Accelerating the Circular Economy: How AI and Machine Learning Are Revolutionizing Sustainable Polymer Design

This article provides a comprehensive exploration of the transformative role of artificial intelligence (AI) and machine learning (ML) in designing recyclable and sustainable polymers.

Accelerating the Circular Economy: How AI and Machine Learning Are Revolutionizing Sustainable Polymer Design

Abstract

This article provides a comprehensive exploration of the transformative role of artificial intelligence (AI) and machine learning (ML) in designing recyclable and sustainable polymers. Targeted at researchers, scientists, and drug development professionals, it details foundational concepts, methodologies, optimization strategies, and validation techniques. The scope covers from the fundamental principles of polymer informatics and data-driven property prediction to the practical application of generative models for novel monomer discovery. It addresses key challenges in model training, data scarcity, and multi-objective optimization for balancing performance with recyclability. Finally, it evaluates the real-world impact and comparative advantages of AI-driven approaches over traditional methods, concluding with future directions for biomedically-relevant, closed-loop material cycles.

The AI-Polymer Nexus: Core Concepts and Data-Driven Foundations for Sustainable Material Discovery

The synthetic polymer industry, while foundational to modern society, faces an existential crisis due to its reliance on fossil feedstocks and the generation of persistent waste. The core challenge is the historical design paradigm focused solely on performance and cost, neglecting end-of-life. This whiteparescribes a fundamental shift towards polymers with intrinsic recyclability and a minimized environmental footprint from synthesis to disposal. This pursuit is now being radically accelerated by Artificial Intelligence (AI). AI-driven research provides a framework to navigate the vast chemical space, predict polymer properties, deconstruct pathways, and optimize for circularity from the initial design stage. This guide details the technical methodologies and experimental paradigms central to this interdisciplinary field.

Core Design Strategies and Quantitative Data

The following table summarizes key polymer design strategies for enhanced recyclability, their mechanisms, and current performance metrics.

Table 1: Strategies for Designing Recyclable Polymers

| Design Strategy | Chemical Mechanism | Key Metric (Typical Target/Current Best) | Recycling Efficiency | Challenges |

|---|---|---|---|---|

| Dynamic Covalent Networks | Reversible bonds (e.g., Diels-Alder, transesterification) enable network rearrangement. | Tg: 25-120°C; Stress Relaxation Time: 1-1000 s at elevated T | >95% property retention after 5 cycles | Catalyst stability, creep resistance at use temperature. |

| Depolymerizable Polymers | Designed to revert to pure monomer under specific triggers (e.g., chemical, thermal). | Depolymerization Yield: >90%; Monomer Purity: >99% | Essentially closed-loop | Integrating trigger sensitivity with material stability during use. |

| Chemical Recycling to Virgin Feedstock | Backbone cleavage (hydrolysis, glycolysis, pyrolysis) to monomers or oligomers. | Conversion Rate: 70-95%; Energy Input: 2-5 MJ/kg | High-quality output, but often energy-intensive | Separation of additives, catalyst cost and poisoning. |

| Mechanochemical Triggered Breakdown | Incorporation of labile bonds sensitive to mechanical force (e.g., shear during reprocessing). | Scission Efficiency: Quantified via sonochemistry or ball milling | Emerging technology | Precise control over scission location and rate. |

| Biodegradable Polymers (where appropriate) | Enzymatic or hydrolytic cleavage to benign products in specific environments. | Mineralization Rate (e.g., in industrial compost): >90% in 180 days | Not typically for material recovery, only carbon cycle | Requires specific environmental conditions; potential microplastic issue if incomplete. |

Experimental Protocols for Key Evaluations

Protocol 3.1: Evaluating Chemical Recyclability via Glycolysis

- Objective: To quantify the depolymerization yield and purity of monomers/oligomers from polyesters like PET or novel analogs.

- Materials: Polymer sample (granulated, ~5g), ethylene glycol (excess, 50ml), zinc acetate catalyst (0.5 wt% relative to polymer), nitrogen atmosphere, round-bottom flask, condenser, heating mantle.

- Procedure:

- Charge flask with polymer, glycol, and catalyst. Purge with N₂ for 15 min.

- Reflux at 197°C under N₂ with stirring for a predetermined time (e.g., 2-8 h).

- Cool mixture. Precipitate products in cold water, filter, and dry under vacuum.

- Analyze yield gravimetrically. Characterize products via NMR, GPC, and HPLC to determine monomer/oligomer composition and purity.

- AI Integration: Machine learning models (e.g., Random Forest, GNNs) can predict optimal catalyst, solvent, temperature, and time for novel polymer structures.

Protocol 3.2: Assessing Dynamic Covalent Network Recyclability

- Objective: To measure property retention after multiple reprocessing cycles of a vitrimer or related material.

- Materials: Cured polymer sample, hot press or parallel plate rheometer, tensile testing apparatus.

- Procedure:

- Characterize initial sample (Tensile strength, modulus, elongation at break via ASTM D638; gel fraction via Soxhlet extraction).

- Reprocessing Cycle: Grind sample into powder. Place in mold and subject to hot press at temperature T_reprocess (above topology freezing transition temperature Tv) under pressure for a set time (e.g., 20 min).

- Cool, demold, and re-characterize mechanically and via gel fraction.

- Repeat steps 2-3 for 4-5 cycles.

- Key Analysis: Plot normalized mechanical properties (cycle N / cycle 1) vs. cycle number. Rheology can quantify stress relaxation time and Tv.

Protocol 3.3: Life Cycle Assessment (LCA) Screening

- Objective: To compare the environmental footprint of a novel recyclable polymer vs. incumbent.

- Methodology (Cradle-to-Gate with Recyclability Assessment):

- Goal & Scope: Define functional unit (e.g., 1 kg of polymer film with equivalent tensile strength).

- Inventory Analysis (LCI): Use AI tools to scour chemical databases and Ecoinvent for inventory data on novel monomers. For synthesis, model energy use from lab-scale reactions scaled via process simulation.

- Impact Assessment: Calculate impacts (Global Warming Potential, Fossil Resource Scarcity, Land Use) using models like ReCiPe 2016.

- Circularity Modeling: Incorporate closed-loop and open-loop recycling scenarios using allocation or system expansion methods.

- AI Integration: Generative models can propose monomer structures optimized for both performance and pre-calculated LCA scores based on predicted synthesis routes.

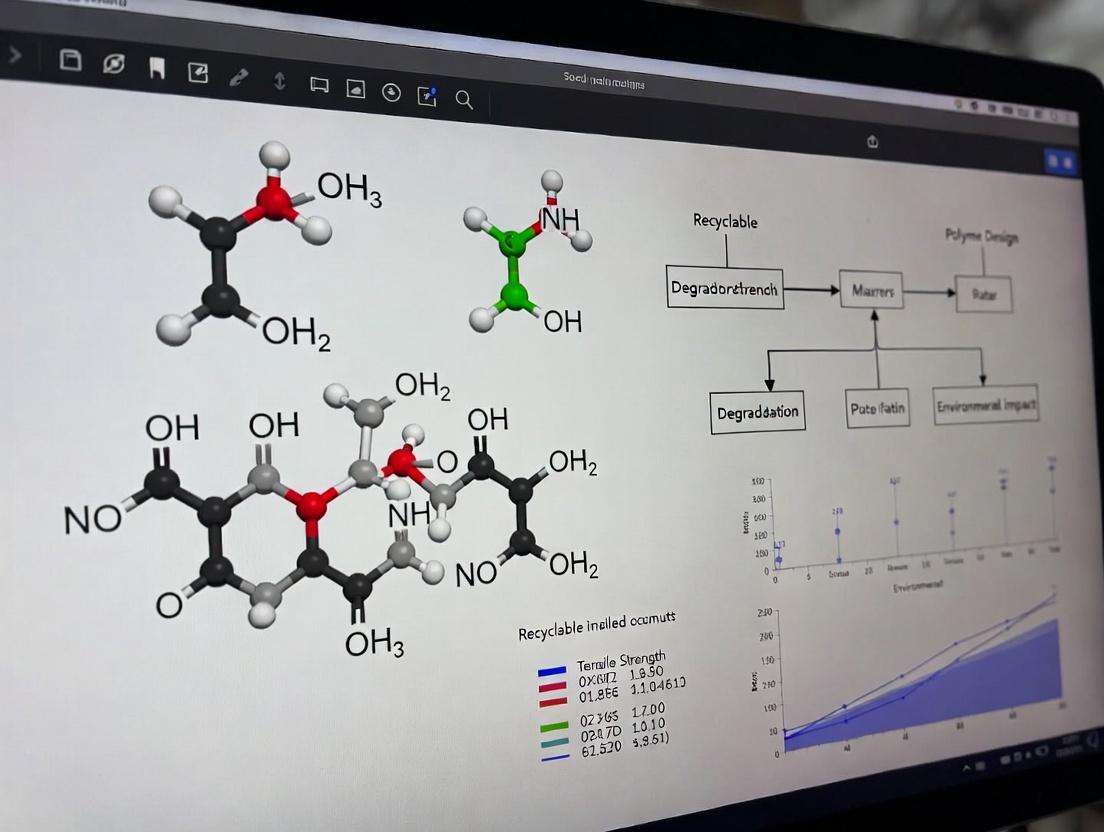

Visualization of Workflows and Pathways

Title: AI-Driven Design Cycle for Sustainable Polymers

Title: Chemical Recycling Pathways to Monomer

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Research Reagents for Recyclable Polymer Studies

| Reagent/Material | Function | Key Consideration for Sustainability |

|---|---|---|

| Diamines with Cleavable Units (e.g., cystine-based, disulfide-containing) | Monomers for polyamides/polyurethanes; introduce dynamic or reducible bonds. | Sourcing from bio-based precursors (e.g., amino acids). |

| Lactone/Lactam Monomers (e.g., MVL, caprolactone, caprolactam) | For ring-opening polymerization to (re)depolymerizable polyesters/polyamides. | Preference for monomers derived from biomass fermentation. |

| Dynamic Crosslinkers (e.g., difunctional Diels-Alder partners, triacylhydrazines) | To form reversible crosslinks in elastomers and thermosets, enabling reprocessing. | Ensure catalyst-free reversibility or use benign catalysts. |

| Depolymerization Catalysts (e.g., Zn(OAc)₂, organocatalysts like TBD, enzymes) | Facilitate selective backbone cleavage during chemical recycling. | Select for low toxicity, high activity, and recoverability. |

| Tagged/Traceable Monomers (isotopically labeled or with fluoro-tags) | Enable precise tracking of material flow through recycling streams in lab studies. | Use minimal quantities to reduce waste and cost. |

| Compatibilizers for Blends (reactive oligomers, block copolymers) | Improve interface in recycled polymer blends, maintaining properties. | Design to be recyclable themselves, avoiding permanent additives. |

