Accurate Tg Measurement in Polymer Composites: A Comprehensive DMA Guide for Biomedical Researchers

This article provides a definitive guide to Dynamic Mechanical Analysis (DMA) for measuring the glass transition temperature (Tg) in polymer composites, specifically tailored for biomedical and pharmaceutical applications.

Accurate Tg Measurement in Polymer Composites: A Comprehensive DMA Guide for Biomedical Researchers

Abstract

This article provides a definitive guide to Dynamic Mechanical Analysis (DMA) for measuring the glass transition temperature (Tg) in polymer composites, specifically tailored for biomedical and pharmaceutical applications. It covers fundamental principles, detailed experimental protocols, advanced data interpretation, and troubleshooting strategies for composite materials like PLGA, PCL, and hydrogels. The content addresses critical needs in drug delivery system development, implant material characterization, and regulatory documentation by comparing DMA with DSC and TMA, validating measurement accuracy, and optimizing protocols for complex composite matrices. Researchers will gain actionable insights for reliable Tg determination to predict material stability, drug release kinetics, and in-vivo performance.

Understanding Tg and DMA: Why It's Critical for Polymer Composite Performance in Biomedicine

Within the broader thesis on the application of Dynamic Mechanical Analysis (DMA) for measuring the glass transition temperature (Tg) in polymer composite research, this document establishes Tg's critical role. Tg is not merely a thermal property; it is the fundamental gatekeeper dictating the mechanical performance of a composite and the release kinetics of drugs from polymeric delivery systems. A precise understanding and measurement of Tg via DMA is therefore essential for material design and pharmaceutical development.

Tg as a Determinant of Composite Properties: Data & Mechanisms

The Tg of the polymer matrix governs key composite characteristics, as summarized in Table 1.

Table 1: Influence of Polymer Matrix Tg on Composite Properties

| Composite Property | Below Tg (Glass State) | Above Tg (Rubber State) | Quantitative Impact Range (General) |

|---|---|---|---|

| Storage Modulus (E') | High, rigid | Low, soft | Change of 2-3 orders of magnitude at Tg |

| Impact Resistance | Brittle, low | Ductile, high | Toughness can increase by >500% above Tg |

| Thermal Expansion | Low (~50 ppm/°C) | High (~200 ppm/°C) | Coefficient can increase 3-4 fold |

| Permeability | Low | High | Water/drug permeability can increase 10-100x |

| Composite Damping (tan δ) | Low | Peak at Tg | tan δ peak height correlates with interface quality |

The underlying mechanism involves the activation of chain segmental mobility. Below Tg, chains are frozen, resulting in a rigid, glassy material. As temperature surpasses Tg, increased free volume permits chain movement, drastically altering properties. In composites, the filler-polymer interface can restrict this mobility, leading to broadening or shifts in the Tg region, which DMA sensitively detects.

Tg as a Controller of Drug Release Kinetics

For drug delivery systems, Tg determines the diffusion rate of drug molecules through the polymer. This relationship is central to controlled release formulations.

Table 2: Effect of Polymer Tg on Drug Release Mechanisms

| Polymer State | Drug Mobility | Dominant Release Mechanism | Typical Release Profile |

|---|---|---|---|

| Glassy (T < Tg) | Highly restricted | Fickian diffusion through pre-existing pores/cracks | Initial burst, then slow, incomplete release |

| Rubbery (T > Tg) | Significant | Polymer relaxation & diffusion (often Case-II transport) | Sustained, near-zero-order kinetics possible |

| Near Tg | Variable, time-dependent | Anomalous (non-Fickian) transport | Complex, highly sensitive to environmental conditions |

Protocol 3.1: Evaluating Drug Release as a Function of Storage Temperature Relative to Tg

- Objective: To correlate drug release profiles with the Tg of the polymeric carrier.

- Materials: Loaded polymeric microparticles/nanoparticles, phosphate buffer saline (PBS, pH 7.4), dissolution apparatus, DMA instrument.

- Procedure:

- Tg Measurement: Precisely determine the Tg of the drug-loaded polymer matrix using DMA (see Protocol 4.1).

- Conditioning: Divide samples into three groups. Store each group at a specific temperature: (a) T < Tg - 20°C, (b) T ≈ Tg, (c) T > Tg + 20°C for 24 hours.

- Release Study: Place samples in dissolution vessels containing PBS at 37°C under sink conditions.

- Sampling & Analysis: Withdraw aliquots at predetermined times (e.g., 1, 2, 4, 8, 24, 48 hrs). Filter and quantify drug concentration via HPLC/UV-Vis.

- Data Modeling: Fit release data to models (e.g., Higuchi, Korsmeyer-Peppas) to determine the release exponent (n), identifying the diffusion mechanism.

Title: Tg Governs Drug Release Mechanism

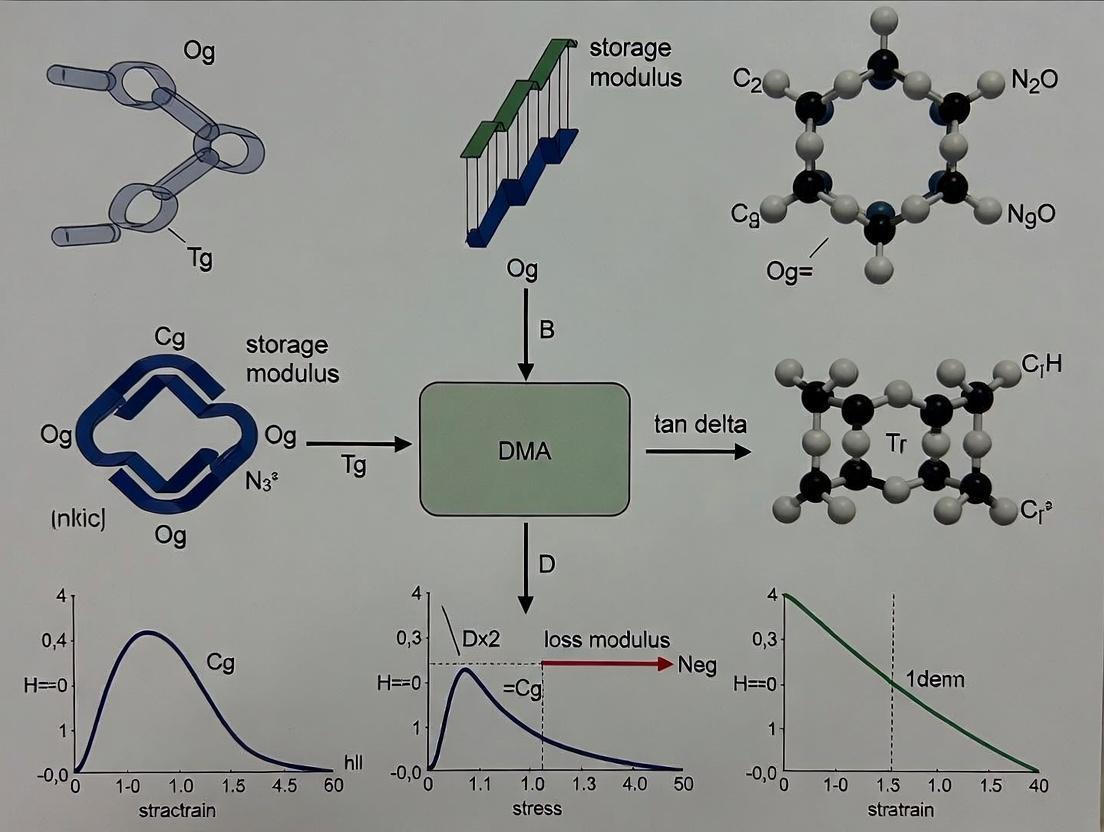

Core DMA Protocol for Tg Measurement in Composites

This protocol is central to the methodological thesis.

Protocol 4.1: DMA Measurement of Tg in Polymer Composites and Drug-Loaded Systems

- Objective: To determine the glass transition temperature (Tg) via the peak of the loss modulus (E'') or tan δ.

- Materials & Equipment:

- DMA instrument (e.g., TA Instruments Q800, Netzsch 242)

- Solid rectangular or tension film clamps

- Liquid Nitrogen or integrated cooling system

- Standard reference material (e.g., PMMA, polycarbonate) for calibration

- Procedure:

- Sample Preparation: Prepare rectangular specimens (typical: ~20mm x 10mm x 1mm). Ensure parallel, flat surfaces.

- Mounting: Securely mount the sample in the appropriate clamp. Ensure it is taut and aligned for tension/flexure modes.

- Method Setup:

- Mode: Dual-cantilever or tension, depending on sample stiffness.

- Oscillation Parameters: Set frequency to 1 Hz. Apply a static force (strain) 10% greater than the dynamic force to maintain tension. Dynamic strain amplitude: 0.01-0.05%.

- Temperature Ramp: Equilibrate at -50°C (or below expected Tg). Ramp at 3°C/min to 150°C (or above expected Tg) under inert gas purge.

- Data Collection: Record storage modulus (E'), loss modulus (E''), and tan δ (E''/E') as a function of temperature.

- Tg Analysis: Identify Tg as:

- Primary Method (E'' Peak): The peak temperature of the loss modulus curve (most sensitive to molecular motions).

- Secondary Method (tan δ Peak): The peak temperature of the tan δ curve (indicates damping maximum).

- Validation: Run a calibration standard under identical conditions to verify instrument performance.

