Advanced Multi-Objective Optimization in Pharmaceutical Extrusion: Balancing Critical Quality Attributes for Enhanced Drug Product Development

This article provides a comprehensive guide to multi-objective optimization (MOO) for pharmaceutical hot-melt and melt extrusion processes.

Advanced Multi-Objective Optimization in Pharmaceutical Extrusion: Balancing Critical Quality Attributes for Enhanced Drug Product Development

Abstract

This article provides a comprehensive guide to multi-objective optimization (MOO) for pharmaceutical hot-melt and melt extrusion processes. Tailored for researchers and drug development professionals, it explores the foundational principles, key process parameters (KPPs) and critical quality attributes (CQAs). It details modern methodological frameworks like Design of Experiments (DoE), mechanistic modeling, and Machine Learning (ML)-assisted optimization for simultaneous enhancement of bioavailability, stability, and manufacturability. The content addresses practical troubleshooting and advanced optimization strategies to resolve common trade-offs, followed by validation techniques and comparative analysis of traditional vs. next-generation continuous manufacturing approaches. The synthesis offers actionable insights for robust, lean, and QbD-compliant extrusion process development.

Core Principles of Extrusion: Defining Parameters, Attributes, and Conflicting Objectives in Pharma

Technical Support Center: Troubleshooting Guides & FAQs

FAQ 1: How do I resolve inconsistent API assay in the final HME product? Answer: Inconsistent assay typically indicates poor mixing or degradation. First, verify your feeder calibration and screw speed synchronization. Ensure the API is pre-blended with a carrier (e.g., HPMCAS) using a V-blender for 15 minutes. Check barrel temperature; if it's too close to the API's degradation point, reduce by 10-20°C. Perform a TGA analysis on the raw API to confirm thermal stability.

FAQ 2: What causes excessive torque or motor overload during extrusion? Answer: Excessive torque is often due to high viscosity of the melt. Immediate actions: 1) Increase barrel temperature in the melting zone gradually (5°C increments). 2) Reduce feed rate by 10-15%. 3) Verify the plasticizer content (e.g., Triethyl Citrate). If the formulation is high in polymer (>70%), consider adding 2-5% w/w plasticizer.

FAQ 3: Why is my extrudate surface rough or exhibiting shark-skinning? Answer: This is a melt fracture phenomenon. It is caused by high shear stress at the die. Solutions include: increasing die temperature by 10-15°C, reducing screw speed, or reformulating with a processing aid (e.g., 0.5-1% w/w glyceryl monostearate). Ensure a smooth, polished die interior.

FAQ 4: How can I improve the dissolution rate of a poorly soluble API via HME? Answer: To enhance dissolution, aim to create an amorphous solid dispersion. Key parameters: Select a suitable polymeric carrier (Soluplus, Kollidon VA64). Maintain a processing temperature above the polymer's Tg but below the API's degradation point. The typical drug load for optimal dissolution is 10-25% w/w. Quench-cool the extrudate on a chilled roller.

Experimental Protocol: Screening of Polymer Carriers for Amorphous Solid Dispersion Objective: To identify the optimal polymer for stabilizing an amorphous API. Method:

- Pre-blending: Physically mix the API with different polymers (e.g., PVP-VA, HPMCAS, Eudragit E PO) at a 20:80 (API:Polymer) ratio in a turbula mixer for 10 min.

- Extrusion: Process each blend using a co-rotating twin-screw extruder (e.g., Leistritz Nano-16). Use a temperature profile from 100°C to 150°C (based on polymer) and a screw speed of 100 rpm.

- Analysis: Mill extrudates and analyze by modulated DSC to confirm amorphous state. Store samples at 40°C/75%RH for 4 weeks and analyze for recrystallization via PXRD.

- Dissolution: Perform USP II dissolution in pH 1.2 and 6.8 buffers.

Quantitative Data Summary: Common HME Polymer Properties

| Polymer (Trade Name) | Typical Tg (°C) | Recommended Processing Temp (°C) | Typical Drug Load Capacity | Key Function |

|---|---|---|---|---|

| Soluplus | ~70 | 120-160 | Up to 25% w/w | Matrix former, enhances solubility |

| Kollidon VA 64 | ~101 | 140-180 | 10-30% w/w | Amorphous stabilizer |

| HPMCAS (LG) | ~120 | 150-190 | 15-40% w/w | pH-dependent release, stabilization |

| Eudragit E PO | ~48 | 110-150 | 10-50% w/w | Taste masking, rapid release |

Quantitative Data Summary: Effect of Process Parameters on Critical Quality Attributes (CQA)

| Process Parameter | Torque (Nm) | Melt Temp (°C) | Dissolution (Q30%) | % Crystallinity |

|---|---|---|---|---|

| Screw Speed (rpm) | ||||

| 100 | 65-70 | 145 | 95 | <1% |

| 150 | 75-80 | 152 | 92 | <1% |

| 200 | 85-95 | 160 | 88 | 3% |

| Barrel Temp (°C) | ||||

| 140 | 80-85 | 142 | 85 | 5% |

| 150 | 70-75 | 150 | 94 | <1% |

| 160 | 65-68 | 158 | 96 | <1% |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item & Supplier | Function in HME Research |

|---|---|

| Kollidon VA 64 (BASF) | Vinylpyrrolidone-vinyl acetate copolymer. Acts as a matrix carrier for amorphous solid dispersions, improves bioavailability. |

| Soluplus (BASF) | Polyvinyl caprolactam-polyvinyl acetate-PEG graft copolymer. Used as a solubilizing agent for melt extrusion. |

| Triethyl Citrate (Sigma-Aldrich) | A common plasticizer to reduce polymer Tg and processing temperature, decreasing shear and degradation risk. |

| HPMCAS - Affinisol (Dow) | Hydroxypropyl methylcellulose acetate succinate. Used for pH-dependent release and stable amorphous dispersions. |

| Meltrex Technology (Abbvie) | A proprietary HME platform for creating solid solutions, often referenced for its industrial application. |

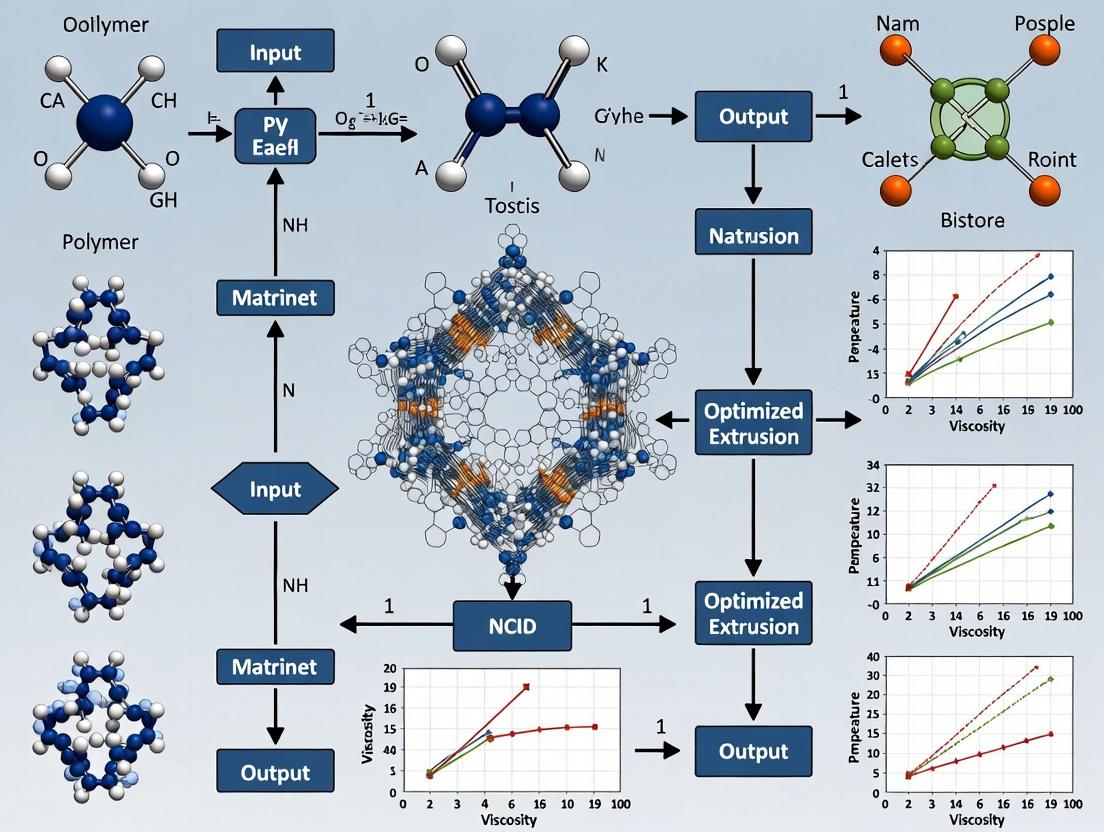

Title: HME Process Workflow for Solid Dispersions

Title: Process Parameters Impact on Product CQAs

Technical Support Center

Troubleshooting Guides & FAQs

Q1: During hot-melt extrusion (HME), my formulation exhibits inconsistent drug content uniformity across the extrudate strand. Which CPPs should I investigate first and how?

A: This is often a result of poor distributive mixing. Primary CPPs to investigate are Screw Design and Temperature.

- Screw Design: Insufficient mixing sections (e.g., kneading blocks, mixing elements) lead to inadequate homogenization.

- Protocol: Conduct a design of experiments (DoE) keeping temperature and screw speed constant. Compare a screw with only conveying elements against one with 2-3 kneading blocks (forward, neutral, reverse). Sample the extrudate at the start, middle, and end of a run. Measure drug content via HPLC.

