Silicon Wafers | Provides an atomically flat, clean, and conductive substrate for polymer film casting and AFM calibration. | P-type, ⟨100⟩, 1 cm x 1 cm pieces, cleaned with piranha solution (Caution: Highly corrosive). |

| High-Purity Solvents | Used to prepare polymer solutions for thin-film formation without introducing impurities that disrupt crystallization. | Anhydrous Chloroform (≥99.8%), HPLC-grade Tetrahydrofuran (THF), stored over molecular sieves. |

| Biomedical-Grade Polymers | The material under study, forming spherulitic structures. Must be of known molar mass and dispersity. | Poly(L-lactic acid) (PLLA, Mw 50-100 kDa), Poly(ε-caprolactone) (PCL, Mw 45-80 kDa). |

| Calibration Gratings | Essential for verifying the lateral and vertical accuracy of the AFM scanner. | TGZ1 (TiO₂ on glass, 10 μm pitch) and PG (1 μm pitch) grids from NT-MDT Spectrum Instruments. |

| Calibrated AFM Probes | Specialized cantilevers for each mode. Spring constant calibration is critical for quantitative nanomechanics. | Tapping: Bruker RTESPA-300 (k~40 N/m); PeakForce QNM: Bruker ScanAsyst-Air (k~0.4 N/m). |

| Anti-Vibration Platform | Isolates the AFM from environmental noise (floor vibrations, acoustic), enabling high-resolution imaging. | A passive or active isolation table (e.g., from Herzan or TMC). |

This document provides application notes and protocols for the study of poly(L-lactic acid) (PLLA), polycaprolactone (PCL), and polyvinylidene fluoride (PVDF) within the framework of a doctoral thesis investigating spherulitic microstructures using Atomic Force Microscopy (AFM). The correlation between crystalline morphology (e.g., spherulite size, lamellar orientation) and functional performance is critical for tailoring these polymers for advanced biomedical applications.

Table 1: Key Properties of PLLA, PCL, and PVDF for Biomedical Applications

| Polymer | Full Name | Glass Transition Temp. (Tg) | Melting Temp. (Tm) | Degradation Time* | Tensile Modulus (GPa) | Key Biomedical Properties |

|---|---|---|---|---|---|---|

| PLLA | Poly(L-lactic acid) | 55-65 °C | 170-190 °C | 12-24 months | 2.7-4.1 | Biodegradable, biocompatible, high strength, osteoconductive |

| PCL | Polycaprolactone | (-65)-(-60) °C | 58-64 °C | 24-36 months | 0.2-0.6 | Biodegradable, highly elastic, slow degradation, drug-permeable |

| PVDF | Polyvinylidene fluoride | (-40)-(-35) °C | 155-192 °C | Non-degradable | 1.5-2.5 | Piezoelectric, excellent chemical stability, high mechanical strength |

Degradation time for *in vivo bulk erosion; varies with crystallinity, MW, and implantation site.

Application Notes

PLLA in Bone Tissue Engineering

PLLA's relatively high modulus and ability to form well-defined spherulites make it suitable for load-bearing scaffolds. AFM imaging reveals that annealing increases spherulite size and lamellar ordering, directly enhancing compressive strength but potentially slowing degradation. Larger spherulites can reduce ductility.

PCL in Drug Delivery & Soft Tissue Regeneration

PCL's low Tg and slow degradation are ideal for long-term drug release systems. AFM phase imaging distinguishes crystalline lamellae from amorphous drug-rich regions. Controlled cooling protocols can tune spherulitic density, directly impacting drug release kinetics—larger spherulites with thicker lamellae typically slow release.

PVDF in Piezoelectric Scaffolds & Sensors

The piezoelectric β-phase is crucial for applications in neural tissue engineering and pressure sensing. Processing (e.g., electrospinning, poling) induces this phase. AFM in Piezoresponse Force Microscopy (PFM) mode is used to map the piezoelectric domains within spherulitic structures, correlating local polarity to global scaffold performance.

Experimental Protocols

Protocol 1: AFM Imaging of Polymer Spherulites (Contact Mode)

Objective: To characterize the surface topography and lamellar structure of isothermally crystallized polymer thin films.

Materials:

- Polymer film sample (spin-coated or melt-pressed, isothermally crystallized)

- Atomic Force Microscope with silicon nitride probes (k ~ 0.12 N/m)

- Vibration isolation table

Procedure:

- Sample Preparation: Prepare PLLA, PCL, or PVDF films by melt-pressing between Teflon sheets at 20°C above Tm, followed by rapid transfer to a hot stage set at the desired crystallization temperature (e.g., 120°C for PLLA, 40°C for PCL, 155°C for PVDF). Crystallize for a set time (e.g., 2 hours).

- Mounting: Secure the film to a 15 mm AFM specimen stub using double-sided adhesive.

- Probe Engagement: Mount the probe and engage on a flat, featureless area of the sample using the instrument's automated engagement routine.

- Scanning Parameters: Set scan size to 20x20 μm for initial overview. Reduce to 5x5 μm for high-resolution lamellar imaging.

- Scan Rate: 1.0 Hz

- Setpoint: Maintain a low, constant force (≈ 5 nN) to minimize sample deformation.

- Data Types: Capture Height (topography) and Deflection (error signal) images simultaneously.

- Image Analysis: Use AFM software to perform flattening and leveling. Measure spherulite radius, lamellar spacing, and surface roughness (Ra).

Protocol 2: Sample Preparation for Correlative Crystallinity Analysis

Objective: To prepare matched samples for AFM and Wide-Angle X-ray Scattering (WAXS) to correlate surface morphology with bulk crystallinity.

Procedure:

- Prepare a set of six identical polymer films following steps in Protocol 1.

- Randomly designate three for AFM analysis (Protocol 1).

- For the remaining three, perform WAXS analysis to determine the degree of crystallinity and crystal polymorph (e.g., α vs. β phase in PVDF).

- Correlate the average spherulite size (from AFM) with the calculated crystallinity (from WAXS) for each polymer under different crystallization conditions.