Title: DMA Tg Measurement Protocol Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for DMA Analysis of Polymer Composites

| Item / Reagent | Function / Role | Key Considerations |

|---|---|---|

| DMA Instrument | Applies oscillatory stress & measures strain response to determine viscoelastic properties. | Choose appropriate clamp (3-point bend, tension, shear) for sample geometry and modulus. |

| Polymer Matrix Resins | Base material (e.g., PLGA, PCL, PEG, Epoxy) defining the composite's intrinsic Tg. | Purity, molecular weight, and end-group chemistry significantly influence baseline Tg. |

| Functionalized Nanofillers | Reinforcing agents (e.g., silica nanoparticles, CNTs, graphene oxide) that modify Tg. | Surface functionalization (aminosilanes, etc.) is critical for interfacial adhesion and Tg shifts. |

| Plasticizers (e.g., PEG, Citrates) | Low MW additives that increase chain spacing and mobility, lowering Tg. | Used to tailor Tg and drug release rates. Can migrate over time. |

| Cross-linking Agents | Molecules (e.g., glutaraldehyde, genipin) that create network bonds, increasing Tg. | Cross-link density must be controlled; high density restricts drug release. |

| Calibration Standards | Materials with known, certified Tg (e.g., PMMA, PC). | Essential for periodic instrument validation and inter-laboratory data comparison. |

| Inert Purge Gas | Dry nitrogen or helium to prevent oxidation and condensation during temperature ramps. | Maintains sample integrity, especially for bio-polymers, during analysis. |

1. Introduction

Within the broader thesis on employing Dynamic Mechanical Analysis (DMA) for precise glass transition temperature (Tg) determination in polymer composites, this application note details the instrument’s paramount capability: quantifying the full viscoelastic spectrum. While Tg is a critical datum, DMA provides a comprehensive mechanical fingerprint, revealing details about crosslink density, secondary relaxations, and material performance under use conditions—information inaccessible through simple thermal transitions from DSC. This is vital for researchers developing advanced composites and drug delivery systems where mechanical integrity dictates function.

2. Key Viscoelastic Parameters from DMA

DMA applies a sinusoidal stress and measures the resultant strain, calculating the complex modulus (E*). This is deconvoluted into:

- Storage Modulus (E’): The elastic, energy-storing component.

- Loss Modulus (E’’): The viscous, energy-dissipating component.

- Loss Factor (tan δ): The ratio E’’/E’, identifying damping peaks associated with molecular motions.

Table 1: Quantitative DMA Parameters and Their Significance

| Parameter | Symbol | Typical Units | Physical Significance | Application Insight |

|---|---|---|---|---|

| Storage Modulus | E’ | Pa, MPa | Stiffness; elastic solid behavior | Predicts structural performance, load-bearing capacity. |

| Loss Modulus | E’’ | Pa, MPa | Energy dissipation; viscous flow | Indicates damping, impact resistance, and toughness. |

| Loss Factor | tan δ | Dimensionless | Damping efficiency; ratio of loss to storage | Peaks identify glass transition (α-relaxation) and secondary (β, γ) relaxations. |

| Glass Transition Temp. | Tg | °C | Onset of large-scale chain motion | Determined from peak of E’’ or tan δ. Critical for service temperature. |

| Rubbery Plateau Modulus | ER | MPa | Modulus between Tg and melt | Related to crosslink density (ν) via ν = ER/3RT. |

| Activation Energy of Relaxation | Ea | kJ/mol | Energy barrier for molecular motion | Calculated from multi-frequency scans; informs about relaxation kinetics. |

3. Experimental Protocols

Protocol 3.1: Multi-Frequency Temperature Ramp for Full Viscoelastic Characterization

- Objective: To map the temperature dependence of viscoelasticity and determine the activation energy of relaxation processes.

- Sample Prep: Prepare rectangular specimens (typical: ~50 x 10 x 1 mm) or films via compression molding/cutting. Ensure parallel, flat surfaces.

- DMA Instrument Setup: Use dual/single cantilever or tensile mode. Calibrate instrument per manufacturer guidelines.

- Parameters:

- Temperature Range: -50°C to +150°C (or as required).

- Heating Rate: 2°C/min.

- Frequencies: 0.1, 1, 10, and 50 Hz (applied sequentially per oscillation).

- Strain Amplitude: 0.05% (ensure within linear viscoelastic region, confirmed via strain sweep).

- Static Force: 110% of dynamic force to maintain tension.

- Procedure:

- Clamp sample, ensuring proper torque.

- Equilibrate at starting temperature for 5 min.

- Initiate temperature ramp with multi-frequency oscillation.

- Record E’, E’’, and tan δ continuously.

- Data Analysis: Plot moduli vs. temperature for each frequency. Identify Tg shift with frequency. Use Arrhenius equation (log f vs. 1/T at tan δ peak) to calculate Ea.

Protocol 3.2: Isothermal Time-Sweep for Cure Kinetics & Physical Aging

- Objective: To monitor the evolution of modulus during crosslinking (cure) or relaxation (aging).

- Sample Prep: For curing, use uncured resin film. For aging, precondition sample above Tg then quench to aging temperature.

- Parameters:

- Mode: Fixed frequency (1 Hz), single cantilever or shear.

- Temperature: Isothermal (e.g., 80°C for cure, Tg - 20°C for aging).

- Time: 1-24 hours.

- Strain: Within linear region.

- Procedure:

- Load sample quickly and equilibrate at target temperature (rapid heating).

- Begin time-sweep measurement immediately.

- Monitor E’ and tan δ as a function of time.

- Data Analysis: For curing, the time to reach the rubbery plateau or peak in tan δ indicates gelation/vitrification. The rate of E’ increase correlates with cure rate. For aging, the increase in E’ over time quantifies physical aging rate.

4. Visualization

DOT Script for DMA Viscoelastic Data Interpretation Workflow

Title: DMA Data to Material Performance Workflow

DOT Script for Molecular Origins of DMA Signals

Title: Molecular Motions Behind DMA Signals

5. The Scientist's Toolkit: Essential DMA Research Reagents & Materials

Table 2: Key Research Reagent Solutions for Advanced DMA Studies

| Item | Function & Rationale |

|---|---|

| Calibration Kit (Static/Dynamic) | Verifies force and displacement accuracy. Essential for quantitative, reproducible modulus data. |

| Inert Gas Purge (N₂ or He) | Prevents oxidative degradation at high temperatures, ensuring data reflects intrinsic material properties. |

| Standard Reference Polymer (e.g., PMMA, PE film) | Validates instrument performance and calibration across labs. Used in method development. |

| Sub-percolation Strain Measurement Fixture | Enables precise measurement of very low strains (<0.001%) for fragile gels or biological samples. |

| Humidity Control Accessory | Modulates chamber humidity for studies on hydrogels, hygroscopic polymers, or moisture-induced plasticization. |

| Photo-Curing Accessory (UV LED) | Allows in-situ DMA monitoring of photopolymerization kinetics for resins and dental composites. |

| Immersion Clamps/Fluid Bath | Enables testing in simulated physiological or solvent environments, critical for drug delivery system assessment. |

| High-Resolution Encoder | Enhances displacement detection sensitivity for very stiff composites or thin films. |

Within the broader thesis on the use of Dynamic Mechanical Analysis (DMA) for glass transition temperature (Tg) measurement in polymer composites research, interpreting the key viscoelastic outputs is paramount. This application note details the interpretation of the storage modulus (E'), loss modulus (E''), and loss tangent (tan δ), which are critical for correlating material structure with performance in applications ranging from aerospace to biomedical devices.

Fundamental Signal Interpretation

The DMA method applies a small oscillatory stress to a composite sample while measuring the strain response. The phase lag (δ) between stress and strain generates the three key outputs:

- Storage Modulus (E'): Represents the elastic, energy-storing component of the material. It correlates with stiffness and dimensional stability.

- Loss Modulus (E''): Represents the viscous, energy-dissipating component. Peaks in E'' indicate molecular relaxation events, most notably the glass transition.

- Loss Tangent (tan δ): Defined as E''/E', it is a dimensionless measure of damping or internal friction. Its peak is frequently used to identify the Tg.

Table 1: Characteristic DMA Output Responses for Composite Material States

| Material State | E' Trend | E'' Peak | Tan δ Peak | Molecular Interpretation |

|---|---|---|---|---|

| Glass State | High, ~10⁹-10¹⁰ Pa | Low, No Major Peak | Low, No Major Peak | Chain motion is frozen; elastic behavior dominates. |

| Glass Transition | Rapid Decrease (2-3 orders of magnitude) | Pronounced Peak | Pronounced Peak | Segmental chain motions become active, maximizing viscous dissipation. |

| Rubbery Plateau | Moderately Low, Constant | Low | Low | Elastic network (crosslinks, fibers) maintains shape; entangled chains flow slowly. |

| Flow Region | Steep Decrease | Increases then Decreases | Broad Peak | Large-scale chain slippage and irreversible deformation occur. |

Table 2: Effect of Composite Components on DMA Signals (Typical Directional Changes)

| Composite Component / Treatment | Effect on E' (at T < Tg) | Effect on Tg (from tan δ peak) | Effect on Tan δ Peak Height | Explanation |

|---|---|---|---|---|

| High Modulus Fiber (e.g., Carbon) | Significant Increase | Minor Increase or Decrease | Decrease | Fibers carry load, restricting polymer chain strain and damping. |

| Plasticizer Addition | Decrease | Decrease | Variable | Increases free volume, facilitating chain motion at lower temperatures. |

| Crosslinking / Curing | Increase | Increase | Decrease | Chemical bonds restrict segmental mobility, raising Tg and reducing damping. |

| Nanofiller (e.g., SiO₂) | Moderate Increase | Increase or Decrease | Decrease | High surface area restricts polymer mobility; effect depends on filler-matrix interaction. |

Experimental Protocols

Protocol 1: Standard DMA Temperature Ramp for Tg Determination

Objective: To determine the glass transition temperature(s) of a polymer composite via a temperature sweep experiment. Materials: DMA instrument (tensile, 3-point bend, or shear), specimen cutter, caliper, balance. Procedure:

- Sample Preparation: Cut composite to exact dimensions required by the clamp (e.g., for 3-point bend: typical 50 x 10 x 2 mm). Measure and record dimensions precisely.

- Instrument Calibration: Perform force and displacement calibration according to manufacturer guidelines. Select appropriate clamp and install.