The development of recyclable and sustainable polymers is a critical challenge in materials science, driven by environmental imperatives and regulatory pressures. Within this broader thesis, polymer informatics emerges as a transformative discipline, applying data-driven approaches to accelerate the discovery and design of next-generation materials. By leveraging machine learning (ML) on Findable, Accessible, Interoperable, and Reusable (FAIR) data, researchers can predict polymer properties, assess environmental impact, and optimize for recyclability at an unprecedented pace, moving beyond traditional trial-and-error methodologies.

The FAIR Data Principle in Polymer Science

FAIR data is the foundational pillar for effective polymer informatics. For data to be machine-actionable—a prerequisite for robust ML—it must adhere to these principles.

Table 1: Application of FAIR Principles to Polymer Data

| FAIR Principle | Polymer-Specific Implementation Example |

|---|---|

| Findable | Assigning Digital Object Identifiers (DOIs) to datasets in repositories like PolyInfo (NIMS), PI1M, or Zenodo with rich metadata (monomer SMILES, polymerization conditions, properties). |

| Accessible | Storing data in open-access, API-enabled repositories (e.g., Materials Cloud, NOMAD) that use standard authentication/authorization protocols. |

| Interoperable | Using standardized ontologies (e.g., Polymer Ontology) and file formats (e.g., JSON-LD, CIF) to describe polymers, processes, and characterization data. |

| Reusable | Providing detailed provenance, experimental protocols, and clear licensing (e.g., CC BY) to enable replication and new analysis. |

Core Machine Learning Workflows

The predictive pipeline in polymer informatics follows a structured workflow, from data curation to model deployment.

Title: Polymer Machine Learning Predictive Pipeline

Key Experimental Protocols and Data Generation

High-quality, standardized experimental data is crucial for training reliable models. Below are detailed protocols for key characterization methods relevant to sustainable polymer design.

Protocol: Gel Permeation Chromatography (GPC) for Molecular Weight Distribution

Objective: Determine the molecular weight (Mn, Mw) and dispersity (Đ) of a synthesized polymer, critical for predicting mechanical properties and degradability.

- Sample Preparation: Dissolve 5-10 mg of dry polymer in 1 mL of appropriate eluent (e.g., THF for PS, PMMA; DMF for polyamides). Filter through a 0.45 μm PTFE syringe filter.

- Column Calibration: Inject a series of narrow dispersity polystyrene (or polymer-appropriate) standards of known molecular weight to create a calibration curve.

- Sample Analysis: Inject 100 μL of filtered sample. Use isocratic flow (1.0 mL/min) through a series of columns (e.g., three PLgel Mixed-C columns). Detect using a refractive index (RI) detector.

- Data Analysis: Use instrument software (e.g., Empower, Cirrus) to calculate Mn (number-average), Mw (weight-average), and Đ (Mw/Mn) relative to the calibration standard.

Protocol: Differential Scanning Calorimetry (DSC) for Thermal Transitions

Objective: Measure glass transition temperature (Tg), melting temperature (Tm), and crystallinity, which inform processing and end-use temperature limits.

- Sample Preparation: Accurately weigh 5-10 mg of polymer into a hermetically sealed aluminum crucible. Use an empty crucible as reference.

- Temperature Program:

- Equilibrate at -50°C.

- First Heat: Ramp at 10°C/min to 200°C (or above Tm). (Removes thermal history).

- Cool: Ramp at 10°C/min back to -50°C.

- Second Heat: Ramp at 10°C/min to 200°C. (Provides reproducible data).

- Data Analysis: Analyze the second heat curve. Tg is taken as the midpoint of the heat capacity step change. Tm and crystallization temperature (Tc) are taken as the peak of endothermic/exothermic events. Enthalpy is integrated from peak area.

Table 2: Representative FAIR Polymer Dataset (Illustrative)

| Polymer ID (SMILES) | Synthetic Route | Mn (kDa) | Đ | Tg (°C) | Tm (°C) | Degradation Temp. Td5% (°C) | Solubility in Green Solvents | Source DOI |

|---|---|---|---|---|---|---|---|---|

| CC(=O)OC(C)C (PMMA) | Free Radical | 85.2 | 1.12 | 105 | - | 287 | Low in Ethanol | 10.1016/xxx |

| C1CCCCC1 (Polycyclooctene) | ROMP | 120.5 | 1.08 | -65 | 55 | 410 | High in Cyclopentyl Methyl Ether | 10.1021/yyy |

Signaling Pathways for Degradable Polymer Design

Designing for recyclability often involves incorporating cleavable linkages or stimuli-responsive groups. The following diagram maps a conceptual "degradation signaling pathway" triggered by a specific stimulus.

Title: Chemical Pathways for Triggered Polymer Degradation

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Polymer Informatics & Sustainable Design Experiments

| Item | Function/Benefit for Sustainable Polymer Research |

|---|---|

| Mechanistic Transfer (MERT) Polymerization Initiators | Enable controlled radical polymerization (ATRP, RAFT) for precise architectures (block, gradient) from diverse monomers, optimizing property sets. |

| Functional Monomers with Cleavable Linkers | Monomers containing esters, carbonates, or acetals allow backbone engineering for chemical recyclability or biodegradability. |

| Green Solvent Kits (e.g., Cyrene, 2-MeTHF) | Reduce environmental impact of synthesis and processing. Essential for training ML models on green processability. |

| Enzyme Cocktails (e.g., Lipases, Cutinases) | Standardized biocatalysts for evaluating enzymatic degradation rates, providing quantitative data for ML models of biodegradability. |

| High-Throughput Parallel Synthesizer (e.g., Chemspeed) | Automates synthesis of polymer libraries, generating large, consistent FAIR datasets for model training. |

| Bench-top GPC/SEC System with Multiple Detectors | Provides essential Mn, Mw, Đ data. Coupling with light scattering (LS) and viscometry (IV) detectors offers absolute molecular weights and structural insights. |

Future Outlook and Integration

The convergence of FAIR data, advanced ML models (particularly graph neural networks for polymer representations), and automated robotic synthesis platforms (self-driving labs) forms the future of sustainable polymer discovery. This integrated pipeline will rapidly close the design-make-test-analyze cycle, systematically identifying polymers that meet stringent criteria for performance, recyclability, and low environmental persistence, thereby accelerating the transition to a circular materials economy.

Key Molecular Descriptors and Features for Predicting Polymer Sustainability Metrics

This technical guide is framed within a broader thesis on employing artificial intelligence (AI) to accelerate the design of recyclable and sustainable polymers. Predicting key sustainability metrics from molecular structure is a fundamental challenge. This document details the core molecular descriptors and experimental methodologies that serve as both foundational data and validation tools for AI models in this research domain.

Key Molecular Descriptors and Features

Molecular descriptors are quantitative representations of a polymer's chemical structure that correlate with its properties. For sustainability metrics, descriptors can be categorized as shown in the table below.

Table 1: Categorization of Key Molecular Descriptors for Polymer Sustainability

| Category | Descriptor Name | Quantitative Representation | Primary Linked Sustainability Metric |

|---|---|---|---|

| Topological | Number-average MW (Mₙ) | g/mol | Recyclability (processability), Biodegradation rate |

| Weight-average MW (M_w) | g/mol | Mechanical Property Retention, Durability | |

| Degree of Polymerization (DP) | Unitless | Embodied Energy, End-of-Life Fate | |

| Branching Density | Branches per 1000 C atoms | Recyclability (thermo-mechanical), Biodegradability | |

| Chemical | Hydrolysis Rate Constant (k) | L mol⁻¹ s⁻¹ | Biodegradation Rate, Hydrolytic Degradation |

| Glass Transition Temp (T_g) | °C or K | Service Temperature, Energy for Reprocessing | |

| Functional Group Count (e.g., ester, ether) | mol% | Chemical Recyclability, Degradability | |

| Hildebrand Solubility Parameter (δ) | (MPa)^1/2 | Solvent-Based Recycling Efficiency | |

| Electronic/ Quantum | Highest Occupied Molecular Orbital (HOMO) Energy | eV | Oxidative Degradation Resistance |

| Lowest Unoccupied Molecular Orbital (LUMO) Energy | eV | Photodegradation Susceptibility | |

| Partial Atomic Charges | e | Hydrolytic & Enzymatic Cleavage Sites | |

| Environmental Fate | Octanol-Water Partition Coeff (Log P) | Unitless | Bioaccumulation Potential, Ecotoxicity |

| Ultimate Biodegradation (OECD 301B) | % Theoretical CO₂ | Biodegradability in Environment |

Experimental Protocols for Descriptor Validation

Accurate measurement of both descriptors and the resulting sustainability metrics is critical for model training.

