Accuracy vs Precision in Impurity Analysis: A Comprehensive Guide to Method Validation for Drug Development

This article provides a targeted guide for analytical scientists and pharmaceutical researchers on designing, executing, and troubleshooting accuracy and precision studies for impurity analysis methods.

Accuracy vs Precision in Impurity Analysis: A Comprehensive Guide to Method Validation for Drug Development

Abstract

This article provides a targeted guide for analytical scientists and pharmaceutical researchers on designing, executing, and troubleshooting accuracy and precision studies for impurity analysis methods. Covering foundational concepts (ICH Q2(R2) and USP <1225>), methodological best practices for spiking studies and statistical evaluation, common troubleshooting scenarios, and advanced validation strategies for comparative analysis, it offers a complete framework for ensuring reliable and regulatory-compliant impurity data critical for drug safety and quality control.

Understanding Accuracy and Precision: Core Concepts for Reliable Impurity Data

Defining Accuracy, Precision, and Specificity in the Context of Impurities

In the rigorous field of pharmaceutical impurity analysis, the validation of analytical methods rests on foundational metrological concepts. Accuracy, precision, and specificity are distinct but interrelated parameters critical for ensuring the reliability of data used in drug development and quality control. This comparison guide delineates these parameters, provides experimental data from common techniques, and contextualizes them within ongoing research on method validation.

Conceptual Comparison and Definitions

- Accuracy: The closeness of agreement between a measured value and an accepted reference value. For impurities, it reflects how correctly the method quantifies the true amount of an impurity present.

- Precision: The closeness of agreement among a series of measurements obtained from multiple sampling of the same homogeneous sample. It describes the method's reproducibility and repeatability, independent of its truth.

- Specificity: The ability to assess unequivocally the analyte (impurity) in the presence of components that may be expected to be present, such as excipients, degradation products, or matrix components. It ensures the signal measured is solely from the target impurity.

Comparative Experimental Data from Analytical Techniques

The following table summarizes typical validation data for a hypothetical impurity "X" (at 0.1% specification) analyzed by two common techniques: High-Performance Liquid Chromatography with UV detection (HPLC-UV) and Liquid Chromatography-Mass Spectrometry (LC-MS). Data is compiled from common protocol outcomes in recent literature.

Table 1: Method Performance Comparison for Impurity X Analysis

| Parameter | HPLC-UV Method | LC-MS Method | Acceptance Criteria (Typical ICH Q2) |

|---|---|---|---|

| Accuracy (% Recovery) | 98.5% ± 2.1 | 99.8% ± 1.5 | 98-102% recovery |

| Precision (Repeatability, %RSD) | 2.5% RSD (n=6) | 1.2% RSD (n=6) | NMT 5% RSD |

| Specificity | Resolution > 2.0 from closest peak; forced degradation studies show no co-elution. | Selective ion monitoring (m/z 255.1); no isobaric interference in stressed samples. | Peak purity passes; no interference. |

Detailed Experimental Protocols

Protocol 1: Assessing Accuracy and Precision via Spike/Recovery

- Objective: To determine the accuracy and precision of an impurity method by spiking a known amount of impurity into a drug substance matrix.

- Methodology:

- Prepare a placebo sample (drug product without API) or a pure API sample.

- Spike the sample with impurity X at three levels: 0.05%, 0.10%, and 0.15% of the API concentration (n=3 per level).

- Analyze all samples using the validated method (e.g., HPLC-UV conditions: C18 column, mobile phase gradient, 1.0 mL/min, 230 nm detection).

- Calculate the percentage recovery:

(Measured Concentration / Spiked Concentration) * 100. - Report accuracy as mean recovery across all levels. Report precision as the relative standard deviation (%RSD) of the recoveries at each level.

Protocol 2: Demonstrating Specificity via Forced Degradation

- Objective: To prove the method's ability to separate and quantify impurity X from degradation products and matrix.

- Methodology:

- Subject the drug product to stress conditions: acid/base hydrolysis, oxidative, thermal, and photolytic stress.

- Analyze stressed samples alongside an unstressed control and a reference standard of impurity X.

- For HPLC-UV, confirm that the peak for impurity X is pure (via diode array spectral analysis) and baseline-resolved (Resolution > 2.0) from all other peaks.

- For LC-MS, use extracted ion chromatograms for the specific mass-to-charge ratio (m/z) of impurity X. Confirm no other degradation product shares the same m/z and retention time.

Logical Relationship of Validation Parameters

Title: Interdependence of Key Validation Parameters

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Impurity Method Validation

| Item | Function in Validation |

|---|---|

| Certified Reference Standards | Provides an accurate reference value for the target impurity, essential for establishing method accuracy and specificity. |

| Forced Degradation Reagents (e.g., HCl, NaOH, H₂O₂) | Used in stress studies to generate degradation products and challenge the specificity of the method. |

| High-Purity Mobile Phase Solvents (HPLC/LC-MS grade) | Minimizes baseline noise and spurious peaks, critical for achieving low detection limits and precise quantification of trace impurities. |

| Stable Isotope-Labeled Internal Standards (for LC-MS) | Corrects for matrix effects and instrument variability, significantly improving the accuracy and precision of quantitative results. |

| Chromatography Columns with Different Selectivities | Used in specificity protocols to demonstrate the separation of the impurity from interfering species is robust and not column-dependent. |

Within a broader thesis on accuracy and precision testing for impurity analysis methods research, this comparison guide objectively evaluates the performance of the key regulatory frameworks governing analytical method validation: the International Council for Harmonisation (ICH) Q2(R2) guideline and the United States Pharmacopeia (USP) General Chapter <1225>. These documents are not "products" in a commercial sense, but are standard-setting frameworks whose "performance" is measured by their specificity, clarity, and comprehensiveness in ensuring robust analytical methods for drug development.

The following table summarizes the quantitative and categorical expectations for key validation parameters as outlined in ICH Q2(R2) (Step 5 version, effective 2025) and USP <1225> (official December 1, 2024). Data is synthesized from current regulatory documents and implementation guides.

Table 1: Comparison of Validation Parameter Expectations

| Validation Parameter | ICH Q2(R2) Expectations (Quantitative Impurity Test) | USP <1225> Expectations (Category I: Quantitative) | Comparative Note |

|---|---|---|---|

| Accuracy | Recommended: Comparison to a reference standard/specified procedure or recovery of spiked analyte. Data: Report as % recovery or difference between mean and accepted true value with confidence intervals. | Similar: Determine by spiking known amounts into sample matrix or comparison to a reference standard. Data: Report as % recovery of known added amount. | Conceptual alignment. ICH Q2(R2) newly emphasizes reporting with confidence intervals. |

| Precision | Repeatability: Minimum of 9 determinations covering specified range (e.g., 3 concentrations/3 replicates) or 6 determinations at 100% test concentration. Report as %RSD. Intermediate Precision: Evaluate effects of random events (days, analysts, equipment). Report as %RSD. | Repeatability: Minimum of 6 determinations at 100% of test concentration. Data as standard deviation or %RSD. Intermediate Precision: Same conceptual approach; "within-laboratory variations." | Core principles identical. ICH Q2(R2) provides more prescriptive options for repeatability study design. |

| Specificity | Must demonstrate ability to assess analyte unequivocally in presence of expected components (impurities, matrix). Use representative chromatograms/spectra. For impurities, ensure resolution from other peaks. | Must demonstrate that the method measures the analyte free from interference due to other components. Uses terms "specific" (ideal) and "selective" (measurable in presence of others). | High alignment. ICH Q2(R2) integrates terminology within "specificity." |

| Quantitation Limit (LOQ) | Based on Signal-to-Noise (10:1), Standard Deviation of Response/Slope, or visual evaluation. Must be validated by accuracy/precision at the LOQ. | Typically determined as Signal-to-Noise (10:1) or based on standard deviation of response and slope. Requires demonstration of acceptable accuracy and precision. | Direct alignment in approaches and acceptance. |

| Forced Degradation Studies | Explicitly required under "Specificity" for stability-indicating methods. Must demonstrate method stability-indicating power and discrimination from degradation products. | Referenced under "Selectivity" and in other chapters (e.g., <1225> itself mentions "degradants"). Expectation is established practice but less explicitly detailed in <1225>. | ICH Q2(R2) provides more explicit, structured expectations within the validation guideline. |

Experimental Protocols for Key Validation Parameters

The following detailed methodologies are cited from and aligned with both ICH Q2(R2) and USP <1225> expectations for accuracy and precision testing of an impurity analysis method.

Protocol 1: Accuracy Assessment via Spiked Recovery

- Preparation: Prepare a placebo mixture matching the drug product composition without the active or the target impurity.

- Spiking: Spike the placebo with the impurity reference standard at three concentration levels (e.g., 50%, 100%, and 150% of the specification limit). Prepare a minimum of three replicates per level.

- Analysis: Analyze the spiked samples using the candidate analytical method (e.g., HPLC-UV).

- Calculation: For each level, calculate the percentage recovery:

(Measured Concentration / Spiked Concentration) * 100. - Reporting: Report individual recoveries, mean recovery, and confidence interval (per ICH Q2(R2)) for each level. Acceptance criteria (e.g., 95-105% recovery) should be pre-defined.