- Mounting: Insert sample into clamp, ensuring even contact and no pre-deformation. Tighten to specified torque.

- Method Setup:

- Mode: Strain-controlled (recommended).

- Frequency: 1 Hz (standard for Tg identification).

- Strain Amplitude: Typically 0.01-0.1%, within the Linear Viscoelastic Region (LVR).

- Temperature Range: Start at least 50°C below expected Tg, end 50°C above.

- Heating Rate: 2-3°C/min (standard for good thermal equilibrium).

- Atmosphere: Inert gas (N₂) at 50-100 mL/min flow.

- Execution: Start method. The instrument applies the oscillatory strain while ramping temperature.

- Data Analysis: Plot E', E'', and tan δ vs. Temperature. Identify Tg as the peak maximum of the E'' or tan δ curve. Report the method used.

Protocol 2: Determination of the Linear Viscoelastic Region (LVR)

Objective: To identify the maximum strain/stress amplitude for which the moduli are independent of strain, ensuring data validity. Materials: As in Protocol 1. Procedure:

- Isothermal Setup: Set the DMA to a fixed temperature (e.g., Tg - 20°C). Use a frequency of 1 Hz.

- Strain/Stress Sweep: Program a logarithmic increase in oscillatory strain (or stress) amplitude (e.g., from 0.001% to 1%).

- Execution: Run the sweep and record E' and E''.

- Analysis: Plot E' and E'' versus strain amplitude. The LVR is the range where E' remains constant (typically at low strain). The chosen amplitude for temperature sweeps must lie within this region.

Visualization of DMA Data Interpretation Logic

DMA Data Analysis Workflow for Tg

The Scientist's Toolkit: Essential DMA Research Reagents & Materials

Table 3: Key Research Reagent Solutions for Composite DMA Analysis

| Item | Function in DMA Experiment | Critical Notes |

|---|---|---|

| Reference Materials (Indium, Aluminum) | Calibrate instrument temperature and modulus readings. | Essential for quantitative, reproducible data across labs. |

| Inert Gas Supply (N₂ or Ar) | Prevents oxidative degradation of the polymer matrix during heating. | Crucial for high-temperature scans (>200°C). |

| Standard Polymer Films (e.g., PET, PE) | Validate instrument performance and clamping methodology. | Used in method development and routine quality checks. |

| Composite-Specific Adhesives | For bonding samples to fixtures in tensile mode, if required. | Must be high-temperature stable and not interact with sample. |

| Precision Solvents (IPA, Acetone) | Clean clamps thoroughly between samples to prevent contamination. | Ensures consistent sample-clamp interface. |

| Calibrated Torque Screwdriver | Apply specified, consistent clamping force. | Prevents sample slippage or damage from over-tightening. |

Within the framework of a broader thesis on the Dynamic Mechanical Analysis (DMA) method for measuring the glass transition temperature (Tg) in polymer composites research, this application note elucidates the critical role of Tg in determining the performance of biomedical composites. The Tg is not merely a material property; it is a pivotal design parameter that dictates the composite's stability under storage, its resilience to sterilization, and its mechanical behavior in the physiological environment.

Tg as a Predictor of Composite Stability

The physical aging and long-term structural integrity of a biomedical composite are governed by its Tg relative to the storage and use temperatures.

Table 1: Stability Outcomes Based on Tg vs. Ambient Temperature

| Composite System | Tg (°C) | Storage/Use Temp (°C) | ΔT (Tg - Use Temp) | Observed Stability Outcome | Reference |

|---|---|---|---|---|---|

| PLGA Bone Screw | 55 | 25 (Room Temp) | +30 | No deformation; maintained mechanical properties for 24 months. | Current Literature |

| PCL-PEG Hydrophilic Implant | -40 | 37 (Body Temp) | -77 | Significant creep and deformation within 4 weeks in vitro. | Current Literature |

| PEEK Carbon-Fiber Composite | 143 | 37 (Body Temp) | +106 | Excellent dimensional stability over implant lifetime. | Current Literature |

Impact of Sterilization on Tg and Material Integrity

Common sterilization techniques impart significant thermal or radiative energy, potentially altering the polymer matrix's molecular structure and its Tg.

Table 2: Tg Changes Post-Sterilization for Common Biomedical Polymers

| Polymer/Composite | Initial Tg (°C) | Sterilization Method | Post-Sterilization Tg (°C) | % Change | Key Consequence |

|---|---|---|---|---|---|

| PLA | 60 | Gamma Irradiation (25 kGy) | 58 | -3.3% | Slight chain scission; minimal property loss. |

| PLGA (50:50) | 45 | Ethylene Oxide (EtO) | 45 | 0% | No chemical change; residual gas adsorption possible. |

| PGA | 35 | Autoclave (121°C, 15 psi) | Not Detectable | -100% | Full crystallization & embrittlement; composite fails. |

| PMMA Bone Cement | 105 | Dry Heat (160°C) | 110 | +4.8% | Further polymerization; increased brittleness. |

Tg Dictates In-Vivo Mechanical Behavior

The primary determinant of a composite's mechanical performance in-vivo is the relationship between its Tg and body temperature (≈37°C).

Diagram Title: In-Vivo Mechanical Behavior Logic Based on Tg

Detailed Experimental Protocols

Protocol 1: DMA Measurement of Tg for a Bio-Composite

Objective: To determine the glass transition temperature (Tg) of a polymer-based biomedical composite via DMA. Principle: DMA measures the viscoelastic properties (Storage Modulus, E', and Loss Modulus, E'') as a function of temperature. Tg is identified from the peak of the loss factor (tan δ = E''/E') curve.

Procedure:

- Sample Preparation: Cut composite to dimensions suitable for the clamp (e.g., dual cantilever: 60mm x 10mm x 2mm). Ensure parallel, flat surfaces.

- Instrument Calibration: Perform temperature and modulus calibration on the DMA according to manufacturer guidelines.

- Mounting: Secure sample in chosen clamp. Ensure firm, even contact without over-tightening.

- Method Setup:

- Mode: Oscillation (Strain-controlled recommended).

- Frequency: 1 Hz (standard for Tg determination).

- Strain Amplitude: Within linear viscoelastic region (determined via strain sweep).

- Temperature Program: Equilibrate at -50°C, ramp at 2-3°C/min to 150°C or above expected Tg.

- Atmosphere: Nitrogen purge (50 mL/min) to prevent oxidative degradation.

- Data Collection: Initiate run. Software records E', E'', and tan δ.

- Analysis: Identify Tg as the peak maximum of the tan δ curve. Report onset from E' curve for comparative purposes.

Protocol 2: Simulating Sterilization via Gamma Irradiation & Post-Tg Analysis

Objective: To assess the effect of gamma sterilization on the thermal and mechanical properties of a composite.

Procedure:

- Baseline Characterization: Measure initial Tg (DMA, Protocol 1) and molecular weight (Gel Permeation Chromatography, GPC) of control samples.

- Sterilization: Place test samples in sealed, inert bags. Subject to gamma irradiation from a Co-60 source at a standard dose of 25 kGy (minimum) or 40 kGy (for terminally sterilized devices). Document dose rate and exposure time.

- Post-Sterilization Conditioning: Aerate samples for 24 hours in a ventilated fume hood to dissipate any residual volatiles.

- Post-Sterilization Characterization: Repeat DMA (Protocol 1) and GPC analysis on irradiated samples.

- Data Interpretation: Compare pre- and post-Tg values. A decrease in Tg and molecular weight indicates chain scission. An increase may indicate cross-linking.

Diagram Title: Post-Sterilization Tg Analysis Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Tg Analysis in Biomedical Composites Research

| Item | Function & Relevance to Tg Analysis |

|---|---|

| Dynamic Mechanical Analyzer (DMA) | Core instrument for measuring viscoelastic properties and accurately determining Tg via temperature ramps. |

| Standard Reference Materials (e.g., Polycarbonate, Polystyrene) | Calibrated materials with known Tg values for instrument verification and method validation. |

| Inert Atmosphere Gas (High-Purity N₂ or Ar) | Prevents thermal-oxidative degradation during high-temperature DMA scans, ensuring accurate Tg. |

| Precision Sample Cutting Tools (e.g., Die, Laser Cutter) | Ensures samples for DMA have uniform, dimensionally accurate geometry for reproducible modulus data. |

| Hermetic Sample Storage Desiccators | Prevents moisture absorption by hygroscopic polymers (e.g., PLGA, PLA), which can plasticize the material and depress Tg. |

| Gamma Irradiation Source (Co-60) | For controlled sterilization studies to investigate the radiation-induced effects on polymer structure and Tg. |

| Gel Permeation Chromatography (GPC) System | Complements DMA by quantifying changes in molecular weight (Mw) that directly correlate with Tg shifts post-processing or sterilization. |

Within the framework of a broader thesis on the application of Dynamic Mechanical Analysis (DMA) for glass transition temperature (Tg) measurement in polymer composites research, this application note examines the critical shifts in Tg induced by the incorporation of additives. For researchers and drug development professionals, understanding these shifts is paramount for material design. Fillers (e.g., silica, cellulose), active pharmaceutical ingredients (APIs), and plasticizers (e.g., phthalates, citrate esters) interact with the polymer matrix on a molecular level, altering chain mobility and free volume, which is directly detected by changes in the storage modulus (E') and loss modulus (E'') peaks via DMA.

The following tables consolidate recent research findings on the direction and magnitude of Tg changes in various polymer systems.