Protocol for Determining Molecular Weight and Dispersity (Đ)

Objective: To measure Mₙ, Mw, and Dispersity (Đ = Mw/Mₙ) via Gel Permeation Chromatography (GPC). Materials: Polymer sample, appropriate HPLC-grade solvent (e.g., THF, DMF), polystyrene or polymethyl methacrylate calibration standards. Method:

- Dissolve 5-10 mg of polymer in 10 mL of solvent and filter through a 0.2 µm PTFE membrane.

- Set GPC system with refractive index (RI) detector. Use a series of three columns with varying pore sizes.

- Inject 100 µL of sample. Elute at a flow rate of 1.0 mL/min.

- Analyze chromatogram using calibration curve to calculate Mₙ, M_w, and Đ.

Protocol for Assessing Hydrolytic Degradation Kinetics

Objective: To determine the hydrolysis rate constant under controlled conditions. Materials: Polymer film (~100 µm thick), phosphate buffer solution (pH 7.4, 0.1 M), controlled temperature bath. Method:

- Pre-weigh polymer films (initial mass = m₀).

- Immerse films in 20 mL of buffer solution in sealed vials. Incubate at 37°C or 60°C to accelerate.

- At predetermined intervals (e.g., 1, 7, 30 days), remove samples (n=3), rinse with DI water, and dry to constant mass (m_t).

- Measure mass loss (%) = [(m₀ - m_t)/m₀] * 100. Plot mass loss vs. time; fit to a kinetic model (e.g., pseudo-first-order) to estimate rate constant k.

Protocol for Determining Ultimate Aerobic Biodegradability

Objective: To measure the percentage of polymer carbon converted to CO₂ using the OECD 301B (Ready Biodegradability: CO₂ Evolution) test. Materials: Polymer powder (<250 µm), mineral medium, activated sludge inoculum, CO₂-free air, sealed bioreactors with NaOH traps. Method:

- Prepare test vessels containing polymer (20-100 mg of organic carbon), inorganic medium, and a defined inoculum. Include controls (inoculum blank, reference compound).

- Aerate continuously with CO₂-free air. Pass evolved CO₂ through 0.1N NaOH traps.

- At regular intervals (2-3 days), titrate NaOH traps with 0.1N HCl to quantify CO₂ evolution.

- Continue for up to 28 days. Calculate % biodegradation = [(CO₂)test - (CO₂)blank] / (Theoretical CO₂) * 100.

Visualization of Data Relationships and Workflows

Diagram 1: AI-Driven Polymer Sustainability Prediction Workflow

Diagram 2: Descriptor Impact on Sustainability Metrics

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Research Reagents and Materials for Polymer Sustainability Analysis

| Item Name | Function/Benefit | Key Application |

|---|---|---|

| Tetrahydrofuran (THF), HPLC Grade | Low UV cutoff, excellent solvent for many polymers. Essential for GPC analysis. | Molecular weight characterization (GPC/SEC). |

| Polystyrene Calibration Standards | Narrow dispersity standards for column calibration. | Creating calibration curve for relative molecular weight determination. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Simulates physiological conditions for hydrolytic degradation studies. | In vitro hydrolytic degradation kinetics testing. |

| Activated Sludge Inoculum | Diverse microbial community from a wastewater treatment plant. | Source of microorganisms for OECD 301B biodegradability testing. |

| Sodium Hydroxide (NaOH) 0.1N Solution | Traps evolved CO₂ as carbonate for titration. | Quantifying CO₂ evolution in biodegradation assays. |

| Deuterated Solvents (e.g., CDCl₃, DMSO-d₆) | Allows for NMR analysis without signal interference. | Structural confirmation, end-group analysis, monomer conversion. |

| Thermogravimetric Analysis (TGA) Calibration Standards | Certified materials with known magnetic/curie transition temperatures. | Calibrating TGA for accurate thermal stability/decomposition data. |

| Enzymes (e.g., Lipase, Proteinase K) | Catalyze specific bond cleavage (ester, amide). | Assessing enzymatic degradability pathways. |

This whitepaper details the technical integration of Life Cycle Assessment (LCA) data into artificial intelligence (AI) models, framed within a broader doctoral thesis on AI for Designing Recyclable and Sustainable Polymers. The central hypothesis posits that by systematically training machine learning (ML) models on structured, high-quality LCA inventories, researchers can predict the environmental footprint of novel polymers and guide molecular design toward circularity and reduced impact. This approach is critical for researchers and pharmaceutical development professionals who are increasingly mandated to consider the environmental ramifications of material choices, including polymer excipients and delivery systems.

Foundational LCA Data for AI Training

Life Cycle Assessment provides the quantitative environmental inventory data essential for AI training. The core data types are summarized below.

Table 1: Core LCA Impact Category Data for Polymer Design

| Impact Category | Unit | Example Data for Polyethylene (PE) | Relevance to Polymer Design |

|---|---|---|---|

| Global Warming Potential (GWP) | kg CO₂-eq/kg polymer | 1.8 - 2.2 | Guides low-carbon monomer selection & energy-efficient synthesis. |

| Abiotic Resource Depletion (fossil) | MJ, kg Sb-eq | 75 - 85 MJ (energy) | Encourages bio-based or recycled feedstocks. |

| Water Consumption | m³/kg polymer | 0.05 - 0.10 | Critical for assessing bio-polymer agricultural phases. |

| Land Use Change | kg C deficit/kg | Variable (bio-based) | Informs sustainability of biomass sourcing. |

| Human Toxicity | kg 1,4-DCB-eq/kg | 0.3 - 0.5 | Flags hazardous monomers/solvents for replacement. |

Table 2: LCA Phase Contribution Data Structure for AI Input

| Life Cycle Phase | Energy Input (MJ/kg) | Key Output Flows | Link to Design Levers |

|---|---|---|---|

| Raw Material Extraction | 30-40 (Fossil-based) | Crude oil, natural gas | Feedstock choice (virgin vs. recycled). |

| Monomer Production | 25-35 | Ethylene, catalysts | Reaction pathway efficiency. |

| Polymerization | 10-20 | Polymer resin, waste solvents | Process condition optimization (temp, catalyst). |

| End-of-Life (Recycling) | -5 to -15 (Credit) | Recycled granulate, avoided virgin material | Designing for mechanical/chemical recyclability. |

Experimental Protocol: Curating and Integrating LCA Data for ML

Protocol 1: Building an LCA Inventory Database for Polymer AI

- Objective: Assemble a structured, harmonized database of polymer LCA data from public and proprietary sources.

- Materials: LCA software (e.g., openLCA, SimaPro), Python/R for data wrangling, SQL or NoSQL database, Polymer property databases (e.g., PoLyInfo).

- Methodology:

- Data Acquisition: Programmatically access LCA databases (e.g., Ecoinvent, USDA LCA Commons, PlasticEurope reports) via APIs or manual curation.

- Data Harmonization: Map all inventory flows to a common ontology (e.g., the Environmental Product Declaration (EPD) system). Normalize all impact assessment results to standard methods (e.g., ReCiPe 2016 Midpoint (H)).

- Feature Engineering: For each polymer entry, combine LCA data (GWP, water use) with molecular descriptors (monomer SMILES, functional groups, molecular weight) and processing conditions (polymerization temp, catalyst type).

- Database Schema: Create a linked table structure:

Polymer_ID<->Molecular_Descriptors<->Synthesis_Params<->LCA_Inventory_Flows<->Impact_Category_Scores.

Protocol 2: Training a Multi-Task Neural Network for Impact Prediction

- Objective: Train a model to predict multiple LCA impact scores from molecular structure and process parameters.

- Materials: PyTorch/TensorFlow, RDKit (for molecular featurization), curated LCA-polymer database from Protocol 1.

- Methodology:

- Input Representation: Convert monomer SMILES strings into molecular graphs (nodes=atoms, edges=bonds) or fixed-length fingerprints (Morgan fingerprints).

- Model Architecture: Implement a Multi-Task DNN or Graph Neural Network (GNN). A shared backbone learns general polymer features, with separate output "heads" for each impact category (GWP, Toxicity, etc.).

- Training & Validation: Split data 70/15/15 (train/validation/test). Use mean squared error (MSE) loss for each impact head. Employ k-fold cross-validation to ensure robustness.

- Interpretation: Use attention mechanisms (in GNNs) or SHAP values to identify which molecular substructures (e.g., aromatic rings, halogen groups) contribute most to high environmental impact.

Visualizing the AI-LCA Workflow

Title: AI-LCA Integration and Design Workflow (100 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Tools for LCA-AI Polymer Research

| Item / Solution | Function in Research | Example Vendor/Software |

|---|---|---|

| openLCA / SimaPro | Core LCA software for calculating impact scores from inventory data. | GreenDelta / PRé Sustainability |

| RDKit | Open-source cheminformatics toolkit for converting SMILES to molecular descriptors and fingerprints. | rdkit.org |

| PyTorch Geometric | Library for building Graph Neural Networks (GNNs) on polymer molecular graphs. | pyg.org |

| Ecoinvent Database | Comprehensive, background LCA inventory database for upstream processes (energy, chemicals). | ecoinvent.org |

| Cambridge Structural Database (CSD) | Provides crystallographic data for understanding polymer packing and stability. | ccdc.cam.ac.uk |

| ReaxFF Force Field | Reactive force field for molecular dynamics simulations of polymer degradation/recycling. | Materials Design, SCm |

| LCA Collaboration Server | Platform for versioning, sharing, and collaboratively managing LCA project data. | openLCA Nexus |

The pursuit of recyclable and sustainable polymers demands a paradigm shift in materials design. Traditional discovery is slow, resource-intensive, and often fails to balance performance with end-of-life considerations. This whitepaper details the evolution of fundamental AI models, from classical Quantitative Structure-Activity Relationship (QSAR) approaches to modern deep learning architectures, framing them as essential tools for accelerating the design of polymers that are inherently recyclable, degradable, or derived from sustainable feedstocks. By accurately predicting complex structure-property relationships, these models enable the in silico screening of vast chemical spaces to identify candidates that meet stringent criteria for performance, processability, and environmental impact.