Protocol 2: Precision Evaluation (Repeatability & Intermediate Precision)

- Repeatability:

- Prepare a homogeneous sample of drug product spiked with an impurity at 100% of the specification limit.

- Analyze this sample six times independently (six separate sample preparations) by the same analyst, using the same instrument, on the same day.

- Calculate the % Relative Standard Deviation (%RSD) of the six reported impurity concentrations.

- Intermediate Precision:

- Design a study incorporating intentional variations: e.g., different analysts (2), different days (2), and potentially different instruments (if available).

- Analyze the same spiked sample level as in repeatability (minimum 6 analyses per variation combination). A full design might yield 12-24 total determinations.

- Calculate the overall %RSD from all determinations to assess the method's robustness under within-laboratory variations.

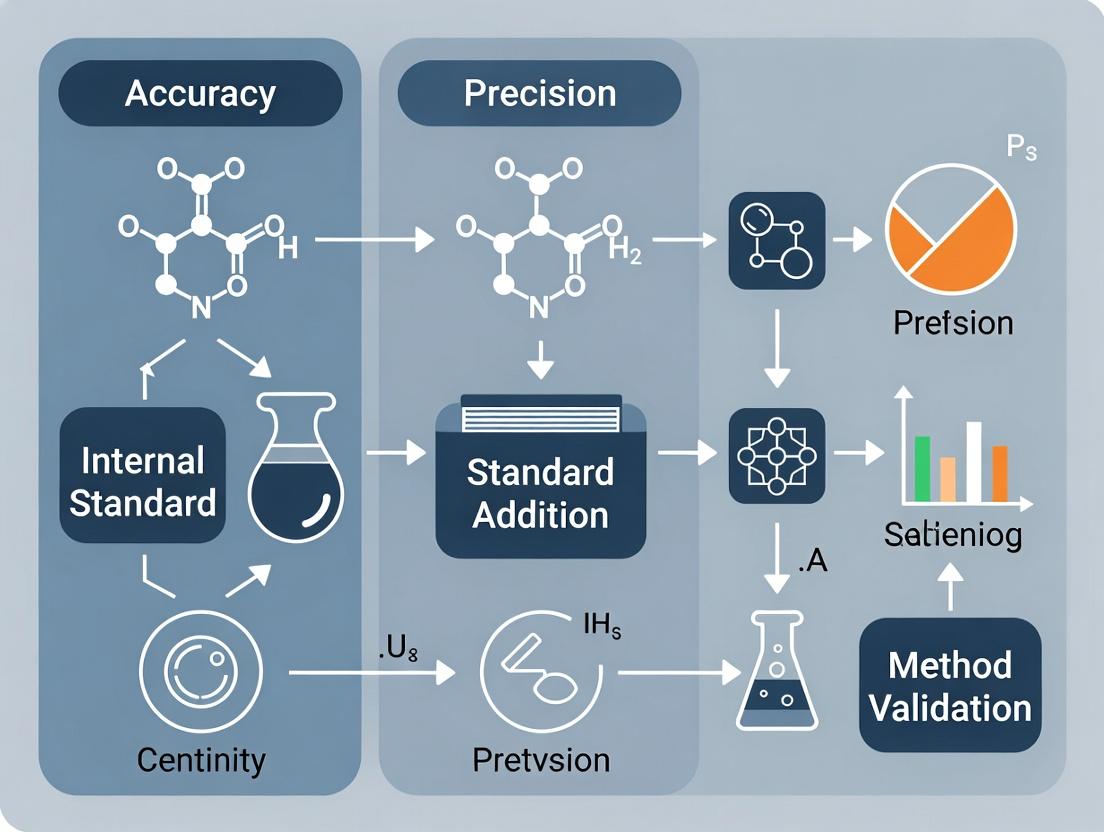

Accuracy & Precision Validation Workflow

The Scientist's Toolkit: Research Reagent Solutions for Impurity Method Validation

Table 2: Essential Materials for Validation Experiments

| Item | Function in Validation |

|---|---|

| High-Purity Impurity Reference Standards | Certified, well-characterized standards are critical for spiking experiments (accuracy) and establishing target concentrations for precision and LOQ. |

| Placebo Matrix (Drug Product/API-specific) | Mimics the sample matrix without the target analytes. Essential for accurate recovery studies to assess matrix effects. |

| Qualified Chromatographic Column | The specified column (brand, chemistry, dimensions) is a critical method parameter. Consistency is vital for precision and specificity studies. |

| Mass Spectrometry-Grade Solvents & Reagents | High-purity mobile phase components reduce background noise, crucial for achieving required sensitivity (LOQ) and clean chromatograms for specificity. |

| Certified Volumetric Glassware & Balances | Ensures accurate and precise preparation of standard solutions, spiked samples, and mobile phases, directly impacting accuracy results. |

| Stable, Well-Characterized System Suitability Standards | A reference mixture used to verify system performance (resolution, precision, tailing) before each validation run, ensuring data integrity. |

Regulatory Guideline Focus Comparison

The Critical Role of Accuracy/Precision Testing in Drug Safety and Quality

Ensuring the accuracy and precision of impurity analysis methods is a foundational pillar of modern pharmaceutical development. Within the broader thesis on method validation, rigorous testing of these parameters directly dictates the reliability of safety assessments and the consistency of drug product quality. This guide compares the performance of key analytical techniques—High-Performance Liquid Chromatography (HPLC), Gas Chromatography (GC), and Capillary Electrophoresis (CE)—in quantifying genotoxic impurity 2-aminopropiophenone in a model active pharmaceutical ingredient (API).

Comparative Performance of Analytical Techniques for Impurity Quantification

The following table summarizes the experimental results from a method validation study assessing accuracy (% recovery) and precision (%RSD) for the quantification of 2-aminopropiophenone at the 0.05% specification threshold.

Table 1: Accuracy and Precision Data for Impurity Analysis (n=6)

| Analytical Technique | Mean % Recovery (Accuracy) | Intra-day Precision (%RSD) | Inter-day Precision (%RSD) | Limit of Quantification (LOQ) |

|---|---|---|---|---|

| HPLC-UV (C18 Column) | 99.8 | 0.95 | 1.82 | 0.0025% |

| GC-MS (MS Detection) | 101.2 | 1.32 | 2.15 | 0.0010% |

| CE-UV | 98.5 | 2.10 | 3.78 | 0.0050% |

Key Findings: GC-MS demonstrates superior sensitivity (lowest LOQ), crucial for trace-level genotoxic impurities, while HPLC-UV offers the best combination of accuracy and precision for this specific application. CE-UV, while advantageous for charged molecules, showed higher variability in this context.

Experimental Protocols

Sample Preparation and Spiking Protocol

- API Solution: A 10 mg/mL solution of the model API was prepared in a water:acetonitrile (70:30 v/v) mixture.

- Impurity Stock Solution: A primary stock solution of 2-aminopropiophenone (1.0 mg/mL) was prepared in acetonitrile.

- Spiked Samples: Working standard solutions were spiked into the API matrix at 0.03%, 0.05%, and 0.075% levels relative to API concentration to construct a calibration curve and assess recovery.

- Sample Vials: All samples were prepared in low-adsorption, amber glass vials.

HPLC-UV Method (Primary Comparison Method)

- Column: ZORBAX Eclipse Plus C18, 4.6 x 150 mm, 3.5 µm.

- Mobile Phase: Gradient elution with 20mM potassium phosphate buffer (pH 3.0) and acetonitrile.

- Flow Rate: 1.0 mL/min.

- Detection: UV at 245 nm.

- Injection Volume: 10 µL.

- Column Temperature: 30°C.

- Run Time: 20 minutes.

GC-MS Method

- Column: DB-5MS capillary column (30 m × 0.25 mm, 0.25 µm).

- Injection: Split mode (10:1), 250°C.

- Oven Program: 50°C hold for 2 min, ramp to 300°C at 15°C/min, hold for 5 min.

- Carrier Gas: Helium at 1.2 mL/min constant flow.

- Detection: MS in Selected Ion Monitoring (SIM) mode; quantifier ion m/z 135.

Data Analysis for Accuracy & Precision

- Calibration Curve: Peak area vs. concentration plotted for six levels. Linearity required R² > 0.995.

- Accuracy: Calculated as (Mean Measured Concentration / Spiked Concentration) x 100%.

- Precision: Intra-day precision (%RSD) assessed from six replicates at the 0.05% level on the same day. Inter-day precision assessed from six replicates analyzed over three consecutive days.