- Temperature: Too low a barrel temperature can prevent proper polymer melt and reduce mixing efficiency.

- Protocol: At a fixed screw speed and feed rate, run extrusion at temperatures below, at, and above the polymer's melt temperature (Tm). Measure torque, specific mechanical energy (SME), and analyze strand homogeneity via near-infrared (NIR) spectroscopy.

Q2: I am observing excessive degradation of my thermolabile API. The melt temperature is within the API's stability range. What could be the cause?

A: Degradation can be driven by thermal history and shear stress, not just setpoint temperature. Key CPPs are Screw Speed and Temperature Profile.

- Screw Speed: Higher screw speeds increase shear rate and SME, generating frictional heat, raising the actual melt temperature beyond setpoints.

- Protocol: Perform a stability study. Extrude at low (e.g., 100 rpm), medium (200 rpm), and high (300 rpm) speeds while monitoring melt pressure and torque. Use a melt thermocouple to measure actual melt temperature. Analyze API degradation products via HPLC-MS. Correlate degradation % with calculated SME.

- Temperature Profile: An improperly ramped profile can cause localized overheating.

- Protocol: Implement a gradual "ramp-up" profile from feed zone to die zone instead of a uniform high temperature. Compare degradation levels using the two profiles at identical screw speeds.

Q3: My process is suffering from unstable feed, leading to surging and variable strand diameter. How can I troubleshoot this?

A: This is directly related to Feed Rate and its interaction with Screw Speed.

- Feed Rate to Screw Speed Ratio (Feed Load): An imbalance causes the screw to be either starved or overfed.

- Protocol: Establish a stable feed factor. Start with a low feed rate and gradually increase screw speed until the extruder torque stabilizes. Record this ratio. Systematically vary the Feed Rate (±10%, ±20%) at this fixed ratio and monitor pressure stability and strand diameter (using laser micrometer). Aim for a feed load (Q/N) that gives stable pressure.

Q4: For my amorphous solid dispersion, I need to maximize dissolution rate while ensuring physical stability. How can CPPs be used to balance these objectives?

A: This is a core multi-objective optimization challenge. Temperature and Screw Design critically influence both molecular dispersion (dissolution) and the generation of excess free energy (instability).

- Protocol: Set up a DoE with two factors: Temperature (levels: Tm of polymer, Tm+20°C) and Screw Design Intensity (levels: mild mixing, aggressive mixing). Responses: 1) Dissolution Rate (Q15min), 2) Glass Transition Temperature (Tg), and 3) Enthalpy Relaxation (aging indicator after storage). Use a response surface model to find the CPP set that gives >85% dissolution while minimizing Tg depression and enthalpy relaxation.

Table 1: Impact Range of Individual CPPs on Critical Quality Attributes (CQAs)

| Critical Process Parameter (CPP) | Primary Impact on CQAs | Typical Range (Pharma HME) | Key Risk if Too Low | Key Risk if Too High |

|---|---|---|---|---|

| Barrel Temperature | Melt viscosity, Degradation, API solubility | 70°C - 200°C | Poor mixing, High torque, Unmelted material | API/Polymer degradation, Volatilization |

| Screw Speed (RPM) | Residence time, Shear rate, SME | 100 - 500 rpm | Long residence time, Low throughput | High shear heat, Degradation, Poor feed |

| Feed Rate | Throughput, Feed load, Pressure | 0.1 - 5.0 kg/hr | Starved flow, Surging | Overloading, Torque overload |

| Screw Design | Mixing efficiency, Shear intensity, Conveying | N/A (Configurable) | Poor dispersion | Excessive shear, Degradation, Hot spots |

Table 2: Example DoE Matrix for CPP Interaction Study

| Experiment Run | Temp. (°C) | Screw Speed (rpm) | Feed Rate (kg/hr) | Screw Design | Resulting SME (kWh/kg) | Degradation (%) | Dissolution % (Q30) |

|---|---|---|---|---|---|---|---|

| 1 | 150 | 200 | 0.5 | Mild Mixing | 0.12 | 0.3 | 78 |

| 2 | 170 | 200 | 0.5 | Aggressive Mixing | 0.18 | 1.1 | 95 |

| 3 | 150 | 300 | 0.5 | Aggressive Mixing | 0.25 | 2.5 | 97 |

| 4 | 170 | 300 | 0.5 | Mild Mixing | 0.15 | 0.8 | 82 |

| 5 | 160 | 250 | 0.75 | Standard | 0.16 | 0.9 | 88 |

Experimental Protocols

Protocol 1: Determining Optimal Feed Load for Stability Objective: To find the feed rate to screw speed ratio (Q/N) that minimizes pressure surging. Materials: Twin-screw extruder, feeder, polymer/API blend, pressure transducer, data logger. Method:

- Set a constant, moderate barrel temperature profile.

- Fix screw speed (N) at 200 rpm.

- Start feeder at a low rate (Q=0.2 kg/hr). Record mean pressure (P) and standard deviation over 5 mins.

- Incrementally increase Q in steps of 0.1 kg/hr, recording P and its variability at each step.

- Calculate Feed Load (Q/N) for each step.

- Analysis: Plot pressure variability (CV%) vs. Feed Load. The optimal zone is at the minimum plateau of the curve.

Protocol 2: Assessing Screw Design Impact on Mixing via Specific Mechanical Energy (SME) Objective: To correlate screw design intensity with mixing efficiency using SME as a process signature. Materials: Extruder with torque readout, two screw configurations (conveying vs. mixing), blend. Method:

- Run extrusion with Screw Config A (highly conveying) at fixed T, N, and Q.

- Record steady-state torque (τ in Nm) and screw speed (N in rpm).

- Calculate SME: SME (kWh/kg) = (τ * N * 2π) / (Mass flow rate in kg/h * 60000).

- Repeat with Screw Config B (with kneading blocks).

- Analyze extrudate samples for content uniformity.

- Analysis: Higher SME from Config B indicates greater energy input for mixing. Correlate SME value with RSD of drug content.

Visualizations

Diagram 1: CPP Influence on HME Product CQAs

Diagram 2: Multi-objective Optimization Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for Extrusion Process Optimization Research

| Material / Solution | Function / Relevance in CPP Studies | Example Vendor/Product |

|---|---|---|

| Model Polymer (e.g., Copovidone, HPMCAS) | Acts as the carrier matrix. Different grades allow study of melt viscosity and drug-polymer interaction. | BASF Kollidon VA64, Ashland AquaSolve |

| Thermolabile Model API (e.g., Ibuprofen, Itraconazole) | Used as a marker to study degradation kinetics under varying CPPs (Temp, Shear). | Sigma-Aldrich |

| Tracer (e.g., Methylene Blue, TiO2) | Inert particulate used in distributive mixing studies to visualize and quantify mixing efficiency of screw designs. | Sigma-Aldrich |

| Stabilizer / Antioxidant (e.g., BHT, Vitamin E TPGS) | Used to decouple oxidative degradation from thermal/shear degradation in CPP studies. | Sigma-Aldrich, Eastman |

| Melt Flow Index (MFI) Tester | Characterizes polymer viscosity, a key input for predicting behavior under CPPs. | Tinius Olsen |

| In-line NIR Probe | Provides real-time data on drug concentration and moisture, essential for CPP dynamic control studies. | Metrohm, Thermo Fisher |

| Specific Mechanical Energy (SME) Calculator | Software/tool to compute SME from torque and throughput, a key integrative parameter linking CPPs. | Custom Excel tool or PAT software |

Context: This support center provides troubleshooting guidance for researchers conducting experiments within a multi-objective optimization of hot melt extrusion (HME) or other extrusion processes for amorphous solid dispersion (ASD) formulation. The goal is to efficiently identify and mitigate issues related to key CQAs.

FAQs & Troubleshooting Guides

Solubility/Dissolution Section

Q1: During dissolution testing of my extruded ASD, I observe a "spring and parachute" effect where initial supersaturation is high but plummets rapidly. What is the cause and how can I optimize the formulation? A: This indicates recrystallization of the active pharmaceutical ingredient (API) from the supersaturated state. The "parachute" (stabilization) is failing.

- Primary Causes: Inadequate polymer selection/concentration, insufficient drug-polymer interactions, or suboptimal extrusion processing leading to poor miscibility.

- Troubleshooting Protocol:

- Characterize: Use powder X-ray diffraction (PXRD) on filtered dissolution samples to confirm recrystallization.

- Reformulate: Increase the concentration of a crystallization-inhibiting polymer (e.g., HPMC-AS, PVP-VA).

- Optimize Process: Increase extrusion barrel temperature (within stability limits) and/or screw speed to enhance molecular dispersion. Ensure adequate mixing via screw design (e.g., incorporating kneading elements).

- Key Experiment: Solubility/Dissolution Enhancement Screening

- Protocol: Prepare small-scale binary mixtures (API + polymer) via solvent casting or miniaturized melt mixing. Subject to non-sink dissolution testing (e.g., µDISS Profiler). Monitor concentration vs. time for 4-6 hours.

- Data to Collect: Maximum supersaturation (Cmax), area under the dissolution curve (AUC), time to precipitate (Tprecip).

Q2: My extrudate shows poor dissolution performance despite a seemingly amorphous PXRD trace. What could be wrong? A: The API may be present as nano/micro-crystalline domains not detected by PXRD, or phase separation may occur upon contact with dissolution media.

- Troubleshooting Steps:

- Use modulated differential scanning calorimetry (mDSC) to detect subtle enthalpic relaxation events indicative of phase separation.

- Perform solid-state nuclear magnetic resonance (ssNMR) to probe molecular-level mixing and intimacy of drug-polymer interactions.

- Analyze dissolution media filtrate via dynamic light scattering (DLS) for nano-precipitates.

