A Practical DFT Workflow for Polymer Reaction Energies: From Principles to Biomedical Applications

This article provides a comprehensive, step-by-step guide to Density Functional Theory (DFT) calculations for determining polymer reaction energies, tailored for researchers and drug development professionals.

A Practical DFT Workflow for Polymer Reaction Energies: From Principles to Biomedical Applications

Abstract

This article provides a comprehensive, step-by-step guide to Density Functional Theory (DFT) calculations for determining polymer reaction energies, tailored for researchers and drug development professionals. It covers foundational concepts like choosing functionals for large systems, building polymer models, and defining reaction coordinates. The guide details methodological workflows for energy calculations, transition state searches, and solvent effects. It addresses common pitfalls in convergence, dispersion forces, and system size, offering optimization strategies. Finally, it discusses validating results against experimental data and comparing DFT methods. The goal is to equip scientists with a robust framework to accurately model polymerization, degradation, and functionalization reactions relevant to biomaterials and drug delivery systems.

Understanding the Basics: DFT Fundamentals for Polymer Energy Calculations

Why DFT? The Role of Quantum Mechanics in Polymer Reaction Modeling

Classical molecular mechanics (MM) and coarse-grained models fail to accurately describe the making and breaking of chemical bonds during polymer synthesis and degradation. These reactions involve complex electronic rearrangements, transition states, and subtle energy differences that are inherently quantum mechanical. Density Functional Theory (DFT) provides a computationally tractable framework to calculate these electronic structures and reaction energies with sufficient accuracy for predictive modeling.

Within a thesis workflow for polymer reaction energies, DFT serves as the essential first-principles engine. It generates the foundational thermodynamic and kinetic parameters—such as reaction enthalpies, activation barriers, and regioselectivity indices—that inform higher-level models or guide experimental synthesis.

Key Applications & Quantitative Data

DFT calculations are applied to solve critical problems in polymer reaction modeling. The following table summarizes representative quantitative data from recent studies.

Table 1: DFT-Calculated Energy Barriers and Selectivities for Key Polymerization Reactions

| Polymerization Type | Monomer Example | Catalyst/Initiator System | Calculated ΔG‡ (kcal/mol) | Key Selectivity Predicted (e.g., % meso) | Primary Functional/Basis Set | Reference Year |

|---|---|---|---|---|---|---|

| Ring-Opening Polymerization (ROP) | rac-Lactide | Organocatalyst (e.g., TBD) | 18.2 - 22.5 | 70-85% isotactic preference | ωB97X-D/6-31G(d,p) | 2023 |

| ATRP (Atom Transfer Radical Poly.) | Methyl Methacrylate (MMA) | CuBr/PMDETA complex | 12.8 (activation) | ~100% head-to-tail | M06-2X/6-311+G(d,p) (SDD for Cu) | 2022 |

| ROMP (Ring-Opening Metathesis Poly.) | Norbornene derivatives | Grubbs 3rd Gen. catalyst | 14.5 - 16.0 | >95% trans vinylene | B3LYP-D3/def2-SVP (LANL2DZ for Ru) | 2024 |

| Step-Growth (Esterification) | Terephthalic Acid & Ethylene Glycol | p-Toluenesulfonic acid (model) | 28.7 | N/A (reaction energy: -5.3 kcal/mol) | M06-2X/6-31+G(d,p) | 2023 |

| Controlled Radical (RAFT) | Styrene | Dithiobenzoate CTA | 23.1 (fragmentation) | Chain-length dependent k_p | DLPNO-CCSD(T)/def2-TZVP // PBE0-D3/def2-SVP | 2024 |

Table 2: Comparison of DFT Functionals for Polymer Reaction Energy Accuracy

| Functional Class | Example Functional | Typical Error vs. High-Level CCSD(T) | Best Suited For | Computational Cost |

|---|---|---|---|---|

| Generalized Gradient (GGA) | PBE, BLYP | ±5 - 10 kcal/mol | Initial geometry scans, large systems | Low |

| Meta-GGA | M06-L, SCAN | ±3 - 7 kcal/mol | Solid-state polymer phases | Low-Medium |

| Hybrid | B3LYP, PBE0 | ±2 - 5 kcal/mol | General-purpose reaction pathways | Medium |

| Hybrid with Dispersion | ωB97X-D, M06-2X | ±1 - 4 kcal/mol | Recommended: Non-covalent interactions, organocatalysis | Medium-High |

| Double-Hybrid | B2PLYP-D3 | ±1 - 2 kcal/mol | Benchmarking smaller model reactions | High |

Detailed Experimental Protocols

Protocol 3.1: DFT Workflow for Radical Polymerization Propagation Barrier

Objective: To calculate the free energy barrier (ΔG‡) for the propagation step of acrylate polymerization.

Software: Gaussian 16, ORCA, or CP2K. Step-by-Step Methodology:

System Preparation & Model Chemistry Selection:

- Build initial structures of the propagating radical chain (e.g., methyl acrylate trimer radical) and the incoming monomer (methyl acrylate) using a molecular builder (e.g., Avogadro, GaussView).

- Select Functional & Basis Set: Use a hybrid functional with dispersion correction (e.g., ωB97X-D). For atoms C, H, O: use 6-31G(d) or def2-SVP basis set for initial optimization; for final single-point energy, use a larger basis set (e.g., 6-311+G(d,p) or def2-TZVP).

Geometry Optimization:

- Optimize the geometries of the Reactant Complex (propagating chain + monomer) and the Product Complex (elongated chain) to their local energy minima.

- Calculation Setup:

Opt=(VeryTight, CalcFC) Freq. TheFreqkeyword calculates vibrational frequencies to confirm a minimum (no imaginary frequencies).

Transition State (TS) Search:

- Use the Synchronous Transit Guided Quasi-Newton (QST2/QST3) method, providing the optimized reactant and product structures as input.

- Alternatively, perform a Potential Energy Surface (PES) scan by constraining the forming C–C bond distance, then optimize from the approximate TS geometry.

- Calculation Setup:

Opt=(QST3, TS, NoEigenTest) Freq.

Frequency & Intrinsic Reaction Coordinate (IRC) Analysis:

- Run a frequency calculation on the optimized TS structure. Validate: It must have exactly one imaginary frequency (negative value), corresponding to the reaction coordinate.

- Perform an IRC calculation in both forward and reverse directions to confirm the TS correctly connects the reactant and product minima.

- Calculation Setup:

IRC=(Forward, Reverse, MaxPoints=50, CalcFC).

Thermochemical Analysis & Barrier Calculation:

- From the frequency (

Freq) calculations on the Reactant, TS, and Product, extract the Gibbs free energy (G) at the desired temperature (e.g., 298.15 K). - Calculate: ΔG‡ = G(TS) - G(Reactant Complex). Report in kcal/mol.

- From the frequency (

Solvent Correction (Implicit Model):

- Perform a single-point energy calculation on the optimized gas-phase structures using an implicit solvation model (e.g., SMD, CPCM) for a solvent like toluene or water.

- Add the solvation correction to the gas-phase Gibbs free energy to obtain ΔG‡(solv).

Protocol 3.2: Modeling Organocatalytic ROP Selectivity

Objective: To predict the stereoselectivity (e.g., meso vs. racemic enchainment) in the ring-opening polymerization of rac-lactide catalyzed by an organic base.

Construct Diastereomeric Transition States:

- Build two model TS structures where the catalyst activates the monomer and the propagating chain attacks the carbonyl carbon. One leads to a meso dyad (like stereochemistry), the other to a racemic dyad (unlike stereochemistry).

High-Level Optimization & Frequency:

- Optimize both TS structures using a dispersion-corrected hybrid functional (e.g., M06-2X) with a medium basis set (e.g., 6-31G(d)). Run frequency calculations to verify TS and obtain thermal corrections.

High-Accuracy Single-Point Energy:

- Perform a more accurate single-point energy calculation on the optimized TS geometries using a larger basis set (e.g., def2-TZVP) and/or a higher-level method (e.g., DLPNO-CCSD(T) as a benchmark).

Selectivity Calculation:

- Compute the free energy difference: ΔΔG‡ = G‡(racemic) - G‡(meso).

- Predict the diastereomeric ratio (dr) using the Boltzmann distribution: dr = exp(-ΔΔG‡ / RT).