Diagrams

Title: AFM Spherulite Analysis Workflow

Title: Structure-Property Relationship Logic

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for AFM Spherulite Research

| Item | Function | Example Product/Catalog # |

|---|---|---|

| Polymer Pellets (Medical Grade) | Raw material for film fabrication. High purity ensures consistent crystallization. | PLLA: Lactel Absorbable Polymers B6013-1; PCL: Sigma-Aldrich 440744; PVDF: Sigma-Aldrich 427155. |

| Hot Press with Digital Control | To create uniform, thin melt-pressed films for crystallization studies. | Carver Auto Series Heated Press. |

| Precision Temperature Hot Stage | Provides exact isothermal crystallization temperature (Tc) control. | Linkam LTS420 or THMS600 stage. |

| Silicon AFM Probes (Contact Mode) | For high-resolution topography imaging of soft polymers. Low spring constant prevents damage. | Bruker DNP-10 or Olympus OMCL-RC800. |

| Conductive AFM Probes (PFM Mode) | Coated with Pt/Ir for piezoelectric domain imaging of PVDF. | Budget Sensors ElectriMulti75-G. |

| AFM Calibration Grating | Verifies scanner accuracy in X, Y, and Z dimensions for quantitative measurements. | TGZ01 or TGXYZ02 (NT-MDT). |

| Double-Sided Adhesive Tape | Secures polymer film to AFM stub without chemical contamination. | Ted Pella Conductive Carbon Tape. |

| WAXS/DSC Instrument Access | For correlative analysis of bulk crystallinity and thermal properties. | In-house or collaboration-based. |

Mastering AFM for Spherulites: Sample Prep, Imaging Modes, and Drug Delivery Insights

Within a broader thesis focused on Atomic Force Microscopy (AFM) imaging of polymer spherulite structures, sample preparation is paramount. The protocols for thin film casting, melt-crystallization, and substrate selection directly dictate the morphology, size, and quality of spherulites, which are critical for reliable AFM analysis. These application notes detail standardized methodologies to ensure reproducible preparation of semicrystalline polymer samples for high-resolution topographical and phase imaging.

Experimental Protocols

Protocol 1: Solution-Cast Thin Film Preparation

This protocol is ideal for polymers soluble in common organic solvents (e.g., PCL, PEO, PS).

Materials:

- Polymer pellets or powder.

- High-purity solvent (e.g., toluene, chloroform, tetrahydrofuran).

- Clean substrate (see Substrate Choice section).

- Spin coater or precision casting stage.

- Vacuum desiccator or oven.

Methodology:

- Prepare a 0.5-2.0 wt% polymer solution by dissolving the polymer in the chosen solvent. Stir at room temperature or elevated temperature (e.g., 40-50°C) until fully dissolved (typically 2-24 hours).

- Filter the solution through a 0.2 or 0.45 μm PTFE syringe filter directly onto the substrate to remove dust and undissolved aggregates.

- For Spin Casting: Place substrate on spin coater chuck. Dispense 50-100 μL of filtered solution onto the substrate. Spin at 1500-3000 rpm for 30-60 seconds. This produces films ~50-200 nm thick.

- For Drop Casting: Deposit a small volume (10-50 μL) of filtered solution onto a static, level substrate.

- Solvent Evaporation: Allow the solvent to evaporate slowly under a glass petri dish for initial drying (1-2 hours), then place the sample in a vacuum desiccator (< 0.1 mBar) for a minimum of 12 hours to remove residual solvent.

- Proceed to melt-crystallization (Protocol 3) or store in a desiccator.

Protocol 2: Melt-Crystallization for Spherulite Growth

This protocol controls thermal history to nucleate and grow well-defined spherulites.

Materials:

- Prepared thin film (from Protocol 1) or polymer piece on a substrate.

- Programmable hot stage with temperature controller (±0.1°C stability).

- Inert atmosphere (Nitrogen or Argon) supply (optional but recommended).

- Optical microscope for in-situ monitoring (optional).

Methodology:

- Place the sample on the hot stage.

- Melting: Heat the sample to a temperature 20-30°C above its melting point (Tₘ). Hold at this temperature for 5-10 minutes to erase all prior thermal history and crystal nuclei.

- Nucleation: Rapidly quench (cool) the sample to a crystallization temperature (Tₓ) between Tₘ and the glass transition temperature (Tɡ). The chosen Tₓ dictates spherulite growth rate and final size (see Table 1).

- Isothermal Crystallization: Hold the sample at Tₓ for a defined period. Crystallization time can range from minutes to several hours, depending on polymer and Tₓ.

- Quenching: After the desired crystallization time, rapidly quench the sample to room temperature or below Tɡ to halt crystallization.

Protocol 3: Substrate Preparation and Choice

Substrate properties (surface energy, roughness, conductivity) significantly influence film wetting, crystallization kinetics, and AFM imaging mode compatibility.

Protocol for Silicon Wafer Substrates (Most Common):

- Cleaving: Use a diamond scribe to cleave a prime-grade silicon wafer (often with native oxide layer, Si/SiO₂) into ~1 cm x 1 cm pieces.

- Cleaning: Sonicate substrates sequentially in acetone, isopropanol, and deionized water (5 min each). Dry under a stream of dry nitrogen or argon.

- Plasma Treatment (Hydrophilic Surface): Treat cleaned substrates with oxygen plasma (e.g., 100 W, 30 sec) to create a clean, hydrophilic, high-energy surface. Use within 15 minutes of treatment for consistent film spreading.

- Alternative Treatments: For hydrophobic surfaces (e.g., for polystyrene), use silanization (octadecyltrichlorosilane, OTS) or simply use freshly cleaved mica.

Data Presentation

Table 1: Effect of Crystallization Temperature (Tₓ) on Poly(ε-caprolactone) (PCL) Spherulite Morphology

| Crystallization Temp (Tₓ), °C | Average Spherulite Diameter (μm) | Spherulite Growth Rate (μm/min) | Observed Maltese Cross Clarity (AFM Phase) | Recommended for AFM Imaging |

|---|---|---|---|---|

| 30 | 50 - 200 | 5.2 ± 0.8 | Low, fine structure | For high-density studies |

| 40 | 100 - 300 | 1.5 ± 0.3 | High, distinct | Optimal balance |

| 45 | 300 - 600 | 0.4 ± 0.1 | Very High, coarse lamellae | For single spherulite analysis |

| 48 | >1000 (impinged) | <0.1 | High, but impinged | Limited, for boundary studies |

Data representative of PCL (Mₙ ~80,000) isothermally crystallized from melt on Si/SiO₂. Growth rates measured via polarized optical microscopy.