Stability Section

Q3: My optimized extrudate, initially amorphous, recrystallizes after 1 month under 25°C/60%RH accelerated stability conditions. How do I diagnose and fix this? A: This is a critical failure of physical stability, often due to moisture absorption or inadequate Tg.

- Diagnostic Workflow:

- Test: Perform gravimetric vapor sorption analysis on the API, polymer, and extrudate. Correlate moisture uptake with PXRD/mDSC data from stability samples.

- Analyze: Determine the glass transition temperature (Tg) of the extrudate via DSC. The rule of thumb is Tg > storage temperature + 50°C for reasonable stability.

- Mitigation Protocol:

- Formulation: Incorporate a hydrophobic polymer (e.g., Eudragit RL/RS) or antiplasticizer. Use polymers with high Tg (e.g., PVP-VA has Tg ~110°C).

- Process: Optimize extrusion quench cooling rate to minimize free volume. Consider annealing steps if proven to increase stability.

- Packaging: Implement high-barrier, desiccant-containing packaging immediately post-extrusion and milling.

Content Uniformity Section

Q4: I am observing high variability in API assay results across different segments of my extruded strand. What are the main process-related culprits? A: This indicates poor mixing or inconsistent feed during extrusion.

- Troubleshooting Guide:

- Symptom: Cyclic variation. → Cause: Poor feeder calibration or pulsation. Solution: Re-calibrate feeders, use hoppers with agitation, switch to a more consistent feeder type (e.g., loss-in-weight).

- Symptom: Random variation. → Cause: Segregation of pre-mix due to particle size/density differences. Solution: Pre-process via granulation or use twin-screw extrusion with downstream feed ports for precise API introduction.

- Symptom: Steady drift. → Cause: Gradual degradation or thermal history gradient. Solution: Verify thermal stability, ensure consistent barrel temperature control.

- Experimental Protocol for Uniformity Testing:

- Collect sequential samples (~1cm segments) along the entire extrudate strand after process equilibrium.

- Weight and dissolve each segment in suitable solvent.

- Analyze via HPLC-UV. Calculate % label claim and RSD (%).

Solid-State Section

Q5: How can I definitively prove the formation of a single-phase amorphous solid solution versus a nano-crystalline dispersion or phase-separated system? A: A combination of orthogonal techniques is required.

- Diagnostic Experimental Cascade:

Title: Solid-State Diagnosis Cascade for Extrudates

Table 1: Common Polymer Carriers for HME & Key Properties

| Polymer (Example) | Tg (°C) ~ | Hygroscopicity | Key Function in CQA Optimization |

|---|---|---|---|

| PVP-VA (Kollidon VA 64) | 105 | Moderate | Dissolution enhancer, stability via high Tg |

| HPMC-AS (AQOAT) | 120 | Low-Moderate | Superior precipitation inhibition in GI pH |

| Soluplus (BASF) | 70 | Low | Good wetting, often used as ternary component |

| Eudragit E PO | 45 | Low | Gastric solubility, aids processability |

| PEG 6000 | -60 | High | Plasticizer, can reduce stability |

Table 2: Impact of Extrusion Parameters on CQAs

| Process Parameter | Primary CQA Impact | Typical Optimization Goal | Risk if Improper |

|---|---|---|---|

| Barrel Temperature | Stability, Solid-State | Achieve full melting/mixing without degradation | Degradation or incomplete amorphization |

| Screw Speed (RPM) | Content Uniformity, Solid-State | Sufficient residence time & shear for mixing | Poor uniformity or excessive shear heat |

| Feed Rate | Content Uniformity | Match screw speed for optimal fill level | Strand porosity or inconsistent output |

| Screw Configuration | All CQAs | Balance distributive vs. dispersive mixing | Poor dissolution or stability due to heterogeneity |

| Quench Cooling Rate | Solid-State, Stability | Rapidly freeze in amorphous state | Re-crystallization during cooling |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in CQA Identification/Optimization |

|---|---|

| Polymer Library (e.g., PVP, HPMC, PVP-VA, HPMC-AS, Soluplus) | Screening for optimal drug-polymer miscibility, dissolution enhancement, and stability. |

| Plasticizers/Antiplasticizers (e.g., Triacetin, Citrates, TEC) | Modifies Tg, improves processability, and can impact physical stability. |

| Thermal Stabilizers (e.g., BHT, Ascorbyl Palmitate) | Mitigates API/polymer degradation during high-temperature extrusion. |

| Nucleation Inhibitors (e.g., TPGS, Poloxamer 407) | Added as ternary components to inhibit recrystallization in dissolution media. |

| Flow Aids (e.g., Colloidal Silica) | Added post-extrusion to improve handling of milled powder for downstream content uniformity. |

| pH Modifiers (e.g., Organic Acids/Bases) | Incorporated to alter microenvironmental pH for dissolution tailoring. |

| Model APIs (e.g., Itraconazole, Griseofulvin, Indomethacin) | Poorly soluble compounds with well-characterized behavior for method development. |

Troubleshooting Guides & FAQs

Troubleshooting Guide: API Degradation During Hot-Melt Extrusion (HME)

Problem: Active Pharmaceutical Ingredient (API) degradation observed in extrudate, leading to reduced potency and stability.

Potential Causes & Solutions:

- Cause 1: Melt temperature exceeds API degradation temperature.

- Action: Perform thorough Thermal Analysis (DSC, TGA) to establish degradation onset. Optimize barrel temperature profile. Consider plasticizers to lower processing temperature.

- Cause 2: Excessive shear stress causing mechanical degradation.

- Action: Reduce screw speed (RPM). Modify screw configuration to less aggressive mixing elements. Increase powder feed rate to lower specific mechanical energy (SME).

- Cause 3: Residual moisture or excipient incompatibility.

- Action: Pre-dry API and polymer. Screen for alternative, more stable polymeric carriers (e.g., from PVP-VA to Soluplus).

Troubleshooting Guide: Poor Extrudate Characteristics

Problem: Extrudate exhibits die swelling, shark-skinning, or is too brittle for downstream milling.

Potential Causes & Solutions:

- Cause 1: Inadequate melt strength or viscoelastic properties.

- Action: Adjust polymer/plasticizer ratio. Incorporate a processing aid (e.g., stearic acid). Optimize die temperature and draw-down speed.

- Cause 2: Insufficient mixing leading to heterogeneous solid dispersion.

- Action: Increase residence time using reverse-conveying or kneading elements. Validate homogeneity using DSC and XRPD.

Frequently Asked Questions (FAQs)

Q1: How do I initially screen polymers for a new API in a multi-objective context? A: Employ a quality-by-design (QbD) approach. Start with miscibility prediction via Hansen Solubility Parameters. Use small-scale film casting or twin-screw melt mixing to create prototypes. Test these for crystallinity (XRPD), dissolution, and accelerated stability. This data informs the first Design of Experiment (DoE) for extrusion.

Q2: What is the most critical parameter to monitor during HME for optimizing bioavailability and stability? A: There is no single parameter. You must monitor the interplay between Melt Temperature (T) and Specific Mechanical Energy (SME). T directly impacts chemical stability, while SME impacts the degree of mixing, dispersion quality, and potential for amorphous stabilization. A process window must be defined where both are within acceptable ranges.

Q3: How can I improve the processability of a high-melting-point API without compromising stability? A: The key is to lower the processing temperature required to form a molecular dispersion. Strategies include:

- Using polymeric carriers with lower glass transition temperatures (Tg).

- Incorporating safe and effective plasticizers (e.g., triethyl citrate, PEG).

- Exploring co-crystal or salt forms of the API that have lower melting points but equivalent bioactivity.

Q4: My formulation shows excellent in vitro dissolution but poor in vivo bioavailability. What could be the issue? A: This often points to a stability-processability trade-off. The polymer/carrier system chosen for good extrusion may not maintain supersaturation in the gastrointestinal tract (poor spring and parachute effect), or the API may precipitate rapidly. Re-formulate with precipitation inhibitors (e.g., HPMC-AS) and assess using advanced in vitro models (e.g., biphasic dissolution).

Experimental Data & Protocols

Table 1: Quantitative Trade-off Analysis for Model API "X"

Data from a representative DoE studying a BCS Class II API processed via HME.

| Formulation (API:Polymer:Plasticizer) | Processing Temp (°C) | SME (kWh/kg) | % Amorphous Content | 24h Dissolution (%) | % API Degradation | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 20:80:0 (PVP-VA) | 160 | 0.32 | 100 | 95 | 0.8 | 12.5 |

| 30:70:0 (PVP-VA) | 165 | 0.38 | 100 | 99 | 2.1 | 8.7 |

| 30:65:5 (PVP-VA:TEC) | 150 | 0.35 | 100 | 98 | 0.5 | 5.2 |

| 20:80:0 (Soluplus) | 140 | 0.28 | 100 | 88 | 0.2 | 15.1 |

Detailed Protocol: Preparation and Characterization of Solid Dispersions via Hot-Melt Extrusion

Objective: To produce an amorphous solid dispersion of a BCS Class II API and characterize the key multi-objective parameters: physical stability, dissolution (bioavailability proxy), and extrudate mechanical properties.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- Pre-blending: Precisely weigh API and polymer carrier. Mix in a turbula mixer for 15 minutes to ensure homogeneous powder blend.

- Hot-Melt Extrusion:

- Use a co-rotating twin-screw extruder.

- Set temperature profile along barrels from feed zone to die. The maximum temperature must be above the polymer's Tg but below the API's degradation temperature (from TGA).

- Set screw speed (e.g., 100-300 RPM) and feed rate to achieve a target SME.

- Collect the extrudate as it exits the die, cool on a conveyor belt, and pelletize.