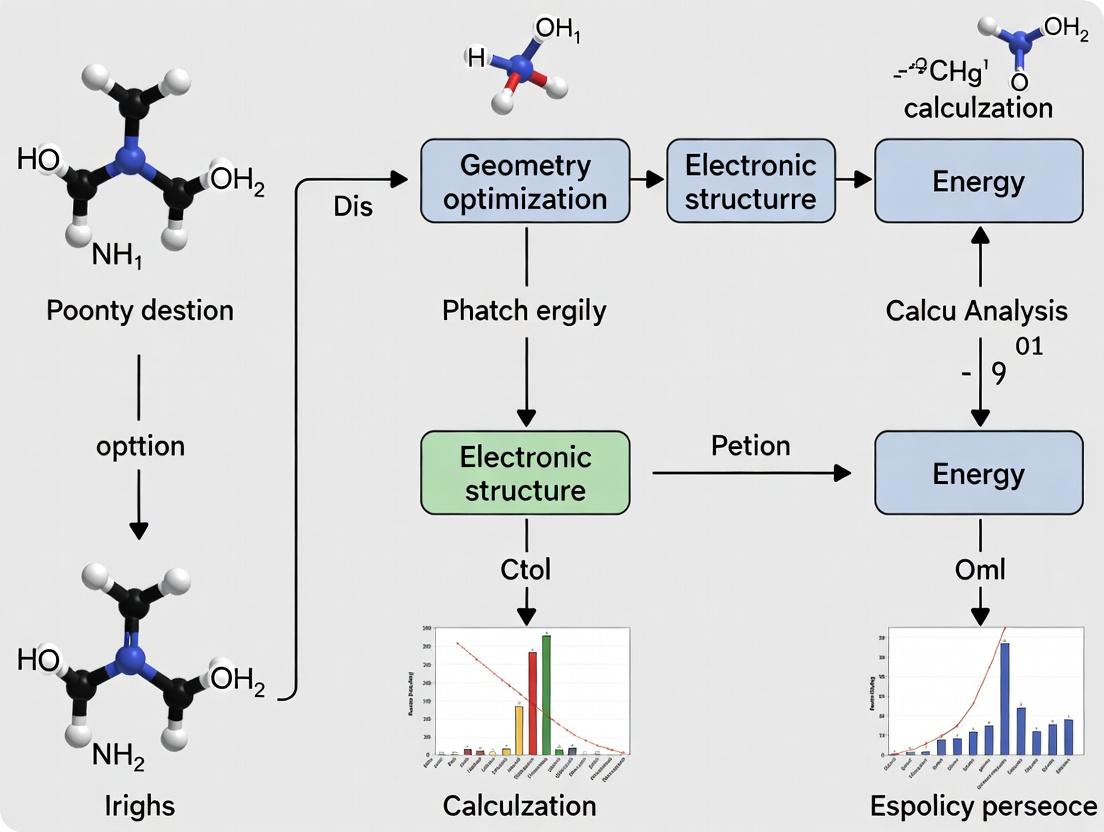

Visualization: DFT Workflow & Reaction Pathways

Title: DFT Workflow for Polymer Reaction Kinetics

Title: Catalytic Cycle for Coordination-Insertion Polymerization

Table 3: Key Reagents & Computational Tools for DFT Polymer Modeling

| Item / Resource Name | Category | Function / Purpose in DFT Workflow | Example / Note |

|---|---|---|---|

| Gaussian 16 | Software Suite | Comprehensive package for running DFT calculations, including optimization, TS search, frequency, and IRC. | Industry standard, user-friendly interface. |

| ORCA | Software Suite | Powerful, efficient quantum chemistry program. Excellent for open-shell systems (radicals) and high-level coupled-cluster benchmarks. | Free for academics, strong support for DFT functionals. |

| CP2K | Software Suite | Performs DFT calculations using mixed Gaussian and plane-wave methods. Optimal for large periodic systems (e.g., polymers in bulk). | Open-source, excellent for solid-state/materials. |

| Avogadro | Software | Open-source molecular builder and visualizer. Used to construct initial monomer, catalyst, and polymer chain models. | Critical for preparing input geometries. |

| BASIS SET EXCHANGE | Web Portal | Repository for obtaining basis set definitions in formats for all major quantum codes. | Ensures consistency and access to latest basis sets. |

| ωB97X-D Functional | DFT Method | Range-separated hybrid functional with empirical dispersion. Recommended default for polymer reactions due to good treatment of non-covalent interactions. | Part of the "Jacob's Ladder" of functionals. |

| def2-TZVP Basis Set | Basis Set | Triple-zeta valence polarization basis set. Used for final, high-accuracy single-point energy calculations on optimized structures. | Offers good accuracy/computational cost balance. |

| SMD Solvation Model | Implicit Model | Continuum solvation model based on electron density. Used to calculate solvent effects on reaction energies and barriers. | Implemented in Gaussian, ORCA. Specify solvent (e.g., Solvent=Toluene). |

| High-Performance Computing (HPC) Cluster | Hardware | Essential for running DFT calculations on model systems with >100 atoms or using high-level methods. | Calculations are computationally intensive. |

Application Notes: DFT Workflow for Polymer Reaction Energy Analysis

Within the broader thesis on developing a robust Density Functional Theory (DFT) calculation workflow for polymer reaction energies, understanding the interplay of core thermodynamic concepts is critical. These concepts form the foundational language for interpreting computational results and linking them to experimentally observable polymer properties like reactivity, stability, and degradability.

Enthalpy (ΔH) quantifies the heat change of a reaction at constant pressure. In polymer reactions—such as polymerization, crosslinking, or degradation—a negative ΔH indicates an exothermic process, often driving reactions like chain-growth polymerization. DFT calculates this via the total electronic energy difference between products and reactants, often corrected for zero-point energy and thermal contributions.

Gibbs Free Energy (ΔG) is the central determinant of spontaneity, incorporating both enthalpy and entropy (ΔS): ΔG = ΔH - TΔS. For polymer systems, entropic contributions (e.g., chain conformational freedom) are significant. A negative ΔG predicts a thermodynamically favorable reaction. DFT-derived ΔG is essential for predicting equilibrium constants in reversible polymerizations or depolymerization.

Reaction Coordinate is a conceptual pathway tracing the progression from reactants to products, often mapped to a geometric parameter like bond length or angle. In computational workflows, it is visualized via Potential Energy Surface (PES) scans or Nudged Elastic Band (NEB) calculations, identifying transition states (saddle points) and intermediates.

Reaction Energy is the overall energy change (often approximated by ΔE, ΔH, or ΔG) for the conversion of reactants to products. For polymer drug conjugates, this energy dictates the stability of the linker chemistry in physiological conditions.

Table 1: Key Thermodynamic Outputs from DFT Polymer Reaction Calculations

| Quantity | DFT Calculation Method | Relevance to Polymer Reactions | Typical Target Accuracy |

|---|---|---|---|

| Total Electronic Energy (E) | Self-consistent field (SCF) solution of Kohn-Sham equations. | Baseline for all energy differences. | ±1 kJ/mol (challenging) |

| Enthalpy (H) | H = E + ZPE + H(translational, rotational, vibrational) | Predicts exo/endothermic nature of polymerization steps. | ±10 kJ/mol |

| Gibbs Free Energy (G) | G = H - TS, with S calculated from vibrational frequencies. | Determines thermodynamic feasibility and equilibrium yields. | ±10-20 kJ/mol |

| Activation Energy (Ea) | Energy difference between reactant and transition state. | Predicts kinetics of propagation, crosslinking, or degradation. | ±15-25 kJ/mol |

Experimental & Computational Protocols

Protocol 1: DFT Calculation of Polymerization Reaction Enthalpy and Gibbs Free Energy

Objective: To compute ΔH and ΔG for a monomer addition step in a radical polymerization.

- System Preparation: Model the reacting species. For a propagating poly(methyl methacrylate) (PMMA) chain, use a short oligomer (e.g., a dimer radical) and a fresh MMA monomer. Employ a termination cap (e.g., methyl group) for the unreactive chain end.

- Geometry Optimization: Optimize the structures of the reactant complex (propagating radical + monomer) and the product (elongated chain radical) using a functional like ωB97X-D and a basis set like 6-31G(d). Apply dispersion correction.

- Frequency Calculation: Perform a vibrational frequency calculation on each optimized structure at the same level of theory.

- Confirm minima (no imaginary frequencies).

- Extract thermal corrections to enthalpy (Hcorr) and Gibbs free energy (Gcorr) at the desired temperature (e.g., 298.15 K).

- Single-Point Energy Calculation: Compute a higher-accuracy single-point energy (Esp) for each optimized structure using a larger basis set (e.g., 6-311++G(d,p)).

- Energy Analysis:

- ΔE = Esp(product) - Esp(reactant)

- ΔH = ΔE + ΔHcorr (where ΔHcorr = Hcorr(product) - Hcorr(reactant))

- ΔG = ΔE + ΔGcorr (where ΔGcorr = Gcorr(product) - Gcorr(reactant))

- Validation: Compare ΔH with experimental polymerization heats where available (e.g., ~56 kJ/mol exothermic for MMA).

Protocol 2: Locating Transition States and Mapping Reaction Coordinates

Objective: To find the transition state and plot the reaction pathway for a polymer cyclization reaction.

- Initial Guess: Generate a plausible guess for the transition state (TS) geometry, often by constraining the forming/bond-breaking distance.

- Transition State Optimization: Use a method like QST2, QST3, or the Berny algorithm (e.g.,

opt=ts) to optimize to a first-order saddle point. - TS Verification: Run a frequency calculation on the optimized TS structure. A single imaginary frequency corresponding to the expected reaction motion confirms a valid TS.

- Intrinsic Reaction Coordinate (IRC) Calculation: From the verified TS, run an IRC calculation in both forward and reverse directions to confirm it connects the correct reactant and product minima.

- Reaction Coordinate Plot: Use the IRC path length (or a key geometric parameter) as the x-axis and the electronic energy (or Gibbs free energy) as the y-axis to construct the reaction profile diagram.

Visualization of DFT Workflow and Concepts

Title: DFT Workflow for Polymer Reaction Energy & Pathway

Title: Reaction Coordinate Diagram with Key Energies

The Scientist's Toolkit: DFT Polymer Reaction Research

Table 2: Essential Computational Reagents & Tools

| Item | Function in Polymer Reaction DFT Studies | Example/Note |

|---|---|---|

| DFT Software Suite | Provides the core engines for quantum mechanical calculations. | Gaussian, ORCA, VASP, CP2K, NWChem. |

| Chemical Model System | A computationally tractable representation of the polymer reaction. | Oligomers (3-8 monomers), simplified catalysts, implicit solvation models (e.g., SMD, PCM). |

| Exchange-Correlation Functional | Approximates quantum effects governing electron interactions; critical for accuracy. | B3LYP (general), ωB97X-D (long-range, dispersion), M06-2X (metals, non-covalent). |

| Basis Set | A set of mathematical functions describing electron orbitals. | 6-31G(d) (optimization), 6-311++G(d,p) (high-accuracy energy), def2-TZVP. |

| Dispersion Correction | Accounts for weak van der Waals forces, crucial in polymer stacking. | Grimme's D3, D3(BJ). Often integral to modern functionals. |

| Solvation Model | Mimics the effect of a solvent (e.g., water, toluene) on reaction energies. | Polarizable Continuum Model (PCM), Solvation Model based on Density (SMD). |

| Transition State Search Method | Algorithm to locate first-order saddle points on the PES. | QST2/QST3, Nudged Elastic Band (NEB), Dimer method. |

| Vibrational Frequency Code | Calculates vibrational modes to verify stationary points and derive thermal corrections. | Built into major DFT packages. Essential for obtaining H and G. |

| Visualization & Analysis Software | For building models, visualizing orbitals, and analyzing reaction pathways. | Avogadro, VESTA, GaussView, Jmol, VMD. |

Accurate modeling of polymer reaction energies using Density Functional Theory (DFT) requires careful initial construction of the molecular system. This stage is critical within the broader thesis workflow: the reliability of subsequent quantum chemical calculations on reaction energetics, barrier heights, and electronic properties is fundamentally dependent on a realistic initial structural model. This document provides application notes and detailed protocols for constructing polymer models suitable for DFT studies, focusing on monomer selection, oligomer generation, and the application of Periodic Boundary Conditions (PBC) to simulate extended polymeric environments.