Evolution of Modeling Paradigms: From QSAR to Deep Learning

Classical QSAR/QSPR for Polymers

Quantitative Structure-Property Relationship (QSPR) modeling for polymers uses calculated molecular descriptors to correlate structural features with macroscopic properties.

Core Methodology:

- Descriptor Calculation: Generate numerical representations for polymer repeating units or oligomers. Common descriptors include:

- Topological indices (e.g., Wiener index).

- Geometric descriptors (e.g., van der Waals volume).

- Electronic descriptors (e.g., HOMO/LUMO energies from semi-empirical methods).

- Compositional descriptors (e.g., number of specific atom types).

- Feature Selection: Reduce descriptor dimensionality using methods like Principal Component Analysis (PCA) or genetic algorithms to avoid overfitting.

- Model Construction: Apply linear (Multiple Linear Regression - MLR) or non-linear (Support Vector Regression - SVR, Random Forest - RF) algorithms to build the predictive model.

- Validation: Assess model performance using cross-validation and external test sets.

Experimental Protocol for QSPR Model Development:

- Data Curation: Compile a consistent dataset of polymer properties (e.g., glass transition temperature Tg, density, solubility parameter) from literature or experimental work.

- Structure Representation: Define and sketch the canonical repeating unit using a tool like ChemDraw.

- Descriptor Generation: Use software like Dragon, PaDEL-Descriptor, or RDKit to compute descriptors.

- Data Preprocessing: Clean data, handle missing values, and normalize descriptor values.

- Modeling Suite: Utilize platforms like KNIME, Orange, or scikit-learn in Python to implement MLR, SVR, and RF algorithms.

- Validation Metrics: Report Q² (cross-validated R²), R² for external test set, and Root Mean Square Error (RMSE).

Deep Learning for Polymer Informatics

Deep learning models automatically learn hierarchical feature representations from raw or minimally processed molecular inputs, capturing complex, non-linear relationships.

Core Architectures:

- Graph Neural Networks (GNNs): Directly operate on molecular graphs where atoms are nodes and bonds are edges.

- Convolutional Neural Networks (CNNs): Applied to fixed-dimensional representations like molecular fingerprints or images of 2D structures.

- Multimodal Models: Combine multiple data types (e.g., sequence, conditions, spectroscopic data).

Experimental Protocol for GNN-based Property Prediction:

- Data Preparation: Represent each polymer repeating unit as a graph with node features (atom type, hybridization) and edge features (bond type).

- Model Architecture: Implement a Message Passing Neural Network (MPNN) using frameworks like PyTorch Geometric or DeepChem.

- Training Loop: Use a mean squared error loss function and an Adam optimizer. Employ a validation set for early stopping.

- Deployment: The trained model takes a SMILES string or graph representation as input and outputs predicted property values (e.g., Tg, tensile strength).

Table 1: Performance Comparison of AI Models for Predicting Polymer Glass Transition Temperature (Tg)

| Model Type | Specific Algorithm/Architecture | Dataset Size (Polymers) | Average RMSE (K) | R² (Test Set) | Key Advantage for Sustainable Design |

|---|---|---|---|---|---|

| Classical QSPR | Support Vector Regression (SVR) | ~500 | 18.5 | 0.82 | Interpretability; identifies key structural fragments affecting Tg. |

| Classical QSPR | Random Forest (RF) | ~500 | 15.2 | 0.87 | Handles non-linearity well; provides feature importance. |

| Deep Learning | Graph Neural Network (GNN) | ~10,000 | 12.1 | 0.93 | Superior accuracy on large datasets; learns complex patterns. |

| Deep Learning | Directed Message Passing NN (D-MPNN) | ~15,000 | 10.8 | 0.95 | State-of-the-art for molecular property prediction. |

| Transfer Learning | Pre-trained GNN on small molecules, fine-tuned on polymers | ~5,000 | 11.5 | 0.94 | Effective with limited polymer-specific data. |

Table 2: AI-Predicted Properties Critical for Sustainable Polymer Design

| Target Property | Relevant AI Model | Prediction Accuracy (Typical R²) | Relevance to Sustainability & Recyclability |

|---|---|---|---|

| Glass Transition Temp (Tg) | GNN, RF | 0.90 - 0.95 | Determines processing conditions and service temperature. |

| Degradation Rate (Hydrolytic/Enzymatic) | GNN with attention | 0.75 - 0.85 | Crucial: Predicts environmental fate and compostability. |

| Flory-Huggins Interaction Parameter (χ) | GNN on polymer pairs | 0.80 - 0.88 | Predicts miscibility for polymer blends from recycled streams. |

| Mechanical Strength | CNN on stress-strain curves | 0.82 - 0.90 | Ensures performance parity with virgin materials. |

| Viscosity (Melt Flow Index) | SVR with topological descriptors | 0.85 - 0.92 | Key for processability in recycling (extrusion, molding). |

Key Methodologies and Visualization

Workflow for AI-Driven Sustainable Polymer Discovery

AI-Driven Sustainable Polymer Discovery Workflow

Graph Neural Network Architecture for Polymers

GNN Architecture for Polymer Property Prediction

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Tools and Platforms for AI Polymer Research

| Category | Item/Software | Function in Research | Key Consideration for Sustainability |

|---|---|---|---|

| Data Curation | Polymer Property Databases (PoLyInfo, PubChem) | Source experimental data for model training. | Prioritize data on biobased monomers and degradation studies. |

| Descriptor Calculation | RDKit, Dragon, PaDEL-Descriptor | Generate molecular fingerprints and descriptors for QSPR. | Open-source (RDKit) reduces barriers; ensures reproducibility. |

| Deep Learning Framework | PyTorch Geometric, DeepChem, TensorFlow | Build and train GNNs and other deep learning models. | GPU acceleration is essential for screening ultra-large libraries. |

| High-Performance Computing | Cloud Platforms (AWS, GCP) or Local GPU Clusters | Provide computational power for training large models. | Cloud scaling allows for efficient, on-demand resource use. |

| Sustainability Assessment | LCA Software (openLCA) & Toxicity Predictors (TEST) | Integrate with AI pipeline to filter designs by environmental impact. | Critical for thesis: Embeds sustainability metrics early in design. |

| Cheminformatics | Knime, Jupyter Notebooks | Create reproducible workflows for data processing and modeling. | Facilitates collaboration and open science in sustainable materials. |

From Prediction to Synthesis: AI Methodologies for De Novo Design of Recyclable Polymers

This whitepaper, situated within the broader thesis on AI for designing recyclable and sustainable polymers, addresses a critical challenge in materials science: the intentional design of polymers for predetermined end-of-life (EoL) outcomes. Traditional polymer discovery is heuristic and rarely prioritizes recyclability or degradability from inception. Generative artificial intelligence (AI) coupled with inverse design presents a paradigm shift, enabling the de novo generation of monomer and polymer structures optimized for specific performance and EoL profiles, such as chemical recyclability, biodegradability in targeted environments, or compatibilization for existing recycling streams.

Core Technological Framework

Generative AI Models for Molecular Design

Modern approaches utilize deep generative models to explore the vast chemical space of possible monomers and polymers.

- Variational Autoencoders (VAEs) & Graph Neural Networks (GNNs): Encode molecular graphs (SMILES/SELFIES strings or graph representations) into a continuous latent space. Decoding from this space allows for the generation of novel, valid structures.

- Generative Adversarial Networks (GANs): A generator creates candidate structures, while a discriminator evaluates their authenticity against known polymers, driving the generation of realistic molecules.

- Transformers & Language Models: Treat molecular representations as a language, learning the "syntax" and "grammar" of chemistry to generate novel sequences (monomers).

The Inverse Design Loop

Inverse design flips the traditional process: it starts with a set of target properties (e.g., glass transition temperature Tg > 100°C, hydrolytic degradation rate k at pH 7) and EoL outcomes (e.g., full depolymerization to monomers at 150°C in catalyst X), and iteratively uses AI to identify structures satisfying them.

Diagram Title: Generative AI Inverse Design Workflow for Polymers

Key Property Prediction Models & Data

AI-driven property prediction is essential for high-throughput screening of generated structures. Key models target both performance and EoL properties.

Table 1: Critical Predictive Models for Polymer EoL Design

| Property Category | Specific Property | Typical AI Model | Key Dataset/Descriptor | Quantitative Benchmark (Recent SOTA) |

|---|---|---|---|---|

| Thermal Performance | Glass Transition Temp (Tg) | Graph Convolutional Network (GCN) | Polymer Graph (nodes: atoms, edges: bonds) | MAE: ~8-12°C on diverse test sets |

| Mechanical Performance | Young's Modulus (E) | Message Passing Neural Network (MPNN) | Repeat unit SMILES + chain length distribution | MAE: ~0.5-1.0 GPa (log scale) |

| Degradation & EoL | Hydrolytic Rate Constant (k) | Directed Message Passing NN (D-MPNN) | Molecular fingerprints + environmental conditions | Classification Accuracy (Fast/Slow): >85% |

| Recyclability | Depolymerization Yield | Ensemble of Random Forests | Quantum-chemical descriptors (DFT-calculated) | R²: ~0.75-0.85 for specific catalyst classes |

| Toxicity/Bio- safety | Biodegradation Probability | Support Vector Machine (SVM) | Extended-Connectivity Fingerprints (ECFPs) | AUC-ROC: ~0.88-0.92 |

Experimental Protocol for Validation

Validating AI-generated designs requires integrated computational and experimental workflows.