Table 2: Substrate Comparison for Polymer Spherulite AFM Studies

| Substrate | Surface Roughness (Ra) | Key Characteristics | Best For | Protocol Considerations |

|---|---|---|---|---|

| Silicon (Si/SiO₂) | <0.5 nm | Atomically flat, hydrophilic after O₂ plasma, conductive, rigid, inexpensive. | High-resolution tapping/phase mode AFM; electrical modes. | Requires plasma cleaning for consistent film adhesion. |

| Freshly Cleaved Mica | ~0.1 nm | Atomically flat, hydrophilic, negatively charged, insulating. | Ultra-high-resolution AFM; studying very thin films (<50 nm). | Can affect crystallization kinetics due to strong interaction. |

| Gold-coated Si | ~2 nm (depends on Au) | Conductive, modifiable with self-assembled monolayers (SAMs), moderate flatness. | Conductive AFM (c-AFM); electrochemical studies; surface functionalization. | Au roughness can obscure fine lamellar details. |

| Glass (Cover Slip) | ~1-2 nm | Inexpensive, transparent for optical correlation, moderately flat. | Correlative microscopy (AFM + optical). | Clean rigorously; surface heterogeneity can be an issue. |

Mandatory Visualization

Title: Polymer Spherulite AFM Sample Prep & Validation Workflow

Title: Standard Melt-Crystallization Thermal Profile

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials

| Item | Function in Protocol | Example/Specification |

|---|---|---|

| High-Purity Solvents | Dissolving polymer for solution casting. Must be inert and leave minimal residue. | HPLC-grade Chloroform, Toluene, Tetrahydrofuran (stabilizer-free for some polymers). |

| Prime Grade Silicon Wafers | Primary substrate for AFM. Provides ultra-flat, reproducible, and clean surface. | P-type/Boron-doped, ⟨100⟩ orientation, with native oxide (Si/SiO₂). |

| Muscovite Mica Sheets | Alternative atomically flat substrate for ultra-thin films. Easily cleavable. | V-1 or V-2 Grade, 0.25 mm thickness. |

| PTFE Syringe Filters | Critical for removing dust and microgels from polymer solutions prior to casting. | 0.2 μm pore size, 13-25 mm diameter. |

| Programmable Hot Stage | Provides precise thermal control for melt-crystallization protocols. Essential for defined thermal history. | Temperature stability ±0.1°C, cooling/heating rates >10°C/min, with nitrogen purge. |

| Oxygen Plasma Cleaner | Creates a clean, hydrophilic, high-energy surface on Si/SiO₂ wafers for uniform polymer film adhesion and spreading. | RF or low-pressure plasma system. |

| Vacuum Desiccator | Ensures complete removal of residual solvent from cast films to prevent plasticization during crystallization. | With chemical-resistant seal and capable of achieving <0.1 mBar vacuum. |

| Inert Atmosphere | Prevents polymer oxidation/degradation during high-temperature melting stages. | Dry Nitrogen or Argon gas supply with regulator. |

This application note is framed within a broader thesis research program investigating the hierarchical structure-property relationships in semi-crystalline polymer spherulites. The accurate nanoscale morphological and mechanical mapping of soft polymer components (e.g., amorphous regions, early-stage crystallites) is critical. The choice between conventional Tapping Mode and PeakForce Tapping (PFT) fundamentally dictates the quality, resolution, and mechanical integrity of the acquired data on these delicate structures.

Mode Comparison: Principles and Quantitative Data

Tapping Mode (AM-AFM): The cantilever oscillates at resonance, briefly contacting the surface. Feedback maintains a constant amplitude setpoint. The phase contrast signal is qualitatively related to material properties. PeakForce Tapping (PFT): The probe performs a gentle, sinusoidal tap at a frequency (typically 0.5-2 kHz) far below resonance. A feedback loop maintains a user-defined maximum peak force (typically 10s-100s of pN). A force-distance curve is captured on every tap, enabling quantitative nanomechanical mapping.

Table 1: Quantitative Comparison of Tapping Mode vs. PeakForce Tapping for Soft Polymers

| Parameter | Tapping Mode (AM-AFM) | PeakForce Tapping (PFT) |

|---|---|---|

| Interaction Force | Indirectly controlled via amplitude setpoint; can be high. | Directly controlled and minimized (<100 pN achievable). |

| Imaging Speed | High (resonant frequency). | Slower (typically 0.5-2 kHz line rates). |

| Mechanical Data | Qualitative phase contrast. | Quantitative: Modulus (DMT), Adhesion, Deformation, Dissipation. |

| Force Control | Not direct; prone to tip-sample damage on soft materials. | Precise, real-time force control on every cycle. |

| Sample Deformation | Often significant for soft polymers, distorting true morphology. | Minimized, preserving native spherulite structure. |

| Environment | Robust in air; challenging in fluid due to Q-factor reduction. | Excellent performance in both air and liquid. |

Experimental Protocols

Protocol 1: Sample Preparation for Spherulite Imaging

- Material: Poly(L-lactic acid) (PLLA) or Poly(ε-caprolactone) (PCL).

- Solution Casting: Dissolve polymer in appropriate solvent (e.g., chloroform for PLLA) at 1% w/v.

- Film Formation: Drop-cast 20 µL onto a clean glass slide or mica substrate.

- Crystallization: Anneal at a temperature between Tg and Tm (e.g., 120°C for PLLA) for 2 hours to develop spherulites, followed by slow cooling.

- Mounting: Secure the substrate onto a 12 mm AFM metal puck using double-sided tape.

Protocol 2: Tapping Mode Imaging of Polymer Spherulites

- Probe Selection: Use a silicon cantilever (e.g., RTESPA-300) with a resonant frequency of ~300 kHz and a spring constant of ~40 N/m.

- Mounting: Install the probe and align the laser.

- Tuning: Auto-tune the cantilever to find its first resonant peak. Set the drive amplitude to achieve a free air amplitude (A0) of ~50 nm.

- Engagement: Engage onto the sample surface using standard procedures.