Foundational Concepts and Data

Table 1: Model System Selection Criteria for Polymer DFT Studies

| Model Type | Typical Size (Atoms) | Computational Cost (Relative CPU hrs) | Primary Use Case | Key Limitation |

|---|---|---|---|---|

| Monomer | 10-50 | 1 (Baseline) | Screening functional groups, initial conformation search. | Neglects polymer chain effects. |

| Dimer/Trimer | 20-150 | 5-10 | Studying local stereochemistry, dihedral preferences, and nearest-neighbor interactions. | Finite chain effects still significant. |

| Short Oligomer (n=5-10) | 100-500 | 50-200 | Capturing medium-range order, chain folding, and realistic transition states for backbone reactions. | High cost for geometry optimization with high-level functionals. |

| Periodic Model (1D Chain) | 10-50 per unit cell | 20-100 (per SCF) | Simulating infinite chain properties (band structure, conformational regularity, crystal packing). | Requires careful k-point sampling; defect-free. |

Table 2: Common DFT Functionals & Basis Sets for Polymer Modeling

| Functional | Basis Set | Best For | Typical Error vs. Experiment (kJ/mol) |

|---|---|---|---|

| PBE | 6-31G(d) | Initial geometry scans, large oligomers. | ~15-25 (Reaction energies) |

| B3LYP | 6-311++G(d,p) | Ground-state electronic properties, oligomer energetics. | ~10-20 (Reaction energies) |

| ωB97X-D | def2-SVP | Systems with dispersion interactions (chain packing). | ~5-15 (Barrier heights) |

| M06-2X | 6-31+G(d) | Reaction pathways, transition state search in oligomers. | ~5-10 (Reaction energies) |

Protocols

Protocol 1: Building and Optimizing a Monomer Model

Objective: To create a pre-polymerization monomer structure optimized for subsequent oligomer construction. Materials: Chemical drawing software (Avogadro, GaussView), DFT software (Gaussian, ORCA, VASP). Procedure:

- Draw Monomer: Use chemical drawing software to construct the fundamental repeating unit with correct bonding and stereochemistry.

- Conformational Search: Perform a systematic or random conformational search (e.g., using Avogadro's "Conformer Search" or CREST) to identify low-energy conformers. Apply semi-empirical methods (GFN2-xTB) for initial screening.

- Geometry Optimization: Optimize the lowest-energy conformer(s) using DFT.

- Software Command Example (Gaussian):

# opt b3lyp/6-31g(d) geom=connectivity

- Software Command Example (Gaussian):

- Frequency Calculation: Perform a vibrational frequency calculation on the optimized structure to confirm it is a true minimum (no imaginary frequencies).

- Software Command Example (Gaussian):

# freq b3lyp/6-31g(d)

- Software Command Example (Gaussian):

- Charge & Multiplicity: Ensure correct electronic state (typically singlet for closed-shell organic monomers).

Protocol 2: Constructing and Validating an Oligomer Chain

Objective: To assemble a finite-length polymer chain from monomer units for modeling non-periodic chain properties. Procedure:

- Cleave Monomer Termini: Modify the optimized monomer by cleaving appropriate bonds (e.g., replacing a methyl group with the connecting bond) to create "linker-ready" termini.

- Polymerization in Silico: Use the "Polymer Builder" tool in materials modeling suites (Materials Studio, BIOVIA) or manually replicate and connect monomer units via the defined linkage chemistry.

- Manual method: Copy and translate the monomer, then manually form bonds between terminal atoms, adjusting bond lengths and angles.

- Termination: Cap chain termini with appropriate chemical groups (e.g., methyl, hydrogen, hydroxyl) to mimic a finite chain segment.

- Oligomer Optimization: Perform a multi-step optimization. a. Partial Optimization: Freeze dihedral angles along the backbone and optimize only terminal capping groups and side chains. b. Full Optimization: Gradually release constraints, finishing with a full, unconstrained DFT geometry optimization using a moderate functional/basis set (e.g., PBE/6-31G(d)).

- Model Validation: Calculate the oligomer's persistence length or characteristic ratio (if known experimentally) from the optimized structure to assess model realism.

Protocol 3: Applying 1D Periodic Boundary Conditions (PBC)

Objective: To model an infinite, idealized polymer chain for calculating crystalline or regular polymer properties. Procedure:

- Define Unit Cell: Starting from the optimized oligomer (or monomer), define a triclinic unit cell where one lattice vector (a) is aligned with the polymer chain axis and is approximately equal to the projected length of one repeating unit along the chain direction. The other two vectors (b, c) should be large enough (e.g., >20 Å) to prevent spurious interactions between periodic images in non-polymer directions.

- Place Atom in Cell: Ensure the atom(s) of the repeating unit are placed correctly within the unit cell.

- Set Up DFT-PBC Calculation:

- Software Command Example (VASP): In the

INCARfile, setISIF = 2to allow cell shape/volume relaxation. In theKPOINTSfile, use a Monkhorst-Pack grid like1 1 1for a preliminary run, but a finer k-point sampling along the chain direction (e.g.,1 1 16) is critical for accuracy.

- Software Command Example (VASP): In the

- Geometry Optimization under PBC: Optimize both atomic positions and the lattice vector along the chain direction.

- Property Calculation: Once optimized, use the periodic model to calculate electronic band structure, density of states, or linear elastic properties.

Visualizations

Workflow for Building Polymer Models for DFT Studies

Polymer Model Types: Monomer, Oligomer, and Periodic

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Computational Tools

| Item / Software | Function in Polymer Model Building |

|---|---|

| Avogadro | Open-source molecular editor and visualizer for constructing monomers and initial oligomer assembly. |

| Gaussian / ORCA | Quantum chemistry software packages for performing DFT geometry optimizations and frequency calculations on monomers and oligomers. |

| VASP / Quantum ESPRESSO | DFT software designed for periodic systems, essential for PBC calculations on infinite polymer chains. |

| GFN2-xTB | Semi-empirical method for fast conformational searches and pre-optimization of large oligomers. |

| Materials Studio (BIOVIA) | Integrated modeling environment with specialized polymer building tools and interfaces to major DFT codes. |

| CREST (Grimme) | Conformer-Rotamer Ensemble Sampling Tool for robust conformational searching. |

| Pseudopotentials & Basis Sets (e.g., PAW, def2) | Essential for accurate and efficient electron treatment in periodic and large finite systems. |

| High-Performance Computing (HPC) Cluster | Required computational resource for all but the smallest monomer DFT calculations. |

This application note exists within a broader thesis focused on establishing robust Density Functional Theory (DFT) workflows for calculating reaction energies in polymer systems. A central, non-trivial challenge is selecting an exchange-correlation functional that provides chemical accuracy for reaction barriers and energies while remaining computationally feasible for the large, often aperiodic models required to represent polymeric environments. This document provides protocols and data to guide this critical choice.

Quantitative Benchmarking Data

Table 1: Performance of Selected Functionals for Thermochemical Kinetics (Non-Metallic Systems)

Data synthesized from recent benchmarks (e.g., GMTKN55, NICE21) and polymer-relevant studies.

| Functional Class | Example Functional(s) | Mean Absolute Error (MAE) for Reaction Energies (kcal/mol) | Typical Cost Relative to PBE | Recommended for Polymer Reaction Step |

|---|---|---|---|---|

| GGA (Baseline) | PBE, BLYP | 8.0 - 12.0 | 1.0 (Reference) | Preliminary geometry optimization; very large systems |

| Meta-GGA | SCAN, B97M-rV | 4.0 - 6.0 | 1.5 - 2.5 | Single-point energy refinement on GGA geometries |

| Hybrid GGA | B3LYP, PBE0 | 3.5 - 5.0 | 5.0 - 10.0 | Key mechanistic steps for systems <= 200 atoms |

| Hybrid Meta-GGA | ωB97X-V, ωB97M-V | 2.0 - 3.5 | 10.0 - 20.0 | High-accuracy final benchmarks for critical barriers |

| Double-Hybrid | DLPNO-CCSD(T)* (as benchmark) | < 1.0 (Target) | 50.0 - 100+ | Gold-standard reference (small models only) |

| Range-Separated Hybrid | ωB97X-D, LC-ωPBE | 3.0 - 4.5 (for charge-transfer) | 8.0 - 15.0 | Reactions involving excitons or charge separation |

Note: DLPNO-CCSD(T) is a wavefunction method, not a functional, included for accuracy context. Cost depends on implementation, basis set, and system size.