- Characterization:

- Processability: Record torque, pressure, and SME from the extruder software. Visually assess extrudate strand continuity.

- Solid State: Analyze pellets by XRPD and DSC to confirm amorphization/crystallinity.

- Chemical Stability: Use HPLC to assay for API content and degradation products.

- Dissolution Performance: Perform a USP Type II dissolution test in biorelevant media (e.g., FaSSIF).

- Mechanical Properties: Mill pellets and compress into tablets. Use a texture analyzer to determine tensile strength.

Visualizations

Title: Multi-Objective Optimization Workflow for HME Formulation

Title: Core Trade-offs in Pharmaceutical Development

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in MOO of HME | Example(s) |

|---|---|---|

| Polymeric Carriers | Form the amorphous matrix, inhibit recrystallization, govern release. Critical for stability & bioavailability. | Soluplus: Enhances solubility. PVP-VA: Good processability. HPMC-AS: Gastric resistance & supersaturation. |

| Plasticizers | Lower processing temperature (aiding stability) and modify extrudate mechanical properties. | Triethyl Citrate (TEC): Common, biocompatible. PEG 6000: Also acts as a carrier. |

| Melt Flow Indexer | Quantifies polymer melt viscosity, a key predictor of processability under shear and temperature. | - |

| Dissolution Media (Biorelevant) | Simulate GI conditions to provide a more predictive measure of in vivo bioavailability. | FaSSIF/FeSSIF: For simulating fasted/fed state intestinal fluid. |

| Process Analytical Technology (PAT) | Enables real-time monitoring and control of Critical Quality Attributes (CQAs). | In-line NIR: Monitors API concentration and solid state. Die Pressure Sensor: Indicates melt viscosity. |

Troubleshooting Guides & FAQs

Q1: How can I troubleshoot poor amorphicity in the final extrudate despite reaching the target extrusion temperature?

A: Poor amorphicity often indicates insufficient mixing or residence time for complete API-polymer dissolution.

- Check: Verify the thermal stability of your API (see TGA/DSC data). If stable, you may need to increase the screw speed or adjust the screw configuration to enhance distributive mixing.

- Protocol: Conduct a Time-Temperature Superposition (TTS) Screening.

- Prepare a standard API-polymer physical mix.

- Perform hot melt extrusion (HME) at a fixed temperature (e.g., Tg of polymer + 50°C) but vary screw speeds (50, 100, 150 RPM).

- Collect samples at each setting.

- Analyze using modulated DSC (mDSC) to measure the enthalpy relaxation peak. Lower enthalpy indicates higher amorphicity.

- Use PXRD as a confirmatory technique for crystalline peaks.

Q2: What are the common causes of API degradation during HME, and how can I mitigate it?

A: Primary causes are excessive shear heat and oxidative degradation.

- Check: Review your thermogravimetric analysis (TGA) onset temperature. Ensure maximum processing temperature is ≥30°C below this point.

- Protocol: Implement a Shear Stress & Atmosphere Control Experiment.

- Run two identical formulations: one under nitrogen purge and one under ambient atmosphere.

- Use two screw designs: a low-shear conveying screw and a high-shear kneading block screw.

- Process at the same barrel temperature profile.

- Analyze samples by HPLC for assay and related substances.

- Data Summary:

| Degradation Factor | Condition | % Assay | Main Degradant (%) |

|---|---|---|---|

| High Shear | Air | 95.2 | 1.8 |

| High Shear | N₂ | 99.1 | 0.3 |

| Low Shear | Air | 98.5 | 0.5 |

| Low Shear | N₂ | 99.6 | 0.1 |

Q3: My process experiences feed bridging or inconsistent torque, leading to poor flow. How can I resolve this?

A: This is typically a feedstock or initial conveying zone issue.

- Check: The particle size and flowability (Carr Index) of your physical mixture. Ensure the feed hopper is jacketed and temperature-controlled to prevent premature softening.

- Protocol: * *Feed Stock Pre-conditioning and Rheology Assessment.

- Mill the API and polymer to a consistent particle size range (e.g., 50-150 µm).

- Blend with 0.5% colloidal silica to improve flow.

- Pre-dry the blend to moisture content <0.5% w/w.

- Use a rheometer with a powder cell to measure the blend's flow stress. Correlate this with observed feeding performance.

Research Reagent Solutions Toolkit

| Item | Function in HME Optimization |

|---|---|

| Polyvinylpyrrolidone-vinyl acetate (PVP-VA) | Common amorphous polymer carrier. Enhances solubility and processability. |

| Hydroxypropyl methylcellulose (HPMC-AS) | pH-dependent polymer. Provides targeted release and inhibits recrystallization. |

| Plasdone S-630 | Copovidone with low Tg. Facilitates processing at lower temperatures to minimize degradation. |

| Polyethylene glycol (PEG) 6000 | Plasticizer. Lowers processing temperature and torque, improving flow. |

| Colloidal Silicon Dioxide | Glidant. Improves powder flow of pre-extrusion blends, ensuring consistent feeding. |

| Butylated hydroxytoluene (BHT) | Antioxidant. Minimizes oxidative degradation of API/polymer during processing. |

Experimental Workflow for Multi-Objective Optimization

Decision Pathway for API Degradation Mitigation

Technical Support Center: Troubleshooting Guides & FAQs for Multi-objective Extrusion Process Research

This support center addresses common issues encountered when building models for the multi-objective optimization (MOO) of extrusion processes in pharmaceutical development.

FAQ 1: My empirical correlation model (e.g., relating screw speed to tablet hardness) performs well in calibration but fails when I change API particle size. Why does this happen and how can I fix it?

- Answer: Empirical models (e.g., Response Surface Methodology - RSM) are interpolative and valid only within the constrained design space used for the experiments. Changing a fundamental material property like API particle size moves you outside that space.

- Solution: Transition towards a hybrid or first-principles approach.

- Diagnostic Check: Perform a Partial Least Squares (PLS) regression on your historical data. Loadings will show which latent variables (e.g., related to material properties) are not being captured by your current model inputs.

- Protocol for Enhancement: Run a new, small-scale Design of Experiments (DoE) incorporating the new particle size as a factor. Use the results to either expand your RSM model or to calibrate a simplified first-principles parameter.

FAQ 2: When implementing a Population Balance Model (PBM) for powder mixing in the feeder, the computational cost is too high for iterative optimization. How can I reduce this?

- Answer: Full-fidelity PBMs are computationally expensive. The goal is to create a reduced-order model (ROM) that retains accuracy but is fast to evaluate.

- Solution: Employ a Model Order Reduction (MOR) technique.

- Experimental Protocol for Data Generation:

- Step 1: Define a representative range of operating conditions (feed rate, screw speed) and material properties (cohesion, particle size distribution).

- Step 2: Run the high-fidelity PBM for a limited set of points covering this range (a space-filling DoE).

- Step 3: Capture key outputs: mixing index variance, residence time distribution.

- Reduction Protocol: Use the generated data to train a Gaussian Process (GP) surrogate model. This surrogate acts as your fast, approximate PBM within the optimization loop.

- Experimental Protocol for Data Generation:

FAQ 3: My first-principles model (e.g., 1D flow/heat equations) predicts barrel temperature inaccurately, leading to poor drug degradation predictions. What's wrong?

- Answer: The discrepancy often stems from inaccurate boundary conditions or missing physics (e.g., viscous dissipation, wall slip).

- Solution: A model calibration and validation workflow.

- Troubleshooting Protocol:

- Step 1: Instrument your extruder with additional, calibrated thermocouples at multiple axial positions.

- Step 2: Run a simple placebo formulation at a standard condition.

- Step 3: Compare the spatial temperature profile against your model's prediction.

- Calibration: If the shape is wrong, your heat transfer coefficients are incorrect. If the temperature rise is under-predicted, you may need to include a viscous dissipation term in your energy equation. Calibrate these parameters using the experimental data.

- Troubleshooting Protocol:

FAQ 4: How do I effectively integrate disparate models (empirical, PBM, thermal) for a unified multi-objective optimization?

- Answer: The key is a structured, sequential coupling framework, not a monolithic model.

- Solution: Implement a modular workflow where outputs of one model become inputs to the next.

- Integration Protocol:

- The PBM (or its surrogate) predicts mixture homogeneity.

- This homogeneity index is fed as a parameter into the first-principles thermal/flow model, affecting viscosity.

- The thermal model predicts temperature and shear history.

- These outputs feed into empirical correlations for final Critical Quality Attributes (CQAs) like dissolution rate and stability.

- Optimization: This chain of models becomes your objective function evaluator within an MOO algorithm like NSGA-II.