- Imaging Parameters:

- Set amplitude setpoint ratio (Asp/A0) to 0.7-0.8 for a "soft" tap.

- Set scan rate to 0.5-1 Hz.

- Acquire both height and phase images simultaneously (512 x 512 pixels).

- Optimization: Adjust setpoint and drive amplitude to minimize phase lag while maintaining stable tracking.

Protocol 3: PeakForce Tapping QNM Imaging of Polymer Spherulites

- Probe Selection: Use a silicon probe with a known spring constant (e.g., ScanAsyst-Air, k ~0.4 N/m). Pre-calibrate the spring constant and optical lever sensitivity.

- Mounting: Install the probe and align the laser.

- Parameter Setup:

- Set PeakForce Frequency to 0.5-1 kHz.

- Set PeakForce Setpoint to 50-150 pN (start high, reduce until deformation is minimal).

- Enable all QNM channels: Height, DMT Modulus, Adhesion, Deformation.

- Engagement: Engage using the PeakForce engagement routine.

- Imaging Parameters:

- Set scan rate to 0.3-0.7 Hz.

- Acquire images at 512 x 512 pixels.

- Calibration: Use a known, homogeneous soft sample (e.g., PDMS) to verify modulus calibration before imaging the polymer sample.

Visualization: AFM Mode Decision Logic

AFM Mode Selection for Soft Polymer Imaging

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for AFM of Polymer Spherulites

| Item | Function/Description |

|---|---|

| Silicon AFM Probes (Tapping Mode) | e.g., RTESPA-300. Stiff levers (~40 N/m) for high-res imaging in air. |

| Silicon Nitride AFM Probes (PeakForce) | e.g., ScanAsyst-Air/Fluid. Softer levers (~0.4-0.7 N/m) for precise force control. |

| PLLA or PCL Polymer | Model semi-crystalline polymers that form well-defined spherulite structures. |

| Optical Grade Mica Substrates | Atomically flat, clean surface for film casting and high-resolution imaging. |

| Chloroform (HPLC Grade) | High-purity solvent for preparing polymer solutions without residue. |

| Calibration Sample (PS/LDPE Blend) | Reference sample with distinct hard/soft domains for verifying tip performance. |

| PDMS Calibration Sample | Sample of known, homogeneous modulus for quantitative nanomechanical calibration in PFT. |

1. Introduction This protocol details a systematic Atomic Force Microscopy (AFM) workflow for the comprehensive morphological analysis of semi-crystalline polymer spherulites, with a focus on poly(L-lactic acid) (PLLA) as a model biodegradable polymer relevant to drug delivery. The methodology is designed to efficiently transition from identifying bulk spherulitic morphology to resolving the nanoscale lamellar crystalline structures, providing critical structure-property insights for controlled-release formulation development.

2. Research Reagent Solutions & Essential Materials Table 1: Essential Materials for Polymer Spherulite AFM Analysis

| Item | Function & Specification |

|---|---|

| Polymer Sample | e.g., Poly(L-lactic acid) (PLLA), MW 50-100 kDa. Model system for studying crystallization kinetics and morphology. |

| Solvent | High-purity chloroform or dichloromethane. For preparing thin films via spin-coating or solution-casting. |

| Silicon Wafer Substrate | Prime grade, p-type. Provides an atomically flat, clean, and conductive surface for sample deposition. |

| AFM Probe (Tapping Mode) | Silicon cantilever, resonant frequency ~300 kHz, spring constant ~40 N/m. For survey imaging with minimal sample damage. |

| AFM Probe (High-Res) | Ultra-sharp silicon tip (radius < 10 nm), high-frequency cantilever (>500 kHz). Essential for resolving lamellar details. |

| Pulsed Force Mode (PFM) Kit | Optional. Enables simultaneous mapping of mechanical properties (elasticity, adhesion) alongside topography. |

| Dry Nitrogen Gas | For sample cleaning and dust removal prior to imaging. |

3. Step-by-Step Imaging Protocol

3.1. Sample Preparation (PLLA Thin Film)

- Solution Preparation: Dissolve PLLA pellets in chloroform at 1% (w/v). Stir at 40°C for 2 hours to ensure complete dissolution.

- Spin-Coating: Deposit 50 µL of solution onto a clean silicon wafer. Spin at 2000 rpm for 60 seconds.

- Controlled Crystallization: Anneal the film on a hotplate at 200°C for 2 minutes to erase thermal history, then rapidly transfer to a second hotplate at 120°C for 30-60 minutes to induce spherulite growth.

3.2. AFM Instrument Setup

- Mount the sample on the AFM magnetic puck.

- Engage the optical microscope to select an area of interest free of major defects.

- Mount the appropriate cantilever and align the laser spot on the cantilever end.

- Tune the cantilever to find its resonant frequency. Set the drive amplitude to 10-20% below resonance for Tapping Mode.

3.3. Multi-Scale Imaging Workflow

Diagram Title: Hierarchical AFM Imaging Workflow for Polymer Spherulites

3.4. Detailed Imaging Parameters Table 2: AFM Imaging Parameters for Each Step

| Step | Objective | Scan Size | Mode | Probe Type | Key Parameters | Target Resolution |

|---|---|---|---|---|---|---|

| 1. Optical Survey | Locate spherulites, assess coverage. | 200x200 µm | Optical | - | Brightfield | ~1 µm |

| 2. Low-Res AFM | Map full spherulite morphology. | 50x50 µm | Tapping Mode | Standard Si (~300 kHz) | Scan rate: 0.8 Hz, Points: 512 | 100 nm |

| 3. High-Res AFM | Resolve fibrillar branches. | 5x5 µm | Tapping Mode | Standard Si | Scan rate: 1.2 Hz, Points: 1024 | 10 nm |

| 4. Lamellar Detail | Image crystal lamellae. | 1x1 µm | Tapping Mode | High-Res Si (<10 nm tip) | Scan rate: 1.5 Hz, Points: 2048 | <2 nm |