Table 2: Cost-Accuracy Trade-off for a Model Polymerization Step (≈150 atoms)

Hypothetical data based on projected performance from benchmark databases.

| Computational Protocol | Functional (Single-Point) | Basis Set | Wall Clock Time (Hours) | Estimated ΔG Error vs. Benchmark (kcal/mol) |

|---|---|---|---|---|

| Protocol A (Screening) | PBE | def2-SVP | 2.5 | ±7.0 |

| Protocol B (Balanced) | PBE0 | def2-SVP | 18.0 | ±4.0 |

| Protocol C (Accurate) | ωB97M-V | def2-TZVP | 65.0 | ±2.5 |

| Protocol D (Benchmark) | DLPNO-CCSD(T)/PBE0 | def2-TZVPP//def2-QZVPP | 240.0 | < 1.0 |

Experimental Protocols

Protocol 3.1: Two-Layered ONIOM-Based Screening for Polymer Reaction Sites

Objective: To efficiently compute reaction energies for a localized active site within a large polymer chain or matrix. Principle: The Our own N-layered Integrated molecular Orbital and molecular Mechanics (ONIOM) method partitions the system into high (active site) and low (environment) layers.

Methodology:

- Model Preparation: From the full periodic or large cluster model, identify the reacting moieties (e.g., radical, monomer, catalyst, chain end). Define a "high-layer" model consisting of these moieties plus immediate substituents (≈30-80 atoms). The remaining polymer scaffold forms the "low-layer."

- Layer Assignment: High Layer: Treated with a accurate, hybrid functional (e.g., ωB97X-D or PBE0) and a double-zeta basis set (def2-SVP). Low Layer: Treated with a fast GGA functional (e.g., PBE) and a minimal basis set (e.g., def2-SV(P)) or Universal Force Field (UFF).

- Geometry Optimization: Optimize the geometry of the entire system using the ONIOM scheme, freezing the positions of atoms far from the active site to reduce cost.

- Energy Evaluation: Perform a high-accuracy single-point calculation on the optimized ONIOM geometry using a larger basis set (e.g., def2-TZVP) on the high layer only, or re-run the ONIOM energy evaluation.

- Validation: Compare key geometric parameters (bond lengths, angles) of the active site between the ONIOM-optimized structure and a full-system optimization at a lower level (e.g., pure PBE). Differences > 0.05 Å or 3° warrant a larger high-layer model.

Protocol 3.2: ΔΔDFT Approach for Systematic Error Cancellation

Objective: To obtain accurate reaction energies by leveraging cancellation of functional error between reactants and products. Principle: Perform high-level calculations on small model systems to derive a "correction" applied to low-level calculations on the full system.

Methodology:

- Define Model Systems: Create small molecular clusters that accurately represent the electronic and steric environment of the reacting functional groups in the full polymer (e.g., model the chain end with a small alkane).

- Compute High-Level Reference: Calculate the reaction energy for the model reaction using a gold-standard method (e.g., DLPNO-CCSD(T)/CBS or a robust hybrid meta-GGA like ωB97M-V/def2-QZVPP). This yields ΔE_high(model).

- Compute Low-Level Model Energy: Calculate the same model reaction energy using the fast, scalable functional chosen for the full polymer system (e.g., PBE/def2-SVP). This yields ΔE_low(model).

- Calculate the ΔΔ Correction: ΔΔ = ΔEhigh(model) - ΔElow(model). This correction embodies the systematic error of the low-level functional for that specific chemical transformation.

- Apply to Full System: Compute the reaction energy for the full polymeric system using the low-level functional: ΔElow(full). The corrected, more accurate reaction energy is: ΔEcorrected(full) = ΔE_low(full) + ΔΔ.

- Error Estimation: Repeat steps 2-4 using 2-3 different high-level methods or basis sets to estimate the uncertainty in the ΔΔ correction.

Mandatory Visualizations

Workflow for Accurate Polymer Reaction Energy Calculation

Functional Selection: Accuracy vs. Computational Cost Trade-off

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Materials for Polymer DFT Workflows

| Item / "Reagent" | Function in Workflow | Notes & Recommendations |

|---|---|---|

| Model Builder Software (Avogadro, GaussView, Materials Studio) | Prepares initial 3D coordinates of polymer clusters or periodic cells from SMILES or repeat units. | Essential for creating chemically sensible starting geometries for large systems. |

| DFT Code with Robust Dispersion (Gaussian, ORCA, CP2K, VASP) | Performs the core electronic structure calculations. | Must include modern dispersion corrections (D3(BJ), D4, vdW-DF). CP2K excels at large periodic systems. |

| ONIOM-Capable Software (Gaussian) | Enables multi-level modeling as per Protocol 3.1. | Critical for applying high-accuracy methods to localized regions. |

| Robust Basis Set Library (def2-SVP, def2-TZVP, 6-31G(d,p)) | Defines the mathematical functions for expanding electron orbitals. | def2 series is recommended for efficiency. Use consistent basis sets for error cancellation. |

| Conformational Sampling Tool (CREST, conformer generators) | Generates an ensemble of low-energy conformers for flexible polymer segments. | Avoids artifacts from a single, potentially non-representative conformation. |

| High-Performance Computing (HPC) Cluster | Provides the necessary CPU/GPU cores and memory for large-scale calculations. | Hybrid functional calculations on >500 atoms require significant parallel resources. |

| Visualization & Analysis (VMD, Multiwfn, IboView) | Analyzes results (orbitals, charges, bonding) and creates publication-quality images. | Key for interpreting reaction mechanisms and electronic structure changes. |

The Critical Role of Basis Sets and Pseudopotentials in Polymer Simulations

Within the broader thesis on establishing a robust Density Functional Theory (DFT) calculation workflow for predicting polymer reaction energies, the selection of basis sets and pseudopotentials is not merely a technical step but a foundational determinant of accuracy, computational cost, and chemical reliability. Polymer systems present unique challenges: they are large, often involve heavy elements, and require the modeling of long-range dispersion interactions and complex electronic environments. A suboptimal choice here can lead to systematic errors that invalidate downstream conclusions on reaction energies, catalysis, or drug-polymer interaction studies crucial for pharmaceutical development.

Core Concepts and Quantitative Comparisons

Basis Sets in Polymer DFT

A basis set is a set of mathematical functions used to construct the molecular orbitals of the system. For polymers, the choice balances describing diffuse electron clouds (e.g., in conjugated backbones) with managing the computational expense of large, repeating units.

Table 1: Common Basis Set Families for Polymer Simulations

| Basis Set Family | Key Characteristics | Ideal For Polymer Use-Case | Typical Cost Factor (Relative to Minimal) |

|---|---|---|---|

| Plane-Wave (PW) | Periodic boundary conditions, defined by energy cutoff (ECUT). Systematic improvability. | Periodic polymer crystals, bulk amorphous phases, surfaces. | High (scales with ECUT^3/ system volume) |

| Gaussian-Type Orbital (GTO) | Localized functions (e.g., 6-31G, cc-pVDZ). Rich chemistry sets. | Isolated polymer chains, oligomer models, reaction center studies. | Medium-High (scales with N^3-N^4) |

| Projector Augmented Wave (PAW) | Combines smooth plane waves with atomic core corrections. | All-electron accuracy with PW efficiency for heavy elements in polymers. | Similar to PW, slightly higher. |

| Atomic Orbital (AO) Numerical | Atom-centered, numerically tabulated. High accuracy per function. | Large organic polymer segments in DFTB or specific codes (FHI-aims). | Low-Medium |

Table 2: Recommended Basis Set Choices for Specific Polymer Properties

| Target Property | Recommended Basis Set / Enhancement | Rationale |

|---|---|---|

| Band Gap | Hybrid functional with diffuse-augmented basis (e.g., aug-cc-pVTZ) or high PW cutoff. | Diffuse functions better describe conduction band states. |

| Reaction Energy | Triple-zeta quality with polarization (e.g., def2-TZVP, cc-pVTZ). | Reduces basis set superposition error (BSSE) critical for energy differences. |

| Dispersion (van der Waals) | Employ empirical correction (DFT-D3) with medium-sized basis (def2-SVP). | Basis set incompleteness error can be partially compensated by D3 correction. |

| Geometric Structure | Double-zeta with polarization (e.g., 6-31G) is often sufficient. | Bond lengths and angles converge with smaller bases than energies. |

Pseudopotentials (PPs) / Effective Core Potentials (ECPs)

PPs replace the core electrons and strong nuclear potential with an effective operator, drastically reducing the number of explicit electrons. This is vital for polymers containing heavy atoms (e.g., metallopolymers, iodine-containing catalysts).

Table 3: Pseudopotential Types and Their Impact on Polymer Simulations

| Pseudopotential Type | Description | Applicability in Polymer Systems |

|---|---|---|

| Norm-Conserving (NCPP) | Strictly preserves charge norm. Requires higher PW cutoffs. | Early transition metals in catalytic sites; good for high-pressure phases. |

| Ultrasoft (USPP) | Allows softer, lower-cutoff potentials. Fewer plane waves needed. | Large organic/metallic hybrid systems; long polymer chains with periodic DFT. |

| Projector Augmented Wave (PAW) | Formal all-electron potential reconstructed from smooth wavefunction. Modern standard for accuracy. | Recommended default for most polymer simulations, especially with heavy elements. |

| Energy-consistent ECPs (e.g., def2-ECPs) | Designed for use with Gaussian basis sets (e.g., def2 series). | Isolated oligomers with heavy atoms like Sn, Pb, or I in the backbone. |

Table 4: Quantitative Impact of PP Choice on Calculation of a Sn-Containing Polymer Unit Cell

| PP Method | Plane-Wave Cutoff (eV) | Lattice Parameter Error vs. Exp. (%) | Total Energy (Ha) | Relative Computational Time |

|---|---|---|---|---|

| USPP (Sn) | 400 | +1.5% | -342.567 | 1.0 (Baseline) |

| NCPP (Sn) | 700 | +0.8% | -342.602 | 2.5 |

| PAW (Sn) | 500 | +0.5% | -342.591 | 1.3 |

Experimental Protocols for Workflow Validation

Protocol 1: Basis Set Convergence for Polymer Reaction Energy

Aim: To determine the minimal basis set for chemically accurate (< 1 kcal/mol error) reaction energies in a polymerization step-growth reaction. Materials: DFT software (e.g., VASP, Quantum ESPRESSO, Gaussian), monomer and dimer molecular models. Procedure:

- Model Building: Geometry optimize the monomer (e.g., ethylene glycol) and the dimer product using a high-level method (e.g., B3LYP/def2-TZVP).