- Integration Protocol:

Summarized Quantitative Data: Model Comparison for Extrusion MOO

Table 1: Comparison of Foundational Modeling Approaches for Pharmaceutical Extrusion

| Modeling Approach | Typical Computational Cost (per run) | Data Requirements | Extrapolation Capability | Primary Use in MOO |

|---|---|---|---|---|

| Empirical (RSM) | Seconds | High (DoE experiments) | Poor | Fast screening of design space; final CQA prediction. |

| Hybrid (PBM Surrogate) | Minutes | Medium (DoE + simulations) | Moderate | Capturing particle-scale phenomena within optimization loop. |

| First-Principles (CFD/1D) | Hours to Days | Low (material properties) | Good | Understanding root causes; generating data for surrogates. |

| Integrated Workflow | Minutes-Hours | High (all of the above) | Best | Final, high-fidelity MOO for process and product design. |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Extrusion Process Modeling & Validation

| Item / Reagent | Function in Research Context |

|---|---|

| PLGA (Poly(lactic-co-glycolic acid)) | Model polymer for studying the impact of rheology and degradation kinetics on process optimization. |

| MCC (Microcrystalline Cellulose) | Inert, high-loading filler excipient used to create robust placebo formulations for model calibration. |

| Hot-Melt Extrusion (HME) Grade API | Active compound with sufficient thermal stability to serve as a benchmark for studying API distribution and degradation. |

| Fluorescent Tracer Dye (e.g., Quinacridone) | Marker for validation of mixing and residence time distribution models via offline analysis (e.g., HPLC, fluorescence microscopy). |

| Thermal Stabilizer (e.g., BHT, Tocopherol) | Used in controlled experiments to decouple oxidative degradation from purely thermal degradation in first-principles models. |

Experimental Workflow Visualization

Title: Foundational Modeling Workflow for Extrusion MOO

Model Integration & Data Flow Diagram

Title: Data Integration Flow for Multi-Objective Extrusion Optimization

Methodologies for MOO: Leveraging DoE, AI, and Hybrid Models for Simultaneous CQA Enhancement

Troubleshooting Guides & FAQs

Q1: Why is my screening design (e.g., Plackett-Burman) showing no significant factors, but I know the process is sensitive? A: This is often due to incorrect factor range selection. If the ranges are too narrow, effects are masked by noise. Re-examine preliminary experiments to ensure the low and high levels for each factor (e.g., screw speed, barrel temperature, feed rate) are set to induce a measurable, practical change. Verify measurement system accuracy for your responses (e.g., tensile strength, dissolution rate).

Q2: During Response Surface Methodology (RSM), how do I handle a lack-of-fit that is statistically significant? A: A significant lack-of-fit indicates your model (often quadratic) does not adequately describe the relationship between factors and responses. Solutions include: 1) Adding additional axial points if using a Central Composite Design (CCD) to better estimate curvature, 2) Transforming the response variable (e.g., log, square root), or 3) Investigating if a higher-order model or inclusion of interaction terms not previously considered is necessary. Ensure there are no systematic errors in data collection.

Q3: My extrusion process shows high variability (noise) that overwhelms the signal in DoE. What can I do? A: First, identify and control nuisance variables. Use blocking in your experimental design to account for known sources of variation (e.g., different raw material batches, operator shifts). Replicate center points to get a better estimate of pure error. Consider using a split-plot design if some factors are harder to change (like screw configuration) than others (like temperature settings).

Q4: How do I choose between a Central Composite Design (CCD) and a Box-Behnken Design (BBD) for RSM in extrusion? A: The choice depends on your operational constraints. Use a CCD if you need to estimate extreme conditions (factorial points at the corners) and are not limited by the factor settings. It requires 5 levels per factor. Use a BBD if you want to avoid extreme factor combinations (e.g., simultaneously highest temperature and highest screw speed) due to safety or physical limits, as it uses only 3 levels per factor and is often more efficient in run count for 3-5 factors.

Q5: How can I implement multi-objective optimization from my RSM data for a drug-loaded filament? A: After building validated regression models for each critical response (e.g., % drug release at 1 hour, filament diameter, mechanical strength), use a desirability function approach. Assign individual desirability functions (d_i) for each response, then maximize the overall composite desirability (D). Software like JMP, Design-Expert, or Minitab can perform this optimization and present a set of optimal factor settings (temperature profiles, screw speed) that balance all objectives.

Experimental Protocols

Protocol 1: Screening via a Fractional Factorial Design for Hot-Melt Extrusion

- Objective: Identify critical process parameters (CPPs) affecting Critical Quality Attributes (CQAs).

- Define Factors & Levels: Select 5-7 factors. Example: Barrel Temperature (Low: 120°C, High: 150°C), Screw Speed (Low: 50 rpm, High: 100 rpm), Feed Rate (Low: 0.5 kg/h, High: 1.0 kg/h), Screw Configuration (Low: Mixing, High: Conveying), Die Diameter (Low: 2mm, High: 3mm).

- Design: Generate a Resolution IV or V fractional factorial design (e.g., 2^(5-1)) using statistical software. This minimizes aliasing of main effects with two-way interactions.

- Randomization: Randomize the run order to mitigate time-based confounding.

- Execution: Perform extrusions according to the randomized matrix. Allow process to stabilize at setpoints for 5 minutes before sample collection.

- Response Measurement: For each run, measure CQAs: filament diameter (laser micrometer), tensile strength (texture analyzer), and dissolution profile (USP apparatus).

- Analysis: Use half-normal plots and ANOVA (p<0.05) to identify significant effects.

Protocol 2: Optimization via Face-Centered Central Composite Design (FCCD)

- Objective: Model curvature and find optimal settings for 2-3 critical factors identified from screening.

- Design: For 3 factors, a full FCCD consists of: 2^k factorial points (8), 2k axial points (6) at ±1 alpha (alpha=1 for face-centered), and n_c center point replicates (e.g., 6). Total ~20 runs.

- Execution: Perform all runs in randomized order. Center points provide pure error estimate.

- Modeling: Fit a second-order polynomial model: Y = β0 + ΣβiXi + ΣβiiXi^2 + ΣβijXiXj.

- Validation: Check model adequacy via ANOVA (R², adjusted R², predicted R², lack-of-fit test). Perform 3-5 confirmation runs at predicted optimum.

Data Presentation

Table 1: Example Screening Design (Plackett-Burman) Results for API-Polymer Filament

| Run Order | Temp (°C) | Screw Speed (rpm) | Feed Rate (kg/h) | Diameter (mm) | Tensile Strength (MPa) | % Release (1h) |

|---|---|---|---|---|---|---|

| 1 | 150 | 100 | 1.0 | 1.72 | 45.2 | 78.5 |

| 2 | 120 | 100 | 0.5 | 1.85 | 52.1 | 65.3 |

| 3 | 150 | 50 | 0.5 | 1.68 | 39.8 | 82.1 |

| ... | ... | ... | ... | ... | ... | ... |

| 12 | 135* | 75* | 0.75* | 1.77 | 47.5 | 72.4 |

*Center Point

Table 2: ANOVA for a Quadratic Model (RSM) on Filament Diameter

| Source | Sum of Squares | df | Mean Square | F-Value | p-value (Prob > F) |

|---|---|---|---|---|---|

| Model | 0.125 | 9 | 0.0139 | 25.67 | < 0.0001 |

| A-Temp | 0.032 | 1 | 0.032 | 59.26 | 0.0001 |

| B-Speed | 0.021 | 1 | 0.021 | 38.89 | 0.0003 |

| AB | 0.004 | 1 | 0.004 | 7.41 | 0.0221 |

| A² | 0.041 | 1 | 0.041 | 75.93 | < 0.0001 |

| B² | 0.018 | 1 | 0.018 | 33.33 | 0.0004 |

| Residual | 0.0054 | 10 | 0.00054 | ||

| Lack of Fit | 0.0038 | 5 | 0.00076 | 2.24 | 0.1932 (not sig.) |

| Pure Error | 0.0016 | 5 | 0.00032 | ||

| R² = 0.9585 | Adj R² = 0.9212 | Pred R² = 0.8421 |

Diagrams

DoE Workflow for Extrusion Optimization

Multi-Objective Optimization via Desirability

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 3: Key Materials for DoE in Pharmaceutical Extrusion

| Item | Function/Justification |

|---|---|

| Twin-Screw Extruder (Lab-scale) | Essential for processing. Must allow precise, independent control over multiple barrel zones (temperature) and screw speed. |

| Polymer Carrier (e.g., HPMC AS, PVP VA64, Eudragit) | The matrix former. Selection is critical based on API properties and desired release profile (immediate, sustained). |

| Active Pharmaceutical Ingredient (API) | The drug substance. Its thermal stability dictates maximum processing temperatures. |

| Plasticizer (e.g., Triethyl Citrate, PEG) | Lowers glass transition temperature of polymer, enabling processing at lower temps to protect heat-sensitive APIs. |

| Laser Micrometer | Provides non-contact, high-precision measurement of filament diameter (a key CQA) for every experimental run. |

| Texture Analyzer/Tensile Tester | Quantifies mechanical properties (tensile strength, elasticity) of extrudates, crucial for downstream handling. |

| Dissolution Testing Apparatus (USP I/II) | Measures drug release profile, the primary performance indicator for the final dosage form. |

| DoE Statistical Software (e.g., JMP, Design-Expert, Minitab) | Used to generate design matrices, randomize runs, perform ANOVA, and conduct multi-objective optimization. |

Technical Support & Troubleshooting Center

This support center provides targeted guidance for researchers implementing machine learning models for Critical Quality Attribute (CQA) profiling within multi-objective extrusion process optimization projects.

Frequently Asked Questions & Troubleshooting Guides

Q1: During ANN training for predicting tablet hardness, my model validation loss plateaus after a few epochs. What could be the cause? A: This is typically caused by insufficient feature engineering or inadequate model capacity for the process complexity. First, ensure your input features capture both raw material properties (e.g., API particle size distribution, excipient moisture) and key extrusion process parameters (e.g., barrel temperature profile, screw speed, feed rate). Consider adding engineered features like specific mechanical energy (SME) or melt viscosity estimates. If the problem persists, incrementally increase the number of hidden layers/neurons and monitor for overfitting using a separate test set. A learning rate scheduler (e.g., ReduceLROnPlateau) can also help the optimizer escape a local minimum.

Q2: My Random Forest model for predicting dissolution rate shows high training accuracy but poor performance on new experimental batches. How do I fix this?

A: This indicates overfitting. Random Forests are prone to this with noisy or small datasets. First, verify your dataset size; a minimum of 50-100 experimental runs per CQA is recommended for robust learning. Implement stricter hyperparameter tuning: reduce max_depth (start with 5-10), increase min_samples_leaf (e.g., to 5), and limit max_features (e.g., to sqrt(n_features)). Use out-of-bag (OOB) error or repeated k-fold cross-validation for more reliable performance estimates during tuning.