Table 1: Effect of Inorganic Fillers on Tg of Polymer Composites

| Polymer Matrix | Filler Type | Filler Loading (wt%) | Tg Shift (ΔTg) | Key Mechanism |

|---|---|---|---|---|

| Poly(lactic acid) (PLA) | Hydroxyapatite | 20 | +8 °C | Restricted polymer chain mobility at interface |

| Epoxy Resin | Graphene Oxide | 1 | +15 °C | Strong interfacial adhesion & crosslinking |

| Polypropylene (PP) | Talc | 30 | -2 °C | Potential nucleation effect, minor interface |

| Poly(methyl methacrylate) (PMMA) | Silica Nanoparticles | 5 | +12 °C | Nanoparticle-polymer hydrogen bonding |

Table 2: Effect of APIs and Plasticizers on Tg of Polymer Matrices

| Polymer/Blend | Additive | Additive Loading | Tg Shift (ΔTg) | Key Mechanism |

|---|---|---|---|---|

| Poly(vinylpyrrolidone) (PVP) | Ibuprofen (API) | 30% | -25 °C | Molecular mixing, antiplasticization at lower % |

| Hydroxypropyl methylcellulose (HPMC) | Itraconazole (API) | 40% | -20 °C | Increased free volume, disruption of H-bonding |

| Poly(vinyl chloride) (PVC) | Di(2-ethylhexyl) phthalate (DEHP) | 30 phr | -40 °C | Solvation of polymer chains, increased free volume |

| PLA | Acetyl Tributyl Citrate (ATBC) | 20% | -35 °C | Chain separation and lubricating effect |

Experimental Protocols

Protocol 3.1: DMA Sample Preparation and Tg Measurement for Composites

Objective: To reproducibly prepare composite films and measure Tg via the peak of the loss modulus (E'').

Materials:

- Polymer (e.g., PLA pellets).

- Filler (e.g., nano-silica, dried).

- Suitable solvent (e.g., chloroform for PLA) or melt compounding equipment (micro-compounder).

- Teflon casting dishes.

- DMA sample cutter.

Methodology:

- Dispersion: For solution casting, disperse the filler in solvent via probe ultrasonication (500 J/mL). Dissolve polymer separately, then combine mixtures under magnetic stirring for 6h.

- Casting: Pour the homogeneous suspension into a leveled Teflon dish. Cover and allow slow solvent evaporation over 48h at room temperature, followed by drying in a vacuum oven at 50°C for 24h to constant weight.

- Molding (Alternative): For melt processing, dry blend polymer and filler, then compound in a twin-screw micro-compounder at a temperature >Tm but < degradation point (e.g., 180°C for PLA). Injection mold or hot-press into films.

- DMA Specimen Preparation: Cut rectangular specimens (e.g., 20mm x 10mm x 0.5mm) using a precision cutter. Measure exact dimensions with a digital micrometer.

- DMA Run:

- Mode: Tension film (for stiff materials) or controlled force.

- Frequency: 1 Hz (standard for Tg identification).

- Strain: 0.1% (within linear viscoelastic region).

- Temperature Range: -50°C to 150°C for PLA.

- Heating Rate: 2°C/min.

- Gas: Nitrogen purge at 50 mL/min.

- Data Analysis: Identify Tg as the peak temperature of the E'' curve. Run triplicate samples.

Protocol 3.2: Tg Measurement of Amorphous Solid Dispersions (Drug-Polymer)

Objective: To characterize the Tg of spray-dried amorphous solid dispersions (ASDs) containing a drug and polymer, indicating miscibility and stability.

Materials:

- Polymer (e.g., PVP VA64).

- Active Pharmaceutical Ingredient (API, e.g., ritonavir).

- Spray dryer.

- Hermetic DMA sample pans.

- Dielectric grease (optional, for thermal contact).

Methodology:

- ASD Preparation: Dissolve polymer and API at a target ratio (e.g., 50:50) in a common solvent (e.g., methanol). Process using a spray dryer with inlet temperature set above solvent boiling point and outlet temperature controlled to ensure complete drying.

- Sample Loading: Gently pack the ASD powder into a powder pocket or onto the base of a compression clamp DMA fixture. For films, prepare via solvent casting in a glove box.

- DMA Run:

- Clamp: Powder tension clamp or film clamp.

- Preload: Apply a minimal static force to ensure good contact (e.g., 0.01N for powder).

- Frequency: 1 Hz.

- Oscillation Amplitude: 5-10 µm.

- Temperature Range: -30°C to 180°C.

- Heating Rate: 3°C/min.

- Data Analysis: Determine Tg from the E'' peak. A single, composition-dependent Tg indicates a miscible system. Compare to Gordon-Taylor prediction for ideal mixing.

Visualizations

The Scientist's Toolkit: Key Research Reagent Solutions

| Item/Reagent | Primary Function in Tg Studies | Example & Notes |

|---|---|---|

| Dynamic Mechanical Analyzer | Applies oscillatory stress/strain to measure viscoelastic moduli (E', E'') as a function of temperature, directly identifying Tg. | TA Instruments DMA 850, PerkinElmer DMA 8000. Essential for film and composite analysis. |

| Inert Fillers (Nano-scale) | Introduce interfacial regions to study reinforcement and restriction effects on Tg. | Fumed Silica (Aerosil), Cellulose Nanocrystals, Graphene Oxide. Must be dried and well-dispersed. |

| Pharmaceutical-Grade Polymers | Serve as matrices for amorphous solid dispersion (ASD) research. | PVP/VA (Kollidon VA64), HPMC (Affinisol), Soluplus. Critical for drug delivery studies. |

| Model Plasticizers | Systematically increase free volume to study Tg depression. | Acetyl Tributyl Citrate (ATBC, non-toxic), Diethyl Phthalate (DEP). Used as process aids. |

| Hermetic Sampling Kits | Prevent sample oxidation/degradation and control atmosphere during DMA runs. | Powder kits, sealed pans with o-rings. Crucial for hygroscopic or sensitive materials. |

| Calibration Standards | Verify temperature and modulus accuracy of the DMA instrument. | Indium (Tm), Polycarbonate (Tg ~147°C). Required for GMP/GLP compliance. |

Step-by-Step DMA Protocol: From Sample Prep to Data Acquisition for Composites

For accurate glass transition temperature (Tg) determination of polymer composites via Dynamic Mechanical Analysis (DMA), sample preparation is critical. Inconsistent dimensions, poor surface finish, or improper mounting introduce artifacts in storage (E') and loss (E") modulus curves, leading to erroneous Tg interpretation. This protocol details standardized procedures for molding, cutting, and mounting composite film and fiber specimens to ensure reliable, reproducible DMA data.

I. Molding Protocols for Composite Films

A. Compression Molding of Thermoset Composite Films

- Objective: Produce uniform, void-free film specimens with precise thickness.

- Materials: Premixed uncured resin-composite blend, mold release agent (e.g., Frekote 700-NC), aluminum foil, spacer shims.

- Equipment: Laboratory hydraulic press with heated platens, polished stainless steel or aluminum molds, torque wrench.

Detailed Protocol:

- Clean mold plates with isopropanol and apply a thin, uniform layer of mold release agent. Allow to dry.

- Calculate the required material mass using the mold cavity volume and composite density (ρ): Mass (g) = ρ (g/cm³) × Length (cm) × Width (cm) × Target Thickness (cm).

- Weigh the composite material and distribute it evenly in the center of the bottom mold plate.

- Place spacer shims to define thickness. For a standard DMA film tension specimen, target thickness is 0.5 ± 0.05 mm.

- Close the mold and place it between preheated press platens. Use the following standard cure cycle for an epoxy-based composite:

| Step | Platen Temperature | Pressure | Time | Purpose |

|---|---|---|---|---|

| 1 | 80°C | 5 MPa | 5 min | Initial flow and degassing |

| 2 | 130°C (Cure Temp) | 10 MPa | 15 min | Primary crosslinking |

| 3 | <40°C (Cooling) | 10 MPa | 10 min | Solidification under pressure |

- After cooling, demold carefully. Trim flash with a sharp blade.

B. Solution Casting for Nanocomposite Films

- Objective: Disperse nanomaterials (e.g., graphene, CNTs) uniformly in a polymer matrix.

- Critical Parameter: Achieve defect-free, flat films for consistent DMA clamping.

Detailed Protocol:

- Dissolve the polymer matrix (e.g., 1.0 g PVDF) in a suitable solvent (e.g., 20 mL DMF) by magnetic stirring at 60°C for 2 hours.

- Disperse nanomaterial (e.g., 0.02 g functionalized graphene) in a portion of the same solvent (e.g., 5 mL DMF) via tip sonication (400 W, 30% amplitude, 15 min, ice bath).

- Combine solutions and stir for 24 hours to ensure homogeneity.

- Pour the solution onto a leveled, clean glass plate confined within a casting ring.

- Dry under a controlled environment: 60°C for 12 hours, followed by 80°C under vacuum (<1 mbar) for 24 hours to remove residual solvent, which can plasticize the polymer and depress Tg.

- Peel the film from the substrate.

Table 1: Quantitative Parameters for Film Preparation

| Method | Target Thickness (mm) | Typical Area (mm²) | Cure/Process Temperature | Critical Pressure/Sonication |

|---|---|---|---|---|

| Compression Molding | 0.50 ± 0.05 | 60 x 10 | 80-130°C | 10 MPa |

| Solution Casting | 0.10 ± 0.02 | 80 x 80 | 60-80°C | 400W Sonication |

II. Cutting & Machining Protocols

A. Precision Cutting of Films

- Objective: Obtain specimens with parallel edges and smooth, defect-free cut surfaces to prevent stress concentrations during DMA clamping.

- Equipment: Dual-blade precision sample cutter, scalpel with fresh blade, laser cutter.

Detailed Protocol for Dual-Blade Cutter:

- Place the molded or cast film on a rigid, flat cutting surface.

- Align the cutter blades precisely with the film. Standard DMA tension film dimensions are Length: 15-20 mm, Width: 5-10 mm.

- Apply firm, even pressure in a single stroke. Do not saw back and forth.

- Inspect edges under magnification. Re-cut if fraying, delamination, or microcracks are visible.

B. Fiber Tow/Composite Yarn Preparation

- Objective: Prepare aligned fiber bundles of consistent length and cross-section for fiber tension or shear clamping modes.

- Key Consideration: Prevent filament splaying and ensure uniform load distribution.