Protocol: Synthesis and EoL Characterization of AI-Designed Depolymerizable Polyesters

Objective: Synthesize novel polyester candidates predicted to undergo selective catalytic depolymerization to monomers, and characterize EoL yield.

Materials: See The Scientist's Toolkit below. Computational Pre-Screening:

- Use a trained generative VAE to produce 50,000 candidate ester monomer structures.

- Screen candidates via a D-MPNN model predicting

depolymerization yieldunder conditions: 1 mol% organocatalyst Cat, 180°C, 4h. - Filter top 100 candidates using a GCN model for

Tg > 50°C. - Perform DFT (Density Functional Theory) calculations on top 10 candidates to estimate activation energy for catalyst insertion.

- Select top 3 monomer designs (M1, M2, M3) for synthesis.

Synthesis & Polymerization:

- Monomer Synthesis: Synthesize M1-M3 via established esterification protocols (e.g., Steglich esterification). Purify via column chromatography. Confirm structure via (^1)H NMR and HRMS.

- Ring-Opening Polymerization (ROP): For each monomer:

- Charge dried flask with monomer (10 mmol) and organocatalyst Cat (0.1 mmol).

- Purge with N₂, add anhydrous solvent (e.g., toluene, 5 mL).

- Stir at 110°C for 24h.

- Precipitate polymer into cold methanol. Dry under vacuum to constant weight. Characterize via GPC and NMR.

EoL Experiment - Catalytic Depolymerization:

- Weigh precisely 200 mg of each polymer (P1, P2, P3) into a microwave vial.

- Add catalyst Cat (2 mg, 1 mol%) and 2 mL of solvent (e.g., diglyme).

- Seal vial, purge with N₂, and heat in a pre-heated metal block at 180°C with stirring for 4 hours.

- Cool reaction mixture. Analyze via:

- Gas Chromatography (GC): Quantify monomer recovery yield using an internal standard.

- NMR: Identify recovered monomer structure and purity.

Data Integration: Report experimental depolymerization yield vs. AI-predicted yield. Feed results (success/failure) back into the generative model's training database to refine future generations.

The Scientist's Toolkit

Table 2: Essential Research Reagents & Materials

| Item Name | Function/Application | Example/Notes |

|---|---|---|

| Organocatalyst Cat | Catalyzes both ROP and controlled depolymerization. Enables closed-loop chemistry. | e.g., TBD (1,5,7-Triazabicyclo[4.4.0]dec-5-ene) or derivatives. |

| Anhydrous Solvents | For moisture-sensitive polymerization (ROP) and depolymerization reactions. | Toluene, THF, diglyme; dried over molecular sieves. |

| Deuterated Solvents | For NMR characterization of monomers and polymers. | Chloroform-d (CDCl₃), DMSO-d₆. |

| Silica Gel | Purification of monomers via flash column chromatography. | 40-63 µm, 60 Å pore size. |

| GPC/SEC System | Determines polymer molecular weight (Mn, Mw) and dispersity (Đ). | Requires appropriate columns (e.g., PS, PMMA standards) and detector (RI, UV). |

| High-Resolution Mass Spectrometer (HRMS) | Confirms exact mass and structure of novel AI-designed monomers. | ESI or MALDI source. |

| Microwave Reactor | Provides precise, rapid heating for depolymerization screening experiments. | Enables high-throughput EoL testing. |

Pathway to Targeted EoL Outcomes

The logical relationship between molecular design levers and specific EoL outcomes is fundamental to guiding the generative AI.

Diagram Title: Molecular Design to EoL Outcome Pathway

The integration of generative AI and inverse design establishes a rigorous, data-driven framework for creating the next generation of sustainable polymers. By explicitly training models on EoL property data and embedding these targets within the generative loop, researchers can accelerate the discovery of materials that meet functional requirements while inherently addressing the environmental imperative of circularity. This approach, central to a thesis on AI for recyclable polymers, moves beyond incremental improvement towards a fundamental re-imagination of polymer design—from the first monomer sketch.

This whitepaper is framed within a broader thesis on AI for designing recyclable and sustainable polymers. The central hypothesis is that machine learning (ML)-driven virtual screening can dramatically accelerate the discovery of next-generation polymer candidates with built-in end-of-life (EOL) functionality, specifically designed for chemical recyclability (e.g., depolymerization to monomers) or predictable biodegradation. This approach shifts the paradigm from post-hoc assessment to proactive, in-silico design of sustainability.

Foundational Concepts & Data Landscape

The screening pipeline requires structured data on polymer properties, EOL behavior, and molecular descriptors.

Table 1: Core Quantitative Data for Polymer EOL ML Models

| Data Category | Key Metrics/Descriptors | Example Values / Range | Primary Source |

|---|---|---|---|

| Polymer Chemical Structure | SMILES string, Molecular weight (Mn, Mw), Chain topology (linear, branched). | Varies by polymer. | PubChem, Polymer Property Predictor & Database (P3DB), proprietary datasets. |

| Thermal Properties | Glass transition temp (Tg), Melting temp (Tm), Decomposition onset temp (Td). | Tg: -50°C to 200°C; Td: 200°C to 500°C. | Experimental literature, computational predictions (e.g., via MD simulations). |

| Chemical Recyclability | Depolymerization yield, Catalyst used, Temperature/Time conditions, Monomer recovery purity. | Yield: 60-99%; Temp: 80°C - 250°C. | Recent literature on chemolysis (hydrolysis, glycolysis, enzymatic). |

| Biodegradation | Mineralization rate (CO2 evolution), Standard test method (e.g., OECD 301B), Degradation half-life, Key enzyme target (e.g., cutinase, lipase). | Mineralization: 5-90% in 28 days; Half-life: weeks to decades. | Bio-Polymer Database, EPA's Computational Toxicology databases, enzyme literature. |

| Molecular Descriptors | Morgan fingerprints (ECFP4), RDKit descriptors, QSAR-ready 2D/3D features. | >200 descriptors possible (e.g., logP, polar surface area, rotatable bonds). | Calculated from structure using RDKit, Dragon software. |

Core Machine Learning Pipeline & Experimental Protocol

Protocol 1: End-to-End HTVS ML Workflow for Polymer EOL Design

Objective: To train and validate ML models that predict chemical recyclability and biodegradation potential from molecular structure.

Step 1: Data Curation & Featurization

- Source: Aggregate data from tables like Table 1. For biodegradation, use databases like Bio-PDB for enzymatic targets.

- Clean: Standardize polymer representations (e.g., canonical SMILES for repeat units). Handle missing data via imputation or removal.

- Featurize: Generate molecular fingerprints (ECFP4, 1024-bit) and a curated set of 150+ physicochemical descriptors using RDKit. For enzyme-targeted biodegradation, compute docking-ready 3D structures.

Step 2: Model Training & Validation

- Algorithm Selection: Employ a multi-model approach: Random Forest (RF) for interpretability, Graph Neural Networks (GNNs) for structure-property relationships, and XGBoost for tabular data performance.

- Task Formulation: Frame as both classification (e.g., biodegradable yes/no under specific conditions) and regression (e.g., predicting depolymerization rate constant).

- Validation: Use stratified k-fold cross-validation (k=5 or 10) to ensure robustness. Hold back a temporally recent or experimentally diverse 20% of data as a final test set.

Step 3: Virtual Screening

- Library Generation: Create a virtual library of candidate polymers using combinatorial chemistry rules (e.g., variations in diols/diacids for polyesters) or generative ML.

- Prediction & Ranking: Apply trained models to the library. Rank candidates by predicted EOL performance (e.g., high depolymerization yield AND high biodegradation rate).

- Explainability: Use SHAP (SHapley Additive exPlanations) analysis to identify substructural features (e.g., ester bonds, cleavable linkages like acetals) driving favorable predictions.

Step 4: Experimental Validation (Downstream)

- Synthesis: Select top 10-20 candidates for synthesis via automated, high-throughput polymer synthesis platforms.

- Characterization: Perform GPC (Mw, PDI), NMR (structure confirmation), and DSC (Tg, Tm).

- EOL Testing:

- Chemical Recycling: Subject to standardized chemolysis conditions (e.g., glycolysis at 190°C with Zn acetate catalyst); measure monomer yield via HPLC.

- Biodegradation: Conduct enzymatic degradation assays with relevant hydrolases (e.g., proteinase K, cutinase) or standardized soil/compost tests (OECD 301B).

Diagram Title: ML-Driven Virtual Screening Workflow for Polymer EOL

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Experimental Validation

| Item / Reagent | Function / Role | Application in Protocol |

|---|---|---|

| RDKit (Open-Source) | Cheminformatics toolkit for molecular featurization (fingerprints, descriptors) and SMILES handling. | Protocol 1, Step 1: Core software for generating ML-ready features from polymer repeat unit structures. |

| Zinc Acetate Dihydrate | Common catalyst for glycolysis, a key chemical recycling method for polyesters like PET. | Protocol 1, Step 4 (EOL Testing): Catalyst for depolymerization reactions to recover monomers. |

| Proteinase K / Candida antarctica Lipase B (CALB) | Model hydrolytic enzymes for assessing enzymatic biodegradation potential of polymers (esp. polyesters). | Protocol 1, Step 4 (EOL Testing): Enzymatic degradation assays to validate ML predictions. |

| Automated Synthesis Platform (e.g., Chemspeed, Unchained Labs) | High-throughput robotic system for parallel polymer synthesis and formulation. | Protocol 1, Step 4 (Synthesis): Enables rapid synthesis of top ML-predicted candidates for validation. |

| OECD 301B Ready Biodegradation Test Kit | Standardized assay setup for measuring ultimate aerobic biodegradability in an aqueous medium. | Protocol 1, Step 4 (EOL Testing): Standard test to determine biodegradation percentage under controlled conditions. |

| SHAP (SHapley Additive exPlanations) Library | Python library for explaining output of ML models, linking features to predictions. | Protocol 1, Step 3: Provides interpretability, identifying chemical motifs responsible for predicted EOL traits. |

Signaling Pathway for Enzyme-Mediated Biodegradation Prediction

A critical sub-task is predicting biodegradation via specific enzymatic pathways.