Q3: How should I handle missing data points from my Design of Experiments (DoE) on a twin-screw extruder before feeding it to the ML models? A: Do not use simple mean imputation for sequential process data. For continuous variables (e.g., melt pressure), use interpolation if the missing segment is short and within a stable operational phase. For categorical variables (e.g., screw configuration code), treat it as a separate category "Not Recorded." Consider using a multivariate imputation technique like MICE (Multiple Imputation by Chasney Equations) if the missing data is extensive, but document this step thoroughly. The best practice is to revisit experimental protocols to minimize data loss.

Q4: When attempting multi-output prediction (e.g., tensile strength and degradation product concentration simultaneously), which algorithm architecture is preferred? A: For highly correlated CQAs (e.g., mechanical properties), a multi-output Artificial Neural Network (ANN) with a shared hidden layer and separate output layers is effective, as it allows the model to learn common representations. For CQAs with potentially different driving factors (e.g., mechanical vs. chemical attributes), ensemble separate Random Forest models may yield more accurate and interpretable results. Use a correlation matrix of your CQAs to guide this decision.

Q5: The SHAP analysis for my Random Forest model highlights screw speed as unimportant for predicting API amorphicity, which contradicts domain knowledge. Why?

A: This likely indicates feature interaction or redundancy. Screw speed's effect may be conditional on barrel temperature or be highly correlated with specific mechanical energy (SME) in your dataset. Check for feature correlations >0.8. If SME is a feature, screw speed's individual importance may be masked. Retrain the model excluding SME to see if screw speed importance increases. Also, try using SHAP's interaction values (shap.TreeExplainer(model).shap_interaction_values(X)) to uncover interdependencies with temperature zones.

Data Presentation: Model Performance Comparison

Table 1: Comparative Performance of ANN vs. Random Forest for Key CQAs in Hot-Melt Extrusion Dataset: 80 experimental runs from a DoE on a copovidone-based formulation.

| Critical Quality Attribute (CQA) | Best Model | R² (Test Set) | MAE (Mean Absolute Error) | Key Predictive Features Identified |

|---|---|---|---|---|

| Tablet Tensile Strength (MPa) | Random Forest | 0.92 | ±0.15 | Specific Mechanical Energy, Melt Temp at Die, Polymer Grade |

| Dissolution at 30 min (%) | ANN (2 hidden layers) | 0.88 | ±4.2 | Barrel Temp Zone 2, Screw Speed, Drug Load, Plasticizer Ratio |

| Degradation Product (%) | Random Forest | 0.95 | ±0.05 | Residence Time, Melt Temp Zone 5, Initial API Moisture |

| Glass Transition Temp (Tg) °C | ANN (1 hidden layer) | 0.96 | ±0.8 | Polymer Type, Drug Load, Cooling Rate |

Experimental Protocol: Generating Data for ML Model Training

Protocol: Integrated DoE for Multi-Objective Extrusion Optimization and CQA Profiling

1. Objective: Systematically generate input-process-output data to train predictive models for CQAs.

2. Materials: (See "Scientist's Toolkit" below).

3. Procedure:

- DoE Design: Create a Central Composite Design (CCD) or definitive screening design. Independent variables must include:

- Material Attributes: API particle size (D10, D50, D90), moisture content, excipient lot.

- Process Parameters: Feed rate (kg/h), screw speed (RPM), barrel temperature profile (Zones 1-7 in °C), screw configuration (conveying, kneading, mixing elements sequence).

- Execution: Run experiments in randomized order. For each run, after achieving steady state (≥3x mean residence time), collect time-synchronized data:

- Input Features: Log all DoE parameters + in-line NIR spectra (every 30s) for blend uniformity.

- Process Responses: Record melt pressure (bar), melt temperature (°C), motor torque (%), and calculate Specific Mechanical Energy (SME).

- Output CQAs: Collect extrudate samples. Analyze for:

- Chemical: Drug content (HPLC), degradation products (HPLC), solid state (mDSC, XRD).

- Physical: Tensile strength, dissolution profile (USP apparatus), moisture content (LOD).

- Data Curation: Align all time-series data, calculate averages and variances for steady-state period. Perform necessary unit conversions and feature scaling (StandardScaler or MinMaxScaler). Split data into training (70%), validation (15%), and hold-out test (15%) sets, ensuring all runs from a single material batch are in the same set to prevent data leakage.

Mandatory Visualization

Diagram Title: ML Workflow for Predictive CQA Profiling in Extrusion

Diagram Title: Multi-output ANN for Concurrent CQA Prediction

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials & Tools for Data-Driven Extrusion Studies

| Item | Function/Description | Example/Supplier (Illustrative) |

|---|---|---|

| Twin-Screw Extruder (Bench-top) | Provides scalable, controllable process environment for DoE execution. Must have modular screw design and multiple barrel zones. | Leistritz Nano-16, Thermo Scientific Process 11 |

| In-line NIR Probe | Real-time monitoring of blend uniformity, moisture, and potential chemical attributes (e.g., drug concentration) during extrusion. | Metrohm NIRS XDS Process Analyzer |

| Process Data Historian | Software to time-synchronize and log all machine parameters (temp, torque, pressure, speed) and sensor outputs. | OSIsoft PI System, HighVista |

| Polymer & Lipid Carriers | Primary matrix formers. Selection dictates melt behavior, drug solubility, and final product performance. | Kollidon VA64, Soluplus, Gelucire, Eudragit |

| Data Science Platform | Environment for developing, training, and validating ANN and Random Forest models. | Python (scikit-learn, TensorFlow/PyTorch), R (caret, randomForest) |

| SHAP (SHapley Additive exPlanations) | Python library for post-hoc model interpretability, critical for understanding feature impact on CQA predictions. | https://github.com/slundberg/shap |

| Differential Scanning Calorimeter (mDSC) | Characterizes solid-state of API in extrudate (crystalline vs. amorphous), a key CQA for stability and dissolution. | TA Instruments Q2000 |

| Dissolution Testing Apparatus | Measures drug release profile, a primary efficacy CQA for solid dosage forms. | USP Apparatus I/II (Baskets/Paddles) |

Troubleshooting Guides & FAQs

FAQ Section

Q1: Why does my mechanistic model fail to converge when integrating momentum balances for non-Newtonian polymer melts? A: Non-convergence often stems from incorrect rheological parameterization or an unstable numerical scheme. Ensure your power-law or Carreau model parameters are fitted to experimental shear rate-viscosity data specific to your formulation. Use a robust ODE solver (e.g., implicit backward differentiation formulas) and implement adaptive step sizing.

Q2: How do I handle missing or noisy process sensor data (e.g., melt pressure, temperature) for hybrid model calibration? A: Implement a two-step data pre-processing protocol: 1) Apply a low-pass filter (e.g., Savitzky-Golay) to reduce high-frequency noise, and 2) Use a Kalman filter or linear interpolation for short, sporadic gaps. For significant missing segments, consider using a simpler mechanistic sub-model to generate synthetic data for calibration, clearly documenting this substitution.

Q3: What is the best strategy to identify which model parameters to estimate from data versus fixing from literature in a hybrid extrusion model? A: Perform a prior sensitivity analysis (e.g., Morris method) on the full parameter set. Parameters with high influence on key outputs (e.g., specific mechanical energy, melt temperature) should be prioritized for estimation. Fix less sensitive parameters to literature values. Always report the source and uncertainty of fixed parameters.

Q4: My multi-objective optimization (MOO) between product quality and energy consumption yields a fragmented Pareto front. What could be wrong? A: A fragmented Pareto front suggests conflicts in constraint handling or discontinuities in the model. Verify that your equality and inequality constraints (e.g., mass balance closures, maximum barrel temperature) are consistently satisfied across all design variable combinations. Check for conditional statements or sharp transitions in material properties within your model code.

Q5: How can I validate a hybrid model when full-scale experimental data is limited for a novel drug-polymer extrusion? A: Employ a tiered validation strategy: 1) Validate mechanistic sub-models (e.g., melting rate) against small-scale benchtop experiments. 2) Use available partial production data for cross-validation (e.g., train on 80% of screw speed settings, test on 20%). 3) Report prediction intervals, not just point estimates, to communicate model uncertainty.

Experimental Protocols

Protocol 1: Calibration of Rheological Parameters for Mechanistic Modeling Objective: Determine the shear viscosity parameters of a drug-polymer blend for momentum balance equations. Materials: See "Research Reagent Solutions" table. Method:

- Prepare a homogeneous mixture of API and polymer excipient.

- Using a capillary rheometer, subject the blend to a series of controlled shear rates (typically 10-1000 s⁻¹) at the target processing temperature.

- Record the resulting shear stress for each rate.

- Fit the data to the chosen viscosity model (e.g., Power Law: η = K * γ̇^(n-1)) using nonlinear least-squares regression.

- Report the consistency index (K), flow index (n), and the R² value of the fit.

Protocol 2: Generating Data for Hybrid Model Training in Twin-Screw Extrusion Objective: Acquire synchronized process and quality data for model calibration and validation. Method:

- Design of Experiments (DoE): Define input variables (e.g., screw speed, feed rate, barrel zone temperatures) using a central composite design.

- Instrumentation: Ensure all sensors (melt pressure transducers, thermocouples, motor torque) are calibrated. Synchronize data acquisition to a single timestamp.

- Steady-State Operation: For each DoE point, run the extruder until steady-state is reached (monitor key variables for stability over 3-5 residence times).

- Product Sampling: At steady-state, collect extrudate samples for offline analysis (e.g., HPLC for API content, DSC for crystallinity, laser diffraction for particle size).