- Single-Point Energy Scan: Using the fixed, optimized geometries, perform single-point energy calculations for each species across a basis set ladder:

- PBE/STO-3G

- PBE/6-31G(d)

- PBE/def2-SVP

- PBE/def2-TZVP

- PBE/def2-QZVP (as reference)

- BSSE Correction: Apply the Counterpoise correction for each basis set to account for artificial stabilization.

- Analysis: Calculate the dimerization energy ΔE = E(dimer) - 2*E(monomer) for each level. Plot ΔE vs. basis set size/time. Identify the point where the energy change is within the target threshold.

Protocol 2: Pseudopotential Benchmarking for a Metallopolymer

Aim: To select the optimal pseudopotential for simulating geometry and electronic structure of a poly(ferrocenylsilane) crystal. Materials: Periodic DFT code (VASP, ABINIT), crystal structure (CSD/ICSD), various PAW/USPP libraries (e.g., GBRV, PSLIB). Procedure:

- Structure Preparation: Obtain/refine the unit cell of the polymer crystal.

- Cutoff Convergence: For each candidate Fe and Si PP, perform a total energy convergence test by increasing the plane-wave energy cutoff in 50 eV steps from 300 to 800 eV. Plot total energy vs. cutoff.

- Property Calculation: At the converged cutoff, calculate:

- Lattice parameters (a, b, c)

- Band gap (PBE, then HSE06)

- Magnetic moment on Fe

- Validation: Compare to experimental XRD and UV-Vis data. The PP yielding the closest agreement across all properties with acceptable cost is selected.

Visualization of Workflow Logic

Title: Basis Set and Pseudopotential Selection Workflow for Polymers

Title: Protocol for Basis Set Convergence Testing

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 5: Key Computational "Reagents" for Polymer DFT Simulations

| Item / Software Solution | Function in Polymer Simulation | Example/Note |

|---|---|---|

| Pseudopotential Libraries | Provide tested, transferable PPs for specific elements. | PSLIB (for PW), GBRV, SG15 (efficiency); def2-ECPs (for GTO). |

| Basis Set Exchange (BSE) | Repository and download tool for Gaussian-type basis sets. | Critical for obtaining consistent, published basis sets (cc-pVXZ, def2-XZVP, etc.). |

| DFT Software with Periodic Capabilities | Enables simulation of crystalline or amorphous bulk polymers. | VASP (PAW), Quantum ESPRESSO (USPP/NCPP), CP2K (GTO/PW mixed). |

| DFT Software for Molecular Models | Enables simulation of oligomers, reaction centers, and chain segments. | Gaussian, ORCA, Psi4. Essential for mechanistic studies. |

| Van der Waals Correction Schemes | Empirically add dispersion forces critical for polymer packing and interaction. | DFT-D3(BJ), vdW-DF, MBD. Must be compatible with basis/PP choice. |

| Visualization & Analysis Tools | To analyze geometry, electronic structure, and charge distribution. | VMD, OVITO, VESTA (structure); p4vasp, Libra (analysis). |

| High-Performance Computing (HPC) Cluster | Provides necessary computational resources for large, periodic, or high-accuracy calculations. | Access to CPU/GPU nodes with high memory and fast interconnects. |

Step-by-Step Workflow: Calculating Polymerization and Degradation Energies

This document outlines a standardized Density Functional Theory (DFT) workflow for calculating reaction energies in polymer systems, as applied within a broader thesis investigating polymer reaction energetics. The protocol is designed for reliability and reproducibility in computational materials science and drug development research.

The Computational Workflow: A Step-by-Step Protocol

Step 1: Initial System Construction & Geometry Preparation

Objective: Generate a physically reasonable starting geometry for the polymer monomer, transition state complex, or product. Protocol:

- Monomer Sketching: Use a molecular builder (e.g., Avogadro, GaussView) to construct the monomer unit. Apply basic chemical constraints (bond lengths, angles).

- Conformational Sampling: For flexible monomers, perform a preliminary conformational search using molecular mechanics (MMFF94 or UFF force field) to identify low-energy conformers. Select the lowest-energy conformer for DFT optimization.

- Polymer Model Setup: For reaction simulations, construct a minimal model system (e.g., dimer, trimer) that captures the essential electronic and steric effects of the polymer chain involved in the reaction.

- File Export: Export the geometry in a standard format (.xyz, .mol, .gjf) for input into the DFT software.

Step 2: Geometry Optimization

Objective: Find the equilibrium ground-state geometry of the constructed system. Protocol:

- Functional & Basis Set Selection: Initiate optimization using a robust, moderately priced functional/basis set combination (e.g., B3LYP/6-31G(d)).

- Convergence Criteria: Set stringent optimization convergence criteria (e.g., forces < 0.00045 Ha/Bohr, displacement < 0.0018 Å, energy change < 1.0e-6 Ha).

- Frequency Calculation: Run a vibrational frequency calculation on the optimized geometry at the same level of theory to confirm it is a true minimum (no imaginary frequencies) or a transition state (one imaginary frequency).

- Output: The final optimized geometry and its total electronic energy (E_opt) are the primary outputs.

Step 3: Single-Point Energy Refinement

Objective: Obtain a highly accurate electronic energy for the optimized geometry using a higher-level theory. Protocol:

- Input Geometry: Use the optimized geometry from Step 2 as the input.

- Higher-Level Theory: Perform a single-point energy calculation using a more advanced functional (e.g., ωB97X-D, M06-2X) and a larger basis set (e.g., 6-311++G(d,p), def2-TZVP). Include an empirical dispersion correction if not inherent to the functional.

- Solvation Model: For reactions in solution, employ an implicit solvation model (e.g., SMD, CPCM) with the appropriate solvent parameters.

- Output: The refined single-point electronic energy (E_SP) is the key result.

Step 4: Energy Value Calculation & Analysis

Objective: Compute the final reaction energy from the refined electronic energies. Protocol:

- Energy Assembly: Collect the E_SP for all reaction components: reactants (R), transition state (TS), and products (P).

- Thermal Correction: Apply the thermal correction to enthalpy (Hcorr) and Gibbs free energy (Gcorr) obtained from the frequency calculation in Step 2.3 to each species: H = ESP + Hcorr, G = ESP + Gcorr.

- Reaction Energy Calculation: Compute the reaction energy (ΔE), enthalpy (ΔH), and free energy (ΔG) using the formulae:

- ΔE = Σ ESP(products) - Σ ESP(reactants)

- ΔG = Σ G(products) - Σ G(reactants)

- Benchmarking: Compare calculated ΔG with available experimental data for known systems to validate the methodological choices.

Data Presentation: Representative Computational Results

Table 1: Comparison of DFT Functionals for Acrylate Polymerization Propagation Energy (ΔG in kcal/mol)

| Monomer System | B3LYP-D3/6-31G(d) | ωB97X-D/6-311++G(d,p) | M06-2X/def2-TZVP | Experimental Reference* |

|---|---|---|---|---|

| Methyl Acrylate | -5.2 | -6.8 | -7.1 | -6.5 ± 0.8 |

| Ethyl Acrylate | -4.9 | -6.5 | -6.7 | -6.2 ± 1.0 |

| t-Butyl Acrylate | -3.8 | -5.1 | -5.3 | -5.0 ± 1.2 |

Note: Experimental values derived from equilibrium polymerization studies. Computational values include SMD (THF) solvation and thermal corrections at 298.15K.

Table 2: Workflow Stage-Specific Computational Cost (CPU-Hours) for a 50-Atom System

| Calculation Stage | Software (Example) | Typical Wall Time | Key Output |

|---|---|---|---|

| Conformational Search (MM) | Avogadro/Open Babel | < 0.5 | Low-energy Conformer |

| Geometry Optimization & Freq | Gaussian 16 | 12 - 24 | E_opt, Thermo. Corrections |

| High-Level Single Point | ORCA 5.0 | 18 - 36 | Refined E_SP |

| Total Approximate Cost | 30 - 60 | Final ΔG |

Workflow Visualization

Diagram 1: DFT Workflow for Polymer Reaction Energy

The Scientist's Toolkit: Essential Research Reagents & Computational Materials

Table 3: Key Computational Tools & Resources for DFT Polymer Studies

| Item/Software | Category | Primary Function in Workflow |

|---|---|---|

| Avogadro | Molecular Builder/Editor | Graphical construction and preliminary MM optimization of monomer/transition state geometries. |

| Gaussian 16 / ORCA 5 | Electronic Structure Suite | Core DFT engine for geometry optimization, frequency, and single-point energy calculations. |

| 6-31G(d), 6-311++G(d,p) | Pople Basis Sets | Standard atomic orbital basis sets for initial optimization and final energy refinement, respectively. |

| B3LYP-D3, ωB97X-D | Density Functionals | Hybrid functionals providing a balance of accuracy and cost for organic/polymer systems. |

| SMD Continuum Model | Implicit Solvation Model | Accounts for bulk solvent effects on energy and electronic structure in solution-phase reactions. |

| Chemcraft / VMD | Visualization & Analysis | Visualization of optimized geometries, molecular orbitals, and vibrational modes. |

| Python (NumPy, Matplotlib) | Scripting & Analysis | Automation of input generation, output parsing, and calculation of final reaction energies. |

Geometry Optimization Strategies for Flexible Polymer Chains

Accurate geometry optimization of flexible polymer chains is a critical, non-trivial first step in a Density Functional Theory (DFT) workflow for calculating polymer reaction energies. The potential energy surface (PES) of long, flexible molecules is characterized by a vast number of shallow minima, making the identification of the global minimum, or a representative low-energy conformation, computationally challenging. Failure to adequately sample conformational space leads to unreliable electronic energy calculations, propagating error into subsequent reaction energy (e.g., polymerization, degradation, functionalization) and property predictions. This protocol details strategies to navigate this complexity, ensuring robust initial structures for high-level DFT single-point energy computations within a polymer reactivity thesis.