Diagram Title: Enzymatic Biodegradability Prediction Pathway

Integrating ML-based high-throughput virtual screening directly into the polymer design cycle represents a transformative approach for sustainable materials science. By prioritizing chemical recyclability and biodegradation at the molecular design stage, this methodology, as part of a broader AI-driven thesis, enables the rapid identification of viable candidates, reducing reliance on trial-and-error experimentation and accelerating the development of a circular polymer economy.

Within the broader thesis on AI for designing recyclable and sustainable polymers, a critical challenge is predicting and balancing three core material properties: the energy required for depolymerization, the rate of enzymatic biodegradation, and key mechanical performance metrics (e.g., tensile strength, Young's modulus). This whitepaper serves as a technical guide for researchers aiming to navigate the inherent trade-offs between end-of-life recyclability/degradability and in-use performance. The integration of AI-driven predictive models with high-throughput experimentation is posited as the pathway to discovering viable, sustainable polymer candidates.

Foundational Concepts & Quantitative Benchmarks

Defining the Core Properties

- Depolymerization Energy (ΔEdepoly): The theoretical or experimental energy barrier (often in kJ/mol) to revert a polymer chain to its monomers, typically via chemical, thermal, or catalytic processes. Lower values favor chemical recyclability.

- Enzymatic Degradation Rate (kdeg): The rate constant (often in h⁻¹ or day⁻¹) describing the cleavage of polymer backbone bonds by specific enzymes (e.g., cutinases, lipases, PETases).

- Mechanical Performance: A suite of properties including Tensile Strength (MPa), Young's Modulus (GPa), and Elongation at Break (%).

Current Quantitative Data Landscape

Table 1 summarizes representative data for common and emerging polymer classes, illustrating the intrinsic trade-offs.

Table 1: Key Property Ranges for Selected Polymers

| Polymer Class / Example | Depolymerization Energy (kJ/mol)* | Enzymatic Degradation Rate (Relative kdeg) | Tensile Strength (MPa) | Young's Modulus (GPa) | Primary Trade-off Observation |

|---|---|---|---|---|---|

| Polyethylene (PE) | 280 - 350 | Very Low (~0) | 15 - 40 | 0.2 - 1.2 | High stability (high ΔE, low k_deg) grants performance but impedes degradation. |

| Polyethylene Terephthalate (PET) | 180 - 250 (glycolysis) | Low (Basal PETase) | 55 - 75 | 2.0 - 4.1 | Engineered enzymes (FAST-PETase) improve k_deg; ΔE remains moderate. |

| Polylactic Acid (PLA) | 120 - 180 | Medium-High (Proteinase K) | 50 - 70 | 3.0 - 4.0 | Lower ΔE aids compostability, but stiffness can be limiting. |

| Aliphatic Polycarbonates (e.g., PPC) | 80 - 150 | High (Lipase) | 20 - 40 | 0.5 - 1.5 | Designed for low ΔE & high k_deg, but mechanical strength is often sacrificed. |

| Polyhydroxyalkanoates (PHA) | 100 - 170 | High (PHA depolymerases) | 20 - 40 | 0.8 - 2.0 | Tunable biodegradability, wide property range based on side-chain. |

| Engineered Polyester (e.g., PEF) | 170 - 230 | Low-Moderate (Cutinase) | 70 - 85 | 3.5 - 5.0 | Improved barrier/strength vs. PET, but degradability is a challenge. |

Representative ranges for chemical recycling pathways (vary by mechanism). *Normalized relative scale; absolute rates depend heavily on conditions.

Experimental Protocols for Key Property Determination

Protocol: Computational Determination of Depolymerization Energy

Objective: Calculate ΔEdepoly via Density Functional Theory (DFT). Methodology:

- Model System Preparation: Construct a simplified oligomer model (e.g., 3-6 repeat units) using molecular modeling software (Avogadro, GaussView).

- Geometry Optimization: Optimize the geometry of the polymer chain and the targeted monomer product(s) at the DFT level (e.g., B3LYP/6-31G*).

- Transition State Search: Locate the transition state (TS) for the depolymerization step (e.g., via backbiting, hydrolysis, or beta-scission) using TS optimization algorithms (e.g., QST2, QST3, or NEB methods).

- Frequency Calculation: Perform a vibrational frequency calculation on the TS to confirm exactly one imaginary frequency, and on reactants/products to confirm minima.

- Energy Calculation: Compute the single-point energy at a higher basis set for all species. ΔEdepoly = E(TS) - E(Polymer Reactant). Include solvation models if relevant (e.g., SMD for enzymatic hydrolysis). Key Software: Gaussian, ORCA, CP2K.

Protocol: High-Throughput Enzymatic Degradation Assay

Objective: Measure the initial enzymatic degradation rate (kdeg) for polymer film libraries. Methodology:

- Substrate Fabrication: Spin-coat or solution-cast polymer candidates into thin films (~10-100 µm thickness) on multi-well plate inserts or glass slides.

- Enzyme Solution Preparation: Prepare buffer (e.g., 50 mM phosphate, pH 7.4 or 8.0) with a purified enzyme (e.g., 0.1-1.0 mg/mL PETase, Lipase). Include a negative control (buffer only).

- Incubation: Add enzyme solution to each polymer film in a 96-well plate format. Incubate with agitation (e.g., 300 rpm) at a controlled temperature (e.g., 30-40°C).

- Real-Time Monitoring:

- Fluorometric: Use a fluorescein-labeled polymer or a dye that precipitates upon chain scission.

- UV-Vis/Turbidimetric: Monitor supernatant absorbance (280 nm) for solubilized oligomers/products.

- pH-Stat Titration: For hydrolysis releasing acid, continuously titrate with base to maintain pH; the titration rate equals the hydrolysis rate.

- Data Analysis: Fit the initial linear portion of product release vs. time to obtain the rate (v0). Normalize by enzyme concentration and surface area to obtain kdeg.

Protocol: Correlating Mechanical Performance with Molecular Structure

Objective: Obtain tensile properties and correlate with computationally accessible descriptors. Methodology:

- Sample Preparation: Prepare dog-bone tensile bars (ASTM D638 Type V) via melt-pressing or micro-injection molding. Anneal if necessary.

- Tensile Testing: Perform uniaxial tensile tests on a universal testing machine (e.g., Instron) at a constant strain rate (e.g., 5 mm/min). Record stress-strain curves.

- Property Extraction: Calculate Young's Modulus (slope of initial linear region), Tensile Strength (peak stress), and Elongation at Break.

- Descriptor Calculation: For the same polymer structure, compute molecular descriptors: fractional free volume, cohesive energy density, backbone flexibility (rotatable bond count), and simulated crystallinity from molecular dynamics.

AI Integration & Predictive Workflow Diagram

The predictive pipeline integrates multi-fidelity data generation and machine learning models.

AI Polymer Design & Validation Pipeline

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagent Solutions for Polymer Degradation & Analysis

| Item | Function/Application | Example/Supplier |

|---|---|---|

| Engineered Hydrolases | Catalyze selective backbone cleavage for degradation rate studies. | Thermobifida fusca cutinase, Ideonella sakaiensis PETase variants (FAST-PETase), Candida antarctica Lipase B (Novozym 435). |

| Fluorogenic Substrate Probes | Enable real-time, high-throughput enzymatic activity screening. | Fluorescein dibutyrate (for esterases), nanoparticle-quenched fluorescent polymer substrates. |

| pH-Stat Autotitrator | Quantifies acid release rate during hydrolysis, providing direct kinetic data. | Mettler Toledo G20, Hanna HI902C with dedicated software. |

| Size Exclusion Chromatography (SEC) Columns | Characterizes molecular weight distribution changes pre- and post-degradation. | Agilent PLgel columns (Mixed-C, MIXED-D) for organic phase; TSKgel columns for aqueous phase. |

| Computational Chemistry Suites | Perform DFT/MD simulations for ΔE and structure-property predictions. | Gaussian 16, Materials Studio, Schrödinger Suite, Rosetta (for enzyme-polymer docking). |

| High-Throughput Film Fabrication | Creates uniform polymer libraries for parallel degradation testing. | Spin Coater (Laurell), GeSiM Nano-Plotter for micro-dispensing. |

| Tensile Testing Micro-Scale | Measures mechanical properties of small-volume novel polymers. | Instron 5848 MicroTester, Deben Microtest. |

| Active Learning Software | Guides iterative experiment selection to optimize AI models efficiently. | ChemOS, custom scripts leveraging scikit-learn or Dragonfly. |

The systematic prediction and balancing of depolymerization energy, enzymatic degradation rate, and mechanical properties represent the core of rational design for sustainable polymers. As detailed in this guide, converging high-fidelity computational screening, automated experimental kinetics, and multi-task AI modeling into a closed-loop framework accelerates the discovery of polymers that fulfill both functional application requirements and circular economy principles. This approach, central to the overarching thesis, provides a replicable roadmap for researchers to deconvolute and optimize these critical trade-offs.