Workflow for Impurity Method Validation

Diagram 1: Impurity Method Validation Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Accuracy/Precision Studies in Impurity Analysis

| Item | Function in Experiment | Critical Quality Attribute |

|---|---|---|

| Certified Reference Standard (CRS) of Impurity | Serves as the primary benchmark for accuracy (recovery) calculations; ensures traceability. | Purity > 98.5%, certified by a recognized standard body (e.g., USP, EP). |

| Highly Purified API (Blank Matrix) | Provides the drug substance matrix for spiking studies, allowing assessment of method selectivity and accuracy in a representative sample. | Confirmed absence of target impurity via orthogonal method. |

| LC-MS Grade Solvents (Water, Acetonitrile, Methanol) | Used for mobile phase and sample preparation; minimizes baseline noise and ghost peaks that affect precision and LOQ. | Low UV absorbance, high purity, minimal particle content. |

| Buffering Salts (e.g., Potassium Phosphate) | Provides consistent pH control in mobile phase, critical for reproducible retention times (precision) and peak shape. | Analytical reagent grade, low heavy metal content. |

| Low-Adsorption/Glass Insert Vials | Sample containers that minimize adsorptive loss of impurity, directly impacting accuracy, especially at trace levels. | Certified for HPLC/GC, chemically inert. |

| System Suitability Test (SST) Mix | A standard mixture used to verify system performance (e.g., plate count, tailing factor) prior to accuracy/precision runs. | Contains compounds to test resolution, peak symmetry, and retention. |

Differentiating Between Drug Substance and Drug Product Impurity Analysis Needs

Within the broader thesis on accuracy and precision testing for impurity analysis methods, a fundamental distinction lies in the analytical requirements for the Drug Substance (DS; active pharmaceutical ingredient, API) versus the Drug Product (DP; final formulated dosage form). This comparison guide objectively evaluates their differing performance needs and experimental approaches.

Core Analytical Comparison

The following table summarizes the primary differences driving impurity method development and validation requirements.

Table 1: Comparative Needs for Impurity Analysis

| Aspect | Drug Substance (API) | Drug Product |

|---|---|---|

| Primary Impurity Focus | Process-related impurities, synthetic intermediates, residual solvents, genotoxic impurities. | Degradation-related impurities formed under stress conditions (heat, light, humidity, pH), drug-excipient interactions, leachables. |

| Sample Matrix Complexity | Relatively simple, homogeneous. May contain residual catalysts or by-products. | Highly complex. Contains multiple excipients (fillers, binders, disintegrants, lubricants, coatings) that can interfere. |

| Typical Quantitative Requirement | Higher sensitivity often needed for low-level process impurities (e.g., ≤0.10%). | May tolerate slightly higher reporting thresholds for degradation products, but must detect all relevant degradants. |

| Key Methodological Challenge | Separation of structurally similar synthetic by-products. | Extraction of API and impurities from the complex matrix without artifact formation. Specificity amidst matrix peaks. |

| Accuracy & Precision Emphasis | Extreme precision for controlling known, often stable, process impurities. Accuracy critical for specification setting. | Robustness of precision against matrix variability (batch-to-batch of excipients). Accuracy through demonstration of recovery from spiked placebo. |

Experimental Data and Protocols

Supporting experimental data highlights these divergent needs. A recent study systematically compared the performance of the same HPLC-UV method when applied to a proprietary API (DS) and its corresponding tablet formulation (DP).

Table 2: Experimental Performance Data for a Common Impurity (Imp-X) at 0.15% Level

| Performance Parameter | Drug Substance Analysis | Drug Product Analysis |

|---|---|---|

| Mean Accuracy (% Recovery) | 99.8% | 98.5% |

| Precision (%RSD, n=6) | 0.9% | 2.7% |

| Signal-to-Noise Ratio | 125 | 48 |

| Peak Tailing Factor | 1.05 | 1.22 |

| Sample Preparation Time | ~10 min (dissolve & dilute) | ~45 min (extraction, sonication, filtration) |

Detailed Experimental Protocols:

Protocol for Drug Substance Accuracy/Precision:

- Materials: High-purity API reference standard, qualified impurity reference standard (Imp-X), appropriate solvent.

- Method: Accurately weigh API and spike with a known amount of Imp-X standard to achieve a 0.15% w/w level. Prepare six independent samples. Dissolve in diluent and analyze by the validated HPLC method. Calculate recovery (%) and relative standard deviation (RSD).

Protocol for Drug Product Accuracy/Precision (Spiked Recovery):

- Materials: API standard, impurity standard (Imp-X), placebo blend (all excipients), finished DP placebo tablets.

- Method: Weigh placebo blend equivalent to one tablet unit into six vessels. Spike with API and Imp-X standard to mimic label claim and 0.15% impurity level. Add diluent, sonicate for 30 minutes with intermittent shaking, cool, and dilute to volume. Centrifuge and filter. Analyze and calculate recovery and RSD, comparing against a standard solution without matrix.

Visualizing the Analytical Workflow Divergence

The logical workflow for establishing impurity methods underscores the different starting points and challenges for DS vs. DP.

Title: Divergent Starting Points for Impurity Method Development

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Comparative Impurity Studies

| Item | Function in DS/DP Impurity Analysis |

|---|---|

| Qualified Impurity Reference Standards | Critical for both DS and DP. Used for peak identification, method development, and accuracy/recovery studies. Must be of high, documented purity. |

| Pharmaceutical Placebo | Essential for DP analysis. A blend of all formulation excipients (without API) used to assess interference, specificity, and to perform spike recovery for accuracy determination. |

| Inert HPLC Columns | Columns with minimal metallic activity (e.g., high-purity silica) are vital to prevent peak tailing of polar impurities, especially for basic APIs and their degradants in both DS and DP. |

| Stability-Indicating Stress Materials | For DP studies: reagents for acid/base hydrolysis, oxidative agents (e.g., H₂O₂), thermal chambers, and photostability chambers to generate degradation impurities. |

| Selective Sample Preparation Sorbents | For complex DP matrices: Use of supported liquid extraction (SLE) or selective solid-phase extraction (SPE) phases to clean up samples, improving accuracy and precision by removing interfering excipients. |

| Mass Spectrometry-Compatible Mobile Phase Additives | For both DS and DP when using LC-MS for impurity identification. Volatile buffers (e.g., ammonium formate) replace non-volatile salts (e.g., phosphate) to enable ionization. |

In impurity analysis for drug development, establishing acceptance criteria is a critical progression from qualitative detection (QL) to quantitative specification limits. This guide compares performance characteristics of key analytical techniques—High-Performance Liquid Chromatography (HPLC), Liquid Chromatography-Mass Spectrometry (LC-MS), and Capillary Electrophoresis (CE)—within the context of accuracy and precision testing for method validation.

Comparison of Analytical Techniques for Impurity Analysis

The following table summarizes core performance metrics based on current method validation studies for impurity quantification.

Table 1: Performance Comparison of Key Analytical Techniques

| Parameter | HPLC-UV/DAD | LC-MS (Single Quad) | Capillary Electrophoresis (UV) |

|---|---|---|---|

| Accuracy (Recovery %) | 98-102% | 95-105% | 90-102% |

| Precision (%RSD) | ≤2.0% | ≤3.5% | ≤3.0% |

| Quantitation Limit (QL) | 0.05% | 0.01% | 0.1% |

| Linearity (R²) | ≥0.999 | ≥0.995 | ≥0.998 |

| Specification Level Typical Range | 0.05%-0.5% | 0.01%-0.2% | 0.1%-1.0% |

| Key Strength | Robustness, Compliance | Sensitivity, Specificity | High Resolution, Low Solvent Use |

| Primary Limitation | Lower Sensitivity | Ion Suppression Effects | Lower Precision |

Detailed Experimental Protocols

Protocol A: Determination of Accuracy and Precision for Impurity Methods

Objective: To establish method accuracy and precision from the QL to the specification limit. Materials: API (Active Pharmaceutical Ingredient), certified impurity standards, HPLC system with DAD, chromatographic column, mobile phase components. Procedure:

- Stock Solution Preparation: Precisely weigh API and impurity standards. Prepare separate stock solutions at a concentration covering the specification limit (e.g., 0.5% w/w relative to API).

- Sample Spiking: Prepare a series of sample solutions spiked with impurities at six concentration levels: at the QL (e.g., 0.05%), at 50%, 100%, and 120% of the specification limit, and two intermediate points.

- Analysis: Inject each concentration level in six replicates (n=6) following the validated chromatographic method.

- Data Analysis:

- Accuracy: Calculate percent recovery for each impurity at each level. Acceptance criterion is typically 98-102%.

- Precision: Calculate the relative standard deviation (%RSD) of the measured concentrations for the six replicates at the 100% specification level. Acceptance criterion is typically ≤2.0%.

Protocol B: Comparative Sensitivity (QL) Study

Objective: To compare the quantitation limits of HPLC-UV and LC-MS for a genotoxic impurity. Materials: Trace impurity standard, LC-MS system (Single Quadrupole), HPLC-UV system. Procedure:

- Serial Dilution: Prepare a serial dilution of the impurity standard from a known high concentration down to sub-ppm levels.

- Instrumental Analysis: Analyze the dilution series on both the LC-MS (using Selected Ion Monitoring mode) and the HPLC-UV (at appropriate λ).

- QL Determination: The QL is defined as the lowest concentration at which the signal-to-noise ratio (S/N) is ≥10, the analyte peak is identifiable, and the accuracy and precision are within ±20%. This concentration is established for both instruments.