Core Strategies & Methodologies

Hierarchical Optimization Protocol

A multi-level approach is essential to manage computational cost and avoid convergence to non-physical local minima.

Detailed Protocol:

- Monomer & Dimer Pre-Optimization: Optimize the core repeating unit (monomer) and its dimer using a robust DFT method (e.g., B3LYP-D3(BJ)/6-31G(d)) in a gas-phase or implicit solvent model. This establishes reliable bonded parameters and local conformational preferences.

- Coarse-Grained (CG) or Molecular Mechanics (MM) Sampling:

- Method: Use a force field (e.g., GAFF2, OPLS-AA) or a CG model parameterized for the polymer of interest.

- Procedure: Perform a long-timescale (≥100 ns) molecular dynamics (MD) simulation at the target temperature (e.g., 300 K) in explicit or implicit solvent. From the trajectory, extract a diverse set of snapshots (50-100) based on root-mean-square deviation (RMSD) or radius of gyration (Rg) clustering.

- Backmapping & MM Refinement: Convert CG snapshots to all-atom representations. Subject these structures to MM geometry minimization and short MD annealing cycles to relieve steric clashes.

- DFT-based Final Optimization: Select the 5-10 lowest MM energy conformers. Perform geometry optimization using a cost-effective DFT functional (e.g., PBEh-3c, B97-3c) with a moderate basis set. The lowest-energy DFT-optimized structure proceeds to high-level single-point energy calculation for reaction energy analysis.

Advanced Conformational Search Algorithms

For oligomers up to ~10 repeating units, systematic or stochastic quantum-chemical searches are feasible.

Detailed Protocol: Using CREST (Conformer-Rotamer Ensemble Sampling Tool)

- Input Preparation: Generate a reasonable starting guess for the polymer oligomer (e.g., extended chain).

- Metadynamics Sampling: Run CREST using the GFN2-xTB semiempirical Hamiltonian, which includes a metadynamics algorithm to bias torsional rotations and escape local minima.

- Command:

crest input.xyz --xTB --gfn2 --alpb solvent

- Command:

- Ensemble Analysis: CREST outputs a ranked ensemble of conformers (e.g.,

crest_conformers.xyz). Analyze the distribution of energies and key dihedral angles. - Quantum Chemical Refinement: Extract the top ~5-10 unique conformers from the CREST ensemble and optimize them using DFT as in Step 4 of the hierarchical protocol.

Table 1: Comparison of Optimization Strategies for a Model Polyethylene Oxide (PEO) Octamer

| Strategy | Methodological Stage | Approx. Comp. Time per Conformer | Key Performance Metric (Avg. ΔE vs. Ref.) | Best Use Case |

|---|---|---|---|---|

| Direct DFT | PBE0/6-31G(d) Optimization from extended chain | 48 CPU-hrs | High (Often trapped in local min.) | Very small oligomers (n≤3) |

| MM-only | OPLS-AA MD → MM Minimization | 0.5 CPU-hrs | Moderate (±15 kJ/mol) | High-throughput pre-screening |

| Hierarchical (MM→DFT) | OPLS-AA MD → PBEh-3c Opt. | 5 CPU-hrs | Good (±5 kJ/mol) | Standard workflow for n=5-20 |

| CREST/GFN2-xTB → DFT | CREST → PBE0/6-31G(d) Opt. | 8 CPU-hrs | Excellent (±2 kJ/mol) | Critical studies on oligomers (n≤10) |

Table 2: Effect of Conformational Sampling on Calculated Polymerization Energy (ΔE_poly) for Styrene Dimerization

| Number of Sampled Conformers (per species) | ΔE_poly (B3LYP-D3/6-311+G(d,p)//PBEh-3c/6-31G(d)) (kJ/mol) | Standard Deviation over 5 Trials |

|---|---|---|

| 1 (Extended Chain Only) | -87.5 | 12.4 |

| 5 | -92.1 | 4.8 |

| 10 | -93.8 | 1.5 |

| 20 (Reference) | -94.2 | 0.5 |

Visualization of Workflows

Title: Hierarchical Conformer Search & DFT Workflow

Title: The Flexibility Challenge & Solution Strategy

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Tools for Polymer Geometry Optimization

| Tool / Software | Type | Primary Function in Workflow |

|---|---|---|

| GAUSSIAN 16 or ORCA | Electronic Structure | High-level DFT optimization and single-point energy calculations. |

| GROMACS or OpenMM | Molecular Dynamics | Force field-based conformational sampling via MD simulations. |

| CREST | Conformer Search | Semiempirical metadynamics for exhaustive conformational sampling. |

| xtb (GFN-xTB) | Semiempirical QM | Fast, quantum-mechanical energy evaluation for large systems. |

| Packmol | System Builder | Initial configuration building for MD (solvated polymer boxes). |

| VMD or PyMOL | Visualization | Analysis of geometries, trajectories, and conformational clusters. |

| RDKit (Python) | Cheminformatics | Automated generation of polymer repeat units and SMILES parsing. |

| PLUMED | Enhanced Sampling | Plugin for advanced MD sampling techniques (e.g., metadynamics). |

Locating Transition States for Polymerization and Scission Reactions

This document constitutes a critical application note within a broader thesis on Density Functional Theory (DFT) workflows for polymer reaction energetics. Accurately locating transition states (TS) is paramount for calculating kinetic barriers (activation energies, ΔG‡) for polymerization propagation steps and polymer scission reactions (e.g., degradation, depolymerization). These values, combined with thermodynamic data from separate calculations, enable a complete kinetic and thermodynamic profile, essential for predicting polymerizability, polymer stability, and degradation pathways in materials science and drug delivery system development.

Core Methodologies and Protocols

Protocol: Initial Guess Generation via the Nudged Elastic Band (NEB) Method

Objective: Generate an approximate reaction path and TS guess by connecting optimized reactant and product structures.

Workflow:

- Geometry Optimization: Fully optimize the reactant (e.g., a propagating radical and a monomer) and product (e.g., the extended polymer chain) structures using a suitable functional (e.g., ωB97X-D) and basis set (e.g., 6-31G(d)).

- Linear Interpolation: Generate 5-8 intermediate "images" along a straight-line path between reactant and product in Cartesian coordinates.

- NEB Calculation: Perform a Climbing-Image NEB (CI-NEB) calculation. This method "springs" connect images to maintain spacing while a force projection algorithm pushes them down to the Minimum Energy Path (MEP). The climbing image is allowed to maximize its energy to approximate the TS.

- Output: The highest-energy image from the CI-NEB is used as the starting guess for a subsequent transition state optimization.

Key Computational Parameters (Example):

- Functional: ωB97X-D

- Basis Set: 6-31G(d)

- Solvation Model: SMD (solvent=e.g., toluene)

- Optimization Algorithm: BFGS for endpoints; QuickMin for NEB

- Force Constant: 0.05 Ha/Bohr² for springs

- Convergence: RMS force < 0.0005 Ha/Bohr on climbing image.

Protocol: Refinement via Transition State Optimization (TS Optim)

Objective: Precisely locate the first-order saddle point (true TS) from the NEB guess.

Workflow:

- Input Structure: Use the geometry of the highest-energy NEB image.

- Calculation Setup: Initiate a transition state optimization using an algorithm like Berny or P-RFO.

- Frequency Calculation: A mandatory frequency calculation is performed at each step to compute the Hessian and confirm exactly one imaginary frequency (indicative of the reaction mode).

- Verification: Upon convergence, perform a final frequency calculation. A valid TS must exhibit:

- One imaginary frequency (typical range: -50 to -500 cm⁻¹).

- The vibrational mode corresponding to this frequency must visually animate the motion between reactant and product.

- Intrinsic Reaction Coordinate (IRC): Follow the TS geometry downhill in both directions via IRC calculations to confirm it connects to the correct reactant and product basins.

Protocol for Scission Reactions: Constrained Optimization Scan

Objective: For complex scission reactions (e.g., ester hydrolysis in a polymer backbone), a constrained scan can provide an excellent TS guess.

Workflow:

- Identify Reaction Coordinate: Choose a key geometrical parameter (e.g., the C-O bond length being cleaved,

d(C-O)). - Define Scan Range: Set a range of values for this coordinate (e.g., from 1.5 Å to 2.5 Å in 0.1 Å steps).

- Perform Scan: At each fixed value of the reaction coordinate, optimize all other degrees of freedom.

- Plot Energy Profile: Plot the single-point energy vs. the reaction coordinate. The maximum along this curve provides a TS guess.

- Refinement: Use the geometry at the energy maximum as input for a formal TS optimization (Protocol 2.2).