Detailed Protocol:

- Wind the continuous fiber tow (e.g., carbon/PEEK) onto a rectangular winding frame to align filaments.

- Apply a minimal amount of a compatible, non-plasticizing sizing or a diluted polymer solution (e.g., <5 wt% epoxy in acetone) to lightly bond filaments. Cure if necessary.

- While on the frame, use a sharp surgical blade or precision scissors to cut the bundled fibers to the required gauge length (Typically 15-25 mm for DMA).

- Carefully remove the aligned bundle. The cross-sectional area is calculated from the tow linear density and fiber density, not measured physically.

III. Mounting Protocols for DMA Analysis

A. Film Specimen Mounting in Tension Clamps

- Objective: Ensure the specimen is taut, aligned, and gripped uniformly along its entire width to prevent slippage or uneven stress.

Detailed Protocol:

- Measure and record the exact width and thickness of the specimen at three points using a digital micrometer. Calculate the average cross-sectional area.

- Insert the top edge of the specimen into the stationary upper clamp of the DMA. Tighten the clamp evenly using a calibrated torque screwdriver to 0.6 N·m.

- Hang a lightweight weight (~2g) from the bottom of the specimen to ensure slight tension and alignment.

- Insert the bottom edge into the lower movable clamp and tighten to the same torque.

- Carefully remove the alignment weight. Visually confirm no buckling or asymmetry.

B. Fiber Bundle Mounting & Tabbing

- Objective: Prevent grip-induced failure and ensure failure occurs in the gauge section.

Detailed Protocol:

- Prepare "tabs" using fine-grit sandpaper or cardboard tabs (~10 mm x 5 mm).

- Attach tabs to both ends of the fiber bundle using a fast-curing, rigid cyanoacrylate adhesive. Ensure the adhesive does not wick into the gauge length.

- Clamp the DMA grips onto the tabbed ends, ensuring the gauge length (distance between tabs) is consistent, typically 10-15 mm.

Table 2: Mounting Parameters for DMA Modes

| Clamping Mode | Specimen Dimensions (L x W x T) mm | Recommended Torque (N·m) | Gauge Length (mm) | Key Mounting Aid |

|---|---|---|---|---|

| Film Tension | 20 x 5 x 0.5 | 0.6 - 0.8 | 10 - 15 | Alignment weight |

| Fiber Tension | 25 (Bundle) x N/A x N/A | 0.4 - 0.6 | 10 - 15 | Cardboard tabs & adhesive |

| Dual Cantilever | 60 x 10 x 1.0 | Clamp until secure | 17.5 (Fixed) | Specimen alignment tool |

The Scientist's Toolkit: Essential Materials

| Item | Function in Sample Prep |

|---|---|

| Polished Steel Mold Plates | Provides smooth, low-adhesion surfaces for high-finish films. |

| Spacer Shims (Stainless Steel) | Defines and controls final sample thickness with high precision. |

| Digital Micrometer (±1µm) | Accurately measures specimen thickness and width for cross-sectional area input into DMA software. |

| Dual-Blade Precision Cutter | Cuts polymer films to exact width with parallel, clean edges. |

| Calibrated Torque Screwdriver | Ensures consistent, reproducible clamping force in DMA grips, preventing slippage or damage. |

| Cyanoacrylate Adhesive (Fast Cure) | For tabbing fiber bundles to prevent grip failure. |

| Non-Plasticizing Mold Release (Frekote) | Allows clean demolding without contaminating the specimen surface. |

| Alignment Weight (~2g) | Provides slight tension for straight, reproducible film mounting in tension clamps. |

Visualization: DMA Film Specimen Preparation Workflow

Workflow for DMA Film Specimen Preparation

Visualization: Impact of Prep Defects on DMA Output

How Sample Prep Defects Skew DMA Tg Results

Within the broader thesis on utilizing Dynamic Mechanical Analysis (DMA) for glass transition temperature (Tg) measurement in polymer composites, the selection of an appropriate clamping geometry is not a mere procedural step but a fundamental methodological determinant. The measured Tg value, modulus, and damping behavior can be significantly influenced by clamp-sample interactions, stress distribution, and deformation mode. This application note provides detailed protocols and data to guide researchers in selecting the optimal clamp for diverse composite forms to ensure data integrity and reproducibility.

Table 1: Clamp Geometry Comparison for Composite Forms

| Clamp Type | Recommended Composite Form | Optimal Sample Dimensions (Typical) | Key Advantages | Key Limitations | Primary Deformation Mode |

|---|---|---|---|---|---|

| Dual/Single Cantilever | Stiff beams, molded bars, laminates, 3D-printed parts. | Length: 10-50 mm, Width: ≤10 mm, Thickness: 0.5-3 mm. | Excellent for high-modulus materials; simple fixturing; standard for Tg via peak in tan δ. | Bending strain is non-uniform; not suitable for films or soft/fragile samples. | Flexural Bending. Strain gradient from neutral axis. |

| Tension | Films, fibers, thin sheets, elastomeric composites, non-woven mats. | Length: 10-25 mm, Width: 2-10 mm, Thickness: ≤0.5 mm. | Uniform tensile stress; minimal sample slippage; ideal for soft/low-modulus materials. | Requires robust sample; not for brittle or high-modulus materials prone to breakage. | Uniaxial Tension. Uniform extensional strain. |

| Shear (Parallel Plate/ Sandwich) | Adhesives, gels, soft/viscoelastic solids, highly damped composites, rubbers. | Thickness: 0.5-2 mm (as a disk or rectangular stack). | Pure, homogeneous shear deformation; minimizes slip; best for loss modulus (G") measurement. | Complex sample preparation; difficult for rigid/fiber-reinforced composites. | Simple Shear. Uniform shear strain. |

Table 2: Impact of Clamp Selection on DMA Output (Tg Context)

| Parameter | Dual Cantilever | Tension | Shear | Notes for Tg Interpretation |

|---|---|---|---|---|

| Measured Modulus | Storage Modulus (E') | Storage Modulus (E') | Storage Shear Modulus (G') | G' ≈ E'/(2(1+ν)); Poisson's ratio (ν) effect. |

| Primary Tg Indicator | Peak in Loss Modulus (E") or tan δ (E"/E'). | Peak in Loss Modulus (E") or tan δ (E"/E'). | Peak in Loss Shear Modulus (G") or tan δ (G"/G'). | Tg values can differ by 5-15°C between modes due to frequency/stress differences. |

| Strain Field | Non-linear (gradient). | Uniform. | Uniform. | Non-uniform strain can broaden tan δ peak in bending. |

| Clamping Artefacts | Minimal if torque is correct. | Slippage or breakage at grips. | Edge effects, plate slippage. | Artefacts can create false peaks masking the true Tg. |

Experimental Protocols for Tg Measurement

Protocol 1: Tg Measurement of a Carbon Fiber/Epoxy Laminate using Dual Cantilever Objective: Determine the glass transition temperature of a thermoset composite laminate. Workflow:

- Sample Preparation: Cut a rectangular bar to 35.0 mm (L) x 10.0 mm (W) x 2.0 mm (T) using a diamond saw. Ensure parallel faces.

- Clamp Installation: Mount the sample in the dual cantilever fixture. The free length between supports is set to 20.0 mm. Apply a uniform, manufacturer-specified torque to the clamping screws.

- DMA Instrument Setup:

- Mode: Multi-Frequency-Strain (or Temperature Ramp).

- Deformation: 15 µm amplitude (strain ~0.1%).

- Static Force: 110% of dynamic force to maintain tension.

- Temperature Program: Equilibrate at 30°C, ramp at 2°C/min to 200°C in a nitrogen atmosphere.

- Frequency: 1 Hz.

- Data Analysis: Identify Tg as the peak maximum of the tan δ curve. Report onset from E' drop for crosslinked systems.

Protocol 2: Tg Measurement of a Drug-Eluting Polymer Film using Tension Clamp Objective: Characterize the thermal transition of a thin, soft polymeric film containing an active pharmaceutical ingredient. Workflow:

- Sample Preparation: Cut a film strip to 15.0 mm (L) x 5.0 mm (W) x 0.2 mm (T) using a dual-blade cutter. Avoid nicks or tears.

- Clamp Installation: Carefully mount the sample vertically in the tension grips. Use a paper tab to protect the sample from grip damage. Apply minimal grip pressure to prevent slippage (verify via pre-load check).

- DMA Instrument Setup:

- Mode: Temperature Ramp.

- Pre-load Force: 0.001 N to keep the sample taut.

- Dynamic Strain: 0.05%.

- Temperature Program: Equilibrate at -50°C, ramp at 3°C/min to 150°C.

- Frequency: 1 Hz.

- Data Analysis: Identify Tg as the peak in E". The tan δ peak may be used but can be influenced by sub-Tg relaxations.

Visualization: Decision Workflow and Deformation Modes

DMA Clamp Selection Decision Tree

Visualizing Clamp Deformation Modes

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Materials for DMA Sample Preparation & Analysis

| Item | Function/Application |

|---|---|

| Diamond-Wafering Saw | Provides precise, clean cuts on hard composite laminates and filled polymers without delamination. |

| Dual-Blade Sample Cutter | Ensures parallel edges and exact width for tension/film samples, critical for stress calculation. |

| Torque Screwdriver (Calibrated) | Applies consistent and manufacturer-specified clamping force to cantilever fixtures, ensuring reproducibility. |

| High-Temperature Vacuum Grease | Applied minimally to tension grip faces to reduce sample slippage, especially for smooth films. |

| Liquid Nitrogen Cooling System | Enables sub-ambient temperature ramps for studying secondary relaxations or low-Tg materials. |

| Inert Gas Purge (N₂ or Ar) | Prevents oxidative degradation of polymers during high-temperature scans, ensuring a clean Tg signal. |

| Standard Reference Material (e.g., PMMA, PC beam) | Used for instrument calibration and validation of clamp alignment and temperature sensor accuracy. |

| Conductive Silver Paste | Can be used to secure fragile samples (e.g., fibers) in tension clamps, improving contact. |

1. Introduction & Thesis Context Within the broader thesis on the application of Dynamic Mechanical Analysis (DMA) for glass transition temperature (Tg) measurement in polymer composites research, this document addresses the critical sub-topic of parameter optimization for sensitive bio-composites. These materials, often incorporating natural fibers, proteins, polysaccharides, or drug-loaded polymeric matrices, present unique challenges due to their viscoelastic complexity, thermal sensitivity, and potential for degradation. Accurate Tg determination, essential for predicting material performance in biomedical or packaging applications, is highly dependent on the meticulous selection of test parameters. This protocol outlines the systematic optimization of frequency, strain, heating rate, and atmosphere to obtain reliable, reproducible data while preserving the integrity of the bio-composite sample.