Visualizing the Method Validation and Specification Workflow

Title: Progression from Impurity Detection to QC

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Impurity Method Development & Validation

| Item | Function / Purpose |

|---|---|

| Certified Reference Standards | Provides a traceable, high-purity substance to accurately identify and quantify impurities. |

| Pharmaceutical-Grade Solvents | Ensures baseline stability, reduces ghost peaks, and maintains column integrity in chromatographic systems. |

| Buffers & Ion-Pairing Reagents | Modifies mobile phase to control selectivity, resolution, and peak shape for ionic or polar impurities. |

| Derivatization Reagents | Chemically modifies impurities lacking a chromophore or fluorophore to enable UV/FL detection. |

| SPE (Solid-Phase Extraction) Cartridges | Isolates and concentrates trace impurities from complex API matrices to achieve required QL. |

| Stability-Indicating Stress Materials | API samples subjected to forced degradation (heat, light, pH) to validate method specificity. |

Practical Strategies: Designing and Executing Accuracy & Precision Studies

This guide compares the performance of different analytical platforms in spiked recovery experiments, a cornerstone of accuracy (trueness) and precision testing for impurity analysis methods. The data underpins the broader thesis that method validation must account for both known specified impurities and potential unknown degradants to ensure drug product safety and efficacy.

Comparative Performance Data

Table 1: Recovery Performance Across Analytical Techniques

Data compiled from recent literature (2023-2024) on spiked impurity recovery in a model Active Pharmaceutical Ingredient (API) matrix.

| Analytical Technique | Known Impurities (Mean % Recovery ± %RSD) | "Unknown" Impurities (Surrogate Spikes) Mean % Recovery ± %RSD | Key Advantage | Key Limitation |

|---|---|---|---|---|

| HPLC-UV/DAD | 98.5 ± 1.2 | 85.3 ± 5.7 (for non-UV active) | Robust, precise, cost-effective for knowns. | Poor detectability for unknowns without chromophore. |

| UHPLC-MS/MS (Targeted) | 99.2 ± 0.8 | 30.4 ± 12.1 (non-targeted ion) | Exceptional sensitivity & specificity for targeted ions. | Recovery highly dependent on ionization efficiency. |

| UHPLC-HRMS (Q-TOF) | 97.8 ± 1.5 | 92.5 ± 3.1 | Accurate mass enables retrospective data mining for unknowns. | Higher operational cost and complexity. |

| GC-MS | 99.0 ± 2.1 | 88.7 ± 4.5 (for volatile surrogates) | Excellent for volatile/semi-volatile impurities. | Requires derivatization for non-volatiles, risk of degradation. |

Table 2: Impact of Sample Preparation on Recovery

Comparison of preparation methods for a spiked impurity at 0.1% level in a tablet formulation.

| Preparation Method | Recovery (%) | Precision (%RSD) | Comment |

|---|---|---|---|

| Direct Dilution | 101.3 | 1.5 | Fast, but high risk of matrix suppression/interference. |

| Solid-Phase Extraction (SPE) | 95.8 | 3.2 | Effective cleanup; recovery loss must be characterized. |

| Liquid-Liquid Extraction (LLE) | 98.2 | 2.8 | Good for separating ionic impurities; solvent intensive. |

| QuEChERS | 99.5 | 2.0 | Efficient for broad impurity classes; becoming standard for screening. |

Detailed Experimental Protocols

Protocol 1: Standard Spiked Recovery for Known Impurities (HPLC-UV)

Objective: To determine the accuracy and precision of an HPLC-UV method for quantifying specified impurities A, B, and C.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Prepare Blank Matrix: Prepare a placebo mixture matching the drug product formulation without the API or target impurities.

- Spike Solution Preparation: Prepare independent stock solutions of impurities A, B, and C. Create a composite spiking solution at a concentration equivalent to 0.15% of the API nominal concentration.

- Spiking: Into six separate aliquots of the blank matrix, add precise volumes of the composite spiking solution to create "spiked samples" at the 0.15% level.

- Sample Preparation: Process each of the six spiked samples through the complete analytical method (extraction, dilution, filtration).

- Control Preparation: Prepare six samples of the placebo matrix without spikes ("blanks") and six samples of the impurity standards in pure solvent ("reference standards").

- Analysis: Inject all samples in a randomized sequence. Calculate the amount of each impurity found in each spiked sample.

- Calculation: % Recovery = (Measured Concentration in Spiked Sample / Theoretical Spiked Concentration) x 100

Protocol 2: Recovery for Unknown Impurities via Forced Degradation Surrogates (UHPLC-HRMS)

Objective: To assess method capability to detect and quantify potential unknown degradants.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Generate Degradants: Subject the API to stressed conditions (acid, base, oxidation, thermal, photolytic) to generate a cocktail of potential degradants.

- Prepare Spiked Sample: Add a small, known volume of the degradation cocktail to the blank matrix. The exact concentration of individual degradants is unknown, but the total spiked volume is recorded.

- Comparative Analysis: Analyze the spiked sample alongside the unstressed API and blank matrix using a UHPLC-HRMS method with a generic, broad gradient.

- Data Processing: Use software to highlight chromatographic peaks present in the spiked sample but absent in the blanks. Integrate these "unknown" peaks.

- Semi-Quantitative Recovery: Assume the degradants have a similar mean response factor to the API. Estimate recovery for the total degradant profile as: Estimated % Recovery = (Total Peak Area of "Unknowns" in Spiked Sample / Total Peak Area of Degradants in Pure Cocktail) x 100

- Identification Effort: Use accurate mass and isotopic patterns to propose structures for major unknown degradants.

Visualizations

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in Spiked Recovery Experiments |

|---|---|

| High-Purity Reference Standards | Certified materials for known impurities to prepare accurate spike solutions. |

| Placebo Formulation | Matrix without API/impurities to assess interference and matrix effects. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Correct for variability in sample prep and ionization (MS methods). |

| Forced Degradation Cocktail | A mixture of stressed API degradants used as a surrogate for "unknown" impurities. |

| QuEChERS Extraction Kits | Standardized kits for efficient, broad-spectrum sample cleanup prior to analysis. |

| Mimetic Chromatography Columns | Columns with stationary phases designed to mimic biological interactions for challenging separations. |

| LC-MS Grade Solvents & Buffers | Essential to minimize background noise and ion suppression in sensitive MS detection. |

| Data Mining Software (e.g., Compound Discoverer, UNIFI) | Processes HRMS data to find, integrate, and tentatively identify "unknown" peaks. |

Sample Preparation Protocols for Accuracy (Recovery) Testing

Accuracy, expressed as percent recovery, is a fundamental validation parameter for impurity analysis methods in pharmaceutical development. It confirms that an analytical method correctly measures the target analyte in the presence of sample matrix. This guide compares common sample preparation techniques for accuracy testing of impurities, framed within a thesis on method validation for trace-level quantification.

Comparison of Sample Preparation Approaches for Recovery Experiments

The following table summarizes key performance data for different spiking strategies used in accuracy/recovery testing, based on current regulatory guidelines and published methodologies.

Table 1: Comparison of Sample Preparation Protocols for Accuracy (Recovery) Testing

| Protocol | Typical Recovery Range (%) | Key Advantage | Primary Limitation | Best Suited For |

|---|---|---|---|---|

| Standard Addition | 95-105 | Compensates for complex matrix effects (ion suppression/enhancement). | More labor-intensive; requires multiple sample preparations. | Complex biological matrices (plasma, tissue). |

| Spiked Placebo (Blend) | 98-102 | Simulates the actual drug product matrix without active interference. | Requires availability of representative placebo. | Solid dosage forms (tablets, capsules). |

| Spiked Drug Substance | 97-103 | Simple and direct; good for process impurity assessment. | Does not account for excipient interactions. | Drug substance (API) impurity profiling. |

| Spiked Pre-Processed Sample | 90-110 | Measures recovery of the analytical step alone. | Does not evaluate total method recovery from initial sample. | Isolating and troubleshooting extraction efficiency. |

Detailed Experimental Protocols

Protocol 1: Spiked Placebo Recovery for Tablet Formulation

This protocol evaluates the accuracy of an impurity method for a finished drug product.

- Materials Preparation: Precisely weigh and finely grind representative placebo blend (all excipients, no API).

- Spiking Solution: Prepare independent stock solutions of the API and each target impurity. Dilute to create a composite spiking solution at concentrations relevant to the specification limit (e.g., 0.1%, 0.5%, 1.0% w/w relative to API).

- Fortification: Add known volumes of the composite spiking solution to accurately weighed portions of placebo powder in volumetric flasks. Prepare triplicates at each concentration level.

- Sample Reconstitution: Add appropriate diluent (mimicking the final method), sonicate, and dilute to volume to extract analytes.

- Analysis & Calculation: Analyze spiked samples alongside unspiked placebo and corresponding calibration standards. Calculate % Recovery = (Measured Concentration of Impurity / Spiked Concentration of Impurity) x 100.

Protocol 2: Standard Addition for Plasma Biomarker Assay

This protocol is critical for bioanalytical methods where matrix effects are significant.

- Control Matrix: Obtain pooled control human plasma (free of target analyte).

- Aliquot & Spike: Aliquot equal volumes of the control matrix into five tubes. To four tubes, add increasing but known volumes of a standard analyte solution. One tube serves as the unspiked control.

- Sample Processing: Subject all tubes to the full sample preparation workflow (e.g., protein precipitation, extraction).

- Analysis & Plotting: Analyze all processed samples. Plot the measured analyte response (e.g., peak area) against the amount spiked. Perform linear regression.

- Recovery Determination: The y-intercept represents the response from any endogenous analyte. The recovery is assessed from the slope and linearity (R²) of the plot, confirming the method's accuracy across the range.