4. Data Analysis & Interpretation Protocol

4.1. Quantitative Morphological Analysis Table 3: Key Quantitative Metrics for Thesis Analysis

| Metric | Measurement Protocol | Relevance to Thesis |

|---|---|---|

| Spherulite Diameter | Measure 50+ spherulites from Step 2 scans using line tools. Report mean ± SD. | Correlates with crystallization rate & drug release kinetics. |

| Radial Growth Rate | Diameter / (crystallization time). From isothermal data. | Fundamental kinetic parameter. |

| Lamellar Periodicity | FFT or line profile analysis of Step 4 scans. Measure peak-to-peak distance. | Relates to crystal thickness (Gibbs-Thomson eqn.) and degradation profile. |

| Surface Roughness (Ra, Rq) | Calculate on 5x5 µm areas (Step 3) using instrument software. | Impacts drug-polymer adhesion and protein adsorption. |

| Phase Contrast Shift | Histogram analysis of phase signal. Higher shift indicates higher stiffness. | Maps local mechanical variation within spherulite. |

4.2. From Image to Thesis: Data Integration Logic

Diagram Title: Linking AFM Data to Drug Release Properties

5. Advanced Protocol: Simultaneous Nanomechanical Mapping For correlating morphology with mechanical properties:

- Mode: Employ PeakForce QNM or Pulsed Force Mode.

- Probe: Use a calibrated probe with known spring constant (~40 N/m) and tip radius.

- Scan: Perform on a 10x10 µm area encompassing a spherulite boundary.

- Analysis: Map reduced elastic modulus (DMT model) and adhesion force. Correlate high modulus with radial lamellar bundles and low modulus with amorphous inter-fibrillar regions.

6. Conclusion This protocol provides a reproducible, multi-scale framework for AFM analysis of polymer spherulites. By systematically linking low-magnitude survey data to high-resolution lamellar detail, researchers can generate robust quantitative morphology data essential for a thesis correlating polymer microstructure with drug release performance in advanced formulation development.

This Application Note provides detailed protocols for the quantitative analysis of semi-crystalline polymer morphology using Atomic Force Microscopy (AFM), within the broader context of thesis research on AFM imaging of polymer spherulite structures. Accurate measurement of lamellar thickness, spherulite diameter, and surface roughness is critical for correlating polymer microstructure with material properties, which is of high relevance to researchers in polymer science, material engineering, and drug development professionals working on polymeric drug delivery systems and excipients.

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item Name | Function & Application | Key Considerations |

|---|---|---|

| Atomic Force Microscope | High-resolution imaging instrument for topographic and phase analysis of polymer surfaces in tapping/non-contact mode. | Critical for nanoscale resolution of lamellae. Must have a phase imaging capability. |

| Sharp Silicon Probes | AFM cantilevers with high resonance frequency for tapping mode imaging of soft polymers. | Tip radius < 10 nm is recommended to resolve fine lamellar structures. |

| Polymer Films (e.g., PLLA, PEO) | Sample material cast or spin-coated onto clean substrates (e.g., silicon wafers, glass). | Crystallization conditions (temp., time) must be strictly controlled for reproducibility. |

| Substrate (Silicon Wafer) | Provides an atomically flat, clean, and inert surface for polymer film preparation. | Must be cleaned via piranha solution or oxygen plasma before use. |

| Image Analysis Software | Software (e.g., Gwyddion, SPIP, MountainsSPIP, ImageJ) for processing AFM data and extracting quantitative metrics. | Must have line profile, grain analysis, and roughness calculation functions. |

| Calibration Grating | Reference sample with known pitch and step height for lateral and vertical AFM calibration. | Used before measurement sessions to ensure scanner accuracy. |

Experimental Protocols

Protocol 3.1: Sample Preparation for Isothermal Crystallization

Objective: To prepare reproducible, thin polymer films with well-developed spherulitic structures.

- Solution Preparation: Dissolve the polymer (e.g., Poly(L-lactic acid) at 1-2 wt%) in a suitable solvent (e.g., chloroform for PLLA) under gentle stirring for 12 hours.

- Substrate Cleaning: Clean a silicon wafer (1x1 cm) by sonication in acetone and isopropanol for 10 minutes each. Dry under nitrogen. Treat with oxygen plasma for 5 minutes to ensure hydrophilicity.

- Film Casting: Deposit 20-50 µL of the polymer solution onto the wafer. Spin-coat at 1500-3000 rpm for 60 seconds to form a thin film (~100 nm).

- Thermal Treatment: Immediately transfer the film to a pre-heated hot stage under a nitrogen atmosphere.

- Melting: Heat to a temperature 30-40°C above the polymer's melting point (Tm) for 5 minutes to erase thermal history.

- Crystallization: Rapidly cool to the desired isothermal crystallization temperature (Tc) and hold for a predetermined time to allow spherulite growth.

- Quenching: Rapidly quench the sample to room temperature to arrest the crystallization process.

Protocol 3.2: AFM Imaging for Morphological Quantification

Objective: To acquire high-quality height and phase images suitable for quantitative analysis.

- AFM Setup: Mount the sample on the AFM stage. Engage a sharp silicon probe (e.g., resonance frequency ~300 kHz, spring constant ~40 N/m).

- Imaging Mode: Use Tapping Mode (or PeakForce Tapping) in air to minimize sample damage.

- Scan Parameters: Set a scan rate of 0.5-1.0 Hz. Adjust the drive amplitude and setpoint to achieve stable, high-contrast imaging. Simultaneously capture Height and Phase signal channels.

- Image Acquisition: Acquire images at multiple magnifications:

- Low Mag (50x50 µm): To capture multiple full spherulites for diameter measurement.

- High Mag (5x5 µm or 2x2 µm): To resolve individual lamellar crystals within a spherulite for thickness measurement.

- Data Saving: Save raw data in the instrument's native format and as an ASCII matrix or TIFF for external analysis.

Protocol 3.3: Quantitative Analysis Workflow

Objective: To extract numerical values for lamellar thickness, spherulite diameter, and surface roughness from AFM images. Software: The following steps are generally performed using dedicated AFM analysis or image analysis software.

Image Pre-processing:

- Apply a 0th or 1st order flattening to remove sample tilt.

- Use a median or Fourier filter to reduce high-frequency noise, if necessary, without distorting features.

Spherulite Diameter Measurement:

- On a low-magnification height or phase image, use a line profile tool to draw a line across the diameter of a spherulite.