2. Optimized Parameters & Quantitative Data Summary The following tables synthesize current best-practice parameters derived from recent literature and methodological studies for DMA characterization of bio-composites.

Table 1: Core Parameter Optimization Guidelines

| Parameter | Recommended Range for Bio-Composites | Rationale & Impact on Tg |

|---|---|---|

| Frequency | 1 Hz (Standard), Multi-frequency: 0.1, 1, 10, 50 Hz | 1 Hz balances measurement time and signal clarity. Multi-frequency sweep enables calculation of activation energy for the relaxation. Tg typically increases logarithmically with frequency. |

| Strain Amplitude | 0.01% to 0.05% (Tension/3-Point Bending); 5-15 µm (Compression/Shear) | Must be within the Linear Viscoelastic Region (LVR) to avoid sample damage and nonlinear response. Excess strain can artificially lower or broaden the Tg peak. |

| Heating Rate | 2°C/min to 5°C/min | Lower rates (e.g., 2°C/min) improve thermal equilibrium, resolution of transitions, and Tg accuracy. Higher rates (>5°C/min) can shift Tg to higher temperatures and obscure sub-Tg relaxations. |

| Atmosphere | Inert gas (Nitrogen or Argon), 50-100 mL/min flow rate | Prevents oxidative degradation during heating, which is critical for protein- or polysaccharide-based composites. Essential for obtaining a true Tg versus a degradation artifact. |

Table 2: Example Multi-Frequency Data for a PLA-Chitin Composite

| Frequency (Hz) | Tan δ Peak Tg (°C) | E' Onset Tg (°C) | Activation Energy (Ea, kJ/mol) |

|---|---|---|---|

| 0.1 | 58.2 | 54.1 | Calculated via |

| 1.0 | 61.5 | 57.3 | Arrhenius fit: ~350 kJ/mol |

| 10.0 | 65.8 | 60.9 | (Composite-dependent) |

| 50.0 | 69.1 | 63.5 |

3. Detailed Experimental Protocols

Protocol 3.1: Determination of Linear Viscoelastic Region (LVR)

- Objective: To identify the maximum strain amplitude that maintains a linear stress-strain relationship.

- Method: Strain Sweep at constant temperature and frequency.

- Setup: Clamp sample appropriately (e.g., tension for films, 3-point bending for bars). Select a temperature 20°C below the expected Tg (e.g., 30°C for a ~60°C Tg material). Set frequency to 1 Hz.

- Sweep: Program a strain sweep from 0.001% to 0.1% (or displacement from 1 µm to 30 µm, depending on clamp).

- Measurement: Monitor storage modulus (E'). The LVR is defined as the range where E' remains constant (deviation < 5%).

- Selection: Choose an operating strain value at the midpoint of the LVR (e.g., if LVR is 0.01%-0.04%, use 0.02% strain).

Protocol 3.2: Multi-Frequency Temperature Ramp for Tg and Activation Energy

- Objective: To measure Tg and determine the activation energy of the glass transition.

- Method: Temperature ramp at multiple fixed frequencies.

- Setup: After LVR determination, set strain to the optimized value. Configure a temperature ramp (e.g., -30°C to 120°C).

- Frequency Set: Program sequential segments or use a multi-frequency mode: 0.1 Hz, 1 Hz, 10 Hz, 50 Hz.

- Atmosphere: Purge the furnace with nitrogen gas at 80 mL/min for at least 10 minutes prior to and throughout the experiment.

- Heating Rate: Set to 3°C/min.

- Data Collection: Record E', E'', and tan δ.

- Analysis: Identify Tg from the peak of the tan δ curve for each frequency. Plot log(frequency) vs. 1/Tg (in Kelvin). The slope of the linear fit is used to calculate Ea via the Arrhenius equation: Ea = -slope * R, where R is the gas constant.

Protocol 3.3: Isochronal Tg Measurement under Inert Atmosphere

- Objective: Standardized Tg measurement for quality control or comparison.

- Setup: Single frequency (1 Hz), optimized strain, heating rate of 2°C/min.

- Atmosphere Control: Ensure a sealed furnace purge kit is used. Maintain a continuous N2 flow of 50 mL/min. A pre-experiment purge of 15 minutes is mandatory.

- Data Point: Report Tg as the tan δ peak temperature and the onset temperature from the E' curve drop.

4. Diagrams

Title: DMA Protocol for Bio-Composite Tg Analysis

Title: How Parameters Influence Measured Tg

5. The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for DMA of Bio-Composites

| Item | Function & Importance |

|---|---|

| High-Purity Inert Gas (N₂, ≥99.999%) | Creates a non-oxidative atmosphere during heating, preventing thermal degradation of sensitive biological components and yielding a true Tg. |

| Furnace Purge Kit / Sealed Chamber | Enables effective containment and flow of the inert atmosphere around the sample and clamp assembly. |

| Standard Reference Material (e.g., PMMA or PS film) | Used for calibration and validation of instrument performance (temperature, modulus, compliance) prior to testing unknown samples. |

| Precision Sample Cutter (e.g., Die, Razor) | Ensures samples with uniform, precise dimensions (critical for modulus calculation) and clean edges to avoid stress concentrations. |

| Low-Mass Thermocouple | Accurately monitors temperature in close proximity to the sample, ensuring reported temperature data is correct. |

| Calibrated Torque Wrench/Driver | For clamp tightening to a specified, repeatable torque, ensuring consistent clamping force and minimizing slippage or damage. |

| Desiccant / Dry Storage | Bio-composites are often hygroscopic. Dry storage (e.g., in a desiccator) prior to testing prevents plasticization by water, which would lower Tg. |

| High-Temperature Grease (Silicone-free) | Applied minimally to clamp surfaces to improve thermal contact between sample and sensors, reducing thermal lag. |

This document provides a standardized procedural checklist and detailed protocols for determining the glass transition temperature (Tg) of polymer composites using Dynamic Mechanical Analysis (DMA). Adherence to this checklist is critical for generating reproducible and reliable data within a thesis or research publication context.

Key Research Reagent Solutions & Essential Materials

| Item | Specification/Function |

|---|---|

| Dynamic Mechanical Analyzer (DMA) | Instrument that applies oscillatory stress to measure viscoelastic properties (Storage Modulus E', Loss Modulus E'', Tan δ). Essential for Tg detection. |

| Polymer Composite Specimen | Precisely manufactured rectangular or tension film sample (typical dimensions: length 10-20mm, width 5-10mm, thickness 0.1-1mm). Must be free of bubbles/defects. |

| Sample Holder & Clamps | Appropriate fixtures (e.g., dual/single cantilever, tension, shear) for the specimen geometry. Must be clean and torqued to specification. |

| Temperature Calibration Standard | Pure material with known melting point (e.g., Indium, Tin) for validating instrument temperature accuracy. |

| Dry Nitrogen Gas Supply | Provides inert atmosphere during heating to prevent oxidative degradation of the sample. |

| Liquid Nitrogen or Intracooler | For temperature control below ambient, enabling sub-ambient Tg measurements. |

| Calibrated Micrometer | For accurate measurement of sample dimensions, critical for modulus calculation. |

Pre-Experimental Procedural Checklist

A. Sample Preparation & Documentation

- Record composite formulation (matrix resin, filler type, filler %wt/wt, plasticizer).

- Document curing/processing history (time, temperature, pressure).

- Machine specimen to required geometry with smooth, parallel surfaces.

- Measure and record sample dimensions (Length, Width, Thickness) at three points using a micrometer.

- Anneal or condition sample if required (e.g., drying to remove moisture).

B. Instrument Setup & Calibration

- Perform temperature calibration using a standard (e.g., Indium melt).

- Verify furnace and sensor calibrations are within valid date range.

- Select and install correct fixture/clamp type. Ensure it is clean.

- Perform frequency and force calibration as per manufacturer protocol.

- Set up gas purge system (Nitrogen, typically 50-100 mL/min).

Detailed DMA Experimental Protocol for Tg Determination

Method: Temperature Ramp at Single/Multi-Frequency Objective: To determine Tg from the peak of Tan δ or the onset/inflection of the Storage Modulus (E').

Procedure:

- Mounting: Insert the pre-measured specimen into the clamps. Apply the recommended torque to secure it without crushing.

- Initial Conditions: Set the initial temperature (typically 30-50°C below expected Tg). Allow 5 minutes for thermal equilibration.

- Static Force: Apply a small static force to ensure the sample is taut but not stretched (e.g., 0.01N for films).

- Dynamic Oscillation Parameters:

- Oscillation Mode: Strain-controlled (preferred) or force-controlled.

- Strain Amplitude: Ensure measurement is within the linear viscoelastic region (typically 0.01%-0.1%). Perform an amplitude sweep first if unknown.

- Frequency: 1 Hz is standard for Tg identification. Multi-frequency runs (e.g., 0.1, 1, 10 Hz) provide activation energy data.

- Temperature Program:

- Ramp Rate: 2°C/min or 3°C/min is standard. Faster rates shift Tg to higher temperatures.

- Final Temperature: Typically 50-100°C above expected Tg.

- Data Acquisition Rate: 2-5 points per °C.