Logical Workflow for Accuracy Testing Protocol Selection

Accuracy Testing Protocol Decision Workflow

The Scientist's Toolkit: Key Reagents & Materials

Table 2: Essential Research Reagent Solutions for Recovery Experiments

| Item | Function in Recovery Testing |

|---|---|

| Certified Reference Standards | High-purity, well-characterized analyte substances for preparing primary stock solutions with traceable concentration. |

| Placebo Matrix | A mixture of all formulation excipients (without API) used to mimic the drug product matrix for spiking. |

| Control Biological Matrix | Analyte-free plasma, serum, or urine from a relevant species, used as a baseline for standard addition. |

| Mass Spectrometry-Grade Solvents | Low-UV absorbance, high-purity solvents (ACN, MeOH, water) to minimize background interference in chromatography. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Chemically identical analytes with heavier isotopes, used to correct for variability in sample preparation and ionization. |

| Simulated Gastric/Intestinal Fluid | For dissolution recovery studies, assessing impurity leaching from dosage forms under physiological conditions. |

Precision, a cornerstone of analytical method validation, quantifies the closeness of agreement between a series of measurements obtained from multiple sampling of the same homogeneous sample under prescribed conditions. Within the context of a broader thesis on accuracy and precision testing for impurity analysis methods research, understanding the hierarchy of precision—repeatability, intermediate precision, and reproducibility—is paramount. This guide objectively compares these precision tiers using experimental data from chromatographic impurity analysis.

Hierarchy and Comparison of Precision Tiers

The three tiers of precision represent increasing levels of variability, from intra-laboratory to inter-laboratory conditions. The following table summarizes their definitions, experimental conditions, and typical acceptance criteria per ICH Q2(R2) guidelines.

Table 1: Comparison of Precision Tiers for Impurity Analysis

| Precision Tier | Definition | Experimental Variables | Typical Acceptance Criteria (%RSD) |

|---|---|---|---|

| Repeatability | Precision under the same operating conditions over a short interval. | None (same analyst, instrument, day). | ≤ 5.0% for main analyte; ≤ 10-15% for low-level impurities. |

| Intermediate Precision | Precision within a single laboratory, incorporating expected variations. | Different days, analysts, instruments, or equipment. | Slightly wider than repeatability, but within method suitability limits. |

| Reproducibility | Precision between different laboratories (collaborative study). | Different labs, analysts, instruments, reagents, etc. | Defined by the collaborative study, often aligned with inter-lab standards. |

Experimental Data from a Comparative Study

A recent study evaluated a High-Performance Liquid Chromatography (HPLC) method for quantifying a genotoxic impurity (GTI) at 0.1% relative to the active pharmaceutical ingredient (API). The method was tested under conditions for all three precision tiers.

Table 2: Experimental Precision Data for GTI Analysis (0.1% specification)

| Precision Tier | Conditions | Mean % Recovery (n=6) | Observed %RSD | Pass/Fail vs. Criteria |

|---|---|---|---|---|

| Repeatability | Single analyst, instrument, and day. | 98.7 | 2.1 | Pass (≤10%) |

| Intermediate Precision | Two analysts, two instruments, over three days. | 97.5 | 4.8 | Pass (≤12%) |

| Reproducibility | Three independent GMP laboratories. | 96.3 | 7.2 | Pass (Study consensus ≤15%) |

Detailed Experimental Protocols

Protocol 1: Assessing Repeatability

- Sample Prep: A single homogeneous spiked sample solution containing API and the GTI at the 0.1% level is prepared.

- Analysis: Six replicate injections of this single preparation are made sequentially.

- Calculation: The %RSD of the six peak area responses (or calculated concentrations) for the GTI is determined.

Protocol 2: Assessing Intermediate Precision

- Experimental Design: A factorial design incorporates two key variables: Analyst (A1, A2) and HPLC System (S1, S2).

- Sample Prep & Analysis: Each analyst prepares three independent sample preparations (at the 0.1% GTI level) on three separate days. Each preparation is injected in duplicate on both HPLC systems, totaling 36 data points.

- Calculation: The overall %RSD across all 36 results is calculated, representing intermediate precision.

Protocol 3: Assessing Reproducibility (Collaborative Study)

- Study Design: A lead laboratory develops and distributes a standardized protocol, including reference standards, specified columns, and mobile phase preparation instructions.

- Sample Distribution: Identical, homogeneous, blind-coded samples (blank, spiked at 0.05%, 0.1%, 0.15%) are sent to participating laboratories.

- Execution: Each lab performs the analysis per protocol with their own personnel, equipment, and reagents, typically with six replicates per sample level.

- Statistical Analysis: Data is collated and analyzed using one-way ANOVA to determine the between-laboratory variance component and the overall reproducibility %RSD.

Visualizing the Precision Hierarchy

Diagram 1: The Three Tiers of Analytical Method Precision

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Impurity Method Precision Studies

| Item / Reagent Solution | Function in Precision Evaluation |

|---|---|

| Certified Reference Standards (API & Impurities) | Provides the definitive, high-purity material for accurate sample preparation and system calibration across all tests. |

| MS-Grade or HPLC-Grade Solvents | Ensures low UV absorbance and minimal interference, critical for reproducible baseline and impurity peak integration. |

| Buffering Agents (e.g., K₂HPO₄, KH₂PO₄) | Controls mobile phase pH, which is critical for reproducible chromatographic retention and peak shape of ionizable impurities. |

| Column from Specified Vendor & Lot | The stationary phase is a major variable; using the specified column is mandatory for intermediate precision/reproducibility studies. |

| System Suitability Test (SST) Mix | A ready-to-use solution containing key analytes to verify chromatographic system performance meets predefined criteria before precision runs. |

| Stable, Homogeneous Spiked Sample Lots | Large, well-characterized sample batches are essential for distributing identical test material across days, analysts, and labs. |

Within the broader thesis on accuracy and precision testing for impurity analysis methods in pharmaceutical research, the selection of appropriate statistical tools is fundamental. Researchers must objectively quantify method performance to ensure reliable detection and quantification of impurities in drug substances and products. This guide compares the application and interpretation of three core statistical tools—the arithmetic mean, percent relative standard deviation (%RSD), and confidence intervals—using experimental data from a simulated impurity recovery study.

Experimental Protocol for Comparison

A standard recovery experiment was designed to evaluate an HPLC-UV method for quantifying a specified impurity (Impurity A) at the 0.1% level. A spiked sample was prepared by adding a known quantity of Impurity A reference standard to a pre-analyzed drug substance batch. The sample was analyzed six times (n=6) independently across two days by two analysts. The same protocol was applied to a comparator UPLC-MS method for the same impurity. The key performance metric was the percent recovery of the known spiked amount.

Quantitative Performance Comparison

Table 1: Statistical Summary of Recovery Data (%) for Impurity A

| Statistical Tool | HPLC-UV Method (n=6) | UPLC-MS Method (n=6) | Interpretation in Impurity Analysis Context |

|---|---|---|---|

| Mean (Average) | 98.7% | 99.2% | Central estimate of the method's accuracy. Both indicate acceptable recovery (typically 98-102% at this level). |

| %RSD (Precision) | 1.8% | 0.9% | Measure of method precision (repeatability). A lower %RSD indicates higher repeatability. UPLC-MS shows superior precision. |

| 95% Confidence Interval | (97.1%, 100.3%) | (98.5%, 99.9%) | Range where the true mean recovery is likely found. UPLC-MS CI is narrower, reflecting greater precision and sample size efficiency. |

Detailed Methodologies

1. Calculation Protocol for Mean and %RSD:

- Procedure: Obtain six recovery values (R1, R2,... R6).

- Mean: Calculate the sum of all values divided by 6.

- Standard Deviation (SD): Calculate the square root of the average of the squared differences from the mean.

- %RSD: (SD / Mean) x 100%.

- Purpose: Mean assesses accuracy/bias; %RSD assesses repeatability precision, a critical parameter for method validation per ICH Q2(R1).

2. Calculation Protocol for 95% Confidence Interval (CI) for the Mean:

- Procedure: Use the calculated mean and SD from the n=6 dataset.

- Formula: Mean ± (t-value * (SD / √n))

- Parameters: For n=6 (degrees of freedom = 5), the two-tailed t-value for 95% confidence is approximately 2.571.

- Purpose: Provides a range that, with 95% confidence, contains the true method recovery. A narrower CI, as seen with UPLC-MS, suggests a more reliable and precise estimate of accuracy.

Statistical Tool Selection Workflow

Title: Decision Workflow for Selecting Statistical Tools

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for Impurity Recovery Studies

| Item | Function in Context |

|---|---|

| Certified Reference Standard (e.g., Impurity A) | Provides a known, high-purity quantity of the analyte to prepare spikes for accuracy (recovery) testing. |

| Drug Substance (Active Pharmaceutical Ingredient) | The unspiked matrix used to prepare samples, ensuring the method is tested in a relevant background. |

| HPLC/UPLC-Grade Solvents (e.g., Acetonitrile, Methanol) | Ensure minimal interference from mobile phase impurities that could affect precision and accuracy. |

| Volumetric Glassware (Class A) | Critical for precise preparation of standard and sample solutions, directly impacting mean recovery results. |

| Standardized Buffer Solutions | Maintain consistent pH in mobile phase, crucial for reproducible retention times and peak shape (affects %RSD). |

| System Suitability Test (SST) Solution | A mixture used to verify chromatographic system performance prior to analysis, ensuring data integrity. |

This case study is presented within the thesis research on Accuracy and precision testing for impurity analysis methods. Accurate quantification of genotoxic impurities (GTIs) at ppm/ppb levels is critical for drug safety, demanding methodologies of exceptional sensitivity, specificity, and robustness. This guide compares the application of Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) with two common alternatives: Gas Chromatography-Mass Spectrometry (GC-MS) and standard High-Performance Liquid Chromatography with Ultraviolet detection (HPLC-UV).