- Data Logging: Record all time-synchronized process data and associated quality results, labeling each with the unique DoE run ID.

Data Presentation

Table 1: Example Parameter Estimation Results from Hybrid Model Calibration

| Parameter | Description | Literature Value | Estimated Value | 95% Confidence Interval | Units |

|---|---|---|---|---|---|

k_melt |

Melting rate constant | 1.5e-3 | 1.72e-3 | [1.65e-3, 1.79e-3] | m²/(s·K) |

C_p |

Specific heat capacity | 1500 | 1420 | [1380, 1460] | J/(kg·K) |

α |

Wall slip coefficient | 0.01 | 0.023 | [0.019, 0.027] | - |

ΔH_rxn |

Heat of degradation | 85.0 | 92.5 | [89.0, 96.0] | kJ/mol |

Table 2: Multi-Objective Optimization Results (Trade-off Analysis)

| Scenario | Screw Speed (RPM) | Melt Temp. (°C) | Specific Mech. Energy (kWh/kg) | Predicted API Degradation (%) | Dominance Status |

|---|---|---|---|---|---|

| A | 300 | 165 | 0.105 | 0.15 | Pareto Optimal |

| B | 400 | 172 | 0.121 | 0.32 | Pareto Optimal |

| C | 350 | 169 | 0.115 | 0.28 | Pareto Optimal |

| D | 250 | 160 | 0.098 | 0.12 | Pareto Optimal |

| E | 400 | 178 | 0.125 | 0.95 | Dominated |

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Extrusion Process Modeling

| Item | Function in Research | Example Product/Chemical |

|---|---|---|

| Model Polymer Excipient | Acts as a carrier; its rheology dictates momentum transfer. | Polyvinylpyrrolidone (PVP K30), Hydroxypropyl cellulose (HPC). |

| Model Active Pharmaceutical Ingredient (API) | Therapeutic compound; its stability limits process conditions. | Metformin HCl, Ibuprofen (heat-stable models). |

| Plasticizer | Modifies polymer rheology for easier processing at lower temps. | Triethyl citrate, Polyethylene glycol (PEG 400). |

| Thermal Stabilizer | Mitigates API/polymer degradation during high-shear processing. | Butylated hydroxytoluene (BHT), Ascorbyl palmitate. |

| Tracer Dye | Visualizes residence time distribution (RTD) for mass balance validation. | Methylene Blue, Titanium Dioxide (food grade). |

| Calibration Standards | For quantifying API content and degradation products via HPLC. | Certified reference standard of the API. |

Visualizations

Title: Hybrid Modeling & Optimization Workflow for Extrusion

Title: Key Variable Interactions in Extrusion MOO

Technical Support Center: Troubleshooting Guides & FAQs

This technical support center is designed for researchers conducting multi-objective optimization experiments within the context of extrusion process research, particularly for applications like polymer-based drug delivery system development. The following guides address common issues encountered when implementing NSGA-II and related evolutionary algorithms.

Frequently Asked Questions

Q1: During my extrusion process optimization, my NSGA-II run converges to a local Pareto front, not the global one. What parameters should I adjust? A: This is often due to insufficient population diversity. Implement the following checks:

- Increase the population size relative to your decision variable count (e.g., from 100 to 200-500).

- Increase the crossover probability (e.g., to 0.9) and use Simulated Binary Crossover (SBX) with a distribution index of 20-30.

- Decrease the mutation probability per variable (e.g., to 1/n, where n=number of variables) but use a polynomial mutation with a high distribution index (e.g., 20).

- Verify your constraint handling method. Use constrained-domination principles properly.

Q2: How do I effectively handle the conflicting objectives of maximizing drug release rate and minimizing polymer degradation in my extrudate, using the Pareto front? A: The Pareto front quantitatively illustrates this trade-off. Follow this protocol:

- Define Objectives: Formally define Objective 1 (Maximize: Cumulative Drug Release at time t) and Objective 2 (Minimize: % Polymer Molecular Weight Reduction).

- Run NSGA-II: After optimization, analyze the non-dominated solution set.

- Apply Decision-Making: Use a post-optimal technique like the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) on the Pareto-optimal solutions. This selects the solution closest to the ideal point (highest release, lowest degradation), facilitating a rational choice for your specific formulation goals.

Q3: My optimization of barrel temperature and screw speed is computationally expensive. How can I reduce the number of fitness evaluations in NSGA-II? A: Employ a surrogate-assisted evolutionary algorithm (SAEA).

- Protocol: Replace some direct extrusion process simulations (fitness evaluations) with a fast, approximate model.

- Start with a Latin Hypercube Sampling (LHS) design to run 50-100 initial extrusion simulations.

- Train a Kriging (Gaussian Process) surrogate model on this data for each objective.

- Run a modified NSGA-II where most evaluations use the surrogate model. Periodically, select promising candidates for evaluation with the true simulation to update the surrogate.

- This hybrid approach can reduce actual simulation calls by 50-70%.

Q4: When visualizing high-dimensional Pareto fronts (more than 3 objectives) from my multi-response extrusion experiment, what methods are recommended? A: For many-objective optimization (>3 objectives), use:

- Parallel Coordinate Plots: Each vertical axis represents one objective (e.g., tensile strength, dissolution rate, degradation, yield). Each line is a Pareto solution.

- Heatmaps of the Pareto Set: Rows are solutions, columns are objectives/decision variables, colored by normalized performance.

- Dimensionality Reduction: Apply Principal Component Analysis (PCA) to the objective vectors and plot the first two principal components.

Table 1: Performance Comparison of MOEAs on Standard Test Problems (ZDT, DTLZ)

| Algorithm | Generational Distance (GD) ↓ | Spacing (SP) ↓ | Hypervolume (HV) ↑ | Computational Time (s) |

|---|---|---|---|---|

| NSGA-II | 0.0025 | 0.015 | 0.825 | 120 |

| MOEA/D | 0.0018 | 0.010 | 0.840 | 145 |

| NSGA-III | 0.0030 | 0.008 | 0.830 | 180 |

| SPEA2 | 0.0022 | 0.012 | 0.820 | 135 |

Table 2: Effect of NSGA-II Parameters on Extrusion Optimization Results

| Parameter Set (Pop Size, Gen) | No. of Pareto Solutions | Max Tensile Strength (MPa) | Min Melt Viscosity (Pa·s) | Function Evaluations |

|---|---|---|---|---|

| 100, 50 | 15 | 42.5 | 1250 | 5000 |

| 200, 100 | 38 | 45.2 | 1100 | 20000 |

| 500, 100 | 72 | 46.1 | 1050 | 50000 |

Experimental Protocols

Protocol 1: Benchmarking Algorithm Performance

- Problem Selection: Choose standard multi-objective test functions (e.g., ZDT1, ZDT2, DTLZ2).

- Algorithm Setup: Code NSGA-II, MOEA/D, and SPEA2 with identical initialization routines.

- Performance Metrics: Calculate Generational Distance (GD), Spacing (SP), and Hypervolume (HV) for each run.

- Statistical Validation: Execute 30 independent runs per algorithm. Perform a non-parametric statistical test (e.g., Wilcoxon rank-sum) to confirm significance of results.

Protocol 2: Calibrating NSGA-II for Twin-Screw Extrusion Process Optimization

- Define Search Space: Set bounds for decision variables: Barrel Temperature (150-200°C), Screw Speed (200-600 rpm), Polymer-Plasticizer Ratio (90:10 to 70:30).

- Formulate Objectives: Mathematically define objectives: Maximize Drug Dissolution Efficiency (DE) at 30 min, Minimize Specific Mechanical Energy (SME) input.

- Implement Constraint: Add a constraint that melt temperature ≤ 210°C.

- Run Optimization: Execute NSGA-II with a population of 100 for 200 generations.

- Validate Pareto Solutions: Physically run 3-5 selected optimal parameter sets on the extruder and compare predicted vs. measured responses.

Visualizations

Title: NSGA-II Workflow for Extrusion Process Optimization

Title: Multi-objective Conflict & Resolution in Extrusion

The Scientist's Toolkit

Table 3: Research Reagent & Software Solutions for Multi-objective Extrusion Studies

| Item | Function/Application | Example/Note |

|---|---|---|

| Polymer Matrix (PLGA) | Main extrudable carrier for drug encapsulation. Degradation rate is a key optimization objective. | Resomer RG 503H, varies in lactide:glycolide ratio. |

| Model Drug (e.g., Theophylline) | A stable, well-characterized compound used to study release kinetics from the extrudate. | Acts as a surrogate for novel API in formulation studies. |

| Plasticizer (Triethyl Citrate) | Lowers processing temperature and melt viscosity, a key decision variable. | Concentration directly impacts mechanical energy input. |

| NSGA-II Software Library | Pre-coded algorithm implementation to avoid coding from scratch. | Platypus (Python), pymoo (Python), or MATLAB's Global Optimization Toolbox. |

| Process Simulator (e.g., Ludovic) | Software to simulate twin-screw extrusion physics, reducing costly trial runs. | Provides data for surrogate model training in SAEAs. |

| Performance Metric Code | Scripts to calculate Hypervolume, Generational Distance, etc. | Essential for benchmarking algorithm performance. |

Technical Support Center & Troubleshooting Hub

Frequently Asked Questions (FAQs)

Q1: During hot-melt extrusion (HME), my amorphous solid dispersion (ASD) shows API degradation. What are the primary causes and how can I mitigate this? A: Primary causes are excessive barrel temperature or long residence time. Mitigation strategies include:

- Use a plasticizer (e.g., triethyl citrate) to lower the required processing temperature.

- Optimize screw speed and feed rate to reduce residence time.

- Consider a polymer with a lower glass transition temperature (Tg) like Soluplus or vinylpyrrolidone-vinyl acetate copolymer (PVP-VA) to enable processing at lower temperatures.