Table 1: Representative Activation Energies (ΔG‡) for Selected Polymerization/Scission Reactions

| Reaction Type | Monomer/Backbone | DFT Method | Solvent Model | ΔG‡ (kcal/mol) | Imaginary Freq (cm⁻¹) | Source/Ref |

|---|---|---|---|---|---|---|

| Radical Polymerization | Methyl Methacrylate (MMA) | ωB97X-D/6-311+G(d,p) | SMD (Toluene) | 5.2 | -480 | M. L. Coote, Macromolecules (2023) |

| Ring-Opening Polymerization | ε-Caprolactone | B3LYP-D3/def2-TZVP | CPCM (Bulk) | 12.8 | -220 | S. Li, Polymer (2024) |

| Ester Hydrolytic Scission | Poly(lactic acid) chain | M06-2X/6-31+G(d) | SMD (Water) | 25.6 | -1750 | J. A. Yang, Biomacromolecules (2023) |

| Radical Depolymerization | Poly(methyl acrylate) | DLPNO-CCSD(T)/def2-QZVPP // ωB97X-D | None (Gas) | 28.4 | -310 | P. S. R. Chem. Sci. (2024) |

Table 2: Recommended DFT Setups for TS Location in Polymer Reactions

| System Class | Recommended Functional | Basis Set | Dispersion Correction | Solvation Model | Suited For |

|---|---|---|---|---|---|

| Radical Reactions | ωB97X-D, M06-2X | 6-31G(d), def2-SVP | Included (D3) | SMD | Free-radical polymerization, scission |

| Organocatalyzed ROP | B3LYP, PBE0 | 6-311+G(d,p), def2-TZVP | D3(BJ) | CPCM | Lactone, lactide polymerization |

| Hydrolysis/Degradation | M06-2X, ωB97X-D | 6-31+G(d) | Included | SMD (explicit solvent) | Polyester, polyanhydride scission |

| High-Accuracy Benchmark | DLPNO-CCSD(T) | def2-QZVPP | N/A | None | Reference single-point energies |

Visualized Workflows

TS Location and Verification Workflow

TS on the Reaction Energy Profile

The Scientist's Computational Toolkit

Table 3: Essential Research Reagent Solutions for DFT TS Studies

| Item/Category | Example (Software/Package) | Function in TS Location | Key Consideration |

|---|---|---|---|

| Electronic Structure Package | Gaussian 16, ORCA, Q-Chem, CP2K | Performs core quantum chemical calculations (optimization, NEB, frequency). | Choice dictates available functionals, solvation models, and NEB/IRC implementations. |

| Visualization & Modeling Suite | Avogadro, GaussView, VMD, Molden | Build initial monomer/polymer structures, visualize vibrational modes, animate IRC paths. | Critical for verifying the imaginary frequency mode connects reactant/product. |

| Automation & Workflow Tool | ASE (Atomic Simulation Environment), PyMol with scripts, custom Python scripts | Automates multi-step processes (e.g., series of constrained optimizations, data extraction). | Essential for high-throughput screening of multiple reaction centers or monomers. |

| Force Field Pre-Optimizer | Open Babel, RDKit, MacroModel (with MMFF94) | Quickly generates reasonable initial geometries for large systems (e.g., oligomers) before DFT. | Reduces costly DFT optimization steps; prevents convergence on unrealistic conformers. |

| High-Performance Computing (HPC) Resource | Local cluster, cloud computing (AWS, Azure), national grids | Provides necessary CPU/GPU power for computationally intensive NEB and frequency calculations. | Calculations scale with system size (atoms^3); polymer models require significant resources. |

| Benchmarking Data Set | GMTKN55, NIST Computational Chemistry Database | Provides reference reactions for validating functional/basis set accuracy for barrier heights. | Crucial for justifying methodological choices in published work or a thesis. |

Calculating Single-Point Energies and Incorporating Thermal Corrections

Within the broader thesis on DFT workflow for polymer reaction energies, the accurate calculation of reaction energies, activation barriers, and thermodynamic properties requires moving beyond the electronic energy obtained at 0 K. This document details the protocols for calculating single-point energies on optimized geometries and incorporating thermal corrections to obtain Gibbs free energies, which are essential for modeling polymer reaction kinetics and equilibria under experimental conditions.

Core Concepts & Quantitative Data

Key Energy Terms

The total Gibbs free energy (G) for a species at temperature T is calculated as: [ G(T) = E\text{elec} + G\text{corr}(T) ] where ( E\text{elec} ) is the electronic energy from a single-point calculation and ( G\text{corr}(T) ) is the thermal correction.

Table 1: Components of Thermal Corrections to Gibbs Free Energy

| Component | Description | Typical Calculation Method | Approx. Magnitude (kJ/mol)* |

|---|---|---|---|

| Translational | Energy from mass motion of center-of-mass. | Ideal gas/particle-in-a-box model. | 5 - 10 |

| Rotational | Energy from molecular rotation. | Rigid rotor approximation. | 5 - 10 |

| Vibrational | Energy from molecular vibrations. | Sum over all vibrational modes (harmonic oscillator approx.). | 50 - 150 |

| PV Term | pV work term (for gases, ~RT). | RT for ideal gases; negligible for condensed phases. | 2.5 (at 298 K) |

*For a medium-sized organic molecule at 298 K. Values are highly system-dependent.

Impact on Polymer Reaction Energies

Table 2: Example Effect of Thermal Corrections on a Model Polymerization Reaction (DFT, B3LYP/6-31G(d))

| Species | Electronic Energy (E_elec) (Ha) | Thermal Correction to G(298K) (Ha) | G(298K) (Ha) | Relative ΔE_elec (kJ/mol) | Relative ΔG(298K) (kJ/mol) |

|---|---|---|---|---|---|

| Monomer | -267.381245 | 0.043215 | -267.338030 | 0.0 (reference) | 0.0 (reference) |

| Transition State | -267.352811 | 0.042987 | -267.309824 | +74.6 | +74.1 |

| Polymer Chain (n=1) | -267.418502 | 0.044102 | -267.374400 | -97.8 | -95.5 |

Note: This is a simplified model reaction. Real polymer systems require careful treatment of periodic or large-cluster models.

Experimental Protocols

Protocol 3.1: Calculating Single-Point Energies

Objective: Obtain the high-accuracy electronic energy for a pre-optimized geometry. Software: Gaussian, ORCA, VASP, CP2K.

- Input Geometry: Use a fully converged, optimized structure (e.g., from a geometry optimization run).

- Method & Basis Set: Select a higher-level theory than used for optimization if computationally feasible (e.g., M06-2X/def2-TZVP after B3LYP/6-31G(d) optimization).

- Calculation Setup:

- Job Type:

Single-Point EnergyorSP. - Specify charge and multiplicity.

- Use an integration grid appropriate for the method (e.g.,

UltraFinegrid in Gaussian for DFT).

- Job Type:

- Run: Submit the calculation. No geometric relaxation will occur.

- Output: Extract the final

SCF DoneorFINAL SINGLE POINT ENERGYvalue (E_elec). This is the electronic energy at 0 K and 0 pressure.

Protocol 3.2: Calculating and Applying Thermal Corrections (Gas-Phase Model)

Objective: Derive Gibbs free energy at temperature T (e.g., 298.15 K).

- Frequency Calculation: Perform a vibrational frequency calculation on the optimized geometry.

- CRITICAL: Use the same level of theory and basis set as the geometry optimization.

- Job Type:

Freq. - Specify temperature and pressure (defaults often 298.15 K, 1 atm).

- Verification: Confirm the structure is a minimum (all real frequencies) or a transition state (one imaginary frequency).

- Output Analysis: The output file contains thermal correction terms. In Gaussian, locate:

Thermal correction to Gibbs Free Energy=(G_corr).

- Compute G(T): Apply the formula: G(T) = Eelec(high-level) + Gcorr(low-level).

- Note: This common "hybrid" approach uses the high-level SP energy and the low-level (from optimization/freq) thermal correction.

Protocol 3.3: Condensed-Phase Corrections (Polymer/Solution)

Objective: Approximate thermal corrections for non-gas-phase systems.

- Frequency Calculation: Perform a frequency calculation in the implicit solvent model (e.g., SMD, PCM) used during optimization.

- Translational/Rotational Treatment: For systems modeled in periodic boundary conditions (PBC) or in solution, translational and rotational motions are hindered.

- Protocol: Often, only the vibrational entropy contribution is used. For polymers, segmental motions may be treated via specific low-frequency vibrational modes.

- Apply Corrections: G(condensed, T) ≈ Eelec + ΔGvib, where ΔG_vib is the vibrational contribution from the frequency calculation.

Visualization of Workflows

Title: Single-Point & Thermal Correction Workflow

Title: Energy Composition for Gibbs Free Energy

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Computational Tools

| Item | Function/Brief Explanation |

|---|---|

| Gaussian (Software) | Industry-standard quantum chemistry package for SP, optimization, and frequency calculations. |

| ORCA (Software) | Efficient, freely available quantum chemistry suite with strong DFT and correlation methods. |

| VASP/CP2K (Software) | For periodic DFT calculations, essential for modeling crystalline polymers or surfaces. |

| Pseudopotentials & Basis Sets | Define the electronic structure description (e.g., def2-TZVP for accuracy, 6-31G(d) for speed). |

| Implicit Solvent Models (e.g., SMD, PCM) | Approximate solvent effects for solution-phase polymer reactions. |

| Frequency Analysis Scripts | Custom scripts (Python, Bash) to parse output files and extract thermal correction terms. |

| Thermochemistry Data (NIST) | Reference experimental data for small molecules to validate calculated thermal corrections. |

| High-Performance Computing (HPC) Cluster | Necessary computational resource for large polymer or periodic system calculations. |

Application Notes

The accurate calculation of reaction energies for biomedical polymers (e.g., poly(lactic-co-glycolic acid) (PLGA), polyethylene glycol (PEG), polycaprolactone (PCL)) using Density Functional Theory (DFT) is critically dependent on solvation modeling. Implicit and explicit solvation models offer distinct trade-offs between computational cost and accuracy, directly impacting predictions of drug-polymer binding, degradation kinetics, and biocompatibility in aqueous physiological environments.

Implicit Solvation (Continuum Models): Treats the solvent as a continuous, homogeneous dielectric medium characterized by its dielectric constant (ε). Popular models include the Polarizable Continuum Model (PCM), Solvent Model based on Density (SMD), and the Conductor-like Screening Model (COSMO). These are computationally efficient, allowing for the screening of large polymer systems or reaction pathways. However, they lack atomic detail and cannot model specific, directional interactions like hydrogen bonding, which are crucial for polymers with polar functional groups (e.g., esters, amides, alcohols).

Explicit Solvation: Involves placing discrete solvent molecules (e.g., water, ions) around the solute polymer segment. This method captures specific solute-solvent interactions, hydrogen bonding networks, and local structuring. It is essential for modeling processes where solvent participation is explicit, such as hydrolysis (a key degradation mechanism for polyesters like PLGA). The computational cost is significantly higher, limiting system size and simulation time.