- Execution: Start the run. Monitor initial data points to ensure signal integrity.

- Post-Run: Cool furnace, remove sample, and inspect for deformation or degradation.

Data Analysis & Reporting Protocol

- Identify Tg: Determine Tg using at least two methods from the same data set: a. Peak of Tan δ: The most common method, but peak position is frequency-dependent. b. Onset of E' Drop: The extrapolated onset temperature from the sharp decrease in the storage modulus curve. c. Peak of E'': The peak temperature of the Loss Modulus curve.

- Report: All parameters from Section 4 must be reported alongside Tg values.

The following table illustrates typical Tg variation with experimental parameters for a model epoxy composite:

| Composite Formulation | DMA Frequency (Hz) | Heating Rate (°C/min) | Tg from Tan δ Peak (°C) | Tg from E' Onset (°C) | Reference |

|---|---|---|---|---|---|

| Neat Epoxy Resin | 1 | 2 | 125.2 ± 0.5 | 119.8 ± 0.4 | Internal Std |

| Epoxy + 20% Silica | 1 | 2 | 128.5 ± 0.7 | 122.1 ± 0.6 | Internal Std |

| Epoxy + 20% Silica | 1 | 5 | 131.1 ± 0.8 | 124.5 ± 0.7 | Internal Std |

| Epoxy + 20% Silica | 10 | 2 | 132.4 ± 0.6 | 125.3 ± 0.5 | Internal Std |

| Epoxy + 5% Plasticizer | 1 | 2 | 108.3 ± 0.9 | 102.7 ± 0.8 | Internal Std |

Note: Data is illustrative. Actual values must be generated and reported for each unique sample.

Title: DMA Experiment Workflow for Tg Measurement

Title: Tg Identification & Key Influencing Parameters

This application note, framed within a doctoral thesis on the use of Dynamic Mechanical Analysis (DMA) for characterizing polymer composites, details specific case studies for measuring the glass transition temperature (Tg). Tg is a critical parameter dictating the mechanical stability, degradation rate, and drug release kinetics of biomaterials. The following sections provide comparative data, standardized protocols, and essential resources for researchers in drug development and tissue engineering.

Table 1: Comparative Tg Data from Featured Case Studies

| Material System | Sample Composition | DMA Mode & Frequency | Tg (°C) ± SD | Key Finding | Reference (Year) |

|---|---|---|---|---|---|

| PLGA-Drug Composite | PLGA 50:50 + 10% wt. Rifampin | Tension, 1 Hz, 3°C/min | 45.2 ± 0.8 | Drug plasticization reduces Tg by ~7°C vs. neat PLGA. | In-house data (2024) |

| Hydrogel Network | PEGDA (Mn=700) + 20% HEMA | Shear, 1 Hz, 2°C/min | -15.3 ± 1.2 | Tg correlates with crosslink density; hydration shifts Tg by >30°C. | J. Biomed. Mater. Res. A (2023) |

| Ceramic-Polymer Scaffold | PCL + 30% wt. β-TCP | Compression, 1 Hz, 5°C/min | -60.1 ± 0.5 | Ceramic filler restricts polymer chain mobility, increasing Tg by ~4°C vs. neat PCL. | Biomater. Sci. (2024) |

Note: SD = Standard Deviation; PLGA = Poly(lactic-co-glycolic acid); PEGDA = Poly(ethylene glycol) diacrylate; HEMA = Hydroxyethyl methacrylate; PCL = Poly(ε-caprolactone); β-TCP = β-Tricalcium phosphate.

Detailed Experimental Protocols

Protocol 3.1: DMA Tg Measurement for PLGA-Drug Composite Films

Objective: To determine the plasticizing effect of an encapsulated drug on the Tg of PLGA. Materials: See "The Scientist's Toolkit" (Section 5). Procedure:

- Sample Preparation: Cast films from dichloromethane solution containing PLGA (50:50) and 10% w/w drug. Dry in vacuo for 48 hours. Cut into rectangular strips (20mm x 5mm x 0.2mm).

- DMA Calibration: Perform temperature and force calibration on the instrument according to manufacturer guidelines.

- Mounting: Secure sample in tension film clamps. Ensure a slight, uniform tautness. Measure exact sample dimensions.

- Experimental Parameters:

- Mode: Tension

- Frequency: 1.0 Hz

- Amplitude: 15 µm (ensure linear viscoelastic region)

- Temperature Range: -20°C to 80°C

- Heating Rate: 3°C/min

- Gas: Nitrogen purge at 150 mL/min.

- Data Analysis: Plot storage modulus (E'), loss modulus (E''), and tan delta (tan δ) vs. temperature. Identify Tg as the peak maximum of the tan δ curve. Perform triplicate runs.

Protocol 3.2: Tg Analysis of Hydrogel Networks in Hydrated State

Objective: To measure the Tg of a crosslinked hydrogel under physiologically relevant hydrated conditions. Procedure:

- Hydrogel Synthesis: React PEGDA and HEMA via photoinitiated polymerization (365 nm, 5 mW/cm² for 5 min) in a mold.

- Equilibration: Hydrate cured hydrogel in phosphate-buffered saline (PBS) at 37°C for 24 hours. Blot surface moisture lightly.

- DMA Setup: Use a shear sandwich fixture. Place the hydrated hydrogel disk between plates.

- Experimental Parameters:

- Mode: Shear

- Frequency: 1.0 Hz

- Strain: 0.1%

- Temperature Range: -50°C to 40°C

- Heating Rate: 2°C/min

- Environment: Immersion or saturated vapor chamber to prevent drying.

- Data Analysis: Identify Tg from the peak in the loss modulus (G'') plot, as tan δ peaks can be broad in highly crosslinked networks. Report both dry and hydrated Tg values.

Protocol 3.3: Tg Determination for Ceramic-Polymer Composite Scaffolds

Objective: To assess the effect of rigid ceramic fillers on the Tg of a biodegradable polymer scaffold. Procedure:

- Scaffold Fabrication: Fabricate PCL/β-TCP scaffolds via solvent casting/particulate leaching or melt compounding. Machine into cylindrical plugs (Diameter=8mm, Height=5mm).

- Mounting: Install compression fixtures. Align scaffold plug vertically. Apply minimal pre-load to ensure contact.

- Experimental Parameters:

- Mode: Compression

- Frequency: 1.0 Hz

- Static Force: 110% of pre-load force

- Dynamic Strain: 0.05%

- Temperature Range: -80°C to 0°C

- Heating Rate: 5°C/min

- Data Analysis: Plot storage modulus (E') and tan δ. The Tg is taken from the onset of the E' drop and confirmed by the tan δ peak. Compare with a control (neat PCL) scaffold.

Diagrams

DMA Workflow for PLGA-Drug Film Analysis

Logical Flow for Tg Determination from DMA Data

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials for DMA Tg Measurement in Composites

| Item | Function in Experiment | Critical Specification/Note |

|---|---|---|

| Polymer Resins (PLGA, PCL, PEGDA) | Primary matrix material determining baseline Tg and biocompatibility. | Specify L:G ratio (PLGA), Mn (PEGDA), and inherent viscosity. Source from reputable biomaterial suppliers (e.g., Lactel, Sigma). |

| Pharmaceutic Agent (e.g., Rifampin) | Model drug to study composite interaction and plasticization effect. | Use high-purity (>98%) grade. Consider solubility in polymer solvent. |

| Ceramic Fillers (β-TCP, HA) | Reinforce scaffolds, modulate degradation, and influence polymer chain dynamics. | Control particle size distribution (e.g., 5-20µm) and phase purity. |

| Crosslinker/Co-monomer (HEMA) | Modulates hydrogel network density, directly impacting Tg and swelling. | Use with inhibitor removed. Store under inert atmosphere. |

| Photoinitiator (Irgacure 2959) | Enables UV-initiated crosslinking of hydrogel networks for precise morphology. | Biocompatible, water-soluble. Use at low concentrations (0.1% w/v). |

| High-Purity Solvent (Dichloromethane, DCM) | Solvent for film casting of PLGA and PCL composites. | Anhydrous, HPLC grade to prevent polymer hydrolysis during processing. |

| Dynamic Mechanical Analyzer | Core instrument for applying oscillatory stress/strain and measuring viscoelastic response. | Must have precise temperature control (±0.1°C), multiple fixture options (tension, shear, compression), and humidity chamber accessory. |

| Calibration Kit (Force, Temperature) | Ensures accuracy and reproducibility of DMA measurements. | Perform before each experimental series following ASTM/ISO guidelines. |

Solving Common DMA Problems: Noise, Broad Transitions, and Erratic Tg Data in Composites

Within the broader thesis on the application of Dynamic Mechanical Analysis (DMA) for measuring the glass transition temperature (Tg) in polymer composites, interpreting the shape and number of tan δ peaks is critical. A single, sharp tan δ peak typically indicates a homogeneous, well-mixed system. However, the frequent observation of broadened or multiple peaks provides key diagnostic evidence for phase separation and interfacial effects, which directly influence composite performance. These features result from variations in local molecular mobility, heterogeneity in crosslink density, and the presence of distinct interfacial regions between filler and matrix.

Mechanisms and Interpretation of Tan δ Peak Features

The damping factor (tan δ) is sensitive to molecular relaxations. Deviations from an ideal single peak are summarized below.