AI-Guided Catalyst Discovery for Controlled Polymerization and Depolymerization (e.g., for PDK plastics)

This whitepaper details a technical framework for the application of artificial intelligence in the discovery of catalysts for the synthesis and recycling of next-generation polymers. This work is situated within the broader thesis that AI-driven molecular design is the pivotal enabler for a circular plastic economy. The primary challenge lies in discovering catalysts that not only efficiently polymerize novel, chemically recyclable monomers (e.g., poly(diketoenamine) or PDK plastics) but also facilitate their selective, energy-efficient depolymerization back to pristine monomers—a requirement for true closed-loop recycling. AI bridges the high-dimensional design space of organometallic complexes and reaction conditions with targeted polymer properties and deconstruction kinetics.

Core AI Methodology & Workflow

Data-Centric Foundation

The AI pipeline requires multi-faceted datasets:

- Catalyst Structures: SMILES or 3D geometries of organocatalysts, transition metal complexes (e.g., based on Zn, Mg, Al, or Earth-abundant metals).

- Polymerization/Depolymerization Kinetics: Experimentally derived rate constants (kp, kdepol), dispersity (Ɖ), monomer conversion, and thermodynamic parameters (ΔH, ΔG).

- Monomer Properties: Electronic (HOMO/LUMO energies, σp), steric (Buried Volume %), and functional group descriptors.

- Reaction Conditions: Solvent, temperature, pressure, and catalyst loading.

Table 1: Representative Dataset for AI Training (Hypothetical Data from Literature)

| Catalyst SMILES | Metal Center | Ligand Type | Monomer | kp (L·mol⁻¹·s⁻¹) | kdepol (s⁻¹) | Final Ɖ | Depolymerization Yield (%) |

|---|---|---|---|---|---|---|---|

| CC[Zn]CC | Zn | β-diketiminate | PDK-M1 | 1.2 x 10² | 5.5 x 10⁻⁴ | 1.08 | 95 |

| C1=CC=C(C[Mg]C)C=C1 | Mg | Phenolate | PDK-M2 | 8.7 x 10¹ | 2.1 x 10⁻³ | 1.15 | 98 |

| [AlH2+]C1=CC=CC=C1 | Al | Cationic | Lactone | 3.4 x 10³ | 7.8 x 10⁻⁵ | 1.21 | 88 |

Model Architecture & Training

A multi-task neural network is typically employed:

- Input Encoding: Molecular graphs of catalysts and monomers using Graph Neural Networks (GNNs) or learned fingerprints.

- Learning Tasks: Simultaneous prediction of (a) polymerization activity/control, (b) depolymerization rate under specific triggers (e.g., acid, heat), and (c) polymer thermal properties (Tg, Tm).

- Active Learning Loop: The model proposes candidate catalysts, which are prioritized for high-throughput computational screening (DFT) and experimental validation. Results feed back to retrain and refine the model.

AI-Guided Catalyst Discovery and Validation Workflow

Detailed Experimental Protocols

Protocol A: High-Throughput Screening of AI-Proposed Catalysts for PDK Polymerization

Objective: To experimentally validate AI-predicted catalysts for the controlled ring-opening polymerization of PDK-based cyclic monomers.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Reaction Setup: In an inert atmosphere (N2 or Ar) glovebox, prepare an array of 1.5 mL glass vials.

- Monomer/Initiation: To each vial, add the PDK monomer (e.g., 7-membered cyclic PDK, 100 mg, 0.5 mmol) and the alcohol initiator (e.g., 1-dodecanol, 0.005 mmol).

- Catalyst Addition: Add the AI-proposed catalyst (0.5 mol% relative to monomer) from a stock solution in dry toluene.

- Polymerization: Seal vials, remove from glovebox, and place on a pre-heated stirring block at the target temperature (e.g., 80°C, 100°C, 120°C).

- Kinetic Sampling: At predetermined time intervals (e.g., 5, 15, 30, 60, 120 min), quench an individual vial by rapid cooling to -20°C and exposure to air.

- Analysis:

- Conversion: Analyze monomer conversion via 1H NMR spectroscopy in CDCl3 by comparing monomer vs. polymer alkene proton integrals.

- Molecular Weight & Dispersity: Purify a portion of the quenched product by precipitation into cold methanol. Analyze via Size Exclusion Chromatography (SEC) in THF against polystyrene standards.

Protocol B: Triggered Depolymerization Efficiency Assay

Objective: To assess the efficiency and selectivity of the AI-predicted catalyst (or a separate depolymerization catalyst) in recovering monomer from the synthesized polymer.

Procedure:

- Polymer Substrate: Use the purified polymer from Protocol A (e.g., 50 mg).

- Depolymerization Conditions: Dissolve the polymer in a suitable solvent (e.g., dichloromethane, 2 mL) in a round-bottom flask.

- Trigger Introduction: Add the chemical trigger (e.g., a strong Brønsted acid like trifluoromethanesulfonic acid, 10 mol%) or set the temperature for thermal trigger (e.g., 150°C).

- Reaction Monitoring: Stir the mixture and monitor the reaction progress by 1H NMR at regular intervals (e.g., every 30 min for 6 h).

- Monomer Recovery: Upon completion (full dissolution of polymer and appearance of monomer peaks), neutralize the reaction mixture (if acid used) with a weak base (e.g., NaHCO3). Extract, dry (MgSO4), and concentrate the monomer.

- Yield & Purity Analysis: Quantify recovered monomer yield gravimetrically and assess purity by NMR. Repolymerize the recovered monomer using Protocol A to confirm fidelity.

Table 2: Key Quantitative Metrics from Validation Experiments (Example)

| Catalyst ID | Poly. Temp (°C) | Time to >95% Conv. (min) | Predicted Ɖ (AI) | Experimental Ɖ (SEC) | Depol. Trigger | Time to >90% Depol. (min) | Monomer Recovery Purity (%) |

|---|---|---|---|---|---|---|---|

| Cat-Zn-AL-01 | 100 | 45 | 1.09 | 1.12 | 1M HCl in THF | 120 | 98.5 |

| Cat-Mg-AL-07 | 80 | 90 | 1.15 | 1.18 | Thermal (150°C) | 180 | 99.1 |

| Cat-Al-AL-12 | 120 | 15 | 1.25 | 1.31 | TfOH (5 mol%) | 30 | 97.8 |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for AI-Guided Catalyst Testing

| Item | Function & Rationale |

|---|---|

| PDK Cyclic Monomers (e.g., 7-membered cyclic diketoenamine) | The foundational, chemically recyclable building block. Purity is critical for controlled polymerization kinetics. |

| AI-Designed Organometallic Catalysts (e.g., Zn(II)/Mg(II) complexes with asymmetric ligands) | The core subject of discovery. Supplied as air-sensitive solids or stock solutions. |

| Dry, Deuterated Solvents (CDCl3, toluene-d8) | For reaction setup in an inert atmosphere and for real-time NMR reaction monitoring. |

| Chemical Depolymerization Triggers (Triflic Acid, p-Toluenesulfonic Acid, HCl solutions) | To selectively cleave the polymer backbone under mild, specific conditions, enabling monomer recovery. |

| High-Throughput Reaction Stations (e.g., Carousel Reactors) | Enables parallel synthesis and kinetic sampling of dozens of AI-proposed catalyst candidates simultaneously. |

| Automated SEC/GPC System | Provides rapid, automated determination of molecular weight and dispersity (Ɖ) for polymer characterization. |

Pathway Visualization: The PDK Polymerization/Depolymerization Cycle

AI-Optimized PDK Polymerization and Depolymerization Cycle

The integration of AI-guided catalyst discovery with high-throughput experimentation establishes a transformative pipeline for sustainable polymer design. For PDK and similar dynamically recyclable plastics, this approach directly accelerates the identification of catalysts that fulfill the dual mandates of precise synthesis and efficient deconstruction. The subsequent phase of this thesis work involves deploying generative AI models to design entirely novel catalyst architectures beyond known chemical spaces and integrating robotic platforms for fully autonomous discovery cycles, moving from AI prediction to synthesized, tested polymer in a single closed loop.

The pursuit of sustainable biomaterials is a cornerstone of modern pharmaceutical science. This case study is situated within a broader research thesis that employs artificial intelligence (AI) and machine learning (ML) to accelerate the design of polymers with engineered life cycles. The specific challenge addressed here is the contradiction between the desired persistence of drug delivery systems in vivo and their problematic persistence in the environment post-excretion. By integrating computational prediction of cleavable linkages, AI-driven polymer property optimization, and biologically triggered depolymerization strategies, we present a framework for creating programmed recyclable polymers. These materials maintain therapeutic functionality while possessing encoded chemical instructions for facile breakdown into reusable monomers under specific, post-use conditions.

Core Polymer Design Strategies for Programmed Recyclability

The design pivots on incorporating stimuli-labile linkages into the polymer backbone or side chains. The stimulus is programmed to activate only after the drug delivery lifecycle.

Key Degradation Triggers and Linkages

Biological Triggers:

- pH-Sensitive Linkages: (e.g., hydrazones, acetals, orthoesters) stable at physiological pH (7.4) but hydrolyze in mildly acidic environments (pH 5.0-6.5) found in endosomes or in certain environmental waste streams.

- Redox-Sensitive Linkages: (e.g., disulfides) stable in the extracellular space but cleave in the reducing environment of the cytoplasm (high glutathione concentration) or via reducing agents in recycling processes.

- Enzyme-Cleavable Linkages: (e.g., peptide sequences, esterase-sensitive groups) designed for hydrolysis by specific enzymes (e.g., lysosomal proteases, esterases) not prevalent in the environment, but which can be introduced in a controlled recycling facility.