- Measure the distance between the radial boundaries where the signal (height or phase contrast) changes sharply. Repeat for at least 20 spherulites from different samples.

Lamellar Thickness Measurement:

- On a high-magnification phase image (which best highlights the crystalline lamellae), draw a line profile perpendicular to the long axis of several aligned lamellae.

- The Full Width at Half Maximum (FWHM) of the peaks in the phase signal profile corresponds to the lamellar width/thickness. Measure at least 50 lamellae.

Surface Roughness Calculation:

- Select a representative, flattened height image. Define a measurement area that excludes extreme defects.

- Calculate the following standard roughness parameters:

- Ra (Average Roughness): The arithmetic average of absolute height deviations.

- Rq (Root Mean Square Roughness): The standard deviation of height values.

- Rz (Average Maximum Height): The average difference between the five highest peaks and five lowest valleys.

Table 1: Representative Quantitative Data from AFM Analysis of PLLA Spherulites Crystallized at Different Temperatures

| Isothermal Crystallization Temperature (Tc) | Average Spherulite Diameter (µm) | Average Lamellar Thickness (nm) | Surface Roughness, Rq (nm) | Notes |

|---|---|---|---|---|

| 120°C | 15.2 ± 3.5 | 8.1 ± 1.2 | 4.5 ± 0.8 | Faster growth, smaller/more numerous spherulites, thinner lamellae. |

| 140°C | 45.7 ± 8.1 | 12.5 ± 2.1 | 11.2 ± 1.5 | Slower growth, larger/less numerous spherulites, thicker lamellae. |

| 150°C | 102.3 ± 15.6 | 16.8 ± 2.8 | 18.9 ± 3.1 | Very slow growth, largest spherulites, thickest lamellae, highest roughness. |

Note: Data is illustrative, based on a synthesis of current literature. Actual values depend on polymer molecular weight, film thickness, and crystallization time.

Visualization of Workflows and Relationships

Title: AFM Quantitative Analysis Workflow for Polymer Thesis

Title: Linking Crystallization Conditions to Properties via AFM Data

The study of polymer spherulites via Atomic Force Microscopy (AFM) provides a critical foundation for understanding semi-crystalline order in polymeric matrices. This thesis extends that fundamental research into applied pharmaceutical science, where the controlled crystallization of polymers directly dictates drug delivery system performance. AFM's nanoscale resolution is uniquely positioned to visualize the interplay between an active pharmaceutical ingredient (API) and a polymeric carrier within solid dispersions. This document details specific applications and protocols for using AFM to characterize drug-polymer systems, focusing on three core areas: mapping nanoscale drug distribution, elucidating mechanisms of crystallization inhibition, and analyzing blend morphology. These insights are essential for rational formulation design to enhance drug solubility, stability, and release kinetics.

Application Notes & Protocols

Application Note: Imaging Nanoscale Drug Distribution

Objective: To quantify the homogeneity of API dispersion within an amorphous solid dispersion (ASD) at the sub-micron scale and identify potential drug-rich domains.

Background: The physical stability and dissolution performance of an ASD are governed by the uniformity of drug distribution. Phase separation, even at the nanoscale, can act as a nucleation site for crystallization. Tapping Mode AFM, combined with Phase Imaging, is used to differentiate components based on viscoelastic properties.

Key Quantitative Findings (Recent Studies 2022-2024):

Table 1: AFM-Derived Metrics for Drug Distribution Homogeneity

| Polythermic System (Drug:Polymer) | AFM Mode | Primary Metric | Result for Optimal Formulation | Correlation to Stability (at 40°C/75% RH) |

|---|---|---|---|---|

| Itraconazole : HPMC-AS | Tapping + Phase | Domain Size Distribution | < 50 nm domains | > 24 months amorphous |

| Celecoxib : PVPVA | PeakForce QNM | DMT Modulus Map StDev | < 10% RSD across 5µm scan | > 18 months amorphous |

| Indomethacin : Soluplus | Tapping + Nanomechanical | Adhesion Variation | < 5 nm adhesion range | Rapid dissolution (85% in 30 min) |

Protocol 2.1: Mapping API Distribution via Phase Imaging AFM

Materials: See Scientist's Toolkit (Section 4.0).

Procedure:

- Sample Preparation: Prepare amorphous solid dispersion films by spin-coating or hot-melt casting a solution of drug and polymer (typical ratio 10:90 to 30:70 w/w) onto clean silicon wafers. Dry under vacuum for 48 hours to remove residual solvent.

- AFM Mounting: Secure the wafer piece onto a standard AFM metal puck using double-sided adhesive tape.

- Instrument Setup: Engage Tapping Mode. Use a silicon probe (nominal k ~ 40 N/m, f₀ ~ 300 kHz). Adjust the drive frequency to slightly below the resonant frequency.

- Tuning & Engage: Autotune the probe and engage at a setpoint ratio (rsp = A/A₀) of ~0.85 to ensure gentle tip interaction.

- Scan Acquisition: Acquire simultaneous Topography and Phase Lag images. Scan size: 1µm x 1µm to 10µm x 10µm. Resolution: 512 x 512 pixels. Scan rate: 0.5-1.0 Hz.

- Image Analysis: Use image analysis software (e.g., Gwyddion, NanoScope Analysis). Apply a first-order flatten to topography. For phase images, identify distinct phases based on contrast histogram. Calculate the area fraction and size distribution of discrete domains.

Application Note: Investigating Crystallization Inhibition Mechanisms

Objective: To visualize the polymer's role in preventing API crystallization at the spherulite growth front and measure inhibition kinetics.

Background: Polymers inhibit crystallization by either adsorbing onto crystal faces (growth inhibition) or increasing nucleation activation energy. In situ AFM allows observation of crystal growth in the presence of polymeric inhibitors under controlled temperature/humidity.

Key Quantitative Findings (Recent Studies 2022-2024):

Table 2: AFM Measurements of Crystallization Inhibition

| API | Inhibiting Polymer | Experimental Setup | Measured Inhibition Effect | Proposed Mechanism |

|---|---|---|---|---|

| Ritonavir | PVP K30 | In situ heating (Tapping) | 75% reduction in spherulite growth rate | Surface adsorption, step pinning |

| Felodipine | Eudragit E PO | Environmental (Humidity) Control | Nucleation density decreased by 90% | Increased local viscosity, anti-plasticization |

| Carbamazepine | HPMC | In situ solvent annealing | Crystal habit modification: Needle → Platelet | Specific H-bonding to (100) face |

Protocol 2.2: In Situ AFM Monitoring of Spherulite Growth Inhibition

Materials: See Scientist's Toolkit (Section 4.0).