Q2: My optimized formulation recrystallizes after 3 months under accelerated stability conditions (40°C/75%RH). What formulation factors should I re-investigate? A: Focus on polymer selection and drug-polymer interactions:

- Polymer Type: Switch to a polymer with stronger anti-plasticization effect and/or specific interactions (e.g., from HPMC-AS to PVP-VA or a cellulose-based polymer with API-specific interactions).

- Drug Load: Re-evaluate the drug-to-polymer ratio. The current load may exceed the solubility limit in the polymer matrix under high humidity.

- Additives: Incorporate a crystallization inhibitor like surfactants (e.g., Poloxamer 407) or mesoporous silica.

Q3: The dissolution profile of my HME-produced ASD shows poor supersaturation maintenance. What could be the reason? A: This often indicates rapid drug recrystallization from the supersaturated state upon dissolution.

- Solution: Incorporate a precipitation inhibitor (e.g., HPMC, PVP, or cellulose derivatives) into the formulation. These polymers stabilize the drug in solution by adsorbing to crystal surfaces or increasing medium viscosity.

Q4: How do I select the most suitable polymer for a new BCS Class II API in an HME process? A: Follow a tiered experimental screening protocol:

- Thermal Compatibility: Use DSC/mTGA to assess degradation temperature and miscibility.

- Solubility Parameter: Calculate Hansen solubility parameters (δ) for API and polymers to predict miscibility (aim for Δδ < 7.0 MPa¹/²).

- Small-Scale Screening: Use solvent casting or quench cooling to create binary blends and test for amorphous state stability and dissolution performance.

Troubleshooting Guides

Issue: Inconsistent Dissolution Results Between Batches

- Check 1: Raw Material Attributes. Verify the particle size distribution and polymorphic form of the input API are consistent.

- Check 2: HME Process Parameters. Ensure barrel temperature zones, screw speed, and torque are recorded and identical. Variability here affects the degree of mixing and API dispersion.

- Check 3: Milling Conditions. Post-extrusion milling can affect surface area and dissolution. Control mill type, speed, and duration.

Issue: High Torque and Screw Blockage During Extrusion

- Cause: The formulation (high drug load, high Tg polymer) may be too viscous at the set temperature.

- Action Plan:

- Immediate: Stop feed, purge barrel with pure polymer.

- Re-formulate: Introduce a plasticizer (e.g., PEG 6000, TEC) in 2-5% w/w increments.

- Adjust Process: Increase temperature in the initial feeding zones if API is thermally stable. Optimize screw configuration to include more kneading elements for better conveyance.

Issue: Poor Content Uniformity in Final Granules/Tablets

- Cause: Inadequate distributive mixing during HME or segregation during downstream processing.

- Solution: Revise screw design to include distributive mixing elements (e.g., combing mixers). For downstream blending, use shorter times and consider dry binders to reduce segregation potential.

Data Presentation: Key Formulation & Performance Metrics

Table 1: Screening of Polymers for API X (Tm = 210°C, Tg = 55°C)

| Polymer (Carrier) | Tg of Polymer (°C) | Δδ (MPa¹/²) | Maximum Drug Load (wt%) for Stable ASD* | Dissolution at 120 min (%) |

|---|---|---|---|---|

| PVP-VA64 | 101 | 4.2 | 25 | 92 |

| HPMC-AS (LF) | 120 | 5.8 | 30 | 85 |

| Soluplus | 70 | 3.5 | 40 | 95 |

| Eudragit E PO | 48 | 6.5 | 20 | 78 |

*Stable after 1 month at 40°C/75% RH, as per XRD analysis.

Table 2: Multi-objective Optimization Results for HME Process (API:Polymer = 20:80)

| Run | Barrel Temp. Profile (°C) | Screw Speed (RPM) | Torque (N·m) | Residual Crystallinity (%) | Dissolution Efficiency (% at 30 min) | Physical Stability (Months at 40°C) |

|---|---|---|---|---|---|---|

| 1 | 140-150-155-160 | 200 | 32 | 0.5 | 65 | 3 |

| 2 | 130-140-145-150 | 300 | 28 | <0.1 | 88 | 6 |

| 3 | 150-160-165-170 | 150 | 41 | <0.1 | 90 | 2 |

Experimental Protocols

Protocol 1: Small-Scale Miscibility & Compatibility Screening via Solvent Casting

- Dissolve the API and polymer at the desired ratio (e.g., 10:90, 20:80, 30:70) in a common volatile solvent (e.g., methanol, dichloromethane).

- Cast the solution onto a flat glass surface (e.g., Petri dish) and allow the solvent to evaporate slowly at room temperature under a fume hood.

- Further dry the films in a vacuum oven (40°C) for 24 hours to remove residual solvent.

- Analyze films using Modulated Differential Scanning Calorimetry (mDSC) to determine a single, composition-dependent Tg, indicating miscibility. Use Hot-Stage Microscopy (HSM) to observe melting behavior.

Protocol 2: Hot-Melt Extrusion Process for ASD Manufacturing (Bench-Scale)

- Equipment: Twin-screw extruder (e.g., 11- or 16-mm co-rotating screws), gravimetric feeder.

- Pre-Processing: Pre-blend the API and polymer (and any plasticizer) using a tumbler mixer for 15 minutes.

- Process:

- Set the barrel temperature profile based on the polymer's Tg and API's melting point (typically 10-30°C above the polymer's Tg).

- Set screw speed between 100-300 RPM. Configure screws with conveying, kneading, and mixing elements.

- Initiate feeder and extrusion. Allow process to stabilize (~10-15 min).

- Monitor torque, pressure, and melt temperature.

- Collect the extrudate strand, cool on a conveyor belt, and pelletize or mill.

- Post-Processing: Mill the strands using a conical mill to obtain granules of 150-500 µm.

Protocol 3: Forced Degradation Stability Study

- Package samples (approx. 1-2g) of the milled ASD in clear glass vials sealed with crimped caps containing a Teflon-lined rubber septum.

- Place samples in stability chambers under the following conditions: 25°C/60% RH, 40°C/75% RH, and 60°C/dry.

- Withdraw samples at predefined intervals (e.g., 0, 1, 2, 3, 6 months).

- Analyze samples using Powder X-Ray Diffraction (pXRD) for crystallinity, HPLC for assay/degradation products, and DSC for Tg shifts.

Mandatory Visualizations

Diagram Title: Multi-Objective Optimization Framework for ASD Development

Diagram Title: Experimental Workflow for ASD Development & Optimization

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for ASD Formulation Research

| Item/Category | Example Products/Brands | Primary Function in ASD Development |

|---|---|---|

| Polymeric Carriers | PVP-VA (Kollidon VA64), HPMC-AS (AQOAT), Soluplus, Eudragit series | Primary matrix former to solubilize and stabilize the API in the amorphous state. Governs dissolution behavior and physical stability. |

| Plasticizers | Triethyl Citrate (TEC), Polyethylene Glycol (PEG 6000), Tributyl Citrate | Lower polymer Tg and melt viscosity, enabling HME at lower temperatures to reduce thermal stress. |

| Surfactants / Precipitation Inhibitors | Poloxamer (Pluronic), TPGS, Polyvinyl caprolactam-polyvinyl acetate-polyethylene glycol (Soluplus) | Enhance wetting, maintain supersaturation, and inhibit drug recrystallization in the dissolution medium. |

| Adsorbents / Mesoporous Carriers | Syloid 244FP, Neusilin US2 | Provide high surface area for API adsorption, potentially stabilizing the amorphous form via confinement. |

| Stability Testing Aids | Controlled Humidity Chambers, Saturated Salt Solutions (e.g., NaCl, KNO3) | Provide precise environmental conditions (Temperature & Relative Humidity) for accelerated stability studies. |

| Analytical Standards | USP/EP Reference Standards for API, Certified Impurity Standards | Essential for validating analytical methods (HPLC, DSC) for assay, degradation products, and purity assessment. |

Technical Support Center: Troubleshooting for MOO in Hot Melt Extrusion

FAQs & Troubleshooting Guides

Q1: During a multi-objective optimization (MOO) run using modeFrontier coupled with a process simulator (e.g., gPROMS FormulatedProducts), the DOE fails with "Simulator execution error." What are the first steps to diagnose this? A1: This typically indicates a failure at the single-process simulation level. Follow this protocol:

- Isolate the Failed Design Point: Check the modeFrontier error log to identify the specific input variable set (e.g., screw speed, barrel temperature, API concentration) that caused the failure.

- Run a Standalone Simulation: Manually input the identified problematic design point into your gPROMS (or equivalent) model and run it outside the MOO workflow. This will provide a more detailed error message from the simulator itself (e.g., "pressure exceedance," "convergence failure in energy balance").

- Check Parameter Boundaries: The most common cause is an infeasible combination of inputs. Verify that the variable ranges defined in your MOO workflow's design of experiments (DOE) stage are physically realistic (e.g., too low torque at too high feed rate). Adjust the variable constraints and restart the DOE.

Q2: When using MATLAB's Optimization Toolbox with a custom HME model, the Pareto front output shows clustered, non-distributed solutions. How can this be improved? A2: Clustered solutions often result from algorithm settings or poorly scaled objectives.

- Protocol for Algorithm Tuning:

- If using

gamultiobj, increase theParetoFractionandPopulationSizeoptions. A larger population explores more of the design space. - Utilize the

distancecrowdingfunction in theDistanceMeasureFcnoption to promote better spread. - Ensure your objective functions (e.g., % crystallinity, dissolution rate @ 15min, process torque) are normalized to similar scales (e.g., 0 to 1). Unbalanced scales bias the algorithm towards one objective.