External Triggers for Post-Use Recycling:

- UV Light: Incorporation of o-nitrobenzyl or coumarin derivatives that undergo photocleavage upon exposure to a specific wavelength (e.g., 365 nm) in a recycling facility.

- Chemical Triggers: Introduction of linkages (e.g., silyl ethers, vinyl ethers) that are stable in biological media but rapidly cleave upon exposure to a specific, benign chemical (e.g., fluoride ions, mild acid) in a closed-loop recycling process.

Quantitative Comparison of Labile Linkages

The selection of a labile linkage is a multi-parameter optimization problem. AI models trained on existing polymer degradation datasets can predict hydrolysis rates and compatibility with drug encapsulation. The following table summarizes key quantitative data for common linkages.

Table 1: Characteristics of Stimuli-Labile Linkages for Recyclable Polymer Design

| Linkage Type | Example Structure | Cleavage Trigger (Post-Use) | Typical Half-Life at Trigger Condition | Monomer Recovery Yield (%)* | Key Advantage for Recycling |

|---|---|---|---|---|---|

| Acetal | Poly(acetal-co-PEG) | pH 5.0 | 2-10 hours | 85-95 | Fast, quantitative hydrolysis to aldehydes and alcohols. |

| Disulfide | Poly(disulfide-amines) | 10 mM GSH / Reducing Agent | 30 min - 2 hours | >90 | Yields pure thiol monomers; orthogonal to biological stability. |

| o-Nitrobenzyl | Poly(o-nitrobenzyl acrylate) | UV Light (365 nm) | Seconds to minutes (light-dependent) | 80-90 | Spatiotemporally precise; no chemical reagents needed. |

| Enzymatic Peptide | GFLG peptide sequence | Cathepsin B Enzyme | 1-5 hours (enzyme-dependent) | 70-85 | High specificity; can be tailored to facility-introduced enzymes. |

| Silyl Ether | Poly(silyl ether carbonates) | Fluoride Ion (F⁻) | <1 hour | >95 | Exceptional stability until trigger; yields high-purity silanols. |

*Theoretical yields from model polymer studies; actual yield depends on polymer architecture and recycling process.

Experimental Protocol: Synthesis & Characterization of a pH-Sensitive, Recyclable Poly(acetal-co-PEG) Nanoparticle

This protocol outlines the creation of a drug delivery vehicle designed for endosomal release and post-use acid-catalyzed recycling.

Materials (The Scientist's Toolkit)

Table 2: Research Reagent Solutions for pH-Sensitive Polymer Synthesis

| Reagent / Material | Function & Explanation |

|---|---|

| Acetal-dimethacrylate Monomer | Forms the pH-degradable backbone. The acetal group is stable at pH 7.4 but hydrolyzes in acidic conditions (pH <6.5). |

| Poly(ethylene glycol) diacrylate (PEGDA, Mn 575) | Provides hydrophilicity, controls nanoparticle size, and enhances biocompatibility. The acrylate ends enable copolymerization. |

| Azobisisobutyronitrile (AIBN) | Thermal free-radical initiator for the polymerization reaction. |

| Paclitaxel (or model drug) | Hydrophobic chemotherapeutic agent for encapsulation efficacy testing. |

| Dichloromethane (DCM) & Dimethylformamide (DMF) | Organic solvents for polymerization and nanoprecipitation. |

| Phosphate Buffered Saline (PBS) at pH 7.4 and 5.0 | For stability (pH 7.4) and degradation/recycling studies (pH 5.0). |

| Dialysis Tubing (MWCO 3.5 kDa) | For purification of nanoparticles and separation of monomers during recycling. |

Stepwise Methodology

Copolymer Synthesis:

- In a flame-dried flask, combine acetal-dimethacrylate (1.0 eq), PEGDA (1.0 eq), and AIBN (0.5 mol%) in anhydrous DCM.

- Purge the solution with nitrogen for 20 minutes to remove oxygen.

- Heat the reaction to 65°C under a nitrogen atmosphere with stirring for 18 hours.

- Cool the mixture and precipitate the polymer into cold diethyl ether. Filter and dry the white solid under vacuum.

Nanoparticle Fabrication & Drug Loading (Nanoprecipitation):

- Dissolve 50 mg of the synthesized polymer and 5 mg of paclitaxel in 5 mL of acetone (organic phase).

- Using a syringe pump, add the organic phase dropwise (1 mL/min) into 20 mL of vigorously stirred deionized water (aqueous phase).

- Allow the mixture to stir uncovered for 6 hours to evaporate the acetone.

- Filter the suspension through a 0.45 µm syringe filter to remove aggregates.

Characterization & In Vitro Release:

- Determine nanoparticle size and zeta potential via Dynamic Light Scattering (DLS).

- Measure drug encapsulation efficiency (EE%) via HPLC after destroying nanoparticles with acetonitrile.

- For release: Place 2 mL of nanoparticle suspension in a dialysis bag (MWCO 3.5 kDa). Immerse in 200 mL of release media (PBS pH 7.4 with 0.1% Tween 80) at 37°C. At predetermined intervals, sample the external medium and analyze by HPLC.

Programmed Recycling Protocol:

- After release study, recover the nanoparticle suspension from the dialysis bag.

- Acidify the suspension to pH 5.0 using 1M HCl.

- Incubate at 37°C with stirring for 48 hours to ensure complete hydrolysis of the acetal backbone.

- Transfer the solution to a dialysis bag (MWCO 1 kDa) against water to separate the small-molecule degradation products (acetaldehyde, PEG diol, original monomer fragments) from any undegraded material.

- Lyophilize the dialysate to recover the monomers for potential repolymerization. Analyze purity via

¹H NMRandGPC.

AI Integration for Design Optimization

The design cycle is closed using AI models:

- Dataset Curation: Compile data on polymer structure (SMILES), labile linkage type, hydrolysis rate constants at different pH levels, and monomer recovery yields.

- Model Training: Train a Graph Neural Network (GNN) to predict the degradation half-life and drug encapsulation efficiency of a candidate polymer structure.

- Inverse Design: Use a generative model (e.g., Variational Autoencoder) to propose novel polymer structures that meet target criteria:

t½ (pH 7.4) > 48h,t½ (pH 5.0) < 12h,EE% > 80%, andMonomer Recovery > 85%. - Synthesis Prioritization: The AI ranks proposed structures by synthetic feasibility, guiding the next experimental iteration.

Diagram 1: AI-Driven Design Cycle for Recyclable Polymers

Diagram 2: Lifecycle of a Programmed Recyclable Polymer DDS

Overcoming Hurdles: Optimizing AI Models and Navigating the Complexities of Sustainable Polymer Design

In the pursuit of designing recyclable and sustainable polymers, Artificial Intelligence (AI) promises accelerated discovery and optimization. However, the application of AI in polymer science is fundamentally constrained by data scarcity. Experimental data on polymer properties—such as tensile strength, degradation rates, recyclability indices, and monomer reactivity ratios—is expensive, time-consuming, and labor-intensive to generate. This whitepaper provides an in-depth technical guide to three pivotal techniques for overcoming data limitations: Small Data Learning, Transfer Learning, and Synthetic Data Generation, specifically framed within AI-driven sustainable polymer research.

Small Data Learning Techniques

Small data learning focuses on extracting maximum information from limited datasets, crucial for novel, unexplored sustainable polymer formulations.

Active Learning

Active learning iteratively selects the most informative data points for experimental validation, optimizing the learning cycle.

Experimental Protocol: Query-by-Committee for Polymer Glass Transition Temperature (Tg) Prediction

- Initialization: Start with a small seed dataset (e.g., 50 polymer compositions with measured Tg).

- Model Committee: Train 3-5 diverse models (e.g., Gaussian Process Regression, Support Vector Regressor, Random Forest) on the current dataset.

- Query Selection: For a large pool of unlabeled candidate polymers (defined by descriptors like molecular weight, functional groups, chain architecture), have each committee model predict Tg. Select the candidate where the predictive variance among committee members is highest.

- Experiment & Update: Synthesize and characterize the Tg (e.g., via Differential Scanning Calorimetry) for the selected candidate. Add this new data point to the training set.

- Iteration: Repeat steps 2-4 until a performance threshold or experimental budget is reached.

Diagram 1: Active Learning Workflow for Polymer Data (98 chars)

Bayesian Optimization

Bayesian Optimization (BO) is a powerful strategy for globally optimizing expensive black-box functions, such as finding a polymer formulation that maximizes biodegradability.

Experimental Protocol: Optimizing Biodegradation Rate

- Objective Function: Define the function f(x) to maximize, where x is a formulation vector (e.g., ratio of monomers A:B:C, crosslinker percentage) and f is the biodegradation rate measured in standard assays.

- Surrogate Model: Place a Gaussian Process (GP) prior over f(x) using the initial data.

- Acquisition Function: Use the Expected Improvement (EI) function to determine the next formulation x to test: x_next = argmax EI(x).

- Experiment & Iterate: Synthesize the formulation x_next, measure its biodegradation rate, and update the GP model with the new observation. Loop until convergence.

Transfer Learning

Transfer learning leverages knowledge from data-rich source domains to boost performance in data-poor target domains relevant to sustainable polymers.

Pre-training on Large Chemical Databases

Models can be pre-trained on massive, general chemical datasets (e.g., PubChem, QM9) to learn fundamental representations of molecular structure.

Experimental Protocol: Fine-tuning for Recyclability Prediction

- Pre-training: Train a Graph Neural Network (GNN) on a dataset of millions of small molecules to predict a general quantum chemical property (e.g., HOMO-LUMO gap).

- Feature Extraction: Use the learned GNN layers as a feature extractor. For each polymer repeat unit, generate a latent vector.