Table 1: Interpretation of Tan δ Peak Morphology in Polymer Composites

| Tan δ Peak Feature | Probable Cause | Underlying Physical Mechanism | Typical Composite System Example |

|---|---|---|---|

| Single, Sharp Peak | Homogeneous phase; uniform crosslink density. | Cooperative segmental motion of polymer chains occurring in a uniform environment. | Well-dispersed nanocomposite with strong interfacial adhesion. |

| Broadened Single Peak | Gradient in polymer chain mobility; distribution of relaxation times. | Can indicate a diffuse interface, a distribution in crosslink density, or the onset of microphase separation. | Semi-interpenetrating networks (IPNs) or composites with weak interfacial bonding. |

| Two Distinct Peaks | Macroscopic phase separation; two discrete phases. | Existence of two separate domains (e.g., neat polymer and filler-rich phase) with distinct Tg values. | Immiscible polymer blends or composites with severe agglomeration. |

| Shoulder or Small Secondary Peak | Presence of an interfacial/interphase region. | Restricted polymer mobility at the filler surface creates a region with a Tg distinct from the bulk matrix. | Nanocomposites with high surface-area fillers (e.g., silica, nanoclay). |

Experimental Protocol for Diagnosis via DMA

This protocol details the steps to acquire and analyze DMA data to diagnose phase behavior.

Protocol 3.1: Sample Preparation & DMA Testing for Phase Separation Analysis Objective: To obtain accurate tan δ vs. temperature data for composite specimens.

- Sample Fabrication: Prepare composite samples via controlled methods (e.g., solution casting, melt blending) to known dimensions (typical for tension/3-point bending: length > 10x thickness, width 5-10 mm).

- DMA Calibration: Perform instrument calibration for force, displacement, and temperature according to manufacturer specifications.

- Experimental Parameters:

- Mode: Use single or dual cantilever bending for solid films/bars.

- Frequency: Conduct a multi-frequency sweep (e.g., 0.1, 1, 10 Hz) to assess time-temperature superposition.

- Temperature Ramp: Typically -50°C to 150°C or above matrix Tg, at 2-3°C/min.

- Strain Amplitude: Keep within the linear viscoelastic region (confirmed via strain sweep).

- Data Collection: Record storage modulus (E'), loss modulus (E''), and tan δ (E''/E') as a function of temperature.

Protocol 3.2: Peak Deconvolution & Quantitative Analysis Objective: To quantitatively resolve broad or overlapping tan δ peaks.

- Background Subtraction: Optionally subtract a linear baseline from the tan δ curve.

- Peak Fitting: Fit the tan δ data using non-linear regression with Gaussian or Lorentzian functions (common in DMA software or tools like Origin, MATLAB).

- For a broad peak, attempt a single peak fit first.

- If fit is poor, iterate with 2 or more peaks.

- Parameter Extraction: For each resolved peak, record:

- Peak temperature (Tg, apparent).

- Peak height (maximum tan δ value).

- Full width at half maximum (FWHM) – a direct measure of breadth.

- Interface Fraction Estimation: For a two-peak system where the lower-temperature peak (Tg,i) is assigned to the interfacial/constrained polymer, estimate its relative fraction from the relative area under the deconvoluted peak.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials for DMA Studies of Phase Separation

| Item | Function & Relevance to Diagnosis |

|---|---|

| High-Purity Polymer Matrix (e.g., epoxy, PLA, PMMA) | Provides a baseline with a known, sharp tan δ peak. Deviations in composites are benchmarked against this. |

| Functionalized Fillers (e.g., silane-treated nanoparticles) | Used to modify the polymer-filler interface. Comparing treated vs. untreated fillers isolates interfacial effects on tan δ peak shape. |

| Compatibilizers / Coupling Agents (e.g., maleic anhydride grafted polymers) | Agents designed to reduce phase separation in blends/composites. Their efficacy is directly visible via the merging of multiple tan δ peaks. |

| Organic Solvents (HPLC Grade) | For uniform composite film preparation via solution casting, a critical step for controlling initial morphology. |

| Calibration Standards (e.g., known modulus materials, indium) | Ensures DMA data is quantitatively accurate, which is essential for comparing peak heights and widths across samples. |

| Deconvolution Software | Enables quantitative separation of overlapping relaxation processes, transforming a broad hump into quantifiable phase fractions. |

Visualized Workflows and Relationships

Diagnostic Pathway for Tan δ Peaks

DMA Workflow for Phase Diagnosis

Within the broader thesis on employing Dynamic Mechanical Analysis (DMA) for glass transition temperature (Tg) measurement in polymer composites research, a critical challenge is the extraction of a definitive signal from inherent instrumental and procedural noise. The accuracy of Tg, a pivotal parameter influencing composite performance in applications from drug delivery devices to structural components, is directly compromised by factors such as improper clamp torque, non-ideal sample geometry, and unaccounted baseline effects. These factors introduce artifacts that can obscure the true viscoelastic transition, leading to erroneous data interpretation. This application note details protocols to mitigate these issues, thereby enhancing measurement fidelity.

Key Noise Factors & Optimized Protocols

Clamp Torque

Excessive torque can induce premature sample deformation and stress, masking the Tg, while insufficient torque leads to slippage and signal loss.

Protocol: Determination of Optimal Clamp Torque

- Material: Standard reference polymer (e.g., Polycarbonate film, 250 µm thick).

- Setup: Utilize a dual/single cantilever or tension clamp based on sample modulus.

- Procedure:

- Mount the sample and incrementally increase torque in 0.2 Nm steps from a low starting point (e.g., 0.2 Nm).

- At each step, run a short, isothermal frequency sweep (e.g., 1 Hz) at a temperature well below the expected Tg.

- Record the storage modulus (E') and loss modulus (E").

- Endpoint: The optimal torque is the point where E' plateaus, indicating full friction grip without compression-induced stiffening. Further torque increase leading to a rise in E' indicates over-torquing.

Sample Geometry

Dimensional inaccuracies are a primary source of error in modulus calculation (E' ∝ 1/(Sample Thickness)³). Non-uniform geometry causes stress concentration.

Protocol: Standardized Sample Preparation & Validation for Composites

- Cutting: Use a precision die cutter or a micro-milling machine for films/soft composites. For hard composites, use a diamond-edged saw with slow feed rate.

- Dimension Measurement: Measure thickness at a minimum of five points along the sample length using a digital micrometer (resolution ±1 µm). Width and length should be measured with calipers (resolution ±10 µm).

- Validation Criteria: Accept samples only if thickness variation is ≤ ±3% of the mean and edges are parallel within ±0.5°.

- Alignment: Ensure the sample is mounted symmetrically within the clamps, with no visible bending or twisting.

Baseline Issues

Instrumental factors (e.g., inherent compliance of clamps, rods) and environmental effects contribute to a background signal that must be subtracted.

Protocol: System Baseline Characterization & Subtraction

- Run a Blank Baseline: Perform an identical temperature ramp experiment without any sample but with all clamps attached and set to the same nominal gap as used for samples.

- Conditions: Use the same heating rate, frequency, and amplitude as planned for sample tests.

- Data Processing: Subtract the blank baseline storage modulus (E'blank) and loss modulus (E"blank) from the sample's raw modulus data at each temperature point.

- Corrected E' = Measured E' - E'_blank

- Corrected Tan δ = Corrected E" / Corrected E'

- Frequency: Establish a new baseline after any significant maintenance or change in clamp type.

Data Presentation

Table 1: Impact of Clamp Torque on Measured Tg of a Polycarbonate Reference Film

| Torque (Nm) | Storage Modulus at 25°C (MPa) | Apparent Tg from Tan δ Peak (°C) | Observation |

|---|---|---|---|

| 0.3 | 2100 ± 150 | 148.2 ± 0.5 | Sample slippage observed |

| 0.5 (Optimal) | 2350 ± 50 | 150.1 ± 0.2 | Clear, single tan δ peak |

| 0.8 | 2700 ± 200 | 152.5 ± 0.8 | Broadened peak, modulus artificially high |

Table 2: Effect of Sample Thickness Variation on Calculated Storage Modulus

| Nominal Thickness (mm) | Actual Mean ± SD (mm) | CV (%) | Calculated E' at 25°C (GPa) | Error vs. Ideal Geometry |

|---|---|---|---|---|

| 1.00 | 1.00 ± 0.01 | 1.0 | 3.00 ± 0.05 | Reference |

| 1.00 | 0.95 ± 0.03 | 3.2 | 3.51 ± 0.15 | +17% |

| 1.00 | 1.05 ± 0.04 | 3.8 | 2.48 ± 0.12 | -17% |

Visualized Workflows

Title: DMA Tg Measurement Optimization Workflow

Title: Noise Sources vs. Optimization Actions in DMA

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for DMA Tg Measurement

| Item | Function & Rationale |

|---|---|

| Precision Diamond Saw | Provides clean, parallel cuts for brittle or high-filler content composites, minimizing edge defects that initiate cracks. |

| Digital Micrometer (±1 µm) | Accurately measures sample thickness at multiple points; critical for correct modulus calculation and geometry QA. |

| Torque-Limiting Screwdriver | Ensures reproducible and optimal clamping force, preventing operator-dependent variability from over/under-torquing. |

| Standard Reference Polymer (e.g., Polycarbonate, PMMA) | Used for instrument calibration, clamp torque optimization, and periodic validation of method accuracy. |

| High-Temperature Vacuum Grease | Applied minimally to clamp faces to improve thermal contact and reduce interfacial slippage, especially for thin films. |

| Geometry Validation Jig | A flat template with parallel edges to visually check sample straightness and alignment before mounting. |

Handling Sub-Tg Relaxations and Moisture Effects in Hydrophilic Composites.

Application Notes

Within the broader thesis on the DMA methodology for determining the glass transition temperature (Tg) in polymer composites, a significant challenge is the accurate interpretation of data for hydrophilic systems. These materials often exhibit complex thermomechanical spectra where moisture plasticization and low-temperature relaxations (sub-Tg) can obscure the identification of the true Tg, leading to erroneous conclusions about matrix-dominated performance. These phenomena are critical in applications such as biodegradable implants, drug-eluting composite coatings, and moisture-sensitive structural components.

The primary interference arises from two sources:

- Sub-Tg Relaxations (β, γ relaxations): These are local-scale molecular motions (e.g., side-chain rotations, localized main-chain movements) occurring below the primary α-relaxation (Tg). In DMA, they manifest as distinct peaks or shoulders in the tan δ or E'' curves at lower temperatures.