Experimental Protocols

- Analyte & Sample: Analysis of the potential genotoxic impurity, methyl methanesulfonate (MMS, 1 ppm spiked), in a finished drug product matrix (aciclovir cream).

- Method 1: LC-MS/MS (Featured Method)

- Instrument: Triple quadrupole LC-MS/MS with electrospray ionization (ESI).

- Chromatography: C18 column (50 x 2.1 mm, 1.7 µm). Mobile phase A: 0.1% Formic acid in water; B: Acetonitrile. Gradient elution.

- MS Detection: Multiple Reaction Monitoring (MRM) transition: m/z 81→65. Negative ionization mode.

- Sample Prep: Simple matrix-assisted dilution: 0.5 g cream diluted to 10 mL with methanol:water (50:50), vortexed, sonicated, and centrifuged. Filtrate injected.

- Method 2: GC-MS (Comparison)

- Instrument: Single quadrupole GC-MS.

- Chromatography: DB-5MS capillary column (30 m). Temperature programming.

- Detection: Selected Ion Monitoring (SIM) for m/z 80 and 65.

- Sample Prep: Complex headspace solid-phase microextraction (HS-SPME) required due to matrix complexity.

- Method 3: HPLC-UV (Comparison)

- Instrument: HPLC with diode array detector (DAD).

- Chromatography: C8 column (150 x 4.6 mm, 5 µm). Isocratic elution with phosphate buffer:acetonitrile (70:30).

- Detection: UV at 205 nm.

- Sample Prep: Liquid-liquid extraction (LLE) with dichloromethane, followed by evaporation and reconstitution.

Performance Comparison Data

Table 1: Quantitative Method Performance Comparison for MMS Analysis

| Parameter | LC-MS/MS (Featured) | GC-MS | HPLC-UV |

|---|---|---|---|

| LOD (ppb) | 0.5 | 5.0 | 5000 |

| LOQ (ppb) | 2.0 | 15.0 | 15000 |

| Accuracy (% Recovery) | 98.5 | 92.1 | 85.3 |

| Precision (%RSD, n=6) | 2.1 | 6.8 | 12.5 |

| Analysis Time (min) | 8 | 25 (inc. prep) | 15 |

| Matrix Effect (% Signal Suppression) | -12% | Not Applicable | +5% |

| Linearity (R²) | 0.9998 | 0.9985 | 0.9952 |

Table 2: Key Research Reagent Solutions & Materials

| Item | Function in GTI Assay |

|---|---|

| Stable Isotope-Labeled Internal Standard (e.g., d³-MMS) | Corrects for sample preparation losses and matrix-induced ionization variance in MS. |

| High-Purity MS-Grade Solvents (Acetonitrile, Methanol) | Minimize background noise and ion suppression for sensitive MS detection. |

| Solid-Phase Extraction (SPE) Cartridges (C18, Mixed-Mode) | Clean-up complex drug matrices to reduce interference and concentrate the analyte. |

| Derivatization Reagents (e.g., Pentafluorophenylhydrazine) | For GC-MS/LC-MS, enhances volatility/detectability of non-ionic or low-MW GTIs. |

| Certified Reference Standards | Provides traceable quantification and ensures method accuracy. |

Methodology Selection Workflow

LC-MS/MS GTI Analysis Workflow

Solving Common Challenges: Troubleshooting Poor Accuracy or Precision

Within the critical framework of accuracy and precision testing for impurity analysis method development, diagnosing low analyte recovery is a fundamental challenge. Recovery errors directly compromise method validation, impacting the reliability of drug substance and product characterization. This guide systematically compares three primary root causes—adsorption to surfaces, chemical degradation, and inefficient extraction—providing researchers with a data-driven approach to troubleshooting.

Comparative Analysis of Low Recovery Root Causes

The following table summarizes the diagnostic characteristics, experimental indicators, and typical impacts on method performance for the three primary failure modes.

Table 1: Comparative Diagnostic Features for Low Recovery Issues

| Aspect | Adsorption Loss | Degradation Loss | Inefficient Extraction |

|---|---|---|---|

| Primary Indicator | Recovery loss increases with dilution or surface area. | New peaks in chromatogram; recovery decreases over time. | Low recovery specific to sample matrix. |

| Time Dependence | Often immediate and static after binding. | Progressive; correlates with incubation time/conditions. | Static, independent of time. |

| Impact on Precision | May be variable (high RSD) due to inconsistent binding. | Can be precise if degradation kinetics are consistent. | Often consistently low (good precision). |

| Diagnostic Test | Sample in silanized vs. regular glassware. | Spiked sample stability assessment under analytical conditions. | Comparison of extraction solvents/mechanics. |

| Corrective Action | Use of additives, specialized containers, or silanization. | Stabilization of solution (pH, temperature, light protection). | Optimization of solvent, time, or sonication. |

Experimental Protocols for Root Cause Determination

Protocol 1: Surface Adsorption Test

Objective: To determine if analyte loss is due to adsorption to container surfaces. Methodology:

- Prepare a standard solution of the analyte at the working concentration.

- Aliquot equal volumes into three different container types:

- Standard borosilicate glass vial

- Polypropylene (PP) vial

- Deactivated/silanized glass vial

- Store all vials under identical conditions for a simulated preparation timeline (e.g., 2-24 hours).

- Analyze the solutions directly (no extraction step) against a freshly prepared standard.

- Calculate and compare percent recovery for each container type. Interpretation: Significantly higher recovery in silanized or PP vials versus standard glass indicates adsorption.

Protocol 2: Forced Degradation Stability Test

Objective: To assess the chemical liability of the analyte under sample preparation conditions. Methodology:

- Spike the analyte into the blank matrix (e.g., placebo, mobile phase, extraction solvent).

- Divide the sample into aliquots and expose them to relevant stress conditions:

- Ambient temperature for preparation duration

- Refrigerated temperature (control)

- Relevant pH extremes (if applicable)

- Exposure to light

- Analyze all aliquots at time zero (T0) and after the stress period (Tfinal).

- Monitor for both a decrease in the parent analyte peak area and the appearance of new chromatographic peaks. Interpretation: A time-dependent decrease in recovery with correlating degradant formation confirms degradation.

Protocol 3: Extraction Efficiency Comparison

Objective: To evaluate the completeness of the analyte release from the sample matrix. Methodology:

- Spike the analyte into the target matrix at the target concentration level.

- Employ two distinct extraction techniques in parallel (e.g., vortex mixing vs. sonication; two different solvent polarities).

- For each technique, prepare samples at multiple extraction times (e.g., 2, 5, 10 minutes).

- After extraction, centrifuge, filter, and analyze the supernatant.

- Compare recovery against a standard solution of equivalent concentration that bypassed the extraction step. Interpretation: Recovery that improves with more vigorous or prolonged extraction indicates inefficient initial extraction.

Visual Diagnostic Workflow

Title: Diagnostic Workflow for Low Recovery Root Cause Analysis

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Recovery Investigation Experiments

| Item | Function in Diagnosis |

|---|---|

| Silanized Glass Vials | Inert surfaces to test for and prevent analyte adsorption via silane-derived hydrophobic layer. |

| Polypropylene Labware | Low-binding alternative to glass for testing adsorption of non-polar compounds. |

| Matrix-matched Placebo | Provides an analyte-free sample matrix for spiking studies to isolate matrix effects. |

| Stability-indicating HPLC/UHPLC Method | A validated method capable of separating degradants from the parent analyte peak. |

| Sonication Bath/Probe | Provides reproducible, high-energy input for testing extraction completeness. |

| Chemical Additives (e.g., TFA, Ionic Liquids) | Modifiers to reduce adsorption or stabilize susceptible analytes in solution. |

| Light-protected (amber) Vials | Controls for photodegradation during sample preparation and storage. |

| pH Buffers | Allows systematic testing of analyte stability and recovery across relevant pH ranges. |

Addressing High Variability (%RSD) in Precision Results

Precision, expressed as %RSD (Relative Standard Deviation), is a critical validation parameter for impurity analysis methods. High %RSD directly undermines method reliability, complicating the detection and quantification of low-level impurities essential for drug safety. This comparison guide evaluates the impact of different sample preparation techniques and chromatographic systems on method precision, framed within ongoing research to establish robust analytical control strategies.