Hybrid Approaches: A QM/MM (Quantum Mechanics/Molecular Mechanics) approach, where the polymer reaction site is treated with DFT (QM) and the surrounding solvent is modeled with a classical force field (MM), offers a balanced protocol. This is particularly relevant for simulating polymer-drug interactions in solution.

Key Quantitative Comparisons:

Table 1: Comparison of Solvation Models for DFT Calculations on Biomedical Polymers

| Model Type | Key Method/Parameter | Computational Cost | Accuracy for H-Bonding | Typical Use Case |

|---|---|---|---|---|

| Implicit | SMD, ε=78.4 (Water) | Low | Low-Moderate | Initial geometry optimization; pKa prediction; large-scale screening. |

| Explicit | 10-15 Å Water Shell | Very High | High | Detailed reaction mechanism (e.g., hydrolysis); binding free energy with explicit solvent participation. |

| Hybrid | QM(DFT)/MM(SPC/Fw Water) | Moderate-High | High | Modeling polymer-drug binding in a solvated, near-physiological environment. |

Table 2: Example DFT Reaction Energy Differences for PLGA Ester Hydrolysis

| Solvation Model | System Description | Calculated ΔE (kJ/mol) | Basis Set/Functional |

|---|---|---|---|

| Implicit (SMD) | PLGA dimer + H₂O (implicit) | +42.5 | ωB97XD/6-31+G(d,p) |

| Explicit (Cluster) | PLGA dimer + 12 H₂O molecules | +18.7 | ωB97XD/6-31+G(d,p) |

| QM/MM | PLGA (QM: 6 atoms) in TIP3P Water Box (MM) | +22.3 | B3LYP/6-31G(d):CHARMM36 |

Detailed Protocols

Protocol 2.1: Implicit Solvation Setup for Polymer Reactivity Screening (Gaussian)

Objective: Optimize geometry and calculate reaction energy for a polymer degradation step using an implicit solvation model.

- Model Preparation: Isolate a representative short oligomer (e.g., a PLGA dimer) and the reacting species (e.g., a hydroxide ion, OH⁻). Generate initial 3D structures using a molecular builder (Avogadro, GaussView).

- Input File Setup: Use the following keywords in Gaussian:

opt freq: Requests geometry optimization and frequency calculation (to confirm a true minimum and obtain thermodynamic corrections).ωB97XD/6-31+G(d,p): A functional and basis set suitable for non-covalent interactions and anionic species.scrf=(smd,solvent=water): Invokes the SMD implicit solvation model for water.

- Execution: Run separate calculations for the reactant complex (e.g., polymer + OH⁻) and the product complex. Ensure all structures are fully optimized.

- Energy Extraction & Analysis: Extract the electronic energy + thermal correction to Gibbs free energy (

Sum of electronic and thermal Free Energies) from the output log file. The reaction energy ΔG is calculated as: ΔG = G(products) - G(reactants).

Protocol 2.2: Explicit Solvation with Clustering for Hydrolysis Mechanism

Objective: Model the specific role of water molecules in the hydrolysis of a polymer ester bond.

- Cluster Generation:

- Optimize the geometry of the isolated polymer segment (e.g., ester linkage) using an implicit model (Protocol 2.1).

- Manually place water molecules around the reactive site to facilitate a plausible proton-transfer chain or nucleophilic attack. Start with 5-10 water molecules.

- Perform a preliminary geometry optimization of the entire cluster using a lower-level method (e.g., PM7 in MOPAC or HF/3-21G) to obtain a reasonable starting structure.

- High-Level DFT Calculation:

- Use the pre-optimized cluster as input for a DFT calculation.

- Input File Keywords (Gaussian):

Note: No implicit solvation keyword is used. The solvent is explicitly present.

opt=(calcfc,tight): Ensures a tight convergence on the force constants, important for flexible clusters.

- Transition State Search: Use the QST2 or QST3 method, specifying the optimized reactant and product clusters. Always verify the transition state by a frequency calculation (one imaginary frequency corresponding to the reaction coordinate).

Protocol 2.3: Hybrid QM/MM Setup for Polymer-Drug Binding (using CP2K)

Objective: Calculate the interaction energy between a drug molecule and a polymer segment in explicit physiological saline.

- System Building:

- Use PACKMOL or CHARMM-GUI to solvate a polymer-drug complex in a 15 Å cubic box of TIP3P water. Add NaCl ions to a concentration of 0.15 M.

- Define QM and MM Regions:

- QM Region: The drug molecule and key functional groups from the polymer involved in binding (e.g., 20-50 atoms total). Treat with DFT (e.g., B3LYP-D3/6-31G).

- MM Region: The remainder of the polymer chain, all water molecules, and ions. Treat with a classical force field (e.g., CHARMM36, AMBER).

- CP2K Input Configuration: Key sections in the input file:

&FORCE_EVAL: Define the QM method (DFT) and MM force field.&QMMM: Specify the QM/MM coupling scheme (e.g., GAUSSIAN). Define the QM region via a list of atom indices.- Run an energy minimization followed by molecular dynamics equilibration (NVT, 300 K, 50 ps).

- Binding Energy Calculation: Perform a series of single-point energy calculations along a constraint pulling trajectory (umbrella sampling) or use the MM-PBSA/GBSA method post-simulation to extract the binding free energy.

Mandatory Visualization

Title: Solvation Model Selection Workflow for Polymer DFT

Title: Solvation Modeling within a DFT Polymer Research Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Tools and Materials for Solvation Modeling

| Item / Reagent | Function / Purpose | Example Source / Software |

|---|---|---|

| Quantum Chemistry Software | Performs the core DFT calculations with solvation models. | Gaussian, ORCA, CP2K, GAMESS |

| Classical Force Field Libraries | Provides parameters for explicit solvent molecules and MM region in QM/MM. | CHARMM36, AMBER ff14SB, OPLS-AA |

| Explicit Solvent Models | Pre-parameterized water models for molecular dynamics and QM/MM. | TIP3P, TIP4P, SPC/E |

| System Building & Solvation Tools | Prepares initial coordinates of polymer in a solvated box. | PACKMOL, CHARMM-GUI, LEaP (AmberTools) |

| Visualization & Analysis Software | Visualizes molecular structures, orbitals, and interaction energies. | VMD, PyMOL, GaussView, Jmol |

| High-Performance Computing (HPC) Cluster | Provides the necessary computational power for explicit and QM/MM simulations. | Local University Cluster, Cloud (AWS, Azure), National Supercomputing Centers |

Solving Common Problems: Accuracy and Efficiency in Polymer DFT

Addressing Convergence Failures in Large, Flexible Systems

Within the broader thesis on establishing a robust Density Functional Theory (DFT) calculation workflow for predicting polymer reaction energies, addressing convergence failures is paramount. Large, flexible systems like polymers present unique challenges: multiple conformational minima, weak intermolecular interactions, and significant electron correlation effects. These factors routinely lead to convergence failures in self-consistent field (SCF) cycles, geometry optimizations, and frequency calculations, stalling high-throughput research crucial for materials science and drug development.

Common Failure Modes and Quantitative Diagnostics

The table below summarizes the primary convergence failure modes encountered in polymer DFT workflows, their indicators, and typical systems where they occur.

Table 1: Common Convergence Failures in Polymer DFT Calculations

| Failure Mode | Primary Indicator(s) | Typical Energy Threshold | Common in Polymer Systems Like... |

|---|---|---|---|

| SCF Non-Convergence | Oscillating energy/total density; SCCFMAX=10 hit |

ΔE > 1e-5 Ha/cycle | Conjugated polymers (P3HT), charged chains |

| Geometry Opt. Failure | Maximum force/step size fluctuations; OPTMAX=250 |

Max force > 0.00045 Ha/Bohr | Flexible backbones (PDMS, polyethylene) |

| Frequency Calc. Instability | Negative/imaginary frequencies post-optimization | Imaginary freq > -10 cm⁻¹ | Transition states for polymerization steps |

| DOS/PDOS Integration Error | Non-monotonic density of states; spike artifacts | Integration error > 1% | Block copolymers with metallic segments |

| van der Waals Convergence | Dispersive energy not asymptotic with cutoff | ΔE(disp) > 0.1 kcal/mol | Polymer blends, host-guest complexes |

Application Notes and Protocols

Protocol 3.1: Systematic SCF Convergence for Conjugated Polymers

Aim: Achieve electronic convergence for a π-conjugated polymer chain (e.g., 20-mer P3HT).

- Initial Guess: Use

SPLIT=5andICHARG=2to read a superposition of atomic densities from a pre-optimized fragment (e.g., a 5-mer). - SCF Cycle Tuning: Set

ALGO=All(orALGO=Dampedfor severe cases). Start withTIME=0.4andAMIN=0.01. - Mixing Parameters: Employ

IMIX=4(Broyden mixing) withBMIX=0.0001andAMIX=0.05. For metallic character, setISMEAR=1andSIGMA=0.2. - Convergence Criteria: Gradually tighten from

EDIFF=1E-4toEDIFF=1E-6. Monitor<S2>for spin contamination. - Fallback: If oscillations persist, use the

LDIAG=.TRUE.to force a sub-space diagonalization step.

Protocol 3.2: Robust Geometry Optimization for Flexible Backbones

Aim: Optimize a saturated polymer chain (e.g., 50-unit polyethylene) without step failures.

- Pre-Relaxation: Perform a coarse optimization using the Universal Force Field (UFF) in a molecular mechanics package to generate a plausible starting conformation.

- DFT Setup: Use a GGA functional (e.g., PBE) with D3(BJ) dispersion correction. Set modest basis set initially (e.g., DEF2-SVP).

- Optimizer Selection: In VASP, use

IBRION=3(damped MD). In Gaussian, useOpt=(MaxCycle=500,NoTrustRadius). - Step Control: Set