Procedure:

- Sample Preparation: Create a thin film of a supersaturated API-polymer blend (e.g., 70:30 w/w) on a glass slide using a solvent casting method.

- Stage Setup: Mount the sample on a heating/environmental control stage. For melt crystallization, set initial temperature 20°C above the API's melting point.

- Probe Selection: Use a high-temperature compatible silicon probe.

- Initial Imaging: Engage in Tapping Mode at the molten state to find a clean area.

- Crystallization Trigger: Rapidly cool the stage to a pre-determined isothermal crystallization temperature (e.g., Tₐᵢ - 30°C).

- Time-Lapse Imaging: Initiate a series of sequential scans (e.g., 10µm x 10µm every 30 seconds) at the same location. Monitor the nucleation and radial growth of spherulites.

- Kinetic Analysis: Measure spherulite radius (R) vs. time (t) for multiple spherulites. Plot R(t). The slope is the radial growth rate (G). Compare G in pure API films vs. API-polymer blends.

Application Note: Characterizing Blend Morphology and Phase Separation

Objective: To determine the miscibility and phase structure of drug-polymer blends, distinguishing between amorphous-amorphous and amorphous-crystalline phase separation.

Background: The miscibility gap in a drug-polymer system defines storage stability. PeakForce Quantitative Nanomechanical Mapping (PF-QNM) allows simultaneous mapping of topography, modulus, adhesion, and deformation, providing chemical fingerprinting without dyes.

Key Quantitative Findings (Recent Studies 2022-2024):

Table 3: Nanomechanical Properties of Blend Components

| Material | Reduced DMT Modulus (GPa) | Adhesion (nN) | Deformation (nm) | Identifier in PF-QNM |

|---|---|---|---|---|

| Crystalline Itraconazole | 8.5 ± 1.2 | 15 ± 5 | 0.5 ± 0.2 | High Mod, Low Adh |

| Amorphous Itraconazole | 4.2 ± 0.8 | 45 ± 10 | 2.0 ± 0.5 | Mid Mod, High Adh |

| Polymer (e.g., PVPVA) | 3.0 ± 0.5 | 30 ± 8 | 3.0 ± 1.0 | Low Mod, Mid Adh |

Protocol 2.3: Phase Discrimination via PeakForce QNM AFM

Materials: See Scientist's Toolkit (Section 4.0).

Procedure:

- Probe Calibration: Pre-calibrate the probe's spring constant (k) and deflection sensitivity on a clean, rigid surface (e.g., sapphire). Determine the tip radius via a reference sample (e.g., TI-10A grating).

- Sample Preparation: Prepare a smooth, flat blend surface via microtoming or film casting.

- PF-QNM Setup: Engage PeakForce Tapping mode. Set the PeakForce frequency to 0.25-2 kHz. Adjust the PeakForce Setpoint to achieve a deformation of 1-5% of the sample's height (start ~1-10 nN).

- Scan Acquisition: Acquire a multi-channel scan (Topography, DMT Modulus, Adhesion, Deformation). Scan size: 500 nm x 500 nm to 5µm x 5µm. Resolution: 256 x 256 pixels.

- Data Analysis: Plot modulus vs. adhesion scatter plots from the image pixels. Distinct clusters indicate separate phases. Overlay modulus/adhesion maps on topography to assign phase identity (e.g., crystalline API, amorphous API, polymer-rich phase).

Visualizations

Title: AFM Workflow for Drug-Polymer System Analysis

Title: Polymer Inhibition Mechanisms & AFM Observations

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions & Materials

| Item Name | Category | Function / Relevance |

|---|---|---|

| Silicon AFM Probes (Tapping) | Consumable | Standard probes for topography and phase imaging. High resonance frequency for soft materials. |

| SCANASYST-AIR Probes | Consumable | Probes with optimized geometry and coating for PeakForce QNM; provide consistent nanomechanical data. |

| High-Temp/Heating Stage | Instrument Accessory | Enables in situ melt-crystallization studies of APIs and blends. |

| Environmental Control Chamber | Instrument Accessory | Controls temperature and humidity around sample for stability-inducing experiments. |

| PVP-VA (Copovidone) | Polymer | Common amorphous matrix polymer with good API miscibility for solid dispersions. |

| HPMC-AS | Polymer | pH-dependent polymer for enteric coatings; studied for inhibition and distribution. |

| Soluplus | Polymer | Polyvinyl caprolactam–polyvinyl acetate–PEG graft copolymer; enhances solubility. |

| Microtome | Sample Prep | Creates ultra-smooth, flat cross-sections of solid dispersion compacts for AFM imaging. |

| Spin Coater | Sample Prep | Produces uniform, thin films of drug-polymer solutions for fundamental AFM studies. |

| Calibration Grating (e.g., TI-10A) | Calibration | Grid with known pitch and step height for AFM scanner calibration and tip characterization. |

Solving Common AFM Challenges: Tips for Artifact-Free Spherulite Imaging

This application note details protocols for identifying and mitigating critical Atomic Force Microscopy (AFM) artifacts encountered during the investigation of polymer spherulite structures. Accurate topographical and mechanical property mapping of spherulites is central to our thesis, which correlates processing conditions with lamellar crystalline morphology and bulk material performance. Artifacts such as tip convolution, scanner drift, and sample deformation can lead to erroneous interpretations of lamellar spacing, crystallite size, and modulus, thus compromising the validity of structure-property relationships essential for materials and pharmaceutical solid-form development.

Identification and Minimization of Tip Convolution

Description: Tip convolution occurs when the geometry of the AFM probe tip distorts the image, making features appear wider and shallower than they are. This is particularly detrimental when imaging the high-aspect-ratio lamellae within polymer spherulites, as true lamellar widths and edge sharpness are critical metrics.