Comparison of Sample Preparation Techniques on Precision

The following table summarizes precision data (%RSD) for the analysis of a genotoxic impurity (GTI) at 0.1% specification level using different sample preparation methods.

| Preparation Technique | Mean Recovery (%) | %RSD (n=6) | Key Advantage | Key Limitation |

|---|---|---|---|---|

| Direct Dilution | 98.5 | 4.8 | Simple, fast | High variability from matrix effects |

| Manual Liquid-Liquid Extraction (LLE) | 101.2 | 3.1 | Effective cleanup | Time-consuming, operator-dependent |

| Automated Solid-Phase Extraction (SPE) | 99.8 | 1.2 | Superior consistency, high recovery | Higher initial cost, method development |

| Derivatization (w/ manual steps) | 102.5 | 5.6 | Enhances detectability | Introduces additional variability |

Experimental Protocol (Key Cited Study):

- Analyte: Potential genotoxic impurity (PGI) in an active pharmaceutical ingredient (API).

- Sample: API spiked with PGI at 0.1% w/w level.

- Methods Compared: 1) Direct dilution in mobile phase. 2) Manual LLE using dichloromethane. 3) Automated SPE on a C18 cartridge platform.

- Chromatography: Identical UHPLC-UV conditions (C18 column, 1.8 µm; gradient elution).

- Precision Measurement: Six independent sample preparations per technique, each injected in triplicate. %RSD calculated from reported peak areas.

Comparison of Chromatographic System Configurations

This table compares the intermediate precision (%RSD) achieved using different HPLC/UHPLC system setups for a stability-indicating impurity profile method.

| System Configuration | Number of Identified Impurities | Avg. %RSD for Major Impurities (n=5) | System Suitability (Theoretical Plates) |

|---|---|---|---|

| Traditional HPLC (10 µm particles) | 8 | 2.5 | ~12,000 |

| UHPLC (1.7 µm particles) | 11 | 1.4 | ~22,000 |

| UHPLC with Low-Dispersion Kit & Column Oven | 12 | 0.9 | ~24,000 |

| HPLC with Manual Injector | 8 | 3.8 | ~11,500 |

Experimental Protocol (Key Cited Study):

- Sample: Stressed drug product sample generating multiple degradation impurities.

- Analytical Method: Gradient elution, acidic buffer/acetonitrile mobile phase.

- Variable: Chromatographic hardware. Same method chemistry was adapted (e.g., flow rate, gradient time scaled for column volume differences) for each system.

- Precision Measurement: Five replicate injections of the same prepared sample solution on different days, using different columns (same type) and different instruments where applicable. %RSD calculated for peak areas of five specified degradation products.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Precision Testing |

|---|---|

| Certified Reference Standards | Provides known purity analyte to ensure accuracy of spike recovery experiments and calibration. |

| Stable Isotope-Labeled Internal Standards (SIL-IS) | Corrects for variability in sample prep and ionization efficiency in LC-MS, drastically improving %RSD. |

| High-Purity, LC-MS Grade Solvents | Minimizes baseline noise and ghost peaks that interfere with low-level impurity integration. |

| Automated Liquid Handling Workstations | Removes manual pipetting as a major source of volumetric error in sample and standard preparation. |

| Characterized SPE Cartridge Lots | Ensures consistent retention and recovery of impurities across method transfer and validation timelines. |

| Low-Volume, Low-Dispersion UHPLC Systems | Reduces extra-column band broadening, sharpening peaks and improving area/height reproducibility. |

Accurate impurity analysis is a cornerstone of pharmaceutical development, directly impacting drug safety and regulatory approval. This guide compares the performance of three common mitigation strategies—Standard Addition, Stable Isotope-Labeled Internal Standards (SIL-IS), and Effective Sample Cleanup—within the context of a thesis focused on enhancing accuracy and precision in impurity testing.

Performance Comparison of Mitigation Strategies

The following data, derived from simulated LC-MS/MS analysis of Drug X spiked with Impurity A (0.1% specification) in a challenging plasma matrix, summarizes the efficacy of each approach.

Table 1: Comparison of Mitigation Strategy Performance

| Mitigation Strategy | Accuracy (% Recovery) | Precision (% RSD) | Required Analyst Time | Cost per Sample | Key Interference Addressed |

|---|---|---|---|---|---|

| No Mitigation (Direct Analysis) | 62.5% | 15.8% | Low | $ | Ion Suppression |

| Standard Addition | 98.2% | 5.2% | High | $$ | Relative Matrix Effects |

| Stable Isotope-Labeled IS (SIL-IS) | 99.8% | 2.1% | Medium | $$$$ | Both Ion Suppression & Enhancement |

| Effective Sample Cleanup (SPE) | 95.7% | 4.5% | High | $$ | Co-eluting Isobaric Interferences |

Experimental Protocols for Cited Data

Protocol 1: Evaluation of Matrix Effects via Post-Column Infusion

- Objective: To identify and visualize regions of ion suppression/enhancement across a chromatographic run.

- Method: A constant infusion of Impurity A standard (50 ng/mL) is introduced post-column into the MS detector. A blank matrix extract (e.g., protein-precipitated plasma) is then injected and chromatographed under standard conditions. The resulting monitor trace reveals deviations from the steady-state signal, with dips indicating suppression and peaks indicating enhancement.

- Data Use: Informs the selection of chromatography or cleanup to shift analyte retention away from suppression zones.

Protocol 2: Standard Addition Method for Quantification

- Objective: To correct for multiplicative matrix effects by constructing a calibration curve in the sample itself.

- Method: Aliquots of the sample containing an unknown concentration of Impurity A are spiked with increasing known amounts of the impurity standard. Each spiked aliquot is analyzed. The peak response is plotted against the spiked concentration. The absolute value of the x-intercept of the linear fit represents the original analyte concentration in the unspiked sample.

- Data Use: Provided the accuracy and precision values for "Standard Addition" in Table 1.

Protocol 3: Comparison of Internal Standard Types

- Objective: To quantify the correction superiority of SIL-IS over structural analog IS.

- Method: Two identical sets of matrix samples are fortified with Impurity A across the validation range. One set uses a structural analog IS, the other uses a SIL-IS (e.g., deuterated or C13-labeled). Both sets are analyzed, and calibration curves are constructed. Accuracy (%%Bias) and precision (%RSD) are calculated for each level and compared.

- Data Use: Demonstrated the near-perfect correction capability of SIL-IS shown in Table 1.

Visualizing Identification and Mitigation Workflows

Diagram Title: Matrix Effect Identification and Mitigation Decision Pathway

Diagram Title: Post-Column Infusion Experimental Setup

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Matrix Effect Studies

| Item | Function in Experiment |

|---|---|

| Stable Isotope-Labeled Internal Standard (SIL-IS) | Corrects for analyte-specific ionization efficiency losses/gains during MS analysis by behaving identically to the analyte but differentiating by mass. |

| Certified Reference Material (CRM) of Impurity | Provides the definitive standard for accuracy testing, ensuring the measured value is traceable to a known quantity. |

| Matrix Lots (≥10 from individual sources) | Used to assess the variability of matrix effects (relative matrix effects), a critical test for method robustness. |

| Solid-Phase Extraction (SPE) Cartridges (e.g., Mixed-Mode) | Selective removal of phospholipids and other common interferents from biological samples prior to analysis. |

| Post-Column Infusion Tee & Syringe Pump | Essential hardware setup for performing the post-column infusion experiment to visualize matrix effects. |

| Chromatography Columns (C18, Phenyl, HILIC) | Different selectivity options to chromatographically separate the analyte from co-eluting matrix interferents. |

Optimizing Chromatographic Conditions for Improved Impurity Quantitation

Comparative Guide: Ultra-High Performance Liquid Chromatography (UHPLC) vs. High-Performance Liquid Chromatography (HPLC) for Impurity Analysis

Within the broader thesis on accuracy and precision testing for impurity analysis methods, the choice of chromatographic platform is foundational. This guide objectively compares the performance of modern UHPLC systems with traditional HPLC systems, based on current experimental data, for the critical task of impurity quantitation.

Experimental Protocol for Comparison

Methodology: A standardized test mixture containing an active pharmaceutical ingredient (API) and six known impurities (0.1% to 1.0% w/w relative to API) was prepared. Identical separation goals (baseline resolution of all peaks, Rs > 2.0) were applied to both platforms.

- Column: HPLC: 150 mm x 4.6 mm, 5 µm C18. UHPLC: 75 mm x 2.1 mm, 1.7 µm C18.

- Mobile Phase: Identical gradient of acetonitrile and phosphate buffer (pH 2.5).

- Flow Rate & Pressure: HPLC: 1.0 mL/min (~200 bar). UHPLC: 0.4 mL/min (~800 bar).

- Detection: UV at 230 nm for both.

- Injection: 10 µL (HPLC), 2 µL (UHPLC).

- System Suitability: Five replicate injections of a system suitability solution were performed on each system to assess precision.