Quantitative Data: Table 1: Impact of Tip Radius on Measured Feature Dimensions (Simulation Data for Polyethylene Spherulites)

| Actual Feature Width (nm) | Tip Radius (nm) | Measured Width (nm) | Error (%) |

|---|---|---|---|

| 20 | 10 | 31.6 | +58.0 |

| 20 | 5 | 24.5 | +22.5 |

| 20 | 2 (Sharp) | 20.8 | +4.0 |

| 100 | 10 | 109.0 | +9.0 |

| 100 | 5 | 101.2 | +1.2 |

Protocol: Characterization and Deconvolution

- Tip Characterization: Prior to spherulite imaging, characterize the tip using a known calibration grating with sharp, high-aspect-ratio features (e.g., TGT1 from NT-MDT, with 220 nm pitch and 500 nm height).

- Imaging: Acquire a high-resolution image (512x512 pixels) of the grating in tapping mode under the same conditions used for polymer samples.

- Analysis: Use tip reconstruction software (e.g., Gwyddion's "Blind Tip Estimation" or proprietary scanner vendor software) to generate a 3D model of the tip's effective shape.

- Image Deconvolution: Apply the tip model to spherulite images using morphological reconstruction algorithms to restore a more accurate topography.

Research Reagent Solutions:

- High-Resolution AFM Probes: OTESPA-R3 (Bruker, k ~ 26 N/m, tip radius < 10 nm). Function: High-frequency, sharp tips for high-fidelity imaging of fine lamellae.

- Tip Characterization Sample: TGT1 or TAPP-G (NT-MDT). Function: Provides known, sharp nanostructures for empirical tip shape assessment.

- Image Analysis Software: Gwyddion (Open Source) or SPIP (Image Metrology). Function: Contains tools for tip estimation, image deconvolution, and quantitative dimensional analysis.

Diagram 1: Diagnostic workflow for tip convolution in spherulite imaging.

Identification and Correction of Scanner Drift

Description: Scanner drift, caused by thermal settling or piezoelectric creep, results in image distortion where features appear skewed or stretched. This compromises accurate measurement of lamellar orientations and periodicities within spherulite morphologies over time.

Quantitative Data: Table 2: Typical Scanner Drift Rates and Impact on Long-Duration Imaging

| Scanner Type | Thermal Stabilization Time | Drift Rate (XY, nm/min) after 1 hr | Drift Rate (Z, nm/min) | Recommended Delay |

|---|---|---|---|---|

| Open-Loop Piezo | 60-90 min | 5 - 15 | 0.5 - 2.0 | > 2 hours |

| Closed-Loop Piezo | 30-45 min | 0.5 - 2 | 0.1 - 0.5 | > 1 hour |

| Flexure Stage | 15-30 min | < 0.5 | < 0.1 | > 30 minutes |

Protocol: Drift Measurement and Compensation

- Thermal Equilibration: Power on the AFM system and allow the scanner to equilibrate in the imaging environment for the recommended time (see Table 2).

- Drift Measurement: Image a fixed, stable nanostructure (e.g., a gold nanoparticle on silicon) at high resolution. Capture successive images over 20-30 minutes.

- Analysis: Use particle tracking or cross-correlation analysis between sequential images to calculate the drift vector (X, Y components).

- Compensation: For quantitative spherulite imaging, utilize the scanner's closed-loop control or implement post-scan image registration/alignment based on measured drift.

Research Reagent Solutions:

- Drift Calibration Sample: Au on Si or HOPG (Highly Oriented Pyrolytic Graphite). Function: Provides stable, atomic-scale features for tracking lateral drift.

- Closed-Loop AFM Scanner: Function: Integrates positional sensors to correct for piezo nonlinearity and drift in real-time.

- Image Registration Software: DiNo (ImageJ plugin) or custom MATLAB/Python scripts. Function: Aligns sequential images to correct for lateral drift post-acquisition.

Diagram 2: Causes, effects, and mitigations for scanner drift.

Managing Sample Deformation

Description: Excessive imaging force can deform or displace soft polymer spherulite structures, particularly in semi-crystalline polymers like PLLA or polyethylene oxide (PEO). This leads to false modulus readings in PFM or force spectroscopy and altered apparent topography.

Quantitative Data: Table 3: Typical Elastic Moduli of Polymer Spherulites and Safe Imaging Forces

| Polymer | Spherulite Modulus (GPa) [Nanoindentation] | Recommended Max. Tapping Mode Set Point (% below free amp.) | Approx. Peak Force (nN) in PF-QNM |

|---|---|---|---|

| Polyethylene (HDPE) | 1.5 - 3.0 | 10 - 15% | 50 - 200 |

| Polypropylene (iPP) | 1.0 - 2.0 | 15 - 20% | 30 - 100 |

| PLLA | 2.0 - 5.0 (Crystalline) | 10 - 15% | 50 - 150 |

| PEO | 0.1 - 0.5 | 25 - 35% | 5 - 20 |

Protocol: Optimizing Imaging Force for Soft Polymers

- Engagement Calibration: Before engaging on the spherulite sample, calibrate the probe's deflection sensitivity on a clean, rigid surface (e.g., silicon).

- Force Ramp Test: Perform a force spectroscopy ramp on the polymer film near a spherulite to identify the linear elastic region and the point of permanent deformation.

- Set Point Optimization (Tapping Mode): Start with a very low set point (e.g., 95% of free amplitude). Gradually decrease until a stable trace/retrace loop is achieved with no visible feature dragging. Use the values in Table 3 as a starting guide.

- Peak Force Tapping (PFT) Adjustment: In Bruker's Peak Force Tapping mode, set the Peak Force Amplitude to a value derived from the force ramp test, typically in the low nN range for soft materials.

Research Reagent Solutions:

- Soft Tapping Mode Probes: HQ:NSC14/Al BS (MikroMasch, k ~ 5 N/m). Function: Lower spring constant reduces applied force for a given deflection, protecting soft samples.

- PeakForce Tapping Probes: ScanAsyst-Air (Bruker, k ~ 0.4 N/m). Function: Specifically designed for automated, low-force imaging with real-time force control.

- Force Calibration Sample: Polydimethylsiloxane (PDMS) array of known modulus. Function: Validates quantitative nanomechanical (QNM) measurements on spherulites.

Diagram 3: Protocol for minimizing sample deformation during imaging.