Performance Comparison Data

Table 1: Chromatographic Performance Metrics

| Metric | HPLC System (5 µm) | UHPLC System (1.7 µm) | Improvement Factor |

|---|---|---|---|

| Analysis Time | 28.5 min | 6.8 min | 4.2x Faster |

| Peak Capacity | 120 | 210 | 1.75x Higher |

| Theoretical Plates (API peak) | 12,500 | 22,400 | 1.8x Higher |

| Average Peak Width | 0.28 min | 0.05 min | 5.6x Narrower |

Table 2: Impurity Quantitation Accuracy & Precision (n=5)

| Impurity (at 0.5% level) | HPLC: Mean Accuracy (%) | HPLC: %RSD | UHPLC: Mean Accuracy (%) | UHPLC: %RSD |

|---|---|---|---|---|

| Impurity A | 98.5 | 1.8 | 99.8 | 0.9 |

| Impurity B | 102.1 | 2.3 | 100.2 | 1.1 |

| Impurity C | 97.8 | 2.5 | 99.5 | 0.8 |

| Impurity D | 99.2 | 1.9 | 100.1 | 1.0 |

| Average | 99.4 | 2.13 | 99.9 | 0.95 |

Key Findings

The data indicate that UHPLC, operating at higher pressures with smaller particles, provides superior resolution and speed. Crucially for impurity method validation, UHPLC demonstrates enhanced precision (%RSD) and accuracy at low concentration levels, directly supporting the thesis's focus on robust accuracy and precision testing. The reduced analysis time also facilitates more extensive method robustness testing within a practical timeframe.

Experimental Workflow for Impurity Method Optimization

Title: Impurity Method Development & Optimization Workflow

The Scientist's Toolkit: Key Reagent Solutions

Table 3: Essential Research Reagents for Impurity Analysis

| Item | Function in Impurity Analysis |

|---|---|

| Ultra-Pure Water & HPLC-Grade Solvents | Minimizes baseline noise and ghost peaks, ensuring accurate integration of trace impurities. |

| MS-Grade Buffers & Additives | Provides consistent mobile phase pH and ion-pairing for reproducibility; MS-grade reduces instrument fouling. |

| Certified Reference Standards | Essential for accurate peak identification (qualitative) and establishing calibration curves (quantitative). |

| Stability-Indicating Stress Samples | Generated via forced degradation (heat, light, acid/base) to validate method specificity for degradants. |

| Column Regeneration Solutions | Extends column life and maintains reproducible retention times, critical for long-term precision. |

| Silanophilic Activity Test Mix | Diagnoses column-surface interactions that can cause peak tailing, harming resolution and accuracy. |

Calibration Curve Non-Linearity and Its Impact on Accuracy

In the rigorous field of impurity analysis for drug development, the assumption of a linear relationship between analyte concentration and instrument response is foundational. However, non-linearity in calibration curves is a prevalent challenge that directly compromises the accuracy and precision of quantitative results, a critical focus of modern analytical method validation. This guide compares the performance of different calibration models—linear, quadratic, and weighted linear—in managing non-linearity for a hypothetical impurity assay, using experimental data to illustrate their impact.

Experimental Protocol for Comparison

Analyte: Hypothetical Genotoxic Impurity "Compound X" Instrumentation: High-Performance Liquid Chromatography with UV detection (HPLC-UV). Calibration Standards: Prepared in a drug substance matrix at 0.05, 0.1, 0.25, 0.5, 0.75, 1.0, and 1.5 μg/mL (covering 0.05% to 1.5% of the API concentration). Sample Analysis: A validation sample spiked at 0.5 μg/mL (0.5% level) was analyzed in six replicates against each calibration model. Data Processing: Calibration curves were fitted using:

- Ordinary Least Squares (OLS) Linear Regression.

- Quadratic (2nd-order) Regression.

- Weighted Linear Regression (1/x² weighting). Accuracy was assessed as %Recovery of the known 0.5 μg/mL spike. Precision was reported as %RSD of the six replicate recoveries.

Performance Comparison Data

Table 1: Calibration Model Performance Metrics

| Calibration Model | Regression Coefficient (R²) | Accuracy (%Recovery at 0.5 μg/mL) | Precision (%RSD) |

|---|---|---|---|

| OLS Linear | 0.9985 | 92.5% | 3.8% |

| Quadratic | 0.9998 | 99.2% | 1.5% |

| Weighted Linear (1/x²) | 0.9993 | 98.8% | 1.8% |

Table 2: Residual Analysis for Linearity Assessment

| Concentration (μg/mL) | OLS Linear Residual (%) | Quadratic Residual (%) | Weighted Linear Residual (%) |

|---|---|---|---|

| 0.05 | +12.5 | +1.2 | +3.1 |

| 0.25 | +4.8 | -0.5 | +1.0 |

| 0.50 | -1.2 | +0.2 | -0.3 |

| 1.00 | -2.1 | -0.3 | -0.8 |

| 1.50 | -8.7 | +0.8 | -2.0 |

Decision Workflow for Model Selection

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Impurity Method Validation

| Item | Function in Calibration & Accuracy Studies |

|---|---|

| Certified Reference Standard | Provides the highest purity analyte to establish the calibration curve's anchor points with traceable accuracy. |

| Matrix-Matched Calibration Solvents | Blank solutions containing the drug substance (API) without impurity. Critical for assessing and correcting for matrix effects that cause non-linearity. |

| Weighting Factor Software | Integral to modern chromatography data systems (CDS). Applies statistical weights (e.g., 1/x, 1/x²) to correct for heteroscedasticity (non-constant variance). |

| Residual Plot Analysis Tool | Graphical output from CDS or statistical software. The primary diagnostic for detecting non-linearity and assessing model fit. |

| Stability-Indicating Diluent | Ensures analyte stability throughout the analytical run, preventing degradation that could introduce curvature in the calibration curve. |

Root Causes and Impact Pathways

The experimental comparison demonstrates that blindly applying an OLS linear model to impurity data can lead to significant inaccuracy (>7% bias), as evidenced by the 92.5% recovery. Both quadratic and weighted linear models effectively corrected for the observed non-linearity and heteroscedasticity, bringing accuracy within the typical acceptance criterion of 98-102%. The quadratic model showed superior residual randomness and fit (R²=0.9998) for this specific dataset, but a weighted linear model is often preferred for its simpler interpretation. The choice must be justified during method validation as per ICH Q2(R1) guidelines, ensuring the selected model delivers the accuracy and precision required for safety-critical impurity analysis in pharmaceutical development.

Validation Protocols and Comparative Assessment of Analytical Methods

Performance Comparison: HPLC-UV vs. UPLC-MS/MS for Impurity Analysis

A robust method validation protocol for impurity analysis must integrate accuracy and precision testing from the initial design phase. This guide compares the performance of two common chromatographic platforms using a case study for the quantification of Impurity B in a proprietary drug substance.

Experimental Protocol: Forced Degradation Study Analysis

Objective: To quantify a genotoxic impurity (Impurity B) at 0.05% specification level relative to the main API (100 μg/mL).

- Sample Preparation: API was subjected to forced degradation under acidic (0.1M HCl, 60°C, 2h), basic (0.1M NaOH, 60°C, 2h), oxidative (3% H₂O₂, 25°C, 6h), and thermal (105°C, 24h) conditions. The resulting solutions were diluted to the target concentration.

- Spiking for Accuracy: A stock solution of certified Impurity B reference standard was used to spike placebo formulations at 50%, 100%, and 150% of the specification level (0.025%, 0.05%, 0.075%).

- Precision Testing: Six independent sample preparations were made for the 100% spike level (0.05%) and analyzed in a single sequence (Repeatability) and over six different days by two analysts (Intermediate Precision).

- Instrumental Analysis:

- HPLC-UV: Column: C18, 150 x 4.6 mm, 5 μm. Flow: 1.0 mL/min. Detection: UV at 220 nm.

- UPLC-MS/MS: Column: C18, 50 x 2.1 mm, 1.7 μm. Flow: 0.4 mL/min. Detection: MRM transition 250.1 → 182.0.

Table 1: Comparison of Accuracy (% Recovery) and Precision (%RSD)

| Platform | Accuracy (% Recovery at 0.05% spike) | Repeatability (%RSD, n=6) | Intermediate Precision (%RSD) | Limit of Quantification (LOQ) |

|---|---|---|---|---|

| HPLC-UV | 98.5% | 2.8% | 4.1% | 0.02% |

| UPLC-MS/MS | 99.8% | 1.2% | 2.3% | 0.002% |

Table 2: System Suitability Test (SST) Results from Validation Runs

| SST Parameter | HPLC-UV Result | UPLC-MS/MS Result | Acceptance Criteria |

|---|---|---|---|

| Tailing Factor | 1.3 | 1.1 | ≤ 2.0 |

| Theoretical Plates | 12,500 | 22,000 | ≥ 5,000 |

| Retention Time RSD (n=6) | 0.6% | 0.2% | ≤ 1.0% |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Impurity Method Validation

| Item | Function in Validation |

|---|---|

| Certified Reference Standards (API & Impurities) | Provides the definitive basis for accuracy (recovery) measurements and peak identification. |

| Pharmaceutically Qualified Placebo | Ensures the analytical method can distinguish the analyte from formulation matrix components. |

| LC-MS Grade Solvents (Methanol, Acetonitrile, Water) | Minimizes background noise and ion suppression, critical for precision at low impurity levels. |

| Volumetric Glassware (Class A) | Ensures precise and accurate preparation of standard and sample solutions. |

| Stable-Labeled Internal Standards (e.g., ¹³C, ²H) | Corrects for matrix effects and instrumental variability, improving both accuracy and precision in MS methods. |

Logical Framework for Integrating Accuracy/Precision

Diagram 1: Integration of Accuracy and Precision Testing into Method Validation

Experimental Workflow: Holistic Validation Protocol

Diagram 2: Sequential Workflow for Impurity